Cap Mould Design . corvaglia modular injection molds: for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Beyond wall thickness, designing effective cooling and material selection can have a large impact. The other half is our clear focus on caps and closures. Using tools such as moldflow, we can consider the part design’s influence on the process. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that is easy to. designing an optimal cap mold requires attention to several factors:

from www.naboplastic.com

designing an optimal cap mold requires attention to several factors: After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. corvaglia modular injection molds: Ensuring a secure seal that is easy to. Beyond wall thickness, designing effective cooling and material selection can have a large impact. a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. The other half is our clear focus on caps and closures. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Using tools such as moldflow, we can consider the part design’s influence on the process.

Plastic Bottle Cap Injection Mould NABO Plastic

Cap Mould Design a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. The other half is our clear focus on caps and closures. Beyond wall thickness, designing effective cooling and material selection can have a large impact. Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. designing an optimal cap mold requires attention to several factors: a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. corvaglia modular injection molds: Using tools such as moldflow, we can consider the part design’s influence on the process.

From www.naboplastic.com

Plastic Bottle Cap Injection Mould NABO Plastic Cap Mould Design Ensuring a secure seal that is easy to. Using tools such as moldflow, we can consider the part design’s influence on the process. designing an optimal cap mold requires attention to several factors: After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. corvaglia modular injection molds: for. Cap Mould Design.

From darrow.en.made-in-china.com

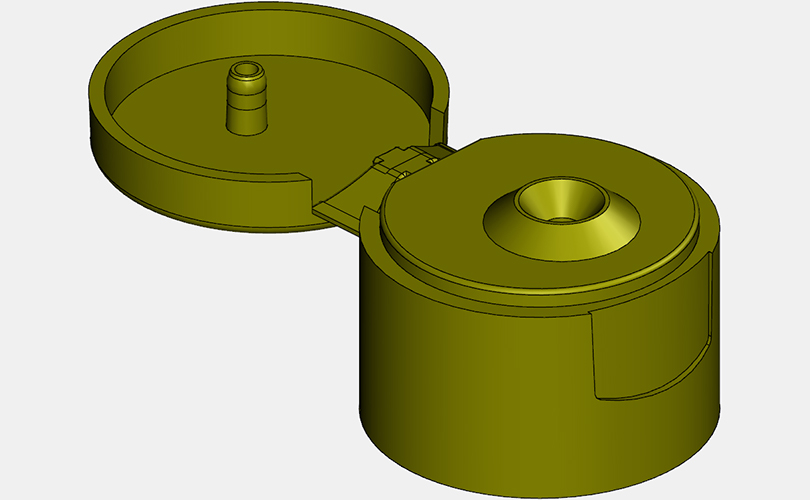

Flip Top Bottle Cap Mould China Injection Molding and Plastic Cap Mould Design The other half is our clear focus on caps and closures. designing an optimal cap mold requires attention to several factors: a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. Ensuring a secure seal that is easy to. After you confirm. Cap Mould Design.

From www.cap-molds.com

Plastic bottle cap mold design and processingTaizhou Shuanghao Plastic Cap Mould Design designing an optimal cap mold requires attention to several factors: Using tools such as moldflow, we can consider the part design’s influence on the process. Ensuring a secure seal that is easy to. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. . Cap Mould Design.

From seacomould.com

cap mould machining Seaco Mould Cap Mould Design corvaglia modular injection molds: for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. After you confirm the cap drawing, we start make mold design based on the cap structure. Cap Mould Design.

From cap-molds.com

China Cap Mould Suppliers,Cap Molds Maker,Engine Oil Cap MouldTaizhou Cap Mould Design After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that is easy to. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Beyond wall thickness, designing effective cooling and material. Cap Mould Design.

From www.taiwanmoldmaker.com

Intertech Eight Cavity Flip Top Cap Mold service information Cap Mould Design a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. Using tools such as moldflow, we can consider the part design’s influence on the process. designing an optimal cap mold requires attention to several factors: corvaglia modular injection molds: in. Cap Mould Design.

From weramold.com

Fliptop cap Mould MOLD DESIGN & MANUFACTURE Cap Mould Design for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. designing an optimal cap mold requires attention to several factors: After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that. Cap Mould Design.

From www.sunmolds.com

China 8 Cavity 5 Gallon Cap Mould Suppliers, Manufacturers Taizhou Cap Mould Design for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Using tools such as moldflow, we can consider the part design’s influence on the process. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. . Cap Mould Design.

From www.sino-pk.com

flip top cap mould Cap Mould Design Ensuring a secure seal that is easy to. designing an optimal cap mold requires attention to several factors: a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. corvaglia modular injection molds: for high volume applications, the goal is to. Cap Mould Design.

From www.jmtmould.com

Cap mould ,Household mould Cap Mould Design After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. The other half is our clear focus on caps and closures. corvaglia modular injection molds: Using tools such. Cap Mould Design.

From www.fliptopplasticcaps.com

stable Plastic Cap Mould , Injection bottle cap mold 2D and 3D drawings Cap Mould Design The other half is our clear focus on caps and closures. designing an optimal cap mold requires attention to several factors: Beyond wall thickness, designing effective cooling and material selection can have a large impact. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and. Cap Mould Design.

From www.bitopmould.com

China flip top cap mould,Taizhou Huangyan Bitop Mould Co.,Ltd. Cap Mould Design The other half is our clear focus on caps and closures. designing an optimal cap mold requires attention to several factors: in this tutorial we'll discuss on flip flop cap mold design or sanitizer. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and. Cap Mould Design.

From xsplasticmoulds.com

Cap Mould Leading Quality Cap Mould Manufacturer Cap Mould Design designing an optimal cap mold requires attention to several factors: Beyond wall thickness, designing effective cooling and material selection can have a large impact. Ensuring a secure seal that is easy to. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. The other half is our clear focus on. Cap Mould Design.

From www.ld-capmould.com

Design Flip top cap mould Maker, Suppliers Cap Mould Design designing an optimal cap mold requires attention to several factors: in this tutorial we'll discuss on flip flop cap mold design or sanitizer. corvaglia modular injection molds: The other half is our clear focus on caps and closures. Using tools such as moldflow, we can consider the part design’s influence on the process. for high volume. Cap Mould Design.

From shinymould.en.made-in-china.com

China Injection Mould, Cutlery Mould, Crate Mould supplier Shiny Tool Cap Mould Design Beyond wall thickness, designing effective cooling and material selection can have a large impact. Ensuring a secure seal that is easy to. designing an optimal cap mold requires attention to several factors: for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Using tools. Cap Mould Design.

From lipengmould.en.made-in-china.com

Hot Selling 16 Cavity Plastic Cosmetic Tube Flip Top Cap Injection Cap Mould Design a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. corvaglia modular injection molds: Beyond wall thickness, designing effective cooling and material selection can have a large impact.. Cap Mould Design.

From cappreformmould.com

8 cavity flip top cap mould Cap Mould Design Ensuring a secure seal that is easy to. corvaglia modular injection molds: designing an optimal cap mold requires attention to several factors: in this tutorial we'll discuss on flip flop cap mold design or sanitizer. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part. Cap Mould Design.

From sunskyindustrial.en.made-in-china.com

Mold OEM Manufacturer China Plastic Flip Top Cap Mould Cap Mould Design Cap Mould Design The other half is our clear focus on caps and closures. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. Beyond wall thickness, designing effective cooling and material selection can have a large impact. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the. Cap Mould Design.

From www.cap-molds.com

flip top cap mould, flip top cap mold, plastic cap mouldTaizhou Cap Mould Design a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Using tools such as moldflow, we can consider. Cap Mould Design.

From www.bitopmould.com

Cosmetic Cap mould,Taizhou Huangyan Bitop Mould Co.,Ltd. Cap Mould Design designing an optimal cap mold requires attention to several factors: Using tools such as moldflow, we can consider the part design’s influence on the process. a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. in this tutorial we'll discuss on. Cap Mould Design.

From www.jmtmould.com

Cap mould ,Household mould Cap Mould Design Ensuring a secure seal that is easy to. Using tools such as moldflow, we can consider the part design’s influence on the process. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. designing an optimal cap mold requires attention to several factors: for high volume applications, the goal is to have as thin. Cap Mould Design.

From www.youtube.com

Unscrewing cap plastic injection mold design concept cases by Cap Mould Design After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. a cap mold, also known as a closure mold or lid mold, is a type of injection mold. Cap Mould Design.

From fliptopcapmould.com

Flip Top Cap Mould Flip Top Closure Mould Plastic Cap Mould Expert Cap Mould Design The other half is our clear focus on caps and closures. corvaglia modular injection molds: a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. Ensuring a secure seal that is easy to. After you confirm the cap drawing, we start make. Cap Mould Design.

From www.abismould.com

The Canada Customer 1x32 Cavity 5000 Pcs Plastic Injection Cap Mould Cap Mould Design for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. corvaglia modular injection molds: After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. The other half is our clear focus on caps and closures.. Cap Mould Design.

From www.moulding-solution.com

Cap MouldCap MouldShinywell Mould Cap Mould Design designing an optimal cap mold requires attention to several factors: The other half is our clear focus on caps and closures. corvaglia modular injection molds: in this tutorial we'll discuss on flip flop cap mold design or sanitizer. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection.. Cap Mould Design.

From www.youtube.com

STRIPPER PLATE MOULD BASIC CONCEPT OF CAP MOULD DESIGN YouTube Cap Mould Design a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Ensuring a secure seal that is easy to. Beyond wall thickness, designing effective cooling. Cap Mould Design.

From www.cap-molds.com

Flip top caps mouldTaizhou Shuanghao Plastic Mould Co., Ltd. Cap Mould Design Ensuring a secure seal that is easy to. Using tools such as moldflow, we can consider the part design’s influence on the process. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. After you confirm the cap drawing, we start make mold design based. Cap Mould Design.

From www.basilius.com

32 Cavity Cap Mold Basilius Inc. Cap Mould Design The other half is our clear focus on caps and closures. Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. a cap mold, also known as a closure mold or lid mold, is a type of injection mold used to produce plastic caps, closures, lids, or.. Cap Mould Design.

From www.youtube.com

Unscrewing cap mold design concept cases by YouTube Cap Mould Design designing an optimal cap mold requires attention to several factors: for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. Beyond wall. Cap Mould Design.

From www.injection-plasticmoulds.com

5 Gallon Plastic Cap Mould Hot Cold Runner 32 Cavity Neck 54 Cm High Cap Mould Design in this tutorial we'll discuss on flip flop cap mold design or sanitizer. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. corvaglia modular injection molds: Beyond wall thickness, designing effective cooling and material selection can have a large impact. The other. Cap Mould Design.

From www.moulding-solution.com

Cap MouldCap MouldShinywell Mould Cap Mould Design designing an optimal cap mold requires attention to several factors: Ensuring a secure seal that is easy to. The other half is our clear focus on caps and closures. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. a cap mold, also. Cap Mould Design.

From www.youtube.com

ENGINE OIL CAP MOLD DESIGN PLASTIC INJECTION MOLD DESIGN OIL CAP 38 Cap Mould Design designing an optimal cap mold requires attention to several factors: Using tools such as moldflow, we can consider the part design’s influence on the process. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Ensuring a secure seal that is easy to. After. Cap Mould Design.

From www.youtube.com

Flip Flop Cap Mold Design or Sanitizer Cap Injection Mould Design Cap Mould Design Ensuring a secure seal that is easy to. in this tutorial we'll discuss on flip flop cap mold design or sanitizer. After you confirm the cap drawing, we start make mold design based on the cap structure & your injection. Beyond wall thickness, designing effective cooling and material selection can have a large impact. a cap mold, also. Cap Mould Design.

From www.youtube.com

Coffee bottle cap mold design for mold making at YouTube Cap Mould Design in this tutorial we'll discuss on flip flop cap mold design or sanitizer. corvaglia modular injection molds: The other half is our clear focus on caps and closures. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. Beyond wall thickness, designing effective. Cap Mould Design.

From dir.indiamart.com

Cap Mold Cap Mould Latest Price, Manufacturers & Suppliers Cap Mould Design Using tools such as moldflow, we can consider the part design’s influence on the process. The other half is our clear focus on caps and closures. Ensuring a secure seal that is easy to. for high volume applications, the goal is to have as thin of a wall section as possible without affecting the part functionality and moldability. . Cap Mould Design.