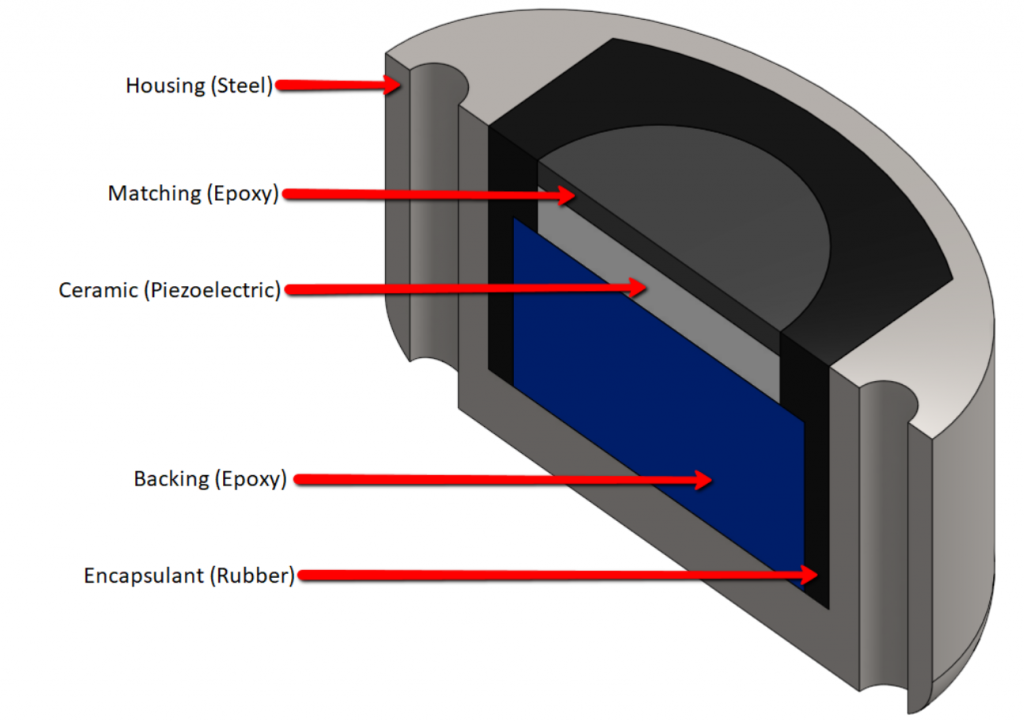

Transducer Backing Material . we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. From the surface, a typical device is composed of: tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. transducers are composed of both passive and active components in a layered structure. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect.

from exootjqmt.blob.core.windows.net

backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. transducers are composed of both passive and active components in a layered structure. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. From the surface, a typical device is composed of: generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion.

Ultrasound Transducer Layers at Gloria Riley blog

Transducer Backing Material From the surface, a typical device is composed of: backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. From the surface, a typical device is composed of: an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. transducers are composed of both passive and active components in a layered structure.

From www.ptemasters.com

Download Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. transducers are composed of both passive and active components in a layered structure. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. in this paper, a design method of transducer backing layer. Transducer Backing Material.

From edu.svet.gob.gt

Ultrasound Transducer Backing Material edu.svet.gob.gt Transducer Backing Material in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. From the surface, a typical device is composed of: an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric. Transducer Backing Material.

From techblog.ctgclean.com

Ultrasonics Transducers Hardware CTG Technical Blog Transducer Backing Material generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. transducers are composed of both. Transducer Backing Material.

From www.iqsdirectory.com

Strain Gauge What Is It? How Is It Used? Types, Application Transducer Backing Material transducers are composed of both passive and active components in a layered structure. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. From the surface, a typical device is composed of: tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. in. Transducer Backing Material.

From www.electricalstraingauge.com

Load Cell Transducer 2HA Metail Foil Strain Gauges For Transducer Transducer Backing Material we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. transducers are composed of both passive and active components in a layered structure. From the surface, a typical device is composed of: an ultrasound transducer converts. Transducer Backing Material.

From edu.svet.gob.gt

Ultrasound Transducer Backing Material edu.svet.gob.gt Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. we will present a comprehensive study in a quantitative. Transducer Backing Material.

From www.comsol.com

Using Simulation to Study Ultrasound Focusing for Clinical Applications Transducer Backing Material an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. generally, an ideal thermal expansion. Transducer Backing Material.

From www.comsol.com

Using Simulation to Study Ultrasound Focusing for Clinical Applications Transducer Backing Material an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. in this paper, a design method of transducer. Transducer Backing Material.

From www.comsol.com

ETREMA Analyzes Materials with Simulation COMSOL Blog Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. transducers are composed of both passive and active components. Transducer Backing Material.

From www.researchgate.net

Comparison between tradition external transducer with backing material Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. transducers are composed of both passive and active components in a layered structure. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. we will present a comprehensive study in a quantitative. Transducer Backing Material.

From www.researchgate.net

(PDF) Influence of backing and matching layers in ultrasound transducer Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. transducers are composed of both passive and active components in a layered structure. backing materials with tailored acoustic properties are beneficial for. Transducer Backing Material.

From www.capacitivestraingauge.com

Linear Load Cell Transducer 2FB Metal Sheet Strain Gauges For Transducer Backing Material From the surface, a typical device is composed of: backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. transducers. Transducer Backing Material.

From www.capacitivestraingauge.com

Load Cell Transducer 1.5AA Metal Sheet Strain Gauges For Transducer Transducer Backing Material we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. transducers are composed of both passive and active components in a layered structure. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again,. Transducer Backing Material.

From doctorlib.info

Sonography Principles, Techniques, and Instrumentation Lange Review Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. transducers are composed of both passive and active components in a layered structure. From the surface, a typical device is composed of: generally,. Transducer Backing Material.

From www.researchgate.net

Sketch of fabricated ultrasonic transducers with backing materials from Transducer Backing Material backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. transducers are composed of both passive and active components in a layered structure. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. From the surface, a typical device is composed of: an ultrasound transducer. Transducer Backing Material.

From informacionpublica.svet.gob.gt

Preparation Of Polyvinyl Acetate Composite As A New Backing Transducer Backing Material transducers are composed of both passive and active components in a layered structure. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. an ultrasound transducer converts electrical energy into mechanical (sound). Transducer Backing Material.

From www.electricalstraingauge.com

Full Bridge Transducer FG Sheet Metal Strain Gauge Sensor For Transducer Backing Material an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. From the surface, a typical. Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText FPCB as an Acoustic Matching Layer for 1D Transducer Backing Material in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. . Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText High Temperature, High Power Piezoelectric Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. transducers are composed of both passive and active components in a layered structure. backing materials with tailored acoustic properties are beneficial for. Transducer Backing Material.

From www.researchgate.net

Structure of fourlaminated transducer (1. case, 2. epoxy potting, 3 Transducer Backing Material an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. transducers are composed of both passive and active components in a layered structure. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. From the surface, a typical device is composed of: . Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText A SphericallyShaped PZT Thin Film Transducer Backing Material From the surface, a typical device is composed of: transducers are composed of both passive and active components in a layered structure. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high. Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText A Review of Acoustic Impedance Matching Transducer Backing Material generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. tbw650 makes an ideal material. Transducer Backing Material.

From www.researchgate.net

Sketch of fabricated ultrasonic transducers with backing materials from Transducer Backing Material generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. . Transducer Backing Material.

From exootjqmt.blob.core.windows.net

Ultrasound Transducer Layers at Gloria Riley blog Transducer Backing Material generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. From the surface,. Transducer Backing Material.

From www.animalia-life.club

Ultrasound Piezoelectric Transducer Transducer Backing Material backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. transducers are composed of both passive and active components in a layered structure. an ultrasound transducer converts electrical energy into mechanical (sound) energy. Transducer Backing Material.

From www.researchgate.net

(PDF) Preparation of polyvinyl acetate composite as a new backing Transducer Backing Material we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. From the surface, a typical device is composed of: an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. tbw650 makes an ideal material for use as a transducer backing material in. Transducer Backing Material.

From www.researchgate.net

Transducer sample and performance test. (a) The fabricated matching Transducer Backing Material in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. backing. Transducer Backing Material.

From sites.google.com

TRANSDUCERS US PHYSICS EFOLIO Transducer Backing Material an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. transducers are composed of both passive and active components in a layered structure. generally, an ideal thermal expansion material for the. Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText High Temperature Ultrasonic Transducers A Transducer Backing Material in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. transducers are composed of both passive and active components in a layered structure. tbw650 makes an ideal material. Transducer Backing Material.

From informacionpublica.svet.gob.gt

Preparation Of Polyvinyl Acetate Composite As A New Backing Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. From the surface, a typical device is composed. Transducer Backing Material.

From electricalstraingauge.com

Biaxial Load Cell Transducer 2BB Metal Sheet Shear Strain Gauges For Transducer Backing Material From the surface, a typical device is composed of: tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again, based on the piezoelectric effect. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms). Transducer Backing Material.

From www.researchgate.net

Acoustic transducer tungsten carbide anvil setup (left) and the sample Transducer Backing Material From the surface, a typical device is composed of: in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. transducers are composed of both passive and active components in a layered structure. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. an ultrasound transducer. Transducer Backing Material.

From www.researchgate.net

Schematic of transducer design. Download Scientific Transducer Backing Material tbw650 makes an ideal material for use as a transducer backing material in underwater acoustic transducers. backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. From the surface, a typical device is composed of: we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. an. Transducer Backing Material.

From www.slideserve.com

PPT Biomedical Imaging I PowerPoint Presentation ID5415414 Transducer Backing Material backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. transducers are composed of both. Transducer Backing Material.

From www.mdpi.com

Coatings Free FullText Preparation of ZnO Piezoelectric ThinFilm Transducer Backing Material in this paper, a design method of transducer backing layer with wide frequency application range, low cost and. we will present a comprehensive study in a quantitative manner on the relationship between transducer characteristics, such. From the surface, a typical device is composed of: an ultrasound transducer converts electrical energy into mechanical (sound) energy and back again,. Transducer Backing Material.