Abrasive Flow Machining Cost . The abrasive media is forced through the workpiece. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous.

from www.mech4study.com

Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. The abrasive media is forced through the workpiece. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the.

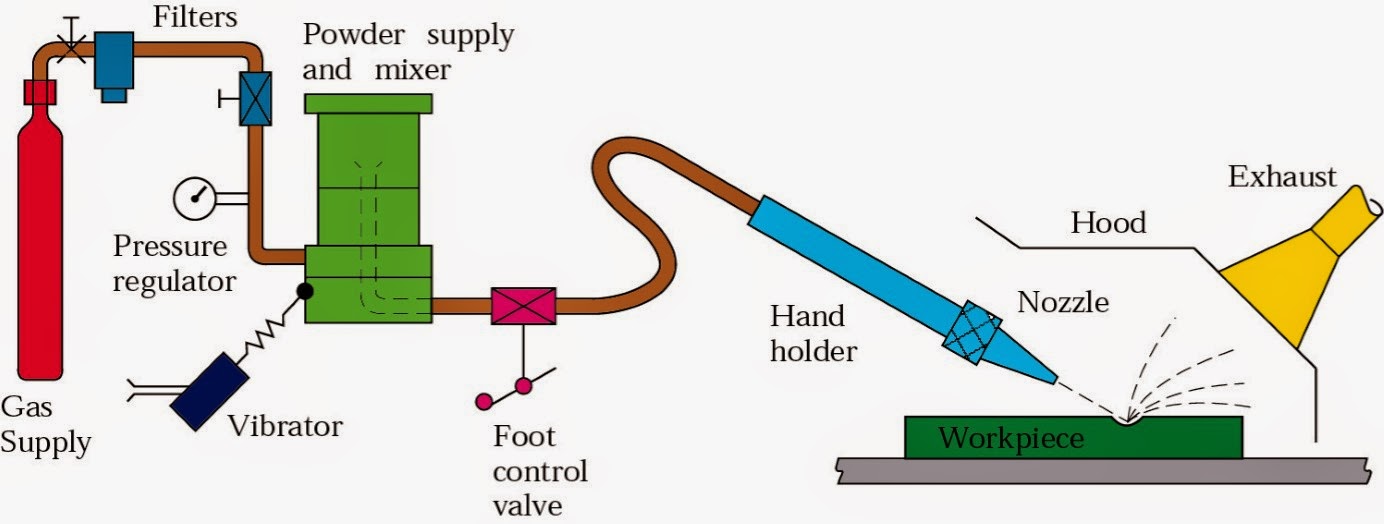

Abrasive Jet Machining Principle, Working, Equipment's, Application

Abrasive Flow Machining Cost Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. The abrasive media is forced through the workpiece.

From winbroflowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with. Abrasive Flow Machining Cost.

From www.waterjet-cutting.com

Abrasive Jet Machining Companies Services Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. The abrasive media is forced through the workpiece. Our extrude hone afm autoflow. Abrasive Flow Machining Cost.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a. Abrasive Flow Machining Cost.

From www.mech4study.com

Abrasive Jet Machining Principle, Working, Equipment's, Application Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. The abrasive media is forced through the workpiece. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Abrasive flow machining (afm) is. Abrasive Flow Machining Cost.

From journals.sagepub.com

Experimental Research into Technology of Abrasive Flow Machining Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On. Abrasive Flow Machining Cost.

From www.researchgate.net

Schematic diagram of abrasive flow machining. Download Scientific Diagram Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive. Abrasive Flow Machining Cost.

From www.youtube.com

Abrasive Flow Machining Services and Industry Information YouTube Abrasive Flow Machining Cost The abrasive media is forced through the workpiece. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive. Abrasive Flow Machining Cost.

From www.mechanicaleducation.com

Abrasive Water Jet Machining Advantages And Disadvantages Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. The abrasive media is forced through the workpiece. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. In contrast to milling or turning, abrasive processes generate less heat,. Abrasive Flow Machining Cost.

From www.researchgate.net

Schematic diagram of abrasive flow machining Download Scientific Diagram Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. The abrasive media is forced through the workpiece. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is. Abrasive Flow Machining Cost.

From www.waterjet-cutting.com

Abrasive Flow Machining Companies Services Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. An extrude. Abrasive Flow Machining Cost.

From www.engineerlive.com

The perfect finish Engineer Live Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. The abrasive media is forced through the workpiece. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. In contrast to milling or turning, abrasive processes generate less heat,. Abrasive Flow Machining Cost.

From www.cadbull.com

Diagram Of Abrasive Flow Machining Mechanism. Cadbull Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts. Abrasive Flow Machining Cost.

From www.researchgate.net

Schematic diagram of the precision machining of abrasive flow Abrasive Flow Machining Cost Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. The abrasive media is forced through the workpiece. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. In contrast to milling or turning, abrasive processes generate less heat,. Abrasive Flow Machining Cost.

From www.extrudehone.com

FGP testimonial, VECTOR Abrasive Flow Machining (AFM) machine Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. The abrasive media is forced through the workpiece. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On projects large or small, we use abrasive flow machining (afm). Abrasive Flow Machining Cost.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media. Abrasive Flow Machining Cost.

From www.researchgate.net

Principle of the abrasive flow machining process [27] (a) AFM during a Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On. Abrasive Flow Machining Cost.

From www.scribd.com

Abrasive Flow Machining PDF Abrasive Metalworking Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. The abrasive media is forced through the workpiece. In contrast to milling or turning, abrasive processes generate less heat,. Abrasive Flow Machining Cost.

From www.indiamart.com

Abrasive Flow Machining (AFM) at best price in Bengaluru by Extrude Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. The abrasive media is forced through the workpiece. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. On projects large or small,. Abrasive Flow Machining Cost.

From www.researchgate.net

27 Schematic illustration of one abrasive flow machining setup. The Abrasive Flow Machining Cost Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Our extrude hone afm autoflow process provides greater control of the abrasive flow. Abrasive Flow Machining Cost.

From www.scribd.com

Abrasive Flow Machining PDF Machining Abrasive Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and. Abrasive Flow Machining Cost.

From electricalworkbook.com

What is Abrasive Flow Finishing (AFF)? Process, Diagram, Working Abrasive Flow Machining Cost The abrasive media is forced through the workpiece. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size. Abrasive Flow Machining Cost.

From www.scribd.com

Abrasive Flow Machining Process Principle, Parameters and Capabilities Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. An extrude. Abrasive Flow Machining Cost.

From mungfali.com

Machining Process Flow Chart Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid. Abrasive Flow Machining Cost.

From www.engineeringchoice.com

What Is Abrasive Jet Machining (AJM)? A Complete Guide Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. Abrasive flow. Abrasive Flow Machining Cost.

From ebrary.net

Abrasive Flow Machining/Finishing Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. The abrasive. Abrasive Flow Machining Cost.

From www.mdpi.com

Processes Free FullText Study of the Polishing Characteristics by Abrasive Flow Machining Cost The abrasive media is forced through the workpiece. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. On projects large or small, we use abrasive flow machining. Abrasive Flow Machining Cost.

From www.researchgate.net

Process course during abrasive flow machining [10]. Download Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Our extrude hone afm autoflow process provides greater control of the abrasive flow. Abrasive Flow Machining Cost.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Abrasive Flow Machining Cost On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining. Abrasive Flow Machining Cost.

From www.youtube.com

Abrasive Flow Machining process YouTube Abrasive Flow Machining Cost In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. Abrasive flow. Abrasive Flow Machining Cost.

From www.scribd.com

Abrasive Flow Machining PDF Abrasive Machining Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. The abrasive media is forced through the workpiece. Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. In contrast to milling or. Abrasive Flow Machining Cost.

From www.scribd.com

Abrasive Flow Machining Process Principle, Parameters and Capabilities Abrasive Flow Machining Cost Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. The abrasive media is forced through the workpiece. An extrude hone, also known as. Abrasive Flow Machining Cost.

From www.waterjet-cutting.com

Abrasive Flow Machining Companies Services Abrasive Flow Machining Cost Abrasive flow machining (afm) is used to deburr, polish or radius surfaces and edges by flowing a semisolid abrasive media over these areas. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. An extrude hone, also known as an abrasive flow machine, is a machine that. Abrasive Flow Machining Cost.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Abrasive Flow Machining Cost The abrasive media is forced through the workpiece. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Abrasive flow machining (afm) is used to deburr, polish or radius. Abrasive Flow Machining Cost.

From www.youtube.com

Working principle of Abrasive Flow Machining (AFM) YouTube Abrasive Flow Machining Cost Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts with intricate or complex internal. In contrast to milling or turning, abrasive processes generate less heat, ensuring the workpiece material remains undamaged. The abrasive. Abrasive Flow Machining Cost.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Abrasive Flow Machining Cost An extrude hone, also known as an abrasive flow machine, is a machine that performs a finishing process using a highly abrasive and viscous. Our extrude hone afm autoflow process provides greater control of the abrasive flow machining process to enhance the. On projects large or small, we use abrasive flow machining (afm) for deburring and polishing any size parts. Abrasive Flow Machining Cost.