How Much Gas Flow For Tig Welding . adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. We need a lot less flow in tig welding. A flow of 15 to 25 cfh will. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. We need a lot less flow in tig welding. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. gas flow rates. Plug the tig welder into a suitable power outlet. The optimal gas flow rate for tig welding varies by the combination of consumables and. Set up the tig welder.

from weldguru.com

The optimal gas flow rate for tig welding varies by the combination of consumables and. We need a lot less flow in tig welding. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. Plug the tig welder into a suitable power outlet. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. gas flow rates. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. A flow of 15 to 25 cfh will. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour.

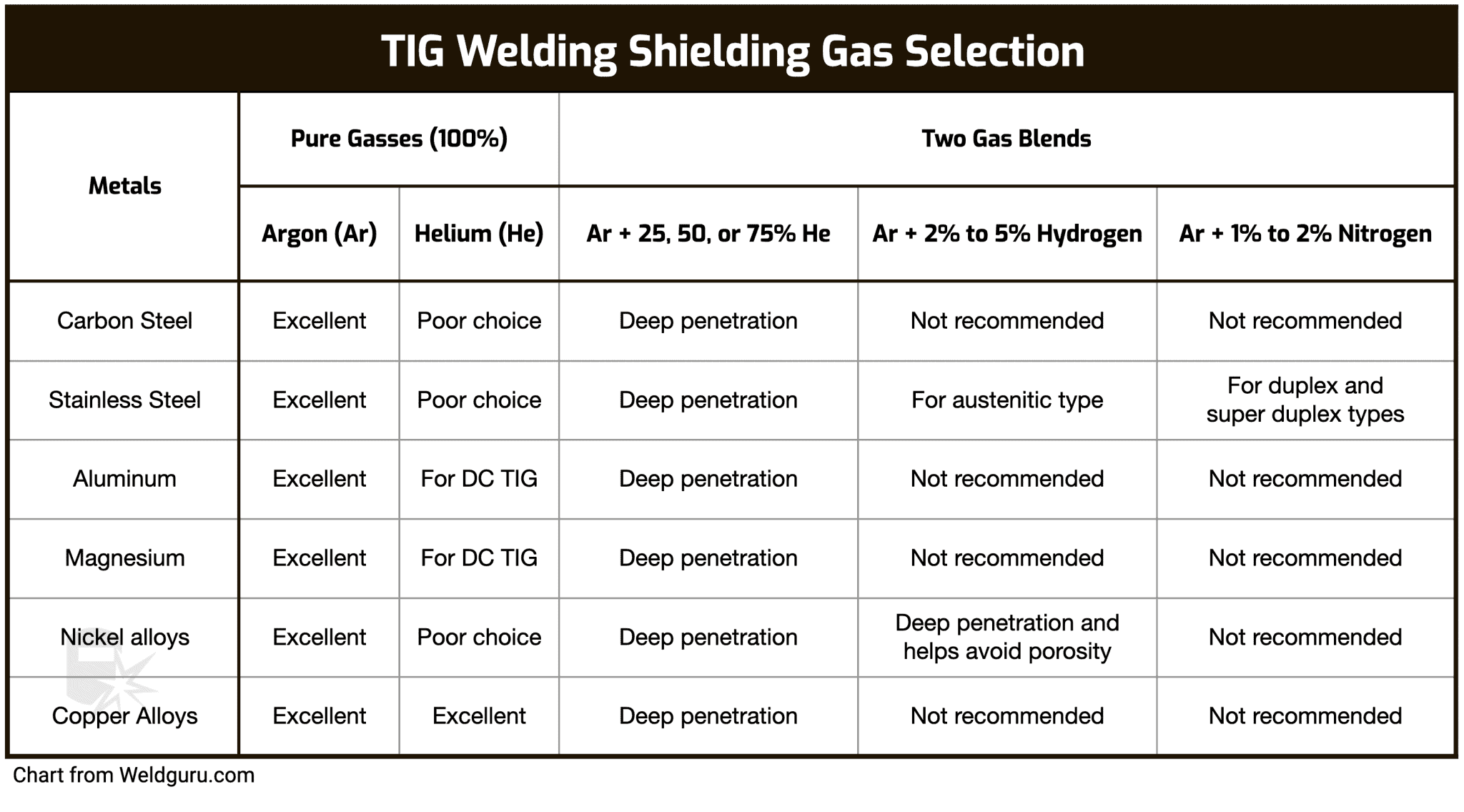

What Gas Should You Use for TIG Welding? (with Chart)

How Much Gas Flow For Tig Welding set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. gas flow rates. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. The optimal gas flow rate for tig welding varies by the combination of consumables and. Plug the tig welder into a suitable power outlet. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A flow of 15 to 25 cfh will. We need a lot less flow in tig welding. Set up the tig welder. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. We need a lot less flow in tig welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) How Much Gas Flow For Tig Welding set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. A flow of 15 to 25 cfh will. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate for tig welding varies by the combination of consumables and. . How Much Gas Flow For Tig Welding.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube How Much Gas Flow For Tig Welding adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. We need a lot less flow in tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most. How Much Gas Flow For Tig Welding.

From lessonzonekendrick.z21.web.core.windows.net

Tig Welding Shielding Gas Chart How Much Gas Flow For Tig Welding Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. We need a lot less flow in tig welding. We need a lot less flow in tig welding. The optimal gas flow rate for tig welding varies by the combination of consumables and. the tig welding gas flow rate for the actual tig welding. How Much Gas Flow For Tig Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. Plug the tig welder into a suitable power outlet. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. We need a lot less. How Much Gas Flow For Tig Welding.

From fitwelding.com

Tig Welding Gas Flow Rate How To Achieve Perfect Gas Flow Rate? Fit How Much Gas Flow For Tig Welding gas flow rates. We need a lot less flow in tig welding. A flow of 15 to 25 cfh will. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Set up the tig welder. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. by understanding. How Much Gas Flow For Tig Welding.

From dxoncacnl.blob.core.windows.net

How Do You Calculate Gas Flow Rate at James Newquist blog How Much Gas Flow For Tig Welding The optimal gas flow rate for tig welding varies by the combination of consumables and. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic. How Much Gas Flow For Tig Welding.

From mavink.com

Mig Welding Gas Flow Rate Chart How Much Gas Flow For Tig Welding A flow of 15 to 25 cfh will. The optimal gas flow rate for tig welding varies by the combination of consumables and. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. We need a lot less flow in tig welding. gas flow rates. Plug the tig welder into a suitable. How Much Gas Flow For Tig Welding.

From workshopinsider.com

Insider's Guide to Gas Tungsten Arc Welding (GTAW) / TIG Welding How Much Gas Flow For Tig Welding adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. The optimal gas flow rate for tig welding varies by the combination of consumables and. gas flow rates. . How Much Gas Flow For Tig Welding.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru How Much Gas Flow For Tig Welding adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. by understanding the factors influencing gas flow. How Much Gas Flow For Tig Welding.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open How Much Gas Flow For Tig Welding set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. Plug the tig welder into a suitable power outlet. The optimal gas flow rate for tig welding varies by the combination of consumables and. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per. How Much Gas Flow For Tig Welding.

From ronsonstorch.com

Selecting the Right Shielding Gas For Your Welding Process RonSon’s How Much Gas Flow For Tig Welding Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. We need a lot less flow in tig welding. Set up the tig welder. Plug the tig welder into a suitable power outlet. The. How Much Gas Flow For Tig Welding.

From prowelderguide.com

Mig Welding Gas Best Types, Guide, TIG and Charts Pro Welder Guide How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. We need a lot less flow in tig welding. gas flow rates. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. Set up the tig welder. the tig welding gas flow rate for the actual tig welding. How Much Gas Flow For Tig Welding.

From dxobykcoh.blob.core.windows.net

Gas Used In Mig Welding Process at Norma White blog How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. Set up the tig welder. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate for tig welding varies by. How Much Gas Flow For Tig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's How Much Gas Flow For Tig Welding Set up the tig welder. We need a lot less flow in tig welding. The optimal gas flow rate for tig welding varies by the combination of consumables and. gas flow rates. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Adequate gas flow for gmaw typically ranges from 35 to 50. How Much Gas Flow For Tig Welding.

From www.mech4study.com

Gas Welding Principle, Working, Equipment, Application, Advantages How Much Gas Flow For Tig Welding Set up the tig welder. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Plug the tig welder into a suitable power outlet. A flow of 15 to 25 cfh will. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness,. How Much Gas Flow For Tig Welding.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele How Much Gas Flow For Tig Welding gas flow rates. Plug the tig welder into a suitable power outlet. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. Set up the tig welder. A. How Much Gas Flow For Tig Welding.

From www.youtube.com

Gas flow meter setup for welding Save gas Tips for gas leak How Much Gas Flow For Tig Welding Plug the tig welder into a suitable power outlet. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate for tig welding varies by the combination of consumables and. We need a lot less flow in tig welding. We need a lot less flow in tig welding. Adequate gas. How Much Gas Flow For Tig Welding.

From www.youtube.com

TIG welding Tungsten Inert Gas welding GTAW welding Gas tungsten How Much Gas Flow For Tig Welding set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. We need a lot less flow in tig welding. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. Plug the tig welder into a. How Much Gas Flow For Tig Welding.

From exoahgqnb.blob.core.windows.net

Welding Techniques For Gas at Ashley Weiner blog How Much Gas Flow For Tig Welding Plug the tig welder into a suitable power outlet. We need a lot less flow in tig welding. gas flow rates. The optimal gas flow rate for tig welding varies by the combination of consumables and. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. set the proper gas flow. How Much Gas Flow For Tig Welding.

From weldingpros.net

How to TIG Weld Steel and Aluminum Basics, Setup and Tips How Much Gas Flow For Tig Welding adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A flow of 15 to 25 cfh will. Set up the tig welder. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. gas flow rates. set the proper gas flow rate, which should be. How Much Gas Flow For Tig Welding.

From fractory.com

OxyAcetylene Welding Explained Gas Welding Fractory How Much Gas Flow For Tig Welding The optimal gas flow rate for tig welding varies by the combination of consumables and. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. Set up the tig welder. gas flow rates. We need a lot less flow in tig welding. adequate gas flow for gmaw. How Much Gas Flow For Tig Welding.

From technologystudent.com

TIG WELDING (Metal Inert Gas) How Much Gas Flow For Tig Welding Plug the tig welder into a suitable power outlet. Set up the tig welder. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. A flow of 15 to 25 cfh will. We. How Much Gas Flow For Tig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's How Much Gas Flow For Tig Welding by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A flow of 15 to 25 cfh will. Set up the tig. How Much Gas Flow For Tig Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide How Much Gas Flow For Tig Welding Set up the tig welder. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. gas flow rates. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. We need a lot less flow in tig welding. Plug. How Much Gas Flow For Tig Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. A flow of 15 to 25 cfh will. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. Set up the tig welder. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly,. How Much Gas Flow For Tig Welding.

From www.researchgate.net

Schematic Diagram of TIG welding process Download Scientific Diagram How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. We need a lot less flow in tig welding. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. A flow of 15 to 25 cfh will. the tig welding gas flow rate for the actual tig welding process. How Much Gas Flow For Tig Welding.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open How Much Gas Flow For Tig Welding the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. A flow of 15 to 25 cfh will. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. We need a lot less flow in tig welding. set the. How Much Gas Flow For Tig Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) How Much Gas Flow For Tig Welding A flow of 15 to 25 cfh will. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. gas flow rates. set the proper gas flow rate, which should be 15 to 20 cubic feet per. How Much Gas Flow For Tig Welding.

From alroys.com

What is TIG welding and how does it work? Alroys How Much Gas Flow For Tig Welding set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. The optimal gas flow rate for tig welding varies by the combination of consumables and. We need a lot less flow in tig welding. We need a lot less flow in tig welding. by understanding the factors influencing. How Much Gas Flow For Tig Welding.

From mavink.com

Mig Welding Gas Flow Chart How Much Gas Flow For Tig Welding Set up the tig welder. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per hour (cfh) for most applications. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. Plug. How Much Gas Flow For Tig Welding.

From mungfali.com

Mig Welding Gas Flow Chart How Much Gas Flow For Tig Welding A flow of 15 to 25 cfh will. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Set up the tig welder. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. set the proper gas flow rate, which should be 15 to 20 cubic feet per. How Much Gas Flow For Tig Welding.

From www.sevencolors.co.jp

Tig Welding Argon Gas Flow Rate sevencolors.co.jp How Much Gas Flow For Tig Welding We need a lot less flow in tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. Set up the tig welder. by understanding the factors influencing gas. How Much Gas Flow For Tig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's How Much Gas Flow For Tig Welding A flow of 15 to 25 cfh will. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Set up the tig welder. Plug the tig welder into a suitable power outlet. gas flow rates. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry. adequate. How Much Gas Flow For Tig Welding.

From resources.arcmachines.com

Tig Welding Gas Flow Rate Arc Machines How Much Gas Flow For Tig Welding The optimal gas flow rate for tig welding varies by the combination of consumables and. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. gas flow rates. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. A flow. How Much Gas Flow For Tig Welding.

From fitwelding.com

Tig Welding Gas for Aluminum The Ultimate Guide to Success Fit Welding How Much Gas Flow For Tig Welding Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A flow of 15 to 25 cfh will. Set up the tig welder. We need a lot less flow in tig welding. by understanding the factors influencing gas. How Much Gas Flow For Tig Welding.