Which Type Of Flux Is Used For Soldering Steel Sheets . For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. They key to successful soldering of stainless steel lies in. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world.

from ar.inspiredpencil.com

Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. When you are soldering any type of sheet metal, it is very important to choose the right flux. They key to successful soldering of stainless steel lies in. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency.

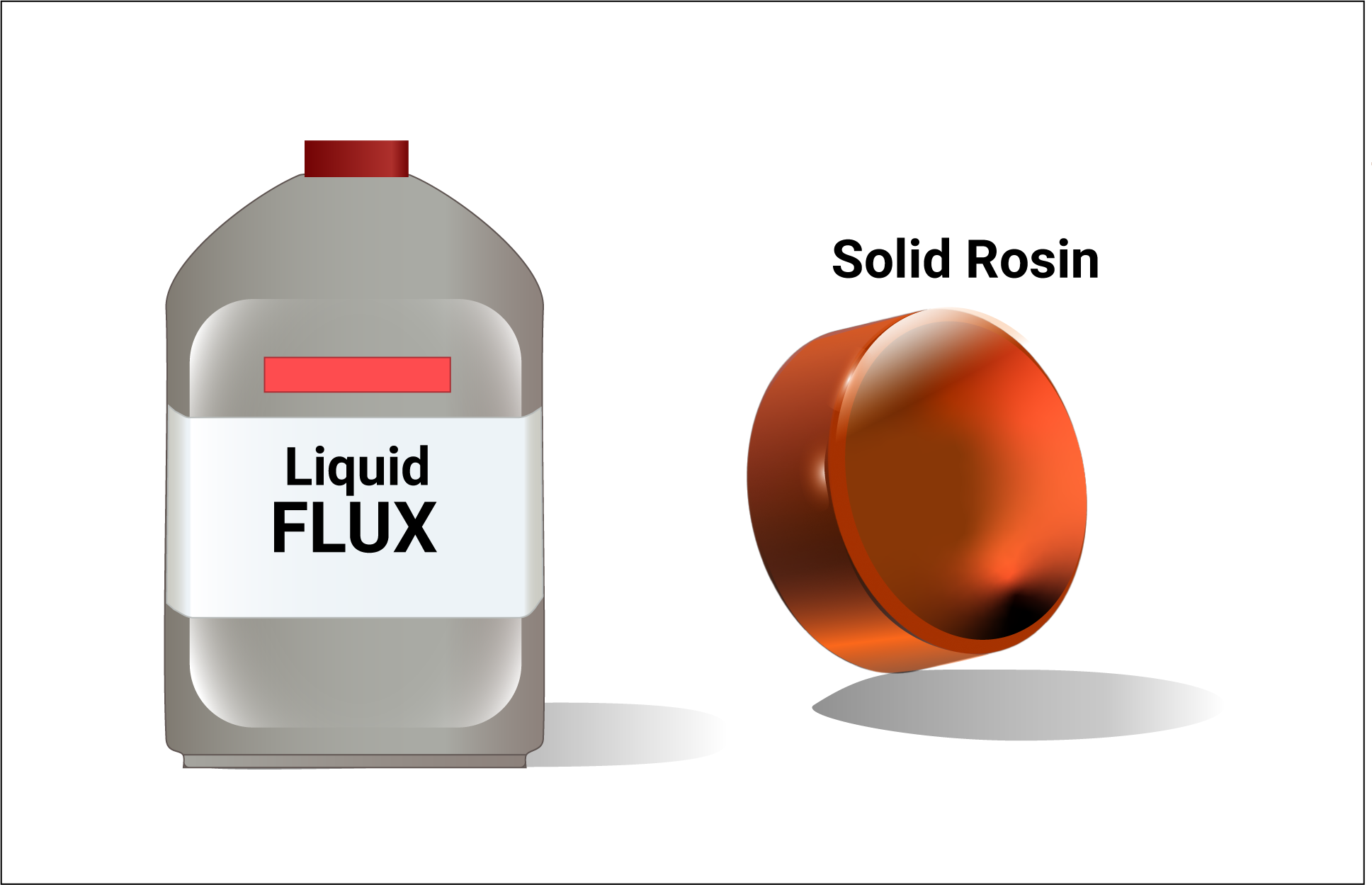

Soldering Flux

Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. They key to successful soldering of stainless steel lies in. When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel.

From www.tech-sparks.com

Distribution process for soldering circuit boardsTechSparks Which Type Of Flux Is Used For Soldering Steel Sheets A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. They key to successful soldering of stainless steel lies in. However, too. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.youtube.com

How to Decide Which Type of Flux to Use and How to Use Flux Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen for the selective soldering process has a great. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.electroncomponents.com

Soldering paste Flux Solder Paste 15gm Buy Online Electronic Which Type Of Flux Is Used For Soldering Steel Sheets A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. They key to successful soldering of stainless steel lies in. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. For soldering galvanized steel, the right. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.youtube.com

How To Use Flux / When To Use Flux Soldering Tutorial HD YouTube Which Type Of Flux Is Used For Soldering Steel Sheets When you are soldering any type of sheet metal, it is very important to choose the right flux. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.makeuseof.com

What Is Solder Paste and What Is It Used For? Which Type Of Flux Is Used For Soldering Steel Sheets When you are soldering any type of sheet metal, it is very important to choose the right flux. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface.. Which Type Of Flux Is Used For Soldering Steel Sheets.

From patabook.com

Types of Soldering and Flux The Home Depot Patabook Home Improvements Which Type Of Flux Is Used For Soldering Steel Sheets In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. When you are soldering any type of sheet metal, it is very important to choose the right flux. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which. Which Type Of Flux Is Used For Soldering Steel Sheets.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. Whilst often overlooked, the flux chosen for. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components Which Type Of Flux Is Used For Soldering Steel Sheets A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. They key to successful soldering of stainless steel lies in. When you are soldering any type of sheet metal, it. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.pinterest.com

flux and soldering Chip Dip, Ceramic Materials, Soldering, Vaseline Which Type Of Flux Is Used For Soldering Steel Sheets However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. When you are soldering any type of sheet metal, it is very important to choose the right flux. Flux is made of an activator and. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.comego.org.mx

COMEGO INICIO Which Type Of Flux Is Used For Soldering Steel Sheets A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. When you are soldering any type of sheet metal, it is very important to choose the right flux. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Proper flux. Which Type Of Flux Is Used For Soldering Steel Sheets.

From ar.inspiredpencil.com

Soldering Flux Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Flux is made of an activator and. Which Type Of Flux Is Used For Soldering Steel Sheets.

From mx.chemtronics.com

Guía Esencial de Flux para Componentes Electrónicos de Soldadura Which Type Of Flux Is Used For Soldering Steel Sheets Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. For soldering galvanized steel, the right flux will get. Which Type Of Flux Is Used For Soldering Steel Sheets.

From solderingrepair.com

What Is Soldering Flux Used for Which Type Of Flux Is Used For Soldering Steel Sheets For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.youtube.com

All About Soldering Flux for Jewelry Making YouTube Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. A great liquid flux that has an. Which Type Of Flux Is Used For Soldering Steel Sheets.

From pcbtoolexpert.com

Top 5 Best Flux For Soldering Electronics PCB Tool Expert Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. For soldering galvanized steel, the right. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.walmart.com

Soldering Flux Paste, 50 Gram Jar, RoHS Compliant, Helps Solder Flow Which Type Of Flux Is Used For Soldering Steel Sheets Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. For soldering galvanized steel, the right flux will get the best hold on. Which Type Of Flux Is Used For Soldering Steel Sheets.

From ar.inspiredpencil.com

Soldering Flux Which Type Of Flux Is Used For Soldering Steel Sheets Flux is made of an activator and a carrier that allows the solder to “wet” to the base. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.desertcart.ae

2 Jar Solder Flux, Flux for Soldering, Rosin Soldering Flux Paste for Which Type Of Flux Is Used For Soldering Steel Sheets However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. They key to successful soldering of stainless steel lies in. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. In solder pastes, flux plays a vital. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.youtube.com

Leaded vs leadfree solder (feat tacky flux) DIY soldering YouTube Which Type Of Flux Is Used For Soldering Steel Sheets However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for. Which Type Of Flux Is Used For Soldering Steel Sheets.

From openletteronthedigitaleconomy.org

Do You Need Flux to Solder Open Letter on the Digital Eeconomy Which Type Of Flux Is Used For Soldering Steel Sheets For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term. Which Type Of Flux Is Used For Soldering Steel Sheets.

From resources.altium.com

Types of PCB Soldering and the Assembly Process Blog Altium Designer Which Type Of Flux Is Used For Soldering Steel Sheets Flux is made of an activator and a carrier that allows the solder to “wet” to the base. They key to successful soldering of stainless steel lies in. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. For soldering galvanized steel, the right. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.grainger.com

LACO, 16 oz, Jar, Soldering Flux 31ME5722407 Grainger Which Type Of Flux Is Used For Soldering Steel Sheets Flux is made of an activator and a carrier that allows the solder to “wet” to the base. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. In solder. Which Type Of Flux Is Used For Soldering Steel Sheets.

From weldingmastermind.com

Can You Use Too Much Flux When Soldering? Here’s the Truth Welding Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen for the selective soldering process has a great. Which Type Of Flux Is Used For Soldering Steel Sheets.

From stellartechnical.com

What Is The Best Way To Solder Galvanized Steel? Which Type Of Flux Is Used For Soldering Steel Sheets A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. When you are soldering any type of sheet metal, it is very important to choose the right flux. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. In solder. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.tilgear.info

Flux Soldering Tilgear Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. When you are soldering any type of sheet metal, it is very important to choose the right flux. For soldering galvanized steel, the right flux will get the. Which Type Of Flux Is Used For Soldering Steel Sheets.

From fractory.com

Soldering Explained Definition, Process, Types Fractory Which Type Of Flux Is Used For Soldering Steel Sheets Flux is made of an activator and a carrier that allows the solder to “wet” to the base. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.pinterest.com

SDG 086 What's the best flux for soldering? A comparison with PCBs Which Type Of Flux Is Used For Soldering Steel Sheets For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized. Which Type Of Flux Is Used For Soldering Steel Sheets.

From yoshida-welding.en.made-in-china.com

TType Soldering Tin Sheet Sac305 Customization Innovative Soldering Which Type Of Flux Is Used For Soldering Steel Sheets They key to successful soldering of stainless steel lies in. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. A great liquid flux that has an active. Which Type Of Flux Is Used For Soldering Steel Sheets.

From polizvisions.weebly.com

Solder flux polizvisions Which Type Of Flux Is Used For Soldering Steel Sheets However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen. Which Type Of Flux Is Used For Soldering Steel Sheets.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Which Type Of Flux Is Used For Soldering Steel Sheets Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Flux is made of an activator and a carrier that allows the solder to “wet” to the. Which Type Of Flux Is Used For Soldering Steel Sheets.

From giowbznjg.blob.core.windows.net

Which Type Of Soldering Flux Is Used For Soldering Aluminum Conductors Which Type Of Flux Is Used For Soldering Steel Sheets However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Whilst often overlooked,. Which Type Of Flux Is Used For Soldering Steel Sheets.

From weldingmastermind.com

What is the Difference Between Solder Paste And Flux? Welding Mastermind Which Type Of Flux Is Used For Soldering Steel Sheets When you are soldering any type of sheet metal, it is very important to choose the right flux. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long term reliability and overall selective soldering. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel. Which Type Of Flux Is Used For Soldering Steel Sheets.

From www.hellopractical.com

What Type of FLUX is Used in Electronics Soldering Which Type Of Flux Is Used For Soldering Steel Sheets Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and efficiency. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder. Which Type Of Flux Is Used For Soldering Steel Sheets.

From studylib.net

Liquid Soldering Flux Which Type Of Flux Is Used For Soldering Steel Sheets When you are soldering any type of sheet metal, it is very important to choose the right flux. Flux is made of an activator and a carrier that allows the solder to “wet” to the base. Proper flux application ensures optimal soldering quality by aiding in metal melting, oxide removal, and reducing solder melting points, which improves joint quality and. Which Type Of Flux Is Used For Soldering Steel Sheets.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes Which Type Of Flux Is Used For Soldering Steel Sheets In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. However, too much flux can lead to spattering, bubble formation, and prolonged volatilization times, affecting quality and efficiency. Whilst often overlooked, the flux chosen for the selective soldering process has a great impact on solder joint quality, long. Which Type Of Flux Is Used For Soldering Steel Sheets.