Grinding Disc Manufacturing Process . It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing.

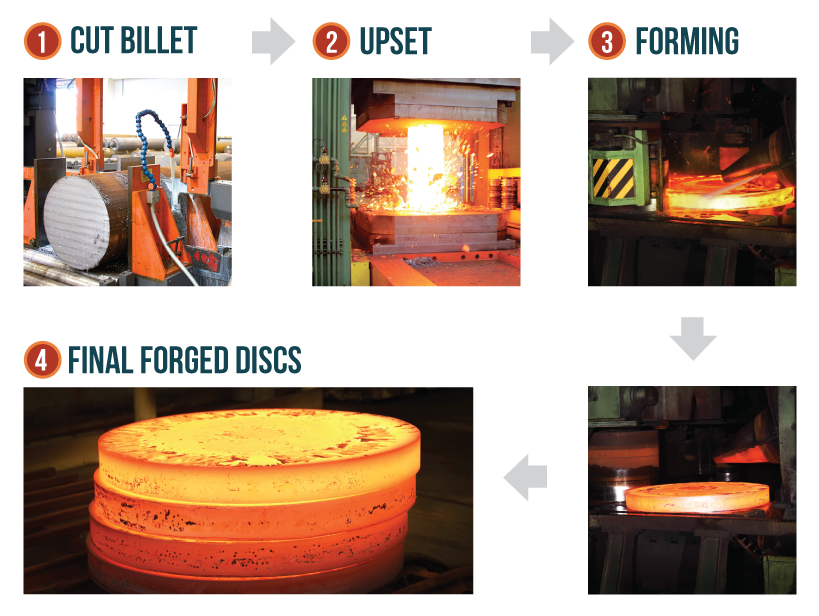

from www.mcinnesrolledrings.com

Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy.

McInnes Rolled Rings

Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These processes form the foundation of what we currently refer to as grinding, which is: It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail.

From www.youtube.com

The amazing Process of Disk Brake Plate Production YouTube Grinding Disc Manufacturing Process Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. This article explores the definition, types, uses, and working process of grinding in detail. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive particles are first crushed to powder. Grinding Disc Manufacturing Process.

From www.kindpng.com

Process Flow Diagram Glass Production Compact Disc Manufacturing Grinding Disc Manufacturing Process (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as. Grinding Disc Manufacturing Process.

From www.youtube.com

brake disc turning and grinding machine YouTube Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive particles are first crushed to powder. Grinding Disc Manufacturing Process.

From www.youtube.com

Grinding Process, Types, Applications and Advantages YouTube Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. These processes form the foundation of what we currently refer to as grinding, which is: Grinding is a precision machining process that uses an abrasive wheel. Grinding Disc Manufacturing Process.

From www.researchgate.net

Manufacturing setup of the electroplating process and grinding wheel Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. These processes form the foundation of what we currently. Grinding Disc Manufacturing Process.

From www.fivesgroup.com

Single and double disc grinding for diverse applications Grinding Disc Manufacturing Process These processes form the foundation of what we currently refer to as grinding, which is: Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. This article explores the definition, types, uses, and working process of grinding in detail. (i) the abrasive particles are first. Grinding Disc Manufacturing Process.

From unitech-ikk.com

Grinding Cutting Black Disk Hardware and Tools Specialized Building Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Grinding is a precision machining process that uses an abrasive wheel or. Grinding Disc Manufacturing Process.

From www.delungrinding.com

China grinding disc manufacturing process manufacturers, grinding disc Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: (i) the abrasive particles are first crushed to powder form and passed over magnetic. Grinding Disc Manufacturing Process.

From e-well.en.made-in-china.com

Sintered Diamond Polishing Disc 4 Inch for Grinding with Turbine Blade Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. This article explores the definition, types,. Grinding Disc Manufacturing Process.

From www.mcinnesrolledrings.com

McInnes Rolled Rings Grinding Disc Manufacturing Process Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. (i) the abrasive particles are first crushed to powder. Grinding Disc Manufacturing Process.

From www.nghexin.co.za

Grinding media manufacturing process www.nghexin.co.za Grinding Disc Manufacturing Process These processes form the foundation of what we currently refer to as grinding, which is: This article explores the definition, types, uses, and working process of grinding in detail. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material,. Grinding Disc Manufacturing Process.

From www.craiyon.com

Aluminum disc manufacturing process on Craiyon Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape. Grinding Disc Manufacturing Process.

From www.usedtirerecycling.com

Rubber Grinding Machine Used Tire Recycling Grinding Disc Manufacturing Process (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These. Grinding Disc Manufacturing Process.

From benchmarkinstitute.org

grinding wheel manufacturing process Cheaper Than Retail Price> Buy Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. These processes form the foundation of what we currently refer to as grinding, which is: Grinding is a. Grinding Disc Manufacturing Process.

From e-well.en.made-in-china.com

4 Inch Diamond Grinding Wheel Disc with Turbine Blade and Sintered Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. These. Grinding Disc Manufacturing Process.

From www.youtube.com

Grinding Process by lourence (mechanical engineering student) YouTube Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision. Grinding Disc Manufacturing Process.

From www.delungrinding.com

China grinding disc manufacturing process manufacturers, grinding disc Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. (i) the abrasive particles. Grinding Disc Manufacturing Process.

From www.youtube.com

How to use a Cutting Disc with an Angle Grinder YouTube Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. These processes form the foundation of what we currently. Grinding Disc Manufacturing Process.

From eureka.patsnap.com

Compositematerial grinding roller, grinding disc, and negative Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These processes form the foundation of what we currently refer to as grinding, which is: It is commonly used in manufacturing. Grinding Disc Manufacturing Process.

From mwi-inc.com

What is the grinding manufacturing process? MWI, Inc. Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape. Grinding Disc Manufacturing Process.

From www.market-prospects.com

What Is Grinding and Its Working Principle and Type? Grinding Process Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Grinding. Grinding Disc Manufacturing Process.

From norseshop.com

Grinding Disc Norse Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. It. Grinding Disc Manufacturing Process.

From www.camarossaudio.com

abrasive grinding wheel manufacturers exclusive designs Grinding Disc Manufacturing Process These processes form the foundation of what we currently refer to as grinding, which is: This article explores the definition, types, uses, and working process of grinding in detail. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. Cutting disc/grinding wheel is made of resin as binder, fiberglass net. Grinding Disc Manufacturing Process.

From blog.indianaprecisiongrinding.com

The Benefits of Double Disc Grinding Grinding Disc Manufacturing Process (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. This. Grinding Disc Manufacturing Process.

From e-well.en.made-in-china.com

Diamond Cup Grinding Wheel Disc with Sintered Manufacturing Process Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. (i) the abrasive particles are first crushed to powder form and passed over magnetic separators. Grinding Disc Manufacturing Process.

From www.myneinc.com

EuroCut Grinding Disc Myne Inc., Grinding Disc Manufacturing Process (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. This article explores the definition, types, uses, and working process of grinding in detail. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. These processes form the foundation of what we currently refer to as. Grinding Disc Manufacturing Process.

From www.youtube.com

Rotary Double Disc Grinding Machine for Bush & Pins YouTube Grinding Disc Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These processes form the foundation of what we currently refer to as grinding, which is: It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. (i) the abrasive. Grinding Disc Manufacturing Process.

From www.researchgate.net

Flow chart of grinding procedure. Download Scientific Diagram Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. (i) the abrasive particles are first. Grinding Disc Manufacturing Process.

From www.hygrade.com

Double Disc Grinding Hygrade Precision Technologies Grinding Disc Manufacturing Process These processes form the foundation of what we currently refer to as grinding, which is: (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. It is commonly. Grinding Disc Manufacturing Process.

From www.researchgate.net

Determination of profileshifted grinding disc. Download Scientific Grinding Disc Manufacturing Process Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. These processes form the foundation of what we currently refer to as grinding, which is: This article explores the definition, types, uses, and. Grinding Disc Manufacturing Process.

From hblueding.en.made-in-china.com

TSegment Diamond Grinding Discs Are Used for Milling Into Existing Grinding Disc Manufacturing Process (i) the abrasive particles are first crushed to powder form and passed over magnetic separators for removing. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These processes form the foundation of what we currently refer to as grinding, which is: This article explores. Grinding Disc Manufacturing Process.

From eureka.patsnap.com

Grinding disc and equipment and method for accurate machining of Grinding Disc Manufacturing Process This article explores the definition, types, uses, and working process of grinding in detail. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. These processes form the foundation of what we currently refer to as grinding, which is: Grinding is a precision machining process. Grinding Disc Manufacturing Process.

From www.youtube.com

How It's Made Cutting Disc Manufacturing Process YouTube Grinding Disc Manufacturing Process Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: (i) the abrasive particles are first crushed to powder form and. Grinding Disc Manufacturing Process.

From www.delungrinding.com

China grinding disc manufacturing process manufacturers, grinding disc Grinding Disc Manufacturing Process Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece. It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and. Grinding Disc Manufacturing Process.

From www.delungrinding.com

China grinding disc manufacturing process manufacturers, grinding disc Grinding Disc Manufacturing Process It is commonly used in manufacturing operations to achieve a smooth surface finish and precise dimensional accuracy. This article explores the definition, types, uses, and working process of grinding in detail. These processes form the foundation of what we currently refer to as grinding, which is: Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material,. Grinding Disc Manufacturing Process.