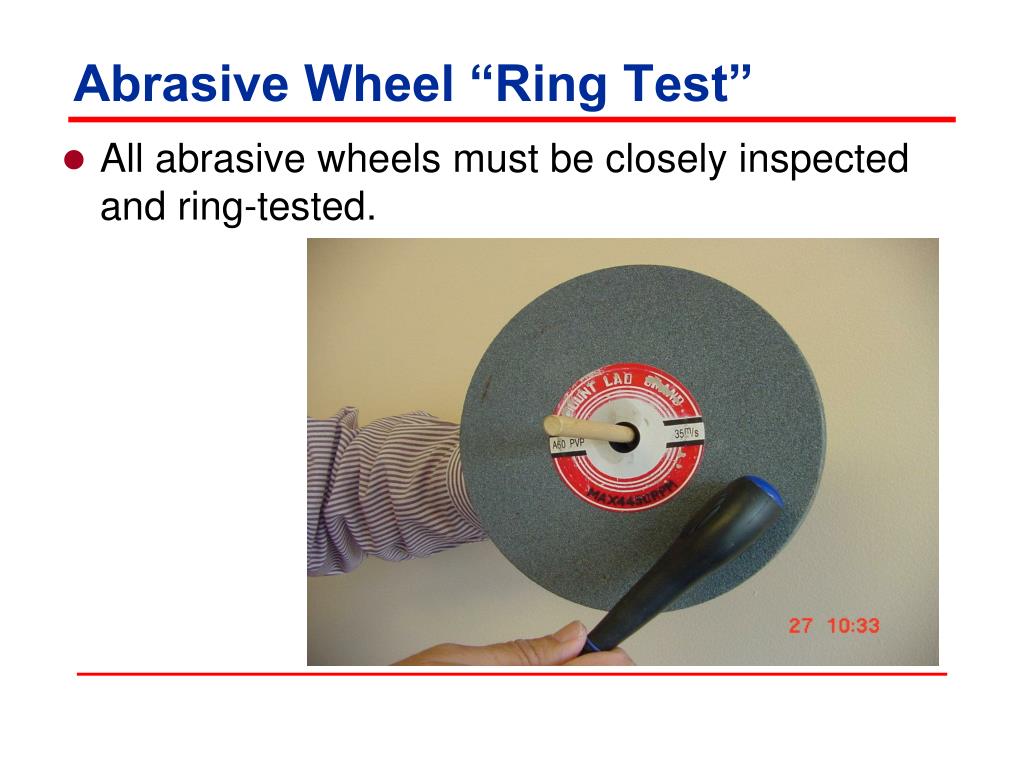

What Test Should Be Performed On Abrasive Wheels . And how do you inspect and test an abrasive wheel? Abrasive wheels must be marked in accordance with annex a of bs en 12413. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. What tests should be performed on an abrasive wheel? Two effective methods to detect cracks are the ring test and the vibration test. Compressed air can be used for cleaning as long as it is less than 30 psi. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Cracks in abrasive wheels are often impossible to see. What test should be performed on abrasive wheels? Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone.

from www.slideserve.com

And how do you inspect and test an abrasive wheel? What tests should be performed on an abrasive wheel? Cracks in abrasive wheels are often impossible to see. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Two effective methods to detect cracks are the ring test and the vibration test. What test should be performed on abrasive wheels? This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder.

PPT General Industry PowerPoint Presentation, free download ID595796

What Test Should Be Performed On Abrasive Wheels Cracks in abrasive wheels are often impossible to see. Two effective methods to detect cracks are the ring test and the vibration test. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Abrasive wheels must be marked in accordance with annex a of bs en 12413. And how do you inspect and test an abrasive wheel? Compressed air can be used for cleaning as long as it is less than 30 psi. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Cracks in abrasive wheels are often impossible to see. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. What test should be performed on abrasive wheels? What tests should be performed on an abrasive wheel?

From entirelysafe.com

Portable Abrasive Wheel Tools and Associated Hazards What Test Should Be Performed On Abrasive Wheels Cracks in abrasive wheels are often impossible to see. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Learn how to inspect grinding wheels for cracks by. What Test Should Be Performed On Abrasive Wheels.

From www.ethiretraining.com

The Safe Use Of Abrasive Wheel ET Hire Training What Test Should Be Performed On Abrasive Wheels Abrasive wheels must be marked in accordance with annex a of bs en 12413. What tests should be performed on an abrasive wheel? Compressed air can be used for cleaning as long as it is less than 30 psi. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Check the diameter. What Test Should Be Performed On Abrasive Wheels.

From trimmers-pro.com

Wheel Abrasive Test What Test Should Be Performed On Abrasive Wheels Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Abrasive wheels must be marked in accordance with annex a of bs en 12413. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Two effective methods to detect cracks are the ring test. What Test Should Be Performed On Abrasive Wheels.

From www.atfsolutions.com

Abrasive Wheels Training — AT&F Solutions What Test Should Be Performed On Abrasive Wheels This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. And how do you inspect and test an abrasive wheel? Compressed air can be used for cleaning as long as it is less than 30 psi. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Check. What Test Should Be Performed On Abrasive Wheels.

From www.kissafety.co.uk

Abrasive Wheels Understanding the Marking System KIS Health and What Test Should Be Performed On Abrasive Wheels Two effective methods to detect cracks are the ring test and the vibration test. Abrasive wheels must be marked in accordance with annex a of bs en 12413. What test should be performed on abrasive wheels? What tests should be performed on an abrasive wheel? This article explains the tests done on abrasive wheels to ensure they meet standards and. What Test Should Be Performed On Abrasive Wheels.

From www.researchgate.net

Specification of abrasive cutting discs used during tests. Download What Test Should Be Performed On Abrasive Wheels Cracks in abrasive wheels are often impossible to see. And how do you inspect and test an abrasive wheel? Two effective methods to detect cracks are the ring test and the vibration test. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Abrasive wheels must be marked in accordance with. What Test Should Be Performed On Abrasive Wheels.

From www.slideserve.com

PPT Hand and Power Tool Safety PowerPoint Presentation, free download What Test Should Be Performed On Abrasive Wheels Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. What test should be performed on abrasive wheels? And how do you inspect and test an abrasive wheel?. What Test Should Be Performed On Abrasive Wheels.

From binictools.com

What test should be performed on abrasive wheels quizlet? Binic Abrasive What Test Should Be Performed On Abrasive Wheels Compressed air can be used for cleaning as long as it is less than 30 psi. Two effective methods to detect cracks are the ring test and the vibration test. What test should be performed on abrasive wheels? Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. What tests should be. What Test Should Be Performed On Abrasive Wheels.

From olivelearning.com.au

Abrasive Wheels Olive Learning What Test Should Be Performed On Abrasive Wheels Two effective methods to detect cracks are the ring test and the vibration test. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Cracks in abrasive wheels are often impossible to see. What test should be performed on abrasive wheels? Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for. What Test Should Be Performed On Abrasive Wheels.

From www.slideserve.com

PPT Abrasive Grinding Wheels PowerPoint Presentation, free download What Test Should Be Performed On Abrasive Wheels Abrasive wheels must be marked in accordance with annex a of bs en 12413. Compressed air can be used for cleaning as long as it is less than 30 psi. What tests should be performed on an abrasive wheel? What test should be performed on abrasive wheels? Learn how to inspect grinding wheels for cracks by tapping them lightly and. What Test Should Be Performed On Abrasive Wheels.

From gnl-consultancy.co.uk

Abrasive Wheels G&L Consultancy Training and Asbestos Management What Test Should Be Performed On Abrasive Wheels This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Two effective methods to detect cracks are the ring test and the vibration test. And how do you inspect and test an abrasive wheel? This guide will. What Test Should Be Performed On Abrasive Wheels.

From thenextroad.com

What test should be performed on abrasive wheels? What Test Should Be Performed On Abrasive Wheels Two effective methods to detect cracks are the ring test and the vibration test. What test should be performed on abrasive wheels? Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Compressed air can be used for cleaning as long as it is less than 30 psi. This article explains the. What Test Should Be Performed On Abrasive Wheels.

From www.youtube.com

Abrasive Wheel Safety Training Health & Safety Training iHasco What Test Should Be Performed On Abrasive Wheels What test should be performed on abrasive wheels? This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Two effective. What Test Should Be Performed On Abrasive Wheels.

From ask.modifiyegaraj.com

What Test Should Be Performed On Abrasive Wheels Asking List What Test Should Be Performed On Abrasive Wheels Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. What test should be performed on abrasive wheels? This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Abrasive wheels must be marked in accordance with annex a of bs en 12413. Two. What Test Should Be Performed On Abrasive Wheels.

From digitalglobaltimes.com

What Test Should Be Performed On Abrasive Wheels Digital Global Times What Test Should Be Performed On Abrasive Wheels Compressed air can be used for cleaning as long as it is less than 30 psi. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Cracks in abrasive wheels are often impossible to see. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a. What Test Should Be Performed On Abrasive Wheels.

From www.osa-abrasives.org

Safety tests of grinding wheels Side load capacity Infocenter oSa What Test Should Be Performed On Abrasive Wheels What tests should be performed on an abrasive wheel? Cracks in abrasive wheels are often impossible to see. Compressed air can be used for cleaning as long as it is less than 30 psi. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. What test should be performed on abrasive. What Test Should Be Performed On Abrasive Wheels.

From www.safetyhub.com

Abrasive Wheel Safety Training Online Safetyhub What Test Should Be Performed On Abrasive Wheels Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Compressed air can be used for cleaning as long as it is less than 30 psi. Cracks in abrasive wheels are often impossible to see. Abrasive wheels must be marked in accordance with annex a of. What Test Should Be Performed On Abrasive Wheels.

From safetymatters.ie

Abrasive Wheels Training Safety Matters What Test Should Be Performed On Abrasive Wheels And how do you inspect and test an abrasive wheel? This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Cracks in abrasive wheels are often impossible to see. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your. What Test Should Be Performed On Abrasive Wheels.

From ncts.teachable.com

Abrasive Wheels National Construction Training & Safety What Test Should Be Performed On Abrasive Wheels Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they. What Test Should Be Performed On Abrasive Wheels.

From safeti.com

Abrasive Wheels Risk Assessment PLUS Free CPD Training What Test Should Be Performed On Abrasive Wheels Two effective methods to detect cracks are the ring test and the vibration test. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. This article explains the. What Test Should Be Performed On Abrasive Wheels.

From www.uksafetystore.com

Abrasive Wheels Poster UK Safety Store What Test Should Be Performed On Abrasive Wheels Two effective methods to detect cracks are the ring test and the vibration test. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Check the diameter of the wheel, as well as. What Test Should Be Performed On Abrasive Wheels.

From novoabrasive.com

Interpretation of the Marking of NovoAbrasive abrasive discs according What Test Should Be Performed On Abrasive Wheels Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Cracks in abrasive wheels are often impossible to see. What tests should be performed on an abrasive wheel?. What Test Should Be Performed On Abrasive Wheels.

From essentialsiteskills.co.uk

The ESS Guide to Abrasive Wheels Training Essential Site Skills What Test Should Be Performed On Abrasive Wheels Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. What test should be performed on abrasive wheels? What tests should be performed on an abrasive wheel? Compressed. What Test Should Be Performed On Abrasive Wheels.

From thenextroad.com

What test should be performed on abrasive wheels? The Next Road What Test Should Be Performed On Abrasive Wheels Abrasive wheels must be marked in accordance with annex a of bs en 12413. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. What test should be performed on abrasive wheels? Compressed air can be used for cleaning as long as it is less than 30 psi. And how do you. What Test Should Be Performed On Abrasive Wheels.

From www.qhsedocuments.com

RISK ASSESSMENT ABRASIVE WHEELS What Test Should Be Performed On Abrasive Wheels Abrasive wheels must be marked in accordance with annex a of bs en 12413. What tests should be performed on an abrasive wheel? Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Cracks in abrasive wheels are often impossible to see. And how do you. What Test Should Be Performed On Abrasive Wheels.

From www.youtube.com

Abrasive Wheel Safety Training YouTube What Test Should Be Performed On Abrasive Wheels Cracks in abrasive wheels are often impossible to see. What tests should be performed on an abrasive wheel? Two effective methods to detect cracks are the ring test and the vibration test. Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. And how do you. What Test Should Be Performed On Abrasive Wheels.

From www.safework.nsw.gov.au

Safe use of abrasive wheels fact sheet SafeWork NSW What Test Should Be Performed On Abrasive Wheels Cracks in abrasive wheels are often impossible to see. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. What tests should be performed on an abrasive wheel? This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Check the diameter of the. What Test Should Be Performed On Abrasive Wheels.

From www.hindustanabrasives.com

What is An Abrasive Grinding Wheel Ring Test? & How to Perform a Ring What Test Should Be Performed On Abrasive Wheels Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. And how do you inspect and test an abrasive wheel? What tests should be performed on an abrasive wheel? Check the diameter of. What Test Should Be Performed On Abrasive Wheels.

From www.kissafety.co.uk

Abrasive Wheels Understanding the Marking System KIS Health and What Test Should Be Performed On Abrasive Wheels This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. And how do you inspect and test an abrasive wheel? Abrasive wheels must be marked in accordance with annex a of bs en 12413. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear. What Test Should Be Performed On Abrasive Wheels.

From www.slideserve.com

PPT General Industry PowerPoint Presentation, free download ID595796 What Test Should Be Performed On Abrasive Wheels Compressed air can be used for cleaning as long as it is less than 30 psi. And how do you inspect and test an abrasive wheel? Abrasive wheels must be marked in accordance with annex a of bs en 12413. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Learn how. What Test Should Be Performed On Abrasive Wheels.

From ask.modifiyegaraj.com

What Test Should Be Performed On Abrasive Wheels Asking List What Test Should Be Performed On Abrasive Wheels Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Compressed air can be used for cleaning as long as it is less than 30 psi. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. And how. What Test Should Be Performed On Abrasive Wheels.

From www.trainingandtestingservices.co.uk

What is abrasive wheel training Training & Testing Services What Test Should Be Performed On Abrasive Wheels And how do you inspect and test an abrasive wheel? Abrasive wheels must be marked in accordance with annex a of bs en 12413. What tests should be performed on an abrasive wheel? Compressed air can be used for cleaning as long as it is less than 30 psi. Two effective methods to detect cracks are the ring test and. What Test Should Be Performed On Abrasive Wheels.

From shoal-safetyinnumbers.com

Abrasive Wheels Awareness Training Shoal What Test Should Be Performed On Abrasive Wheels What test should be performed on abrasive wheels? Abrasive wheels must be marked in accordance with annex a of bs en 12413. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. What tests should be performed on an abrasive wheel? Cracks in abrasive wheels are often impossible to see. Compressed air. What Test Should Be Performed On Abrasive Wheels.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme What Test Should Be Performed On Abrasive Wheels This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. What test should be performed on abrasive wheels? Check the diameter of the wheel, as well as its maximum rated speed, to make sure it is suitable for use with your grinder. Cracks in abrasive wheels are often impossible to see. This. What Test Should Be Performed On Abrasive Wheels.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint What Test Should Be Performed On Abrasive Wheels What tests should be performed on an abrasive wheel? Two effective methods to detect cracks are the ring test and the vibration test. This article explains the tests done on abrasive wheels to ensure they meet standards and work as they should. Learn how to inspect grinding wheels for cracks by tapping them lightly and listening for a clear tone.. What Test Should Be Performed On Abrasive Wheels.