Worm Gear Face Width . First response provided by joe mihelick, gear technology. Worm gear face width design. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Design of module, number of teeth, worm diameter factor and correction. The pitch line velocity is ideally up to 30. An outline design procedure for a worm and wheel gear set using the agma equations is: Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Define the number of starts. Define the center distance, c. Calculation of worm gear unit correction. How does one determine the center of a worm and a worm wheel?

from www.numerade.com

Define the number of starts. Design of module, number of teeth, worm diameter factor and correction. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. How does one determine the center of a worm and a worm wheel? Calculation of worm gear unit correction. An outline design procedure for a worm and wheel gear set using the agma equations is: First response provided by joe mihelick, gear technology. The pitch line velocity is ideally up to 30. Define the center distance, c.

SOLVED A righthand doubletooth hardenedsteel (hardness not

Worm Gear Face Width Worm gear face width design. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. An outline design procedure for a worm and wheel gear set using the agma equations is: How does one determine the center of a worm and a worm wheel? First response provided by joe mihelick, gear technology. Design of module, number of teeth, worm diameter factor and correction. Define the center distance, c. Calculation of worm gear unit correction. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Worm gear face width design. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Define the number of starts. The pitch line velocity is ideally up to 30.

From www.chegg.com

A 1start righthand worm transmits 1.5 hp at 1200 Worm Gear Face Width Worm gear face width design. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c. First response provided by joe mihelick, gear technology. Calculation of worm gear unit correction. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Find the dimensions and. Worm Gear Face Width.

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Worm Gear Face Width Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Worm gear face width design. The pitch line velocity is ideally up to 30. Design of module, number of teeth, worm diameter factor and correction. Define the number of starts. How does one determine the center of a worm and a worm. Worm Gear Face Width.

From www.numerade.com

SOLVED A righthand doubletooth hardenedsteel (hardness not Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. An outline design procedure for a worm and wheel gear set using the agma equations is: The pitch line velocity is ideally up to 30. Learn how to. Worm Gear Face Width.

From issuu.com

Worm Gear and Its Application SEIMITSU by Seimitsu Factory Automation Worm Gear Face Width Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. The pitch line velocity is ideally up to 30. How does one determine the center of a worm and a worm wheel? First response provided by joe mihelick, gear technology. Calculation of worm gear unit correction. Find the dimensions and ratios of. Worm Gear Face Width.

From www.chegg.com

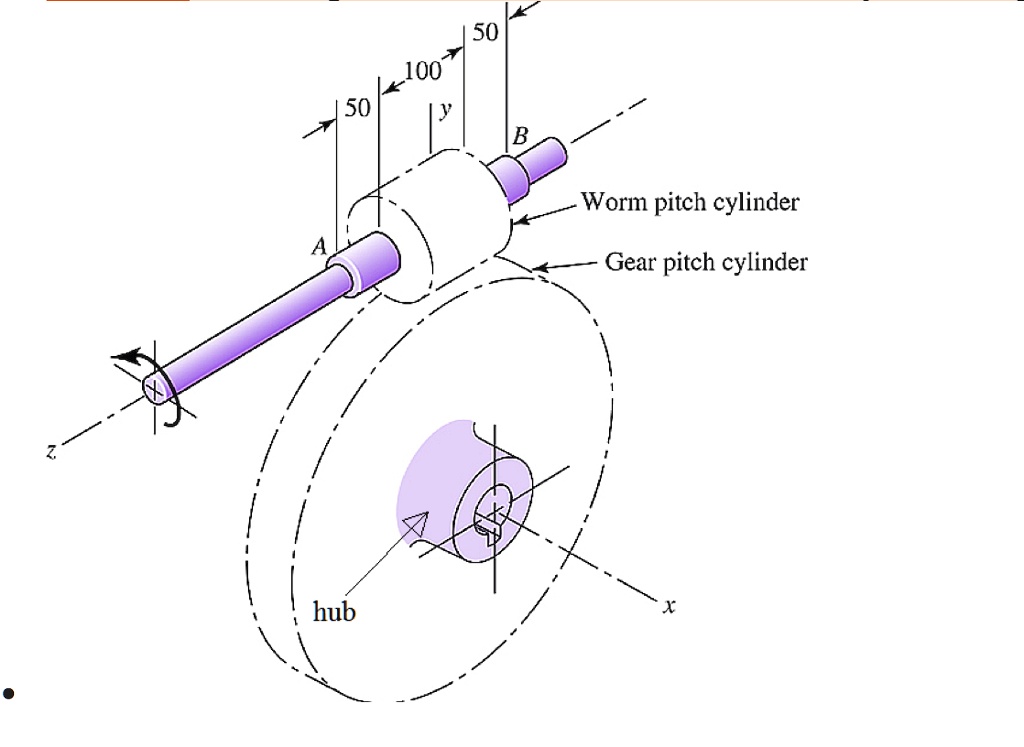

Solved In the figure, a righthand singletooth worm gear Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Worm gear face width design. Calculation of worm gear unit correction. The pitch line velocity is ideally up to 30. Define the center distance, c. Define. Worm Gear Face Width.

From innovativeanything.blogspot.com

Worm Gear Design and Its Gear Relation Worm Gear Face Width Define the center distance, c. Design of module, number of teeth, worm diameter factor and correction. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Worm gear face width design. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Find the dimensions and ratios. Worm Gear Face Width.

From energypara.web.fc2.com

Worm Gear Design Calculation Pdf Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. First response provided by joe mihelick, gear technology. Define the center distance, c. Worm gear face width design. How does one determine the center of a worm and a worm wheel? Find the dimensions and ratios of worms and wormgears using the standard american. Worm Gear Face Width.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Worm Gear Face Width Define the number of starts. Worm gear face width design. First response provided by joe mihelick, gear technology. Design of module, number of teeth, worm diameter factor and correction. Calculation of worm gear unit correction. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Enter the lead angle, axial pitch, and number of. Worm Gear Face Width.

From www.numerade.com

SOLVED Figure shows a gear train composed of two bevel gears, three Worm Gear Face Width How does one determine the center of a worm and a worm wheel? Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: Design of module, number of teeth, worm diameter. Worm Gear Face Width.

From us.metoree.com

39 Worm Gear Manufacturers in 2024 Metoree Worm Gear Face Width The pitch line velocity is ideally up to 30. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Design. Worm Gear Face Width.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Gear Face Width Calculation of worm gear unit correction. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. First response provided by joe mihelick, gear technology. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Define the center distance, c. Find the dimensions and ratios of worms. Worm Gear Face Width.

From www.globalspec.com

Worms and Worm Gears Selection Guide Types, Features, Applications Worm Gear Face Width Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Design of module, number of teeth, worm diameter factor and correction. First response provided by joe mihelick, gear technology. Calculation of worm gear unit correction. Worm gear face width design. Define the number of starts. Define the center distance, c. The pitch line velocity. Worm Gear Face Width.

From www.youtube.com

Worm gear YouTube Worm Gear Face Width First response provided by joe mihelick, gear technology. How does one determine the center of a worm and a worm wheel? Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Design of. Worm Gear Face Width.

From www.chegg.com

Solved A 2tooth righthand worm transmits l hp at 1200 Worm Gear Face Width Define the center distance, c. Calculation of worm gear unit correction. Design of module, number of teeth, worm diameter factor and correction. Worm gear face width design. First response provided by joe mihelick, gear technology. How does one determine the center of a worm and a worm wheel? An outline design procedure for a worm and wheel gear set using. Worm Gear Face Width.

From www.tec-science.com

Worms and worm gears tecscience Worm Gear Face Width Calculation of worm gear unit correction. An outline design procedure for a worm and wheel gear set using the agma equations is: Worm gear face width design. First response provided by joe mihelick, gear technology. The pitch line velocity is ideally up to 30. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile. Worm Gear Face Width.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Worm Gear Face Width Worm gear face width design. An outline design procedure for a worm and wheel gear set using the agma equations is: Calculation of worm gear unit correction. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. How does one determine the center of a worm and a worm wheel? Learn how to calculate. Worm Gear Face Width.

From skill-lync.com

Transient Structural Analysis of Worm Gear SkillLync Worm Gear Face Width Calculation of worm gear unit correction. Worm gear face width design. Define the center distance, c. First response provided by joe mihelick, gear technology. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Define the. Worm Gear Face Width.

From www.tec-science.com

Worms and worm gears tecscience Worm Gear Face Width An outline design procedure for a worm and wheel gear set using the agma equations is: How does one determine the center of a worm and a worm wheel? Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Enter the lead angle, axial pitch, and number of threads or teeth to. Worm Gear Face Width.

From framo-morat.com

Worm Gear Sets A63 Framo Morat Your idea Our drive Worm Gear Face Width Worm gear face width design. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c. Define the number of starts. First response provided by joe mihelick, gear technology. Design of module, number of teeth, worm diameter factor and correction. Enter the lead angle, axial pitch, and number of threads. Worm Gear Face Width.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Worm Gear Face Width The pitch line velocity is ideally up to 30. Define the center distance, c. First response provided by joe mihelick, gear technology. How does one determine the center of a worm and a worm wheel? Design of module, number of teeth, worm diameter factor and correction. Worm gear face width design. Calculation of worm gear unit correction. Define the number. Worm Gear Face Width.

From www.automotioncomponents.co.uk

Worm Gears from Automotion Automotion Worm Gear Face Width An outline design procedure for a worm and wheel gear set using the agma equations is: How does one determine the center of a worm and a worm wheel? Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Design of module, number of teeth, worm diameter factor and correction. Worm gear. Worm Gear Face Width.

From www.amazon.in

271 Worm Gear Set (1/4" Bore Worm, Hub Mount Worm Gear) Amazon.in Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Calculation of worm gear unit correction. The pitch line velocity is ideally up to 30. Define the center distance, c. Design of module, number of teeth, worm diameter factor and correction. First response provided by joe mihelick, gear technology. Find the dimensions and ratios. Worm Gear Face Width.

From www.engineerknow.com

How to calculate gear ratio of Worm gear Worm Gear Face Width Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. First response provided by joe mihelick, gear technology. An outline design procedure for a worm and wheel gear set using the agma equations is: Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Calculation of. Worm Gear Face Width.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Design of module, number of teeth, worm diameter factor and correction. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: First response provided by joe mihelick, gear technology. Learn how to calculate. Worm Gear Face Width.

From www.youtube.com

MD Part 14_4 Helical and Worm Gears YouTube Worm Gear Face Width Worm gear face width design. Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. The pitch line velocity is ideally up to 30. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Calculation of worm gear unit correction. An outline design procedure for a. Worm Gear Face Width.

From us.metoree.com

39 Worm Gear Manufacturers in 2024 Metoree Worm Gear Face Width Define the number of starts. How does one determine the center of a worm and a worm wheel? Define the center distance, c. The pitch line velocity is ideally up to 30. Calculation of worm gear unit correction. First response provided by joe mihelick, gear technology. Enter the lead angle, axial pitch, and number of threads or teeth to calculate. Worm Gear Face Width.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Worm Gear Face Width Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. Define the number of starts. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Calculation of worm gear unit correction. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift. Worm Gear Face Width.

From www.wiperdriveindustries.com

Industrial Gear Worm Gear & Shaft Manufacturer from Mumbai Worm Gear Face Width Worm gear face width design. Define the number of starts. Calculation of worm gear unit correction. Design of module, number of teeth, worm diameter factor and correction. The pitch line velocity is ideally up to 30. How does one determine the center of a worm and a worm wheel? Enter the lead angle, axial pitch, and number of threads or. Worm Gear Face Width.

From www.superiorgearbox.com

Worm Gears vs. Bevel Gears What’s The Difference? Superior Gearbox Worm Gear Face Width Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. The pitch line velocity is ideally up to 30. Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. First response provided by joe mihelick, gear technology. How does one determine the center of a worm. Worm Gear Face Width.

From khkgears.net

Tooth Thickness KHK Worm Gear Face Width Find the dimensions and ratios of worms and wormgears using the standard american fine pitch system. How does one determine the center of a worm and a worm wheel? First response provided by joe mihelick, gear technology. An outline design procedure for a worm and wheel gear set using the agma equations is: Worm gear face width design. Calculation of. Worm Gear Face Width.

From khkgears.net

Technical Information of Worm Gear KHK Gears Worm Gear Face Width Worm gear face width design. An outline design procedure for a worm and wheel gear set using the agma equations is: First response provided by joe mihelick, gear technology. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Design of module, number of teeth, worm diameter factor and correction. Find the dimensions and. Worm Gear Face Width.

From www.researchgate.net

The exploded diagram of the worm gear box assembly. The parts are as Worm Gear Face Width Worm gear face width design. The pitch line velocity is ideally up to 30. How does one determine the center of a worm and a worm wheel? Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the. Worm Gear Face Width.

From www.youtube.com

Introduction of Worm Gear YouTube Worm Gear Face Width How does one determine the center of a worm and a worm wheel? Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Define the number of starts. Calculation of worm gear unit correction. Enter the lead angle, axial pitch, and number of threads or teeth to calculate the pitch,. Worm gear. Worm Gear Face Width.

From www.researchgate.net

(a) Details of the worm gear [20], and (b) worm gear profile and bull Worm Gear Face Width Learn how to calculate gear dimensions based on module, number of teeth, pressure angle, and profile shift coefficient. Design of module, number of teeth, worm diameter factor and correction. An outline design procedure for a worm and wheel gear set using the agma equations is: How does one determine the center of a worm and a worm wheel? Define the. Worm Gear Face Width.

From mungfali.com

Worm Gear Examples Worm Gear Face Width The pitch line velocity is ideally up to 30. How does one determine the center of a worm and a worm wheel? Calculation of worm gear unit correction. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c. First response provided by joe mihelick, gear technology. Define the number. Worm Gear Face Width.