Dust Collector Inlet Size . The first step in designing your system is to draw a floor plan of your shop area. The world’s fastest ductingstep four: A right and a wrong way to design this ductwork. Continue on to the remaining machines using the example above until your main trunk is equal in dia. It must be sized properly to create a “carrying velocity” to keep dirt moving through. On your drawing, sketch out the po. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. The first (right) way uses 6 diameter pipe run all the way to the planer from. To the size of the collector inlet. Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Count the number of 90° and 45° bends in it. Ductwork is used to carry the dirt and air from the collection point to the collector. The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. By dominick dalsanto sales director &.

from www.ebay.com

The first (right) way uses 6 diameter pipe run all the way to the planer from. To the size of the collector inlet. It must be sized properly to create a “carrying velocity” to keep dirt moving through. By dominick dalsanto sales director &. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Ition of your main duct line.be sure to run the ducting so that it ends. Steel grinding dust conveyed @ 3500 feet per minute (velocity). Count the number of 90° and 45° bends in it. A right and a wrong way to design this ductwork. Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch.

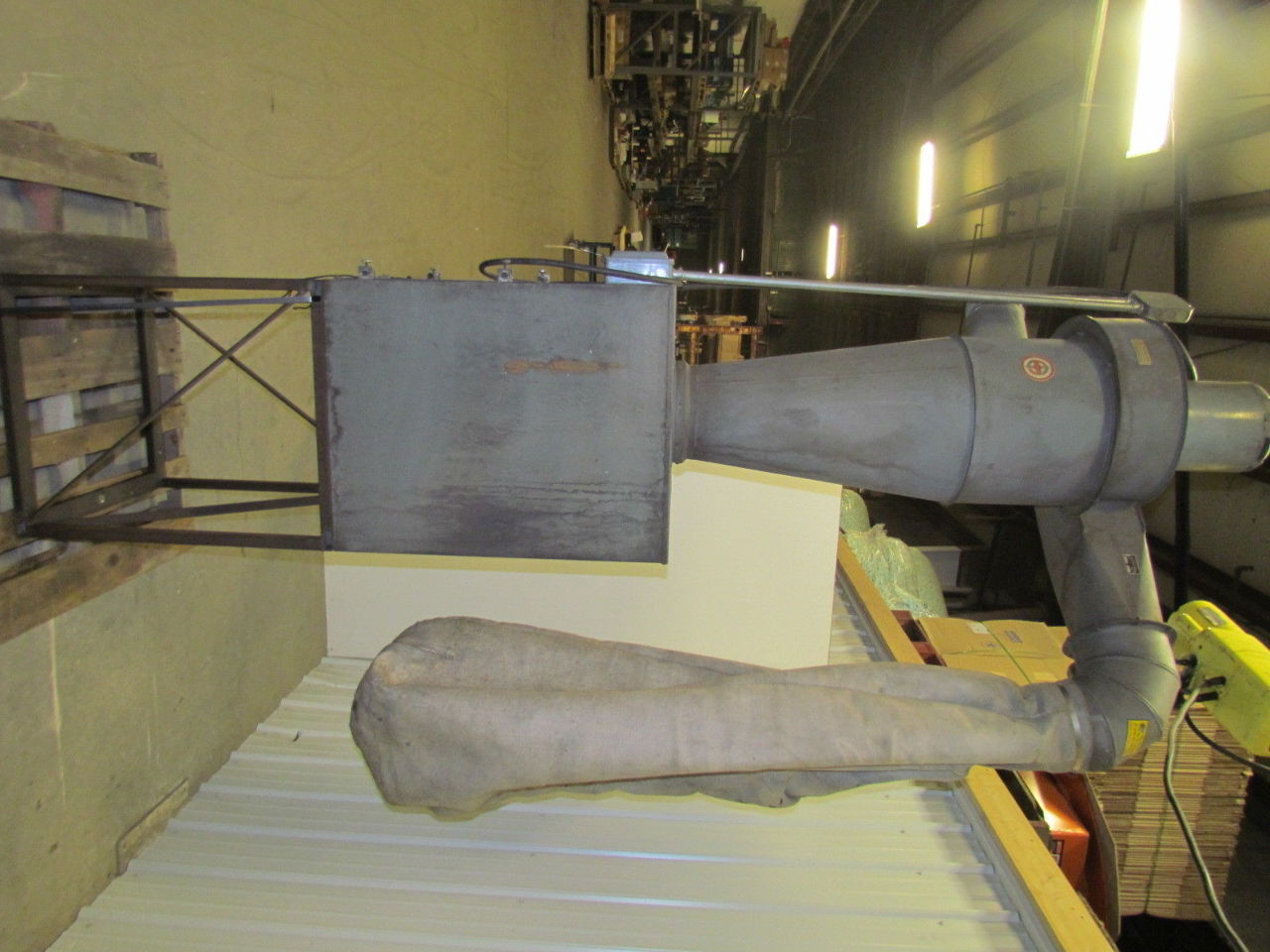

Torit 19FB Dust Collector 2HP 3PH W/Filter Bag + Base 6" Inlet

Dust Collector Inlet Size Steel grinding dust conveyed @ 3500 feet per minute (velocity). Ductwork is used to carry the dirt and air from the collection point to the collector. The world’s fastest ductingstep four: A system where the main trunk line is 6 in diameter. The first step in designing your system is to draw a floor plan of your shop area. Ition of your main duct line.be sure to run the ducting so that it ends. By dominick dalsanto sales director &. Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. It must be sized properly to create a “carrying velocity” to keep dirt moving through. Duct sizing is based on. Steel grinding dust conveyed @ 3500 feet per minute (velocity). Count the number of 90° and 45° bends in it. Continue on to the remaining machines using the example above until your main trunk is equal in dia. The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. On your drawing, sketch out the po. Start by measuring the length of the branch duct in feet.

From surplusrecord.com

300 cfm ICM SS60E, dust collector, 60 sq.ft., 3" inlet diameter, 1/2 Dust Collector Inlet Size A system where the main trunk line is 6 in diameter. Steel grinding dust conveyed @ 3500 feet per minute (velocity). Start by measuring the length of the branch duct in feet. Ductwork is used to carry the dirt and air from the collection point to the collector. Where a branch enters the main duct through a 45° wye, count. Dust Collector Inlet Size.

From www.pinterest.ca

6" Inlet/Outlet Separator How to with Video, Pics and Text Shop dust Dust Collector Inlet Size The first (right) way uses 6 diameter pipe run all the way to the planer from. Start by measuring the length of the branch duct in feet. The first step in designing your system is to draw a floor plan of your shop area. A right and a wrong way to design this ductwork. The world’s fastest ductingstep four: A. Dust Collector Inlet Size.

From www.woodmagazine.com

Dust Collector Basics Dust Collector Inlet Size The first (right) way uses 6 diameter pipe run all the way to the planer from. Steel grinding dust conveyed @ 3500 feet per minute (velocity). Start by measuring the length of the branch duct in feet. To the size of the collector inlet. Where a branch enters the main duct through a 45° wye, count the wye as a. Dust Collector Inlet Size.

From www.centrifugalflowfan.com

Air Inlet Mineral Powder Sintering System Base Dust Collector Fan Dust Collector Inlet Size It must be sized properly to create a “carrying velocity” to keep dirt moving through. A system where the main trunk line is 6 in diameter. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. A right and a wrong way to design this ductwork. Where a branch enters the main duct through a. Dust Collector Inlet Size.

From surplusrecord.com

4700 cfm Extrema DCF327E, baghouse dust collector, 16" inlet, 3 Dust Collector Inlet Size The world’s fastest ductingstep four: Continue on to the remaining machines using the example above until your main trunk is equal in dia. A right and a wrong way to design this ductwork. The first (right) way uses 6 diameter pipe run all the way to the planer from. The dust collector performance ratings should show that at your given. Dust Collector Inlet Size.

From www.reddit.com

Upgraded my Harbor Freight dust collector to twostage r/woodworking Dust Collector Inlet Size The first (right) way uses 6 diameter pipe run all the way to the planer from. Start by measuring the length of the branch duct in feet. Duct sizing is based on. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Count the number of 90° and 45° bends in it. It must be. Dust Collector Inlet Size.

From www.coastmachinery.com

Used Dust Collector Inlet Isolation Damper 18" Coast Machinery Group Dust Collector Inlet Size The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. Ition of your main duct line.be sure to run the ducting so that it ends. A system where the main trunk line is 6 in diameter. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Then,. Dust Collector Inlet Size.

From www.dreamstime.com

4 Inlet Air Suction Blower for Industrial Wood Dust Collector for Wood Dust Collector Inlet Size The first (right) way uses 6 diameter pipe run all the way to the planer from. Duct sizing is based on. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Where a branch enters the main duct through a. Dust Collector Inlet Size.

From www.ebay.com

Torit 19FB Dust Collector 2HP 3PH W/Filter Bag + Base 6" Inlet Dust Collector Inlet Size A right and a wrong way to design this ductwork. Steel grinding dust conveyed @ 3500 feet per minute (velocity). To the size of the collector inlet. The world’s fastest ductingstep four: Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Count the number of 90° and 45° bends in it. By dominick dalsanto. Dust Collector Inlet Size.

From www.baghouse.com

Cartridge Collectors Dust Collector Inlet Size Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. Start by measuring the length of the branch duct in feet. The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. The first (right) way uses 6 diameter pipe run all. Dust Collector Inlet Size.

From www.industrialfumeextractor.com

1.5KW Power Laser Dust Collector 200mm Inlet Diameter 720 * 700 * 1745mm Dust Collector Inlet Size Ition of your main duct line.be sure to run the ducting so that it ends. Steel grinding dust conveyed @ 3500 feet per minute (velocity). It must be sized properly to create a “carrying velocity” to keep dirt moving through. Continue on to the remaining machines using the example above until your main trunk is equal in dia. To the. Dust Collector Inlet Size.

From www.pinterest.com

Dust Collector Inlet Isolation Damper 18″ Dust collector, The Dust Collector Inlet Size The first (right) way uses 6 diameter pipe run all the way to the planer from. Ductwork is used to carry the dirt and air from the collection point to the collector. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. A system where the main trunk line is 6 in diameter. To the. Dust Collector Inlet Size.

From www.wurthmachinery.com

2 Inlet Dust Collector, 2HP/220V Dust Collector Inlet Size The world’s fastest ductingstep four: Continue on to the remaining machines using the example above until your main trunk is equal in dia. The first (right) way uses 6 diameter pipe run all the way to the planer from. The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. To the size. Dust Collector Inlet Size.

From www.ebay.com

Torit 19FB Dust Collector 2HP 3PH W/Filter Bag + Base 6" Inlet Dust Collector Inlet Size Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. A right and a wrong way to design this ductwork. Start by measuring the length of the branch duct in feet. A system where the main trunk line is 6 in diameter. The first (right) way uses 6 diameter. Dust Collector Inlet Size.

From www.youtube.com

Harbor Freight Dust Collector Modification Exterior Discharge Dust Collector Inlet Size A system where the main trunk line is 6 in diameter. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. The world’s fastest ductingstep four: To the size of the collector inlet. By dominick dalsanto sales director &. Ition of your main duct line.be sure to run the ducting so that it ends. Continue. Dust Collector Inlet Size.

From www.industrialfumeextractor.com

1.5 KW Power Laser Dust Collector 200mm Inlet Diameter With Blue Color Dust Collector Inlet Size Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. It must be sized properly to create a “carrying velocity” to keep dirt moving through. By dominick dalsanto sales director &. The world’s fastest ductingstep four: Ition of your main duct line.be sure to run the ducting so that. Dust Collector Inlet Size.

From www.ebay.com

4" Round 6x111/2" Rectangle Dust Collector Air Intake Nozzle Dust Collector Inlet Size The world’s fastest ductingstep four: Ductwork is used to carry the dirt and air from the collection point to the collector. To the size of the collector inlet. The first step in designing your system is to draw a floor plan of your shop area. Duct sizing is based on. Where a branch enters the main duct through a 45°. Dust Collector Inlet Size.

From housebecominghome.com

Central Machinery Dust Collector Inlet House Home Dust Collector Inlet Size It must be sized properly to create a “carrying velocity” to keep dirt moving through. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Duct sizing is based on. By dominick dalsanto sales director &. To the size of the collector inlet. A system where the main trunk line is 6 in diameter. On. Dust Collector Inlet Size.

From www.woodworkingtalk.com

HF 2HP Dust collector inlet upgrade. Woodworking Talk Dust Collector Inlet Size Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Ductwork is used to carry the dirt and air from the collection point to the collector. On your drawing, sketch out the po. Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. The. Dust Collector Inlet Size.

From www.lumberjocks.com

Show me your 5" dust collection fittings!! by CaptainKlutz Dust Collector Inlet Size Continue on to the remaining machines using the example above until your main trunk is equal in dia. A system where the main trunk line is 6 in diameter. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. To. Dust Collector Inlet Size.

From www.researchgate.net

Dust collector of cyclonicvortex action 1 body; 2 gas inlet pipe; 3 Dust Collector Inlet Size Start by measuring the length of the branch duct in feet. Ition of your main duct line.be sure to run the ducting so that it ends. A right and a wrong way to design this ductwork. Steel grinding dust conveyed @ 3500 feet per minute (velocity). A typical grinder uses 500 cubic feet of air per minute (cfm) to control. Dust Collector Inlet Size.

From www.ebay.com

Torit 19FB Dust Collector 2HP 3PH W/Filter Bag + Base 6" Inlet Dust Collector Inlet Size The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. Steel grinding dust conveyed @ 3500 feet per minute (velocity). The first (right) way uses 6 diameter pipe run all the way to the planer from. Ition of your main duct line.be sure to run the ducting so that it ends. Count. Dust Collector Inlet Size.

From www.wurthmachinery.com

2 Inlet Dust Collector, 2HP/110V Dust Collector Inlet Size Start by measuring the length of the branch duct in feet. The first (right) way uses 6 diameter pipe run all the way to the planer from. A system where the main trunk line is 6 in diameter. Count the number of 90° and 45° bends in it. The first step in designing your system is to draw a floor. Dust Collector Inlet Size.

From www.monroeenvironmental.com

Industrial Cartridge Dust Collectors Dry Dust, PM Monroe Environmental Dust Collector Inlet Size Ductwork is used to carry the dirt and air from the collection point to the collector. To the size of the collector inlet. The first step in designing your system is to draw a floor plan of your shop area. A right and a wrong way to design this ductwork. Duct sizing is based on. Count the number of 90°. Dust Collector Inlet Size.

From www.printables.com

Inlet for Mini dust collector by Tibuck Download free STL model Dust Collector Inlet Size A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust. It must be sized properly to create a “carrying velocity” to keep dirt moving through. Ductwork is used to carry the dirt and air from the collection point to the collector. To the size of the collector inlet. Count the number of 90° and 45°. Dust Collector Inlet Size.

From www.amazon.com

Shop Fox W1666 2 HP 1550 CFM Dust Collector Grizzly Dust Collector Dust Collector Inlet Size Duct sizing is based on. The first step in designing your system is to draw a floor plan of your shop area. Ductwork is used to carry the dirt and air from the collection point to the collector. To the size of the collector inlet. A typical grinder uses 500 cubic feet of air per minute (cfm) to control dust.. Dust Collector Inlet Size.

From www.ebay.com

Torit 19FB Dust Collector 2HP 3PH W/Filter Bag + Base 6" Inlet Dust Collector Inlet Size Count the number of 90° and 45° bends in it. The world’s fastest ductingstep four: Ition of your main duct line.be sure to run the ducting so that it ends. Ductwork is used to carry the dirt and air from the collection point to the collector. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each. Dust Collector Inlet Size.

From www.isystemsweb.com

BRF Baghouse Dust Collector Imperial Systems, Inc. Dust Collector Inlet Size Ition of your main duct line.be sure to run the ducting so that it ends. The world’s fastest ductingstep four: A system where the main trunk line is 6 in diameter. By dominick dalsanto sales director &. The first step in designing your system is to draw a floor plan of your shop area. Steel grinding dust conveyed @ 3500. Dust Collector Inlet Size.

From bandarq188.com

Cyclone Separator Working Principle (Dust Separator) Explained (2022) Dust Collector Inlet Size A system where the main trunk line is 6 in diameter. By dominick dalsanto sales director &. Start by measuring the length of the branch duct in feet. Count the number of 90° and 45° bends in it. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Ductwork is used to carry the dirt. Dust Collector Inlet Size.

From surplusrecord.com

3400 cfm Dustek C750, dust collector, 11" S.P., 12" inlet diameter, 75 Dust Collector Inlet Size On your drawing, sketch out the po. Where a branch enters the main duct through a 45° wye, count the wye as a 45° bend for the branch. Count the number of 90° and 45° bends in it. The first step in designing your system is to draw a floor plan of your shop area. A system where the main. Dust Collector Inlet Size.

From www.dustscrubber.com

Cyclone Dust Collector Cyclone Separator ACMAN Dust Collector Inlet Size Duct sizing is based on. A system where the main trunk line is 6 in diameter. Count the number of 90° and 45° bends in it. The first step in designing your system is to draw a floor plan of your shop area. Steel grinding dust conveyed @ 3500 feet per minute (velocity). On your drawing, sketch out the po.. Dust Collector Inlet Size.

From www.pinterest.com

CV1800LH Cyclone Bundle with Filters single phase Clear Vue Dust Collector Inlet Size By dominick dalsanto sales director &. Count the number of 90° and 45° bends in it. Duct sizing is based on. A system where the main trunk line is 6 in diameter. On your drawing, sketch out the po. The dust collector performance ratings should show that at your given static pressure, the cfm it will provide. The world’s fastest. Dust Collector Inlet Size.

From www.pinterest.com

New 6 inch inlet for the Harbor Freight Dust Collector Dust Collector Inlet Size Steel grinding dust conveyed @ 3500 feet per minute (velocity). Duct sizing is based on. Start by measuring the length of the branch duct in feet. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. It must be sized properly to create a “carrying velocity” to keep dirt moving through. A typical grinder uses. Dust Collector Inlet Size.

From www.printables.com

Inlet for Mini dust collector by Tibuck Download free STL model Dust Collector Inlet Size Ductwork is used to carry the dirt and air from the collection point to the collector. Steel grinding dust conveyed @ 3500 feet per minute (velocity). Ition of your main duct line.be sure to run the ducting so that it ends. The first (right) way uses 6 diameter pipe run all the way to the planer from. It must be. Dust Collector Inlet Size.

From www.topmaq.co.nz

Twin Inlet Port For Fm300 2hp Dust Collector TopmaQ Dust Collector Inlet Size On your drawing, sketch out the po. Start by measuring the length of the branch duct in feet. Count the number of 90° and 45° bends in it. Then, prepare a duct sp loss worksheet like worksheet 2 shown below for each branch. Ition of your main duct line.be sure to run the ducting so that it ends. A right. Dust Collector Inlet Size.