Resin Mold Casting Process . Liquid synthetic resin needs a curing agent to harden into rigid. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Essential tools and supplies for resin casting include mixing cups,. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. This mixture is poured into the mold and, due. It’s a simple process that you’ll soon get the hang of. So how do you prepare resin for molds? Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. 1m+ visitors in the past month However, too much hardener or too little epoxy and your resin could be wasted.

from precise-cast.com

Liquid synthetic resin needs a curing agent to harden into rigid. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. It’s a simple process that you’ll soon get the hang of. 1m+ visitors in the past month However, too much hardener or too little epoxy and your resin could be wasted. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. This mixture is poured into the mold and, due.

The Most Comprehensive Casting Process Summary Precise Cast

Resin Mold Casting Process Essential tools and supplies for resin casting include mixing cups,. Liquid synthetic resin needs a curing agent to harden into rigid. It’s a simple process that you’ll soon get the hang of. However, too much hardener or too little epoxy and your resin could be wasted. 1m+ visitors in the past month This mixture is poured into the mold and, due. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. So how do you prepare resin for molds? Essential tools and supplies for resin casting include mixing cups,.

From www.youtube.com

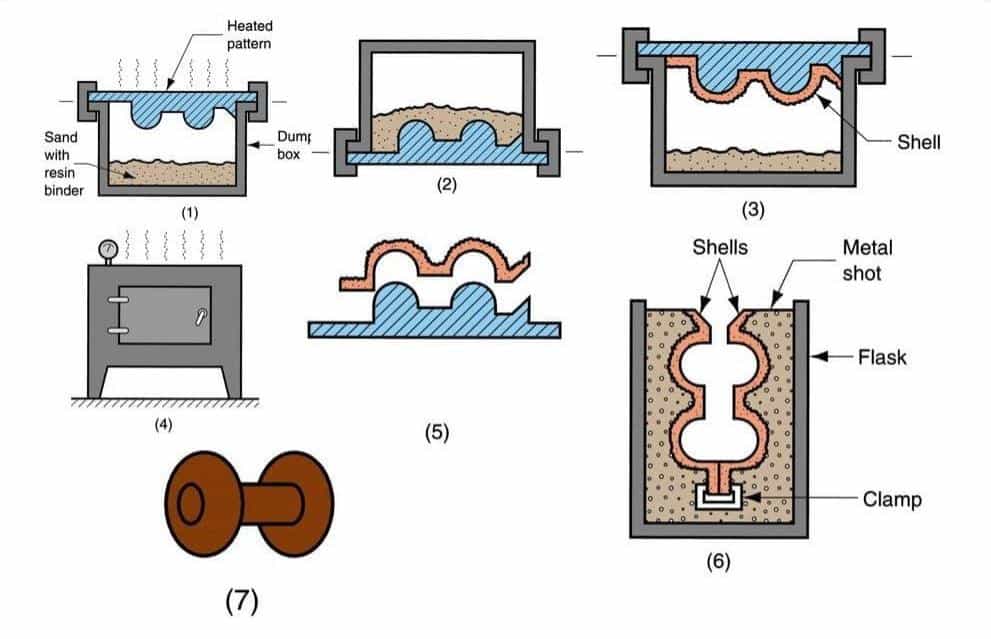

Shell Molding Expandable Mold Casting Processes YouTube Resin Mold Casting Process However, too much hardener or too little epoxy and your resin could be wasted. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Essential tools and supplies for resin casting include mixing cups,. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Resin casting. Resin Mold Casting Process.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Resin Mold Casting Process 1m+ visitors in the past month Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. This mixture is poured into the mold and, due. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. However, too much hardener or too little epoxy and your resin could be wasted. Essential tools. Resin Mold Casting Process.

From www.open.edu

Ceramic mould casting OpenLearn Open University Resin Mold Casting Process Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. It’s a simple process that you’ll soon get the hang of. So how do you prepare resin for molds? Liquid synthetic resin needs a curing agent to harden into rigid. However, too much hardener or too little epoxy and your resin could be wasted. Mixing. Resin Mold Casting Process.

From www.xometry.com

Ceramic Mold Casting Definition, Importance, How It Works Resin Mold Casting Process It’s a simple process that you’ll soon get the hang of. Essential tools and supplies for resin casting include mixing cups,. This mixture is poured into the mold and, due. Liquid synthetic resin needs a curing agent to harden into rigid. Do you ever want to make multiples of a favorite model, like model car parts, or change something from. Resin Mold Casting Process.

From www.intoresin.com

Beginners Guide to Make Resin Molds With Materials Explained IntoResin Resin Mold Casting Process 1m+ visitors in the past month Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Liquid synthetic resin needs a curing agent to harden into rigid. So how do you prepare resin for molds? Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin. Resin Mold Casting Process.

From mechanicstips.blogspot.com.eg

Casting process & it's Types MechanicsTips Resin Mold Casting Process Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Essential tools and supplies for resin. Resin Mold Casting Process.

From www.rocheindustry.com

Handbook Everything You Need to Know About Resin Casting Resin Mold Casting Process However, too much hardener or too little epoxy and your resin could be wasted. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Essential tools and supplies for resin. Resin Mold Casting Process.

From www.moldplasticinjection.com

How To Make Silicone Molds For Resin Casting & Candle Easy Ways On Resin Mold Casting Process Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. So how do you prepare resin for molds? This mixture is poured into the mold and, due. 1m+ visitors in the past month It’s a simple process that you’ll soon get the hang of. However,. Resin Mold Casting Process.

From www.youtube.com

Resin Casting tutorial Pressure Casting Water Clear WC786 Resin YouTube Resin Mold Casting Process This mixture is poured into the mold and, due. 1m+ visitors in the past month Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. However, too much hardener or too little epoxy and your resin could be wasted. Resin casting is a process in. Resin Mold Casting Process.

From www.youtube.com

The expanded polystyrene casting process Expandable Mold Casting Resin Mold Casting Process It’s a simple process that you’ll soon get the hang of. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Liquid synthetic resin needs a curing agent to harden into rigid. So how do you prepare resin for molds? This mixture is poured into the mold and, due. Resin. Resin Mold Casting Process.

From www.youtube.com

Make Molds for Resin Casting Beginner's Guide Easy Mold Making Resin Mold Casting Process However, too much hardener or too little epoxy and your resin could be wasted. Liquid synthetic resin needs a curing agent to harden into rigid. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Essential tools and supplies for resin casting include mixing cups,. So how do. Resin Mold Casting Process.

From www.youtube.com

Advanced Resin Casting Techniques Intro to Using J Molds Part 2 YouTube Resin Mold Casting Process However, too much hardener or too little epoxy and your resin could be wasted. This mixture is poured into the mold and, due. Essential tools and supplies for resin casting include mixing cups,. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. So how do you prepare resin for molds? Resin casting is a casting. Resin Mold Casting Process.

From hackaday.io

Resin casting parts Details Hackaday.io Resin Mold Casting Process Essential tools and supplies for resin casting include mixing cups,. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. This mixture is poured into the mold and, due. 1m+ visitors in the past month So how do you prepare resin for molds? Do you ever want to make multiples. Resin Mold Casting Process.

From omnidexcastings.com

Shell Mold Casting Quality Metal Casting Services Omnidex Resin Mold Casting Process Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Essential tools and supplies for resin casting include mixing cups,. So how do you prepare resin for molds? However, too much hardener or too little epoxy and your resin could be wasted. Resin casting involves pouring epoxy resin. Resin Mold Casting Process.

From dawangcasting.com

Shell Mold Casting Process Dawang Casting Shell Molding Resin Mold Casting Process Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Resin casting is a process in which liquid synthetic resin is mixed with a curing. Resin Mold Casting Process.

From mycrafts.com

Resin Casting Tutorial Multipiece Mold Part 2 Resin Mold Casting Process Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. So how do you prepare resin for molds? Liquid synthetic resin needs a curing agent to harden into. Resin Mold Casting Process.

From www.youtube.com

How I Make Molds for Resin Casting Silicone Rubber Mold YouTube Resin Mold Casting Process Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Liquid synthetic resin needs a curing agent to harden. Resin Mold Casting Process.

From sylcreate.com

How to make and use a twopart silicone mould for resin casting Resin Mold Casting Process So how do you prepare resin for molds? This mixture is poured into the mold and, due. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Do you ever want to make multiples of. Resin Mold Casting Process.

From clearcastingresin.com

Everything You Need to Know About Casting Resin Molds Clear Casting Resin Resin Mold Casting Process So how do you prepare resin for molds? However, too much hardener or too little epoxy and your resin could be wasted. Liquid synthetic resin needs a curing agent to harden into rigid. Essential tools and supplies for resin casting include mixing cups,. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. 1m+ visitors. Resin Mold Casting Process.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube Resin Mold Casting Process It’s a simple process that you’ll soon get the hang of. Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Do you ever want to make multiples of a favorite model, like model car parts,. Resin Mold Casting Process.

From www.omicroncasting.com

5 Different Methods Used in Casting Resin Mold Casting Process Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. So how do you prepare resin for molds? Essential tools and supplies for resin casting include mixing cups,. Resin casting is a casting process. Resin Mold Casting Process.

From www.youtube.com

Moulds for resin casting what can you use Resin Tutorial YouTube Resin Mold Casting Process This mixture is poured into the mold and, due. It’s a simple process that you’ll soon get the hang of. So how do you prepare resin for molds? 1m+ visitors in the past month Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Mixing. Resin Mold Casting Process.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Resin Mold Casting Process 1m+ visitors in the past month Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. So how do you prepare resin for molds? Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. It’s a simple process that you’ll soon get the hang. Resin Mold Casting Process.

From www.pinterest.com

Shell Moulding Foundry Shell Casting Resin Mold Casting Process This mixture is poured into the mold and, due. So how do you prepare resin for molds? Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. However, too much hardener or too little epoxy. Resin Mold Casting Process.

From goodtorial.blogspot.com

How To Make A Mold For Resin Sculpture Resin Mold Casting Process Liquid synthetic resin needs a curing agent to harden into rigid. This mixture is poured into the mold and, due. However, too much hardener or too little epoxy and your resin could be wasted. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. It’s a simple process that you’ll. Resin Mold Casting Process.

From www.resinobsession.com

Molds and Mold Making Archives Page 2 of 2 Resin Obsession Resin Mold Casting Process Essential tools and supplies for resin casting include mixing cups,. 1m+ visitors in the past month Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. Liquid synthetic resin needs a curing agent to harden into rigid. It’s a simple process that you’ll soon get the hang of. Do you. Resin Mold Casting Process.

From www.youtube.com

Resin Casting Tutorial How to Cast Resin YouTube Resin Mold Casting Process Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. So how do you prepare resin for molds? Liquid synthetic resin needs a curing agent to harden into rigid. It’s a simple process that you’ll soon get the hang of. Resin casting involves pouring epoxy resin into molds to create. Resin Mold Casting Process.

From www.resinobsession.com

The Simple Steps To Casting Resin In Silicone Molds Resin Obsession Resin Mold Casting Process Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. It’s a simple process that you’ll soon get the hang of. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. This mixture is poured. Resin Mold Casting Process.

From www.researchgate.net

Three liquid composite molding processes. (a) RTM, the mold is closed Resin Mold Casting Process Essential tools and supplies for resin casting include mixing cups,. This mixture is poured into the mold and, due. Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. So how do you prepare resin for molds? Liquid synthetic resin needs a curing agent to harden into rigid. Mixing and measuring your resin might seem. Resin Mold Casting Process.

From www.open.edu

Resin shell casting OpenLearn Open University Resin Mold Casting Process 1m+ visitors in the past month This mixture is poured into the mold and, due. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. So how do you prepare resin for molds? Resin casting involves pouring epoxy resin into molds to create durable and. Resin Mold Casting Process.

From medium.com

The Complete Guide to DIY Molding & Resin Casting by Jaycon Systems Resin Mold Casting Process Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting is a casting process that that uses liquid synthetic resin and a curing agent along with a mold. This mixture is poured into the mold and, due. It’s a simple process that you’ll soon get the hang of. However, too much hardener or too. Resin Mold Casting Process.

From www.resinobsession.com

How to FastTrack Your Success with Casting Molds Resin Obsession Resin Mold Casting Process Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a. Resin Mold Casting Process.

From www.steel-foundry.com

Resin Coated Sand Mold Casting Process Investment Casting Company Resin Mold Casting Process So how do you prepare resin for molds? It’s a simple process that you’ll soon get the hang of. Do you ever want to make multiples of a favorite model, like model car parts, or change something from a foam/clay design to a plastic. Liquid synthetic resin needs a curing agent to harden into rigid. 1m+ visitors in the past. Resin Mold Casting Process.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Resin Mold Casting Process Mixing and measuring your resin might seem daunting because it’s pretty specific and calculated. 1m+ visitors in the past month Resin casting involves pouring epoxy resin into molds to create durable and glossy custom pieces. So how do you prepare resin for molds? Do you ever want to make multiples of a favorite model, like model car parts, or change. Resin Mold Casting Process.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Resin Mold Casting Process Resin casting is a process in which liquid synthetic resin is mixed with a curing agent, typically at or near room temperature. 1m+ visitors in the past month Essential tools and supplies for resin casting include mixing cups,. Liquid synthetic resin needs a curing agent to harden into rigid. Resin casting involves pouring epoxy resin into molds to create durable. Resin Mold Casting Process.