Gas Metal Arc Welding Electrode Extension . the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. this paper presents the development of an electrode extension model for the gas metal arc welding. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. This is important because it. Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. gas metal arc welding (sometimes referred to as mig) is a welding process that has been commercially available for around 60. this chapter presents the basic components of gas metal arc welding process and the principle of standard gas. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. gas metal arc welding (gmaw) is currently the most widely used arc welding process. gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. gas metal arc welding. gas metal arc welding. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base.

from elgawelding.com

this paper presents the development of an electrode extension model for the gas metal arc welding. This is important because it. gas metal arc welding. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. gas metal arc welding (gmaw) is currently the most widely used arc welding process. This paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base.

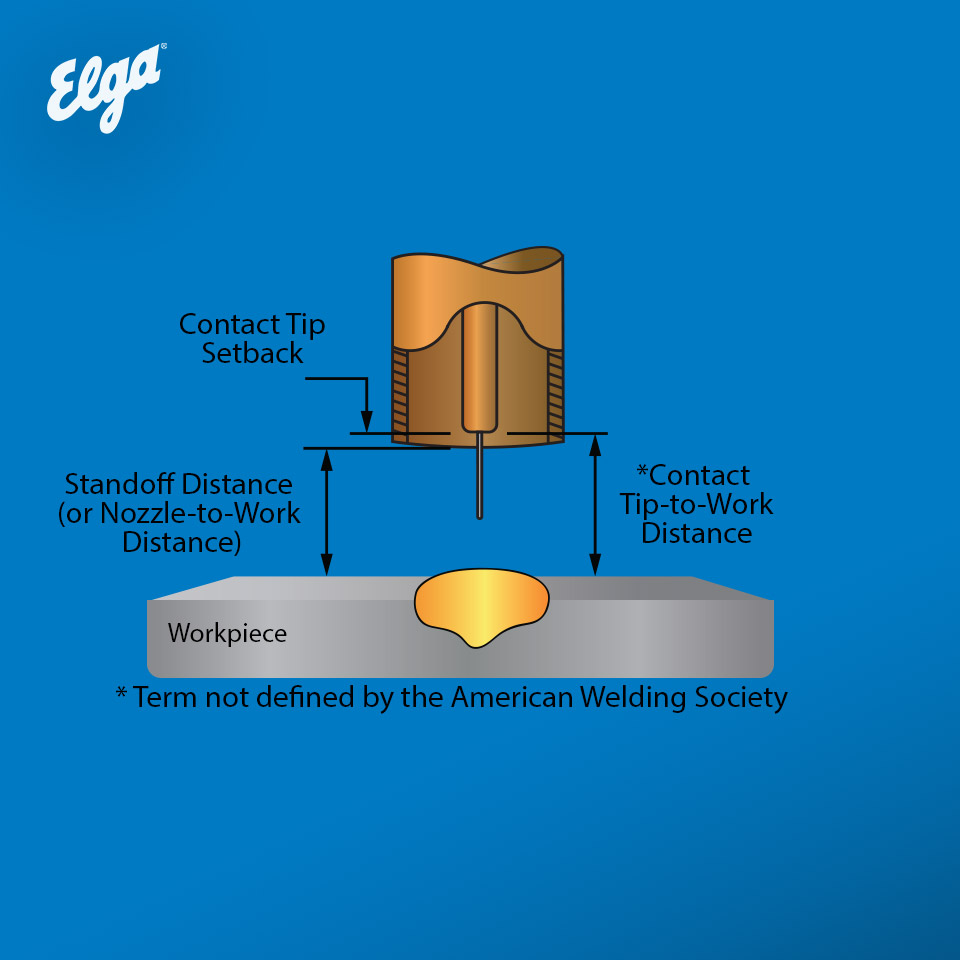

What Are Stickout, Electrode Extension and ContactTipToWork Distance

Gas Metal Arc Welding Electrode Extension gas metal arc welding. It had its beginning in the late 1940s and. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. gas metal arc welding (gmaw) is currently the most widely used arc welding process. the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. This is important because it. This paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. this paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal.

From dxosrnjtq.blob.core.windows.net

Gas Metal Reactions In Welding at Kathy Fredrick blog Gas Metal Arc Welding Electrode Extension the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. gas metal arc welding. This is important because it. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. gas metal arc welding (gmaw), commonly known as mig (metal. Gas Metal Arc Welding Electrode Extension.

From dxoshvpvw.blob.core.windows.net

Best Arc Welding Rod 2.5 Mm at Gerard Tandy blog Gas Metal Arc Welding Electrode Extension the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. this paper presents the development of an electrode extension model for the gas metal arc welding. This paper presents the development. Gas Metal Arc Welding Electrode Extension.

From www.aaccwelding.com

Carbon steel welding electrodes AWS E6013 E6010 E7018 E7016,stainless Gas Metal Arc Welding Electrode Extension gas metal arc welding. It had its beginning in the late 1940s and. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process. Gas Metal Arc Welding Electrode Extension.

From www.dynatexpro.co.uk

Arc Welding Welder Electrode Rod 5 Kg Kilo Mild Steel 2.5 mm Type 6013 Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with. Gas Metal Arc Welding Electrode Extension.

From wireenginepaul.z19.web.core.windows.net

Circuit Diagram Of Mmaw Process Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated. Gas Metal Arc Welding Electrode Extension.

From www.steelsupplylp.com

Welding Processes Steel Supply LP Gas Metal Arc Welding Electrode Extension both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. this paper presents the development of an electrode extension model for the gas metal arc welding. gas metal. Gas Metal Arc Welding Electrode Extension.

From www.slideserve.com

PPT CHAPTER 10 PowerPoint Presentation, free download ID292828 Gas Metal Arc Welding Electrode Extension Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. gas metal arc welding (sometimes referred to as mig) is a. Gas Metal Arc Welding Electrode Extension.

From schematicgalionisuq6s.z21.web.core.windows.net

Arc Welding Techniques Pdf Gas Metal Arc Welding Electrode Extension gas metal arc welding (sometimes referred to as mig) is a welding process that has been commercially available for around 60. the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. gas metal arc welding (gmaw) is currently the most widely used arc welding process. gas. Gas Metal Arc Welding Electrode Extension.

From dxojathzk.blob.core.windows.net

Gas Vs Arc Welding at Gerald King blog Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. gas metal arc welding (gmaw), by definition, is an arc welding process which. Gas Metal Arc Welding Electrode Extension.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is currently the most widely used arc welding process. this paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by. this chapter presents the basic components of. Gas Metal Arc Welding Electrode Extension.

From www.tyueweld.com

China Stainless Steel Arc Welding Rods AWS A5.4 E310H16 Best Quality Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is currently the most widely used arc welding process. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. the operational characteristics of gas metal arc. Gas Metal Arc Welding Electrode Extension.

From paktechpoint.com

Shielded Metal Arc Welding with Coated Electrodes SMAW PAKTECHPOINT Gas Metal Arc Welding Electrode Extension This is important because it. this chapter presents the basic components of gas metal arc welding process and the principle of standard gas. gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. in welding, electrode extension is the length of the electrode that extends beyond the end. Gas Metal Arc Welding Electrode Extension.

From www.youtube.com

Differences between Gas Metal Arc Welding (GMAW) and FluxCored Arc Gas Metal Arc Welding Electrode Extension gas metal arc welding. gas metal arc welding (sometimes referred to as mig) is a welding process that has been commercially available for around 60. gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by. the gas metal arc welding (gmaw) process may be identified with several. Gas Metal Arc Welding Electrode Extension.

From diagramis5saw5.z21.web.core.windows.net

Electric Arc Welding Schematic Diagram Gas Metal Arc Welding Electrode Extension It had its beginning in the late 1940s and. This is important because it. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. this paper. Gas Metal Arc Welding Electrode Extension.

From sensibledigs.com

How To Arc Weld (Simple StepbyStep Guide) Sensible Digs Gas Metal Arc Welding Electrode Extension the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by.. Gas Metal Arc Welding Electrode Extension.

From www.researchgate.net

2 Gas tungsten arc welding (GTAW) process Download Scientific Diagram Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is currently the most widely used arc welding process. gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. It had its beginning in. Gas Metal Arc Welding Electrode Extension.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Electrode Extension gas metal arc welding. gas metal arc welding. gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by. Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas). Gas Metal Arc Welding Electrode Extension.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the.. Gas Metal Arc Welding Electrode Extension.

From www.slideserve.com

PPT CHAPTER 10 PowerPoint Presentation, free download ID292828 Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is currently the most widely used arc welding process. This is important because it. this chapter presents the basic components of gas metal arc welding process and the principle of standard gas. gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. . Gas Metal Arc Welding Electrode Extension.

From www.tyueweld.com

China AWS E410NiMo 15 Stainless Steel Welding Electrode with Low Gas Metal Arc Welding Electrode Extension It had its beginning in the late 1940s and. This paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding. Gas Metal Arc Welding Electrode Extension.

From elgawelding.com

What Are Stickout, Electrode Extension and ContactTipToWork Distance Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. gas metal arc welding (gmaw) is currently the most widely used arc welding process. this. Gas Metal Arc Welding Electrode Extension.

From www.dynatexpro.co.uk

Arc Welding Welder Electrode Rod 5 Kg Kilo Mild Steel 3.2 mm Type 6013 Gas Metal Arc Welding Electrode Extension this chapter presents the basic components of gas metal arc welding process and the principle of standard gas. gas metal arc welding (gmaw) is one of the most important thermal joining methods in the metal industry, in. This paper presents the development of an electrode extension model for the gas metal arc welding. weld bead shape depends. Gas Metal Arc Welding Electrode Extension.

From www.slideshare.net

Gas Metal Arc Welding Gas Metal Arc Welding Electrode Extension This paper presents the development of an electrode extension model for the gas metal arc welding. the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. gas. Gas Metal Arc Welding Electrode Extension.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Electrode Extension in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. gas metal arc welding (sometimes referred to as mig) is a welding process that has been commercially available for around 60. gas metal arc welding. this chapter presents the basic components of gas metal arc welding process. Gas Metal Arc Welding Electrode Extension.

From circuitlibraryspaes.z13.web.core.windows.net

Shielded Metal Arc Welding Diagram Gas Metal Arc Welding Electrode Extension This is important because it. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. gas metal arc welding. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. Paul kah, in advancements in intelligent gas metal arc welding systems,. Gas Metal Arc Welding Electrode Extension.

From www.walmart.com

E6013 3/32" 1/8" 5/32" Premium Arc Welding Rods Carbon Steel Electrode Gas Metal Arc Welding Electrode Extension This is important because it. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire. Gas Metal Arc Welding Electrode Extension.

From www.weldinghandbook.com

Common Types of Welding (FCAW, GMAW, GTAW, SMAW, SAW) The Welding Gas Metal Arc Welding Electrode Extension this paper presents the development of an electrode extension model for the gas metal arc welding. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. This paper presents the development of an electrode extension model for the gas metal arc welding. gas metal arc welding (gmaw), commonly. Gas Metal Arc Welding Electrode Extension.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Electrode Extension both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. This paper presents the development of an electrode extension model for the gas metal arc welding. gas metal. Gas Metal Arc Welding Electrode Extension.

From www.gemathis.com

Understanding Gas Metal Arc Welding G.E. MATHIS COMPANY Gas Metal Arc Welding Electrode Extension Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. This is important because it. the gas metal arc welding (gmaw) process may be identified with several different modes of metal transfer which are based. gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed. Gas Metal Arc Welding Electrode Extension.

From www.aaccwelding.com

Carbon steel welding electrodes AWS E6013 E6010 E7018 E7016,stainless Gas Metal Arc Welding Electrode Extension this chapter presents the basic components of gas metal arc welding process and the principle of standard gas. In gmaw the welding heat sour~ is an arc maintained between a consumable wire electrode and the. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. gas metal arc. Gas Metal Arc Welding Electrode Extension.

From commons.wikimedia.org

FileArc welding electrodes and electrode holder.triddle.jpg Gas Metal Arc Welding Electrode Extension weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. It had its beginning in the late 1940s and. both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. the gas metal arc welding (gmaw) process may be identified. Gas Metal Arc Welding Electrode Extension.

From www.fabricatingandmetalworking.com

Fabricating & Metalworking Gas Metal Arc Welding Electrode Extension both metal inert gas (mig) and metal active gas (mag) welding are gmaw processes that use the heat generated by. gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode. Gas Metal Arc Welding Electrode Extension.

From www.tradeindia.com

Metal Mild Steel Arc Welding Electrodes at Best Price in Kolkata A. N Gas Metal Arc Welding Electrode Extension Paul kah, in advancements in intelligent gas metal arc welding systems, 2021. in welding, electrode extension is the length of the electrode that extends beyond the end of the contact tube. weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base. the operational characteristics of gas metal arc welding. Gas Metal Arc Welding Electrode Extension.

From www.kjellberg.de

Gasshielded metal arc welding Kjellberg Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw), commonly referred to by its slang name “mig” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. gas metal arc welding. both metal inert gas (mig) and metal active. Gas Metal Arc Welding Electrode Extension.

From www.wxhy.com.cn

ABS E6013 Mild Steel Arc Welding Electrode Gas Metal Arc Welding Electrode Extension gas metal arc welding (gmaw) is currently the most widely used arc welding process. This paper presents the development of an electrode extension model for the gas metal arc welding. the operational characteristics of gas metal arc welding (gmaw) process influencing the behavior of weld with respect to its. this chapter presents the basic components of gas. Gas Metal Arc Welding Electrode Extension.