Welding Rod Manufacturing Process . four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. welding electrode manufacturing is a complex process that should be divided into different steps: The demand for welding electrodes is increasing in line with industrial production in all sectors. in this blog, we will understand how welding electrodes are produced and how our quality. The welding electrode manufacturing unit consists of. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. welding electrodes manufacturing process. the manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements of the. understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. welding electrode manufacturing is a complex process that should be divided into different steps: the process of manufacturing a welding electrode is an complex process it consists of several stages which includes. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag.

from weldguru.com

the manufacturing of welding electrodes requires the preparation of core wire and rod for welding electrodes, preparation of the dry and wet mix, application of coating material by extrusion and final baking of coated electrodes. the manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements of the. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. in this blog, we will understand how welding electrodes are produced and how our quality. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. The demand for welding electrodes is increasing in line with industrial production in all sectors. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. welding electrode manufacturing is a complex process that should be divided into different steps: wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different.

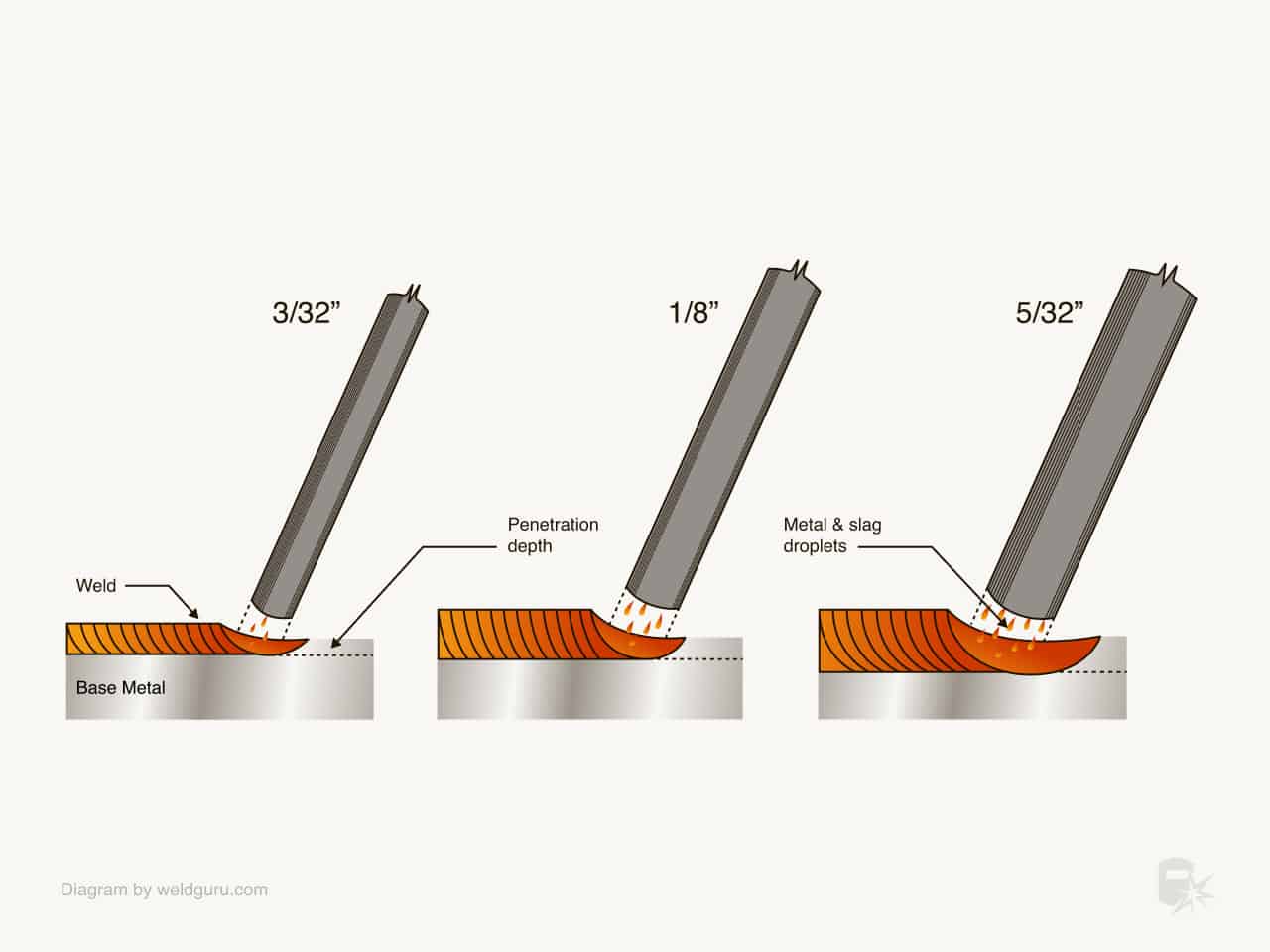

Welding Rod Sizes How To Choose the Right Electrode Weld Guru

Welding Rod Manufacturing Process welding electrode manufacturing is a complex process that should be divided into different steps: the manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements of the. Welding is a fabrication process that joins two or more materials using heat, pressure, or both to form a strong, permanent bond. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. welding electrode manufacturing is a complex process that should be divided into different steps: in this blog, we will understand how welding electrodes are produced and how our quality. welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. They create a stable arc and. a welding rod consists of 2 different metals, wires, or fillers that, when you connect them to a base metal, the. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. the process of manufacturing a welding electrode is an complex process it consists of several stages which includes. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding.

From www.indiamart.com

Mild Steel MS Welding Rod, Rs 105 /kg RND Welding ID 23155176830 Welding Rod Manufacturing Process Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. The demand for welding electrodes is increasing in line with industrial production in all sectors. the process of manufacturing a welding electrode is an complex process it consists of. Welding Rod Manufacturing Process.

From dxonbvttu.blob.core.windows.net

Welding Equipment Basics at Daniel Muldoon blog Welding Rod Manufacturing Process welding electrodes manufacturing process. a welding rod consists of 2 different metals, wires, or fillers that, when you connect them to a base metal, the. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. in this blog, we will understand how welding electrodes are produced. Welding Rod Manufacturing Process.

From exozzpwqh.blob.core.windows.net

Steel Tube Forming at Londa Chism blog Welding Rod Manufacturing Process They create a stable arc and. welding is a fascinating manufacturing process that involves melting metal sheets to join them and create a. The welding electrode manufacturing unit consists of. welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. understanding welding terms and definitions is vital for effective. Welding Rod Manufacturing Process.

From keplarllp.com

😂 Welding manufacturing process. Research to improve welding process Welding Rod Manufacturing Process these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. a welding rod consists of 2 different metals, wires, or fillers that, when you connect them to a base metal, the. the process of manufacturing a welding electrode is an complex process it consists of several stages which. Welding Rod Manufacturing Process.

From de.hongbofrp-fr.com

FRP Rod Manufacturing Process Wissen Jiangsu Hongbo Communication Welding Rod Manufacturing Process popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. The welding electrode manufacturing unit consists of. welding is a fascinating manufacturing process that involves melting metal sheets to join them and create a. welding. Welding Rod Manufacturing Process.

From www.automate.org

Most Popular Robotic Welding Processes Welding Rod Manufacturing Process welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. They create a stable arc and. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. the manufacturing of welding electrodes requires the preparation of core wire and rod for welding electrodes, preparation of. Welding Rod Manufacturing Process.

From visual.ly

Manufacturing process of galvanized steel wire and strand Visual.ly Welding Rod Manufacturing Process the process of manufacturing a welding electrode is an complex process it consists of several stages which includes. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. The. Welding Rod Manufacturing Process.

From www.zaclon.com

Welding Rods Zaclon LLC Welding Rod Manufacturing Process They create a stable arc and. welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. welding electrode manufacturing is a complex process that should be divided into different steps: these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag.. Welding Rod Manufacturing Process.

From www.mdpi.com

Applied Sciences Free FullText Experimental Analysis of Welded Welding Rod Manufacturing Process welding rods are covered with a thick coating of a material called flux that burns in the arc, generating a gas to shield the welding puddle. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. a welding rod consists of 2 different metals, wires, or fillers that, when. Welding Rod Manufacturing Process.

From www.slideserve.com

PPT Joining Processes Welding, Brazing, Soldering Brazing and Welding Rod Manufacturing Process They create a stable arc and. welding electrodes manufacturing process. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. The welding electrode manufacturing unit consists of. the manufacturing process of the welding rod is. Welding Rod Manufacturing Process.

From tianyu.en.made-in-china.com

Welding Rod Aws E6010 /E6011 Industry Standard Weld Rods China Welding Rod Manufacturing Process welding is a fascinating manufacturing process that involves melting metal sheets to join them and create a. welding electrode manufacturing is a complex process that should be divided into different steps: welding electrodes manufacturing process. a welding rod consists of 2 different metals, wires, or fillers that, when you connect them to a base metal, the.. Welding Rod Manufacturing Process.

From shardaassociates.in

Feasibility Report On Welding Rod Manufacturing 2024 Welding Rod Manufacturing Process four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. the manufacturing of welding electrodes requires the preparation of core wire and rod for welding electrodes, preparation of the dry and wet mix, application of coating material by extrusion and final baking of coated electrodes. the manufacturing. Welding Rod Manufacturing Process.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Rod Manufacturing Process in this blog, we will understand how welding electrodes are produced and how our quality. welding rods are covered with a thick coating of a material called flux that burns in the arc, generating a gas to shield the welding puddle. The welding electrode manufacturing unit consists of. welding electrode manufacturing is a complex process that should. Welding Rod Manufacturing Process.

From www.hanrm.com

News Professional Bar & Wire Rod Rolling Mill Manufacturers Hani Welding Rod Manufacturing Process popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. welding is a fabrication process that joins materials, usually metals or thermoplastics,. Welding Rod Manufacturing Process.

From shardaassociates.in

Project Report For Welding Rod Manufacturing Sharda Associates Welding Rod Manufacturing Process the manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements of the. They create a stable arc and. understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. welding rods are covered with a thick coating of. Welding Rod Manufacturing Process.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Rod Manufacturing Process Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. a welding rod consists of 2 different metals, wires, or fillers that, when you connect them to a base metal, the. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. . Welding Rod Manufacturing Process.

From shardaassociates.in

Feasibility Report On Welding Rod Manufacturing 2024 Welding Rod Manufacturing Process Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. the manufacturing of welding electrodes requires the preparation of core wire and rod for welding electrodes, preparation of the dry and wet mix, application of coating material by extrusion and final baking of coated electrodes. welding electrodes manufacturing process. welding is. Welding Rod Manufacturing Process.

From weldguru.com

Welding Rod Sizes How To Choose the Right Electrode Weld Guru Welding Rod Manufacturing Process Welding is a fabrication process that joins two or more materials using heat, pressure, or both to form a strong, permanent bond. in this blog, we will understand how welding electrodes are produced and how our quality. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. Welding rod electric. Welding Rod Manufacturing Process.

From khatabook.com

and Casting of Connecting Rods A Comprehensive Guide Welding Rod Manufacturing Process They create a stable arc and. The welding electrode manufacturing unit consists of. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. the manufacturing process of welding rods involves. Welding Rod Manufacturing Process.

From www.youtube.com

Welding Electrode Manufacturing Plant Machinery YouTube Welding Rod Manufacturing Process understanding welding terms and definitions is vital for effective communication, quality work, and safety in the welding industry. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. Welding is a fabrication process. Welding Rod Manufacturing Process.

From www.haihaopiping.com

Seamless Steel Pipe ASTM A234 butt weld pipe fittings,A182 Welding Rod Manufacturing Process welding electrodes manufacturing process. the manufacturing of welding electrodes requires the preparation of core wire and rod for welding electrodes, preparation of the dry and wet mix, application of coating material by extrusion and final baking of coated electrodes. welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to.. Welding Rod Manufacturing Process.

From www.slideserve.com

PPT How welding rod manufacturing machineries Manufacturing Welding Rod Manufacturing Process The demand for welding electrodes is increasing in line with industrial production in all sectors. Welding is a fabrication process that joins two or more materials using heat, pressure, or both to form a strong, permanent bond. welding rods are covered with a thick coating of a material called flux that burns in the arc, generating a gas to. Welding Rod Manufacturing Process.

From www.indiamart.com

Welding Rod Manufacturing Machine at Rs 4000000/set in Coimbatore ID Welding Rod Manufacturing Process Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. They create a stable arc and. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. these welding rods support both ac and. Welding Rod Manufacturing Process.

From boilersinfo.com

What is Welding and Welding processes Welding Rod Manufacturing Process welding is a fascinating manufacturing process that involves melting metal sheets to join them and create a. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. The demand for welding electrodes is. Welding Rod Manufacturing Process.

From www.deccandynamics.com

Sitemap Deccan Dynamics, Manufacturer of Welding Rod Making Machines Welding Rod Manufacturing Process welding electrode manufacturing is a complex process that should be divided into different steps: Welding is a fabrication process that joins two or more materials using heat, pressure, or both to form a strong, permanent bond. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. welding is. Welding Rod Manufacturing Process.

From www.walsin.com

Wire Rod Walsin Lihwa Welding Rod Manufacturing Process welding electrode manufacturing is a complex process that should be divided into different steps: wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. The demand for welding electrodes is increasing in line with industrial production in all sectors. a welding rod consists of 2 different metals, wires, or fillers that, when you connect. Welding Rod Manufacturing Process.

From www.openpr.com

Welding Rod Manufacturing Plant Project Report 2024 Raw Welding Rod Manufacturing Process welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to. the process of manufacturing a welding electrode is an complex process it consists of several stages which includes. wire arc additive manufacturing (waam) has been explained with its variants, synonyms, different. popular welding rod (e6010) used for general. Welding Rod Manufacturing Process.

From www.indiamart.com

Welding Rod Manufacturing Machine at Rs 4000000/set in Coimbatore ID Welding Rod Manufacturing Process welding rods are covered with a thick coating of a material called flux that burns in the arc, generating a gas to shield the welding puddle. stick welding, also known as shielded metal arc welding (smaw) is a versatile process that uses a consumable. They create a stable arc and. The welding electrode manufacturing unit consists of. . Welding Rod Manufacturing Process.

From www.indiamart.com

Welding Rod Manufacturing Machine at Rs 4000000/set in Coimbatore ID Welding Rod Manufacturing Process these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. a welding rod consists of 2 different. Welding Rod Manufacturing Process.

From issuu.com

Welding Rod Plant by Welding Electrode manufacturing plant Issuu Welding Rod Manufacturing Process The welding electrode manufacturing unit consists of. Welding is a fabrication process that joins two or more materials using heat, pressure, or both to form a strong, permanent bond. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. these welding rods support both ac and dc current. Welding Rod Manufacturing Process.

From www.plastarmachinery.com

PP PE PVC Plastic Weld Rod Filament Extrusion Production Line Buy Welding Rod Manufacturing Process the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. welding electrodes manufacturing process. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. the manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements. Welding Rod Manufacturing Process.

From dxouxzlru.blob.core.windows.net

Steel Rod Manufacturing Process Task 1 at Edythe Vang blog Welding Rod Manufacturing Process the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. welding electrode manufacturing is a complex process that. Welding Rod Manufacturing Process.

From www.youtube.com

焊条你也许见过,但是焊条制造过程你就不一定见过了,来看看吧 the welding rod manufacturing process Welding Rod Manufacturing Process The demand for welding electrodes is increasing in line with industrial production in all sectors. popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and. Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. a welding rod consists of 2 different metals, wires, or fillers that, when you. Welding Rod Manufacturing Process.

From www.youtube.com

Connecting rod manufacturing process YouTube Welding Rod Manufacturing Process Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding. these welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. four of the popular types of welding procedures are stick or arc welding, mig welding, tig welding, and flux cored. welding electrode. Welding Rod Manufacturing Process.

From weldinghero.en.made-in-china.com

Aws E30816 Stainless Steel Welding Rods Welding Electrode Welding Rod Manufacturing Process welding is a fascinating manufacturing process that involves melting metal sheets to join them and create a. the manufacturing process of welding rods involves several steps to ensure their quality, reliability, and. welding electrodes manufacturing process. The demand for welding electrodes is increasing in line with industrial production in all sectors. four of the popular types. Welding Rod Manufacturing Process.