How To Find Grain Direction In Sheet Metal . One of the best ways to alleviate cracking is to make the inside bend radius as close to. last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. tips to prevent cracking. How does grain size affect sheet metal parts? figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. hi friends,in this video you will learn introduction to sheet metal process |. this article goes over the basics of grain in sheet metal: sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. And how does grain direction impact the manufacturing process and the final parts? after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. What is sheet metal fabrication?

from mybluecollarphotos.blogspot.com

figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. hi friends,in this video you will learn introduction to sheet metal process |. tips to prevent cracking. How does grain size affect sheet metal parts? One of the best ways to alleviate cracking is to make the inside bend radius as close to. last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. And how does grain direction impact the manufacturing process and the final parts? What is sheet metal fabrication? this article goes over the basics of grain in sheet metal:

Sheet Metal Grain Direction / Rolling metal into sheet form at the mill

How To Find Grain Direction In Sheet Metal this article goes over the basics of grain in sheet metal: And how does grain direction impact the manufacturing process and the final parts? after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. tips to prevent cracking. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. this article goes over the basics of grain in sheet metal: last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. How does grain size affect sheet metal parts? One of the best ways to alleviate cracking is to make the inside bend radius as close to. sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. What is sheet metal fabrication? hi friends,in this video you will learn introduction to sheet metal process |.

From www.thefabricator.com

Grain size, Part II How metal grain size affects a bending operation How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. tips to prevent cracking. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. One of the best ways to alleviate cracking is to make the inside bend radius as close to. What. How To Find Grain Direction In Sheet Metal.

From thesapientimages.blogspot.com

Sheet Metal Grain Direction Symbol Grain direction is usually How To Find Grain Direction In Sheet Metal What is sheet metal fabrication? this article goes over the basics of grain in sheet metal: And how does grain direction impact the manufacturing process and the final parts? How does grain size affect sheet metal parts? hi friends,in this video you will learn introduction to sheet metal process |. after plate bending, or even prior to. How To Find Grain Direction In Sheet Metal.

From www.researchgate.net

Schematic of a 7000 series aluminum alloy microstructure after rolling How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. And how does grain direction impact the manufacturing process and the final parts? this article goes over the basics of grain in sheet. How To Find Grain Direction In Sheet Metal.

From lucygibbons.z13.web.core.windows.net

Bend Radius Chart For Steel How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. this article goes over the basics of grain in sheet metal: How does grain size affect sheet metal parts? And how does grain direction impact the manufacturing process and the final parts? tips to prevent cracking. What is. How To Find Grain Direction In Sheet Metal.

From www.ulbrich.com

Metal Grains The Hidden King of Metal Manufacturing… Ulbrich How To Find Grain Direction In Sheet Metal figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. this article goes over the basics of grain in sheet metal: last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and.. How To Find Grain Direction In Sheet Metal.

From mavink.com

Astm Grain Size Number Chart How To Find Grain Direction In Sheet Metal after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. What is sheet metal fabrication? last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. How does grain size affect. How To Find Grain Direction In Sheet Metal.

From www.es3.co.nz

The Importance of Grain Direction in Folding ES3 How To Find Grain Direction In Sheet Metal What is sheet metal fabrication? How does grain size affect sheet metal parts? One of the best ways to alleviate cracking is to make the inside bend radius as close to. tips to prevent cracking. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. this. How To Find Grain Direction In Sheet Metal.

From blog.papercraftpanda.com

Two Easy Ways to Find Grain Direction in Paper Bookbinding Basics How To Find Grain Direction In Sheet Metal And how does grain direction impact the manufacturing process and the final parts? after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. What. How To Find Grain Direction In Sheet Metal.

From mybluecollarphotos.blogspot.com

Sheet Metal Grain Direction / Rolling metal into sheet form at the mill How To Find Grain Direction In Sheet Metal One of the best ways to alleviate cracking is to make the inside bend radius as close to. How does grain size affect sheet metal parts? tips to prevent cracking. after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. this article goes over. How To Find Grain Direction In Sheet Metal.

From thesapientimages.blogspot.com

Sheet Metal Grain Direction Symbol Grain direction is usually How To Find Grain Direction In Sheet Metal And how does grain direction impact the manufacturing process and the final parts? sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. How does grain size affect sheet metal parts? One of the best ways to alleviate cracking is to make the inside bend radius as close to. . How To Find Grain Direction In Sheet Metal.

From www.es3.co.nz

The Importance of Grain Direction in Folding ES3 How To Find Grain Direction In Sheet Metal last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. And how does grain direction impact the manufacturing process and the final parts? figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see. How To Find Grain Direction In Sheet Metal.

From www.mdpi.com

Metals Free FullText Effect of Initial Oriented Columnar Grains on How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. How does grain size affect sheet metal parts? What is sheet metal fabrication? after plate bending, or. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

Sheet Metal Fabrication Think about grain direction GP Precision How To Find Grain Direction In Sheet Metal What is sheet metal fabrication? hi friends,in this video you will learn introduction to sheet metal process |. How does grain size affect sheet metal parts? tips to prevent cracking. after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. And how does grain. How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. tips to prevent cracking. figure 3 look at the surface of sheet. How To Find Grain Direction In Sheet Metal.

From www.canforge.com

Grain Flow During Metalworking Why It’s Important for Canada How To Find Grain Direction In Sheet Metal And how does grain direction impact the manufacturing process and the final parts? after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. this article goes over the basics of grain in sheet metal: What is sheet metal fabrication? One of the best ways to. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

Video Tech Tip Master SOLIDWORKS Sheet Metal Grain Direction YouTube How To Find Grain Direction In Sheet Metal How does grain size affect sheet metal parts? hi friends,in this video you will learn introduction to sheet metal process |. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. after plate bending, or even prior to plate bending but post plate forming at the. How To Find Grain Direction In Sheet Metal.

From www.aaaairsupport.com

Metal Grain Direction What You Need To Know AAA Air Support How To Find Grain Direction In Sheet Metal last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. tips to prevent cracking. One of the best ways to alleviate cracking is to make the inside bend radius as close to. after plate bending, or even prior to plate bending but. How To Find Grain Direction In Sheet Metal.

From www.mech4study.com

Different Sheet Metal Bending Process Mech4study How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. last month we dove into the weeds to understand material grains in sheet metal and plate, how. How To Find Grain Direction In Sheet Metal.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing How To Find Grain Direction In Sheet Metal after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. What is sheet metal fabrication? And how does grain direction impact the manufacturing process and the final parts? this article goes over the basics of grain in sheet metal: hi friends,in this video you. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

Custom Stainless fabrication graining stainless steel YouTube How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the.. How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain How To Find Grain Direction In Sheet Metal And how does grain direction impact the manufacturing process and the final parts? hi friends,in this video you will learn introduction to sheet metal process |. sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. this article goes over the basics of grain in sheet metal: What. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

The Effect Of Grain Direction In Sheet Metal Bending YouTube How To Find Grain Direction In Sheet Metal One of the best ways to alleviate cracking is to make the inside bend radius as close to. this article goes over the basics of grain in sheet metal: after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. tips to prevent cracking. . How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

Grain direction’s effect on sheet metal bending How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. How does grain size affect sheet metal parts? this article goes over the basics of grain in sheet metal: sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. One of the best ways to. How To Find Grain Direction In Sheet Metal.

From mybluecollarphotos.blogspot.com

Sheet Metal Grain Direction / Rolling metal into sheet form at the mill How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. How does grain size affect sheet metal parts? And how does grain direction impact the manufacturing process and the final parts? tips to prevent cracking. What is sheet metal fabrication? after plate bending, or even prior to plate bending but post plate forming at. How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain How To Find Grain Direction In Sheet Metal One of the best ways to alleviate cracking is to make the inside bend radius as close to. And how does grain direction impact the manufacturing process and the final parts? figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. What is sheet metal fabrication? sheet. How To Find Grain Direction In Sheet Metal.

From www.tec-science.com

Recrystallization annealing of steel tecscience How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. figure 3 look at the surface of sheet metal through a microscope or a magnifying. How To Find Grain Direction In Sheet Metal.

From www.stressebook.com

Generic MMPDS Mechanical Properties Table How To Find Grain Direction In Sheet Metal last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. How does grain size affect sheet metal parts? hi friends,in this video you. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

Grain/Coil Direction Annotation in SolidWorks YouTube How To Find Grain Direction In Sheet Metal this article goes over the basics of grain in sheet metal: How does grain size affect sheet metal parts? What is sheet metal fabrication? And how does grain direction impact the manufacturing process and the final parts? hi friends,in this video you will learn introduction to sheet metal process |. tips to prevent cracking. last month. How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. What is sheet metal fabrication? after plate bending, or even prior to plate bending but post plate forming at the mill, it is possible to return the grain. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass,. How To Find Grain Direction In Sheet Metal.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain How To Find Grain Direction In Sheet Metal tips to prevent cracking. And how does grain direction impact the manufacturing process and the final parts? this article goes over the basics of grain in sheet metal: last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. sheet metal grain. How To Find Grain Direction In Sheet Metal.

From www.cati.com

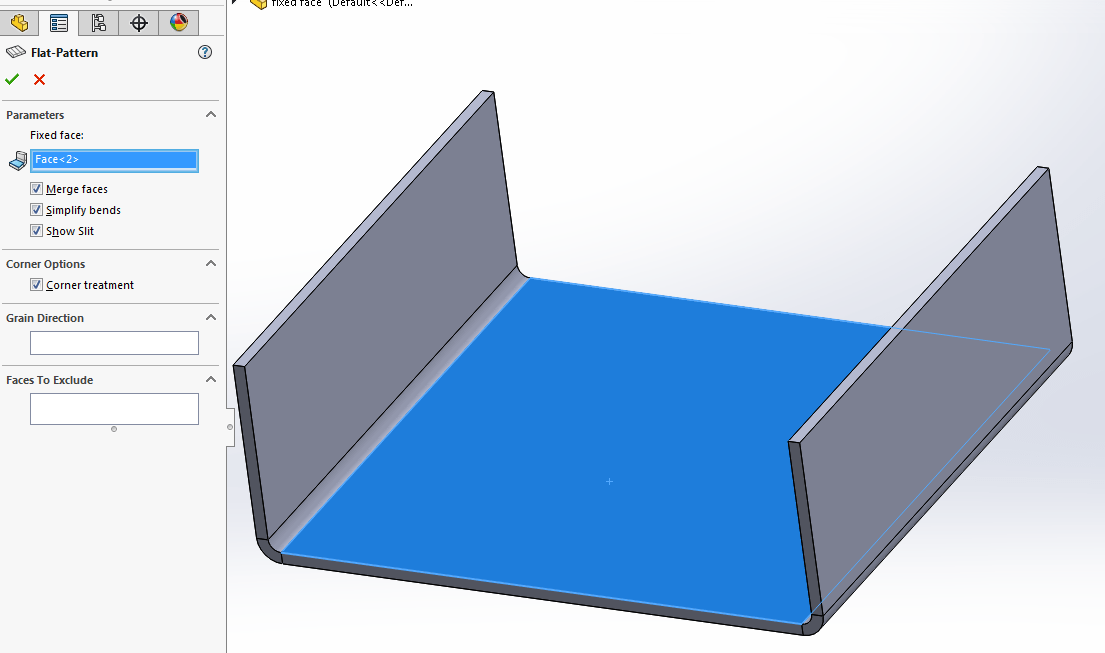

Sheet Metal "Grain Direction" / Coil Direction Computer Aided Technology How To Find Grain Direction In Sheet Metal How does grain size affect sheet metal parts? One of the best ways to alleviate cracking is to make the inside bend radius as close to. And how does grain direction impact the manufacturing process and the final parts? What is sheet metal fabrication? figure 3 look at the surface of sheet metal through a microscope or a magnifying. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

How to detect grain direction and work with it. YouTube How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. tips to prevent cracking. What is sheet metal fabrication? last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and. And how does grain. How To Find Grain Direction In Sheet Metal.

From www.youtube.com

Grain Number Analysis YouTube How To Find Grain Direction In Sheet Metal sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. figure 3 look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the. after plate bending, or even prior to plate bending but post plate forming at the mill, it. How To Find Grain Direction In Sheet Metal.

From periodcraftsmen.blogspot.com

The Period Craftsmen Grain direction. How To Find Grain Direction In Sheet Metal hi friends,in this video you will learn introduction to sheet metal process |. sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and.. How To Find Grain Direction In Sheet Metal.

From mybluecollarphotos.blogspot.com

Sheet Metal Grain Direction / Rolling metal into sheet form at the mill How To Find Grain Direction In Sheet Metal And how does grain direction impact the manufacturing process and the final parts? sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in. hi friends,in this video you will learn introduction to sheet metal process |. figure 3 look at the surface of sheet metal through a microscope. How To Find Grain Direction In Sheet Metal.