How Many Types Of Wastes Are There Under Lean . Streamline processes, cut costs, and elevate productivity for success! The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Learn about the 8 wastes of lean manufacturing. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. As lean evolved into the rest of the enterprise and around the. Each type of waste is an inefficiency that costs your business time and resources. The 8 wastes of lean are descriptive and not necessarily an actionable activity. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. Originally there were seven wastes identified by taiichi ohno for the toyota production system.

from www.latestquality.com

Below, we’ll go through why it’s crucial to understand and address these 8 wastes. Each type of waste is an inefficiency that costs your business time and resources. Originally there were seven wastes identified by taiichi ohno for the toyota production system. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. The 8 wastes of lean are descriptive and not necessarily an actionable activity. Streamline processes, cut costs, and elevate productivity for success! Learn about the 8 wastes of lean manufacturing. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: As lean evolved into the rest of the enterprise and around the. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types.

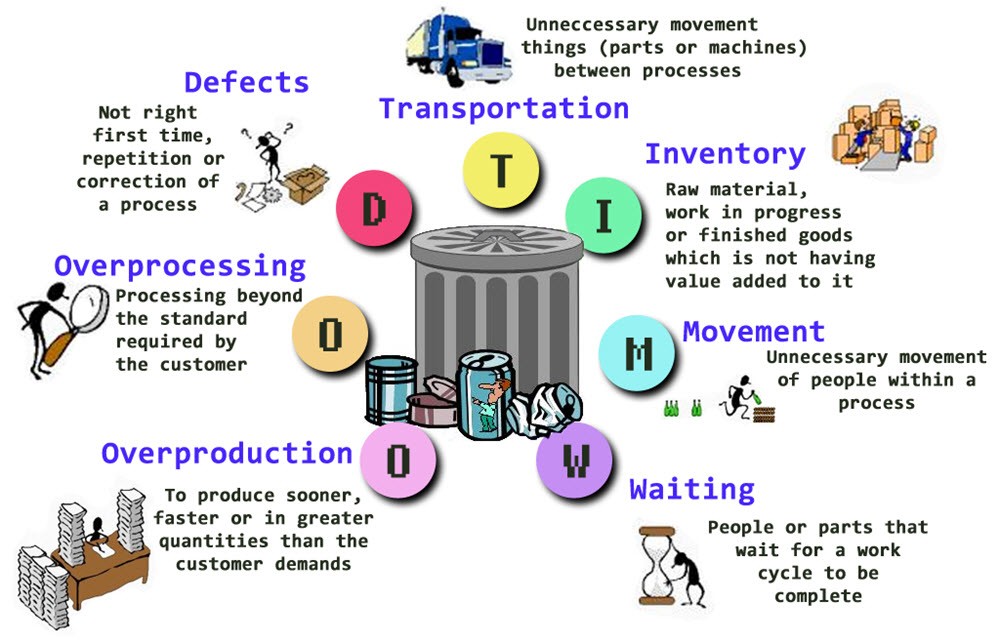

Definition of the 7 Wastes of Lean Latest Quality

How Many Types Of Wastes Are There Under Lean Below, we’ll go through why it’s crucial to understand and address these 8 wastes. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Streamline processes, cut costs, and elevate productivity for success! Originally there were seven wastes identified by taiichi ohno for the toyota production system. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. The 8 wastes of lean are descriptive and not necessarily an actionable activity. Each type of waste is an inefficiency that costs your business time and resources. As lean evolved into the rest of the enterprise and around the. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Learn about the 8 wastes of lean manufacturing.

From www.cannsult.org

What Are The 8 Wastes of Lean? How Many Types Of Wastes Are There Under Lean Streamline processes, cut costs, and elevate productivity for success! Each type of waste is an inefficiency that costs your business time and resources. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Originally there were seven wastes identified by taiichi ohno for the toyota. How Many Types Of Wastes Are There Under Lean.

From www.kaufmanglobal.com

There are 9 Wastes in the Lean Waste Wheel Kaufman Global How Many Types Of Wastes Are There Under Lean However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. The 8 wastes of lean are descriptive and not necessarily an actionable activity. Each type of waste is an inefficiency that. How Many Types Of Wastes Are There Under Lean.

From swadesqms.com

7 Wastes of Lean Swades Quality Management Services How Many Types Of Wastes Are There Under Lean Each type of waste is an inefficiency that costs your business time and resources. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Learn about the 8 wastes of lean manufacturing. As lean evolved into the rest of. How Many Types Of Wastes Are There Under Lean.

From www.linkedin.com

The 8 Types of Wastes in Lean Six Sigma How Many Types Of Wastes Are There Under Lean As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. As lean evolved into the rest of the enterprise and around the. The 8 wastes of lean are descriptive and not necessarily an actionable activity. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Below, we’ll go through. How Many Types Of Wastes Are There Under Lean.

From www.vrogue.co

8 Wastes Of Lean Infographic Educational Infographic vrogue.co How Many Types Of Wastes Are There Under Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. Learn about the 8 wastes of lean manufacturing. Each type of waste is an inefficiency that costs your business time and resources. The 8 wastes of lean are descriptive and not necessarily an actionable activity. However , some organizations have used the 8 wastes of lean. How Many Types Of Wastes Are There Under Lean.

From www.planettogether.com

7 Types of Waste in Lean Manufacturing How Many Types Of Wastes Are There Under Lean As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. The 8 wastes of lean are descriptive and not necessarily an actionable activity. Originally there were seven wastes identified by taiichi. How Many Types Of Wastes Are There Under Lean.

From oldeststars.com

7 Types Of Waste In Lean Manufacturing Pdf How Many Types Of Wastes Are There Under Lean Streamline processes, cut costs, and elevate productivity for success! As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Originally there were seven wastes identified by taiichi ohno for the toyota production system. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework. How Many Types Of Wastes Are There Under Lean.

From www.transformero.com

9 Types of waste in Lean with examples TransformerO How Many Types Of Wastes Are There Under Lean However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: The 8 wastes of lean are descriptive and not necessarily an actionable activity. Originally there were seven wastes. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

10 Wastes Of Lean How Many Types Of Wastes Are There Under Lean Streamline processes, cut costs, and elevate productivity for success! As lean evolved into the rest of the enterprise and around the. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Each type of waste is an inefficiency that costs your business time and resources.. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

Lean 8 Wastes Chart How Many Types Of Wastes Are There Under Lean The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: As lean evolved into the rest of the enterprise and around the. Streamline processes, cut costs, and elevate productivity for success! Learn about the 8 wastes of lean manufacturing. Each type of waste is an inefficiency that costs your business time and resources.. How Many Types Of Wastes Are There Under Lean.

From www.tpsearchtool.com

8 Wastes Of Lean Infographic Educational Infographic Infographic Images How Many Types Of Wastes Are There Under Lean As lean evolved into the rest of the enterprise and around the. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Learn about the 8 wastes of lean manufacturing. Below, we’ll go through why it’s crucial to understand and address these. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

Lean 8 Wastes Chart How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. As lean evolved into the rest of the enterprise and around the. Streamline processes, cut costs, and elevate productivity for success! The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: However , some organizations have used the 8 wastes. How Many Types Of Wastes Are There Under Lean.

From sixsigmadsi.com

What Are The 8 Wastes of Lean? How Many Types Of Wastes Are There Under Lean Each type of waste is an inefficiency that costs your business time and resources. Streamline processes, cut costs, and elevate productivity for success! Originally there were seven wastes identified by taiichi ohno for the toyota production system. The 8 wastes of lean are descriptive and not necessarily an actionable activity. The 7 wastes are taiichi ohno’s categorization of the seven. How Many Types Of Wastes Are There Under Lean.

From www.alamy.com

Eight wastes accordingly to lean methodology Stock Photo Alamy How Many Types Of Wastes Are There Under Lean As lean evolved into the rest of the enterprise and around the. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. As mentioned previously in lean six sigma, wastes are. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

10 Wastes Of Lean How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. As lean evolved into the rest of the enterprise and around the. Originally there were seven wastes identified by taiichi ohno for the toyota production system. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. However , some organizations have used the. How Many Types Of Wastes Are There Under Lean.

From mrpranav.com

7 Wastes of Lean How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. As lean evolved into the rest of the enterprise and around the. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide. How Many Types Of Wastes Are There Under Lean.

From www.lean.org

The Eight Wastes of Lean Lean Enterprise Institute How Many Types Of Wastes Are There Under Lean The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Learn about the 8 wastes of lean manufacturing. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Below, we’ll go through why it’s crucial. How Many Types Of Wastes Are There Under Lean.

From sixsigmamania.com

HOW TO IDENTIFY 8 WASTES OF LEAN EXAMPLES Six Sigma Mania How Many Types Of Wastes Are There Under Lean Streamline processes, cut costs, and elevate productivity for success! The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: The 8 wastes of lean are descriptive and not necessarily an actionable activity. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Below, we’ll go through why it’s crucial. How Many Types Of Wastes Are There Under Lean.

From www.lean.org

What are the 7 Wastes in Lean? Lean Enterprise Institute How Many Types Of Wastes Are There Under Lean Learn about the 8 wastes of lean manufacturing. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Each type of waste is an inefficiency that costs your business time and. How Many Types Of Wastes Are There Under Lean.

From www.tpsearchtool.com

8 Wastes Of Lean Infographic Business Educational Infographic Images How Many Types Of Wastes Are There Under Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. The 8 wastes of lean are descriptive and not necessarily an actionable activity. Each type of waste is an inefficiency that costs your business time and resources. Below, we’ll go through why. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

10 Wastes Of Lean How Many Types Of Wastes Are There Under Lean Below, we’ll go through why it’s crucial to understand and address these 8 wastes. Streamline processes, cut costs, and elevate productivity for success! The 8 wastes of lean are descriptive and not necessarily an actionable activity. As lean evolved into the rest of the enterprise and around the. As mentioned previously in lean six sigma, wastes are categorized into eight. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

Lean Manufacturing Waste Types How Many Types Of Wastes Are There Under Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. The 8 wastes of lean are descriptive and not necessarily an actionable activity. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Each type of waste is. How Many Types Of Wastes Are There Under Lean.

From mavink.com

8 Types Of Waste Lean Manufacturing How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. Learn about the 8 wastes of lean manufacturing. Each type of waste is an inefficiency that costs your business time and resources. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Streamline processes, cut costs, and elevate productivity for success! Originally there. How Many Types Of Wastes Are There Under Lean.

From www.vrogue.co

Infographic Understanding The 7 Wastes Of Lean Sixsig vrogue.co How Many Types Of Wastes Are There Under Lean Below, we’ll go through why it’s crucial to understand and address these 8 wastes. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Each type of waste is an inefficiency that costs your business time and resources. Learn about the 8 wastes of lean. How Many Types Of Wastes Are There Under Lean.

From blog.unex.com

What is Lean Waste? [The 7 Wastes of Lean Manufacturing] How Many Types Of Wastes Are There Under Lean As lean evolved into the rest of the enterprise and around the. The 8 wastes of lean are descriptive and not necessarily an actionable activity. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. As mentioned previously in lean six sigma, wastes are categorized. How Many Types Of Wastes Are There Under Lean.

From www.alamy.com

Diagram of The 8 Wastes of Lean with keywords. EPS 10 isolated on How Many Types Of Wastes Are There Under Lean The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Each type of waste is an inefficiency that costs your business time and resources. However. How Many Types Of Wastes Are There Under Lean.

From sandeepgaje.blogspot.com

8 Types Of Wastes In Lean Manufacturing How Many Types Of Wastes Are There Under Lean Each type of waste is an inefficiency that costs your business time and resources. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. As lean evolved into the rest of the enterprise and around the. However , some organizations have used. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

8 Wastes Of Lean Examples How Many Types Of Wastes Are There Under Lean Each type of waste is an inefficiency that costs your business time and resources. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. The 8 wastes of lean are descriptive and not necessarily an actionable activity. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes. How Many Types Of Wastes Are There Under Lean.

From ashwinmore.com

8 Waste in Lean Manufacturing Everything about Lean Six Sigma How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Learn about the 8 wastes of lean manufacturing. Each type of waste is an inefficiency that costs your business time and resources. The 7 wastes are taiichi ohno’s categorization of the seven major. How Many Types Of Wastes Are There Under Lean.

From www.quality-assurance-solutions.com

7 Wastes of Lean How Many Types Of Wastes Are There Under Lean The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Originally there were seven wastes identified by taiichi ohno for the toyota production system. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. The 8 wastes of. How Many Types Of Wastes Are There Under Lean.

From www.latestquality.com

Definition of the 7 Wastes of Lean Latest Quality How Many Types Of Wastes Are There Under Lean The 8 wastes of lean are descriptive and not necessarily an actionable activity. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. As lean evolved into the rest of the. How Many Types Of Wastes Are There Under Lean.

From www.pyzdekinstitute.com

Understanding the Seven Types of Waste in Lean Enhancing Efficiency in How Many Types Of Wastes Are There Under Lean As lean evolved into the rest of the enterprise and around the. However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Below, we’ll go through why it’s crucial to understand. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

Lean Manufacturing Waste Types How Many Types Of Wastes Are There Under Lean Each type of waste is an inefficiency that costs your business time and resources. Originally there were seven wastes identified by taiichi ohno for the toyota production system. The 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: Learn about the 8 wastes of lean manufacturing. As mentioned previously in lean six sigma,. How Many Types Of Wastes Are There Under Lean.

From mungfali.com

8 Types Of Waste Lean How Many Types Of Wastes Are There Under Lean As lean evolved into the rest of the enterprise and around the. Below, we’ll go through why it’s crucial to understand and address these 8 wastes. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Each type of waste is an inefficiency that costs your business time and resources. However , some organizations have used. How Many Types Of Wastes Are There Under Lean.

From taskoconsulting.com

Lean How Many Types Of Wastes Are There Under Lean However , some organizations have used the 8 wastes of lean as a template to audit their organizational processes to provide a framework for improvement. Streamline processes, cut costs, and elevate productivity for success! Originally there were seven wastes identified by taiichi ohno for the toyota production system. As mentioned previously in lean six sigma, wastes are categorized into eight. How Many Types Of Wastes Are There Under Lean.