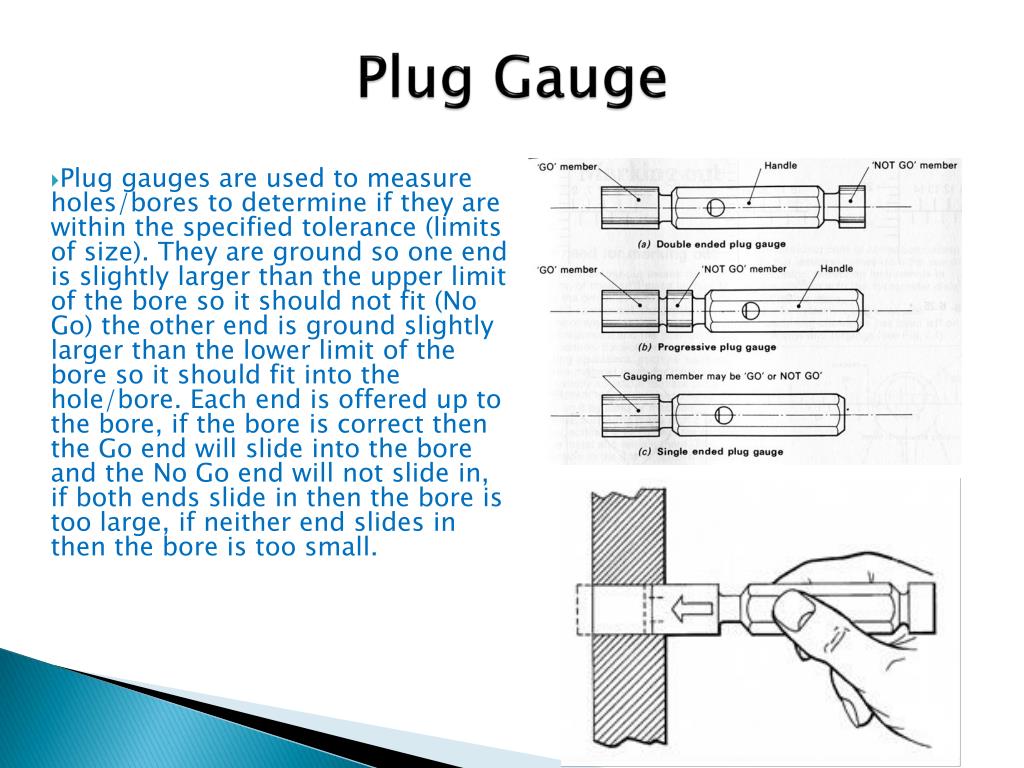

How To Measure Plug Gauge . Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. Join this course on udemy: One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. Therefore i put together this webpage and calculator to help. The difference between any class. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). The plug gage has been found to be highly accurate,. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. In order for the part to pass inspection and be.

from www.slideserve.com

Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Therefore i put together this webpage and calculator to help. The difference between any class. The plug gage has been found to be highly accurate,. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. Join this course on udemy: A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). In order for the part to pass inspection and be.

PPT Gauging Devices PowerPoint Presentation, free download ID4633475

How To Measure Plug Gauge A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). In order for the part to pass inspection and be. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The difference between any class. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. Therefore i put together this webpage and calculator to help. Join this course on udemy:

From www.youtube.com

Plain Plug Gauge & Snap Gauge YouTube How To Measure Plug Gauge The plug gage has been found to be highly accurate,. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. Pin gauge / plug gauge is used to check holes or features to an. How To Measure Plug Gauge.

From fyosjrqgh.blob.core.windows.net

Ear Plug Gauge Size Chart at Anita Allison blog How To Measure Plug Gauge Join this course on udemy: The difference between any class. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. A thread plug gage is designed to check. How To Measure Plug Gauge.

From www.slideserve.com

PPT Gauging Devices PowerPoint Presentation, free download ID4633475 How To Measure Plug Gauge One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. Join this course on udemy: In order for the part to pass inspection and be. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. A thread plug gage is designed to. How To Measure Plug Gauge.

From www.surajmech.com

Types of Gauges How To Measure Plug Gauge A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. Therefore i put together this webpage. How To Measure Plug Gauge.

From piercedbeauty.hubpages.com

The History, Method, and Warnings of Ear Gauging How To Measure Plug Gauge Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. In order for the part to pass inspection and be. The difference between any class. The. How To Measure Plug Gauge.

From westportcorp.com

Understanding How a Thread Plug Gage Is Used WESTport Corp. How To Measure Plug Gauge Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. In order for the part to pass inspection and be. Therefore i put together this webpage and calculator to help. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge. How To Measure Plug Gauge.

From meaninghippo.com

Thread Plug Gauge Calibration Procedure MeaningHippo How To Measure Plug Gauge Therefore i put together this webpage and calculator to help. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. In order for the part to pass inspection and be. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Pin gauge. How To Measure Plug Gauge.

From worldofmanufacturers.blogspot.com

Types and Uses of Plug Gauges How To Measure Plug Gauge The difference between any class. Join this course on udemy: Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. A plug gage is a cylinder. How To Measure Plug Gauge.

From www.judgetool.com

Thread Plug Gages METRIC Hardened Steel Judge Tool & Gage How To Measure Plug Gauge The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. The plug gage has been found to be highly accurate,. Join this course on udemy: A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). Therefore i put together this webpage and calculator to. How To Measure Plug Gauge.

From www.reddit.com

A Gauge to MM plug conversion chart that doesn’t skip sizes r/piercing How To Measure Plug Gauge The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The plug gage has been found to be highly accurate,. A thread plug gage is designed to check the pitch diameter (to the. How To Measure Plug Gauge.

From www.youtube.com

How To Use Thread Plug Gages Technical Series 101 YouTube How To Measure Plug Gauge The plug gage has been found to be highly accurate,. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The difference between any class. The calibration process involves several steps, including. How To Measure Plug Gauge.

From arcticbuffalo.com

3 common methods for measuring plugs Arctic Buffalo How To Measure Plug Gauge In order for the part to pass inspection and be. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Join this course on udemy: The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. The difference between any class. Therefore i put together this. How To Measure Plug Gauge.

From mavink.com

Plug Gauge Tolerance Chart How To Measure Plug Gauge Join this course on udemy: In order for the part to pass inspection and be. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). One of the most frequent questions asked is,. How To Measure Plug Gauge.

From www.torq-n-seal.com

Torq N' Seal® High Pressure Tube Plugs Tips and Tricks How To Measure Plug Gauge Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Therefore i put together this webpage and calculator to help. A thread plug gage is designed to check. How To Measure Plug Gauge.

From ar.inspiredpencil.com

Plugs Gauges Sizes Chart How To Measure Plug Gauge In order for the part to pass inspection and be. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. The difference between any class. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The. How To Measure Plug Gauge.

From medium.com

Types and Uses of Plug Gauges. Plug gauges are available in several How To Measure Plug Gauge The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. The plug gage has been found to be highly accurate,. Join this course on udemy: One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. A thread plug gage is designed to check. How To Measure Plug Gauge.

From twofeatherplugs.com

Ear Gauge Size Chart Two Feather Plugs How To Measure Plug Gauge Join this course on udemy: Therefore i put together this webpage and calculator to help. In order for the part to pass inspection and be. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. A thread plug gage is designed to check the pitch diameter. How To Measure Plug Gauge.

From katejordan.z13.web.core.windows.net

Ear Plug Size Chart How To Measure Plug Gauge A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. Join this course on udemy: Therefore i put together this webpage and calculator to help. The calibration process. How To Measure Plug Gauge.

From www.youtube.com

Plug Gauge And Types of Plug Gauge ( in Hindi Part 4 ) YouTube How To Measure Plug Gauge Therefore i put together this webpage and calculator to help. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. Pin gauge / plug gauge is used to check holes or features to an. How To Measure Plug Gauge.

From apcotool.com

Plain Plug Gauges Apco Tool & Gauge Pte Ltd How To Measure Plug Gauge Join this course on udemy: In order for the part to pass inspection and be. The difference between any class. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. Therefore i put together this webpage and calculator to help. The plug gage has been found to be highly accurate,. One of the. How To Measure Plug Gauge.

From www.dasqua.co.uk

Dasqua Thread gauge Set (plug gauge) M3 M12 Go & No Go How To Measure Plug Gauge Therefore i put together this webpage and calculator to help. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The plug gage has been found to be highly accurate,. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3. How To Measure Plug Gauge.

From www.customplugs.com

Ear Gauge Sizes Explained in Full Custom Plugs How To Measure Plug Gauge The difference between any class. Therefore i put together this webpage and calculator to help. In order for the part to pass inspection and be. The plug gage has been found to be highly accurate,. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). Join this course on udemy: Pin. How To Measure Plug Gauge.

From www.fyougauges.com

How to use API Plug Gages to Measure Tubing&Casing Couplings? How To Measure Plug Gauge The difference between any class. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. Join this course on udemy: Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. A thread plug gage is designed to check the. How To Measure Plug Gauge.

From enginewavyd20s.z21.web.core.windows.net

How To Measure Plug Size How To Measure Plug Gauge The plug gage has been found to be highly accurate,. Join this course on udemy: The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. In order for the part to pass inspection and be. Therefore i put together this webpage and calculator to help. A plug gage is a cylinder designed to. How To Measure Plug Gauge.

From www.youtube.com

How to Measure Plugs & Tunnels YouTube How To Measure Plug Gauge Therefore i put together this webpage and calculator to help. The difference between any class. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The calibration process involves several steps, including. How To Measure Plug Gauge.

From www.mmsonline.com

The Right Gage for Measuring Small Bores Modern Machine Shop How To Measure Plug Gauge The plug gage has been found to be highly accurate,. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. Join this course on udemy: A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). The calibration. How To Measure Plug Gauge.

From eolil7iworkshopfix.z14.web.core.windows.net

Size Chart For Plugs How To Measure Plug Gauge In order for the part to pass inspection and be. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. Therefore i put together this webpage and calculator to help. A thread plug. How To Measure Plug Gauge.

From www.tanfel.com

Industrial Metrology GO and NOGO Thread Plug Gauges Thread Gages How To Measure Plug Gauge The difference between any class. In order for the part to pass inspection and be. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. Join this course on udemy: Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3. How To Measure Plug Gauge.

From www.bonoss.com

Drain Plug Tips 3 Easy Steps to Measure A Oil Plug How To Measure Plug Gauge The difference between any class. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. Therefore i put together this webpage and calculator to help. Join this course on udemy: In order for the part to pass inspection and be. A plug gage is a cylinder. How To Measure Plug Gauge.

From www.slideserve.com

PPT GAUGES PowerPoint Presentation, free download ID3098195 How To Measure Plug Gauge Therefore i put together this webpage and calculator to help. The plug gage has been found to be highly accurate,. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). The difference between any class. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known. How To Measure Plug Gauge.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges How To Measure Plug Gauge Join this course on udemy: One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The plug gage has been found to be highly accurate,. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. A thread plug gage is designed to. How To Measure Plug Gauge.

From giotkvdfr.blob.core.windows.net

Plug Gauge Working at David Fuchs blog How To Measure Plug Gauge Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. The difference between any class. A thread plug gage is designed to check the pitch diameter (to the given pitch / threads per inch). One of the most frequent questions asked is, “how do i choose. How To Measure Plug Gauge.

From www.researchgate.net

Thread ring gauge pitch diameter measurement by CMM. Download How To Measure Plug Gauge Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. One of the most frequent questions asked is, “how do i choose a plug (pin) gauge for my measurement application.”. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known. How To Measure Plug Gauge.

From jordanhumphries.z13.web.core.windows.net

How To Measure Ear Plugs How To Measure Plug Gauge Join this course on udemy: The plug gage has been found to be highly accurate,. A plug gage is a cylinder designed to check the component tolerance of a hole in a product. The difference between any class. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3. How To Measure Plug Gauge.

From www.youtube.com

HOW TO USE THREAD LIMIT PLUG GAUGE YouTube How To Measure Plug Gauge The plug gage has been found to be highly accurate,. Pin gauge / plug gauge is used to check holes or features to an exact diameter, in some cases up to 3 decimal places. The calibration process involves several steps, including physical inspection, measurement of the gage's dimensions against known standards,. One of the most frequent questions asked is, “how. How To Measure Plug Gauge.