Surface Coating Zinc Oxide . Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno.

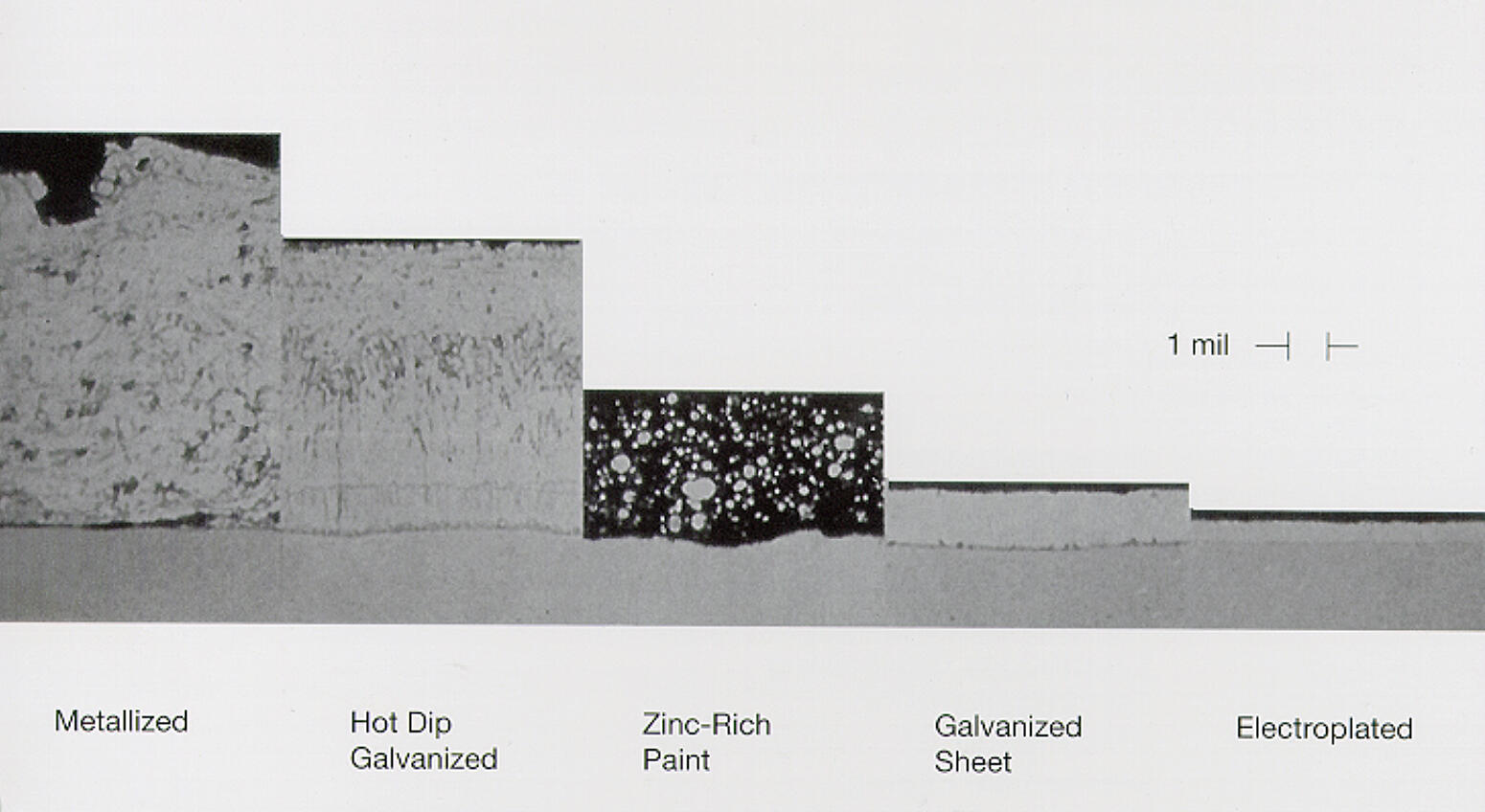

from galvanizeit.org

Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface.

Zinc Coatings for Steel Corrosion… American Galvanizers Association

Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique.

From www.mdpi.com

Coatings Free FullText Porous Zinc Oxide Thin Films Synthesis Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The. Surface Coating Zinc Oxide.

From newatlas.com

Nanostructure coatings remove heat four times faster Surface Coating Zinc Oxide The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. Interest in the use of zinc. Surface Coating Zinc Oxide.

From galvanizeit.org

Surface Condition American Galvanizers Association Surface Coating Zinc Oxide The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples. Surface Coating Zinc Oxide.

From hbsyplastic.en.made-in-china.com

Coating with Reactive Zinc Oxide White Powder Indirect Method China Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The surface functionalization of nps can play a key role in controlling the colloidal. Surface Coating Zinc Oxide.

From niurichem.en.made-in-china.com

Coating with Reactive Zinc Oxide White Powder Indirect Method Zinc Surface Coating Zinc Oxide Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. The highly reactive. Surface Coating Zinc Oxide.

From www.kingchemglobal.com

Zinc oxide for coating Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The surface functionalization of nps can play a key role. Surface Coating Zinc Oxide.

From www.zincoxideaustralia.com.au

Paint & Surface Coatings Zinc Oxide Australia Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. Interest in the use. Surface Coating Zinc Oxide.

From galvanizeit.org

Zinc Coatings for Steel Corrosion… American Galvanizers Association Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can.. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText The Effects of Zinc Oxide/Silicon Dioxide Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. The. Surface Coating Zinc Oxide.

From blog.thepipingmart.com

Zinc Plating vs. Powder Coating What's the Difference Surface Coating Zinc Oxide Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText Application of Xrays Diffraction for Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Influence. Surface Coating Zinc Oxide.

From sendcutsend.com

Zinc Plating vs Powder Coating for Corrosion Resistance SendCutSend Surface Coating Zinc Oxide The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText Comparative Study of AntiCorrosion Surface Coating Zinc Oxide Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by. Surface Coating Zinc Oxide.

From spie.org

Zinc oxide nanostructures at the forefront of new white lightemitting Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study. Surface Coating Zinc Oxide.

From pubs.rsc.org

Biocide mechanism of highly efficient and stable antimicrobial surfaces Surface Coating Zinc Oxide The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc. Surface Coating Zinc Oxide.

From hbchildren.en.made-in-china.com

Paint Coating Zinc Oxide Rutile Zinc Oxide Titanium Dioxide Powder Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and. Surface Coating Zinc Oxide.

From www.pioneermetal.com

Zinc Plating vs. Zinc Flake Coating Processes Explained Surface Coating Zinc Oxide The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Influence of thickness. Surface Coating Zinc Oxide.

From analiticaderetail.com

Magában foglal szakmai Pénzt keres do zinc oxide protect from air Surface Coating Zinc Oxide The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The highly reactive nature of zinc metal allows the coating to readily react with. Surface Coating Zinc Oxide.

From www.corrosionalliance.com

The different types of Zinc filled coatings Corrosion Alliance Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno.. Surface Coating Zinc Oxide.

From www.kraftchemical.com

Zinc Oxide Kraft Chemical Surface Coating Zinc Oxide Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. While the surfaces of coated. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText A ZincRich Coating Fabricated on a Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The. Surface Coating Zinc Oxide.

From www.gandccoatings.com

Zinc Coatings Corrosion Resistant Coating Surface Coating Zinc Oxide The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Interest in the. Surface Coating Zinc Oxide.

From www.glochem.com

Zinc Oxide as a White Pigment in Paints, Coatings, and Plastics Surface Coating Zinc Oxide The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText Application of Xrays Diffraction for Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can.. Surface Coating Zinc Oxide.

From www.superior-tech.net

How zinc coating and the galvanizing process protects iron from rust Surface Coating Zinc Oxide Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a. Surface Coating Zinc Oxide.

From www.mdpi.com

Polymers Free FullText Preparation and Characterization of Surface Coating Zinc Oxide The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface. Surface Coating Zinc Oxide.

From www.researchgate.net

(PDF) Deposition of Zinc Oxide Coatings on Wood Surfaces Using the Surface Coating Zinc Oxide The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. While the surfaces of coated steel. Surface Coating Zinc Oxide.

From nordicgalvanizers.com

Corrosion of zinc coatings Nordic Galvanizers Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The surface functionalization of nps can. Surface Coating Zinc Oxide.

From www.concreteconstruction.net

Organic ZincRich Epoxy Coating Concrete Construction Magazine Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. Interest in the use of zinc. Surface Coating Zinc Oxide.

From pubs.rsc.org

Biocide mechanism of highly efficient and stable antimicrobial surfaces Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Interest in the use of zinc oxide nanoparticles (zno nps) in surface. Surface Coating Zinc Oxide.

From www.researchgate.net

(PDF) Biocide mechanism of highly efficient and stable antimicrobial Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed. Surface Coating Zinc Oxide.

From www2.mdpi.com

Coatings Free FullText Application of Xrays Diffraction for Surface Coating Zinc Oxide The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide unique. The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The presented study is centered on evaluating the surface quality of machine components,. Surface Coating Zinc Oxide.

From creativeoxygenlabs.com

New zinc oxide surface kills airborne viruses and bacteria Creative Surface Coating Zinc Oxide Influence of thickness and coatings morphology in the antimicrobial performance of zinc oxide coatings applied surface science ,. The presented study is centered on evaluating the surface quality of machine components, particularly focusing on the surface characteristics of samples composed of e 355. The use of zno for the functionalization of textile substrates is growing rapidly, since it can provide. Surface Coating Zinc Oxide.

From www.mdpi.com

Coatings Free FullText Surface Modification of Bacterial Cellulose Surface Coating Zinc Oxide The highly reactive nature of zinc metal allows the coating to readily react with atmospheric oxygen and water to form a barrier of zinc oxide layer on the surface. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Interest in the use of zinc oxide nanoparticles (zno nps) in surface. Surface Coating Zinc Oxide.

From www.zincflakecoatings.com

Black Oxide Zinc Aluminum Coating / Galvanic White Passivation Zinc Plating Surface Coating Zinc Oxide While the surfaces of coated steel panels based on cuo/zno nanocomposite pea and coated steel panels based on bio zno. The surface functionalization of nps can play a key role in controlling the colloidal stability followed by interactions between. Interest in the use of zinc oxide nanoparticles (zno nps) in surface coatings and films has increased as its incorporation can.. Surface Coating Zinc Oxide.