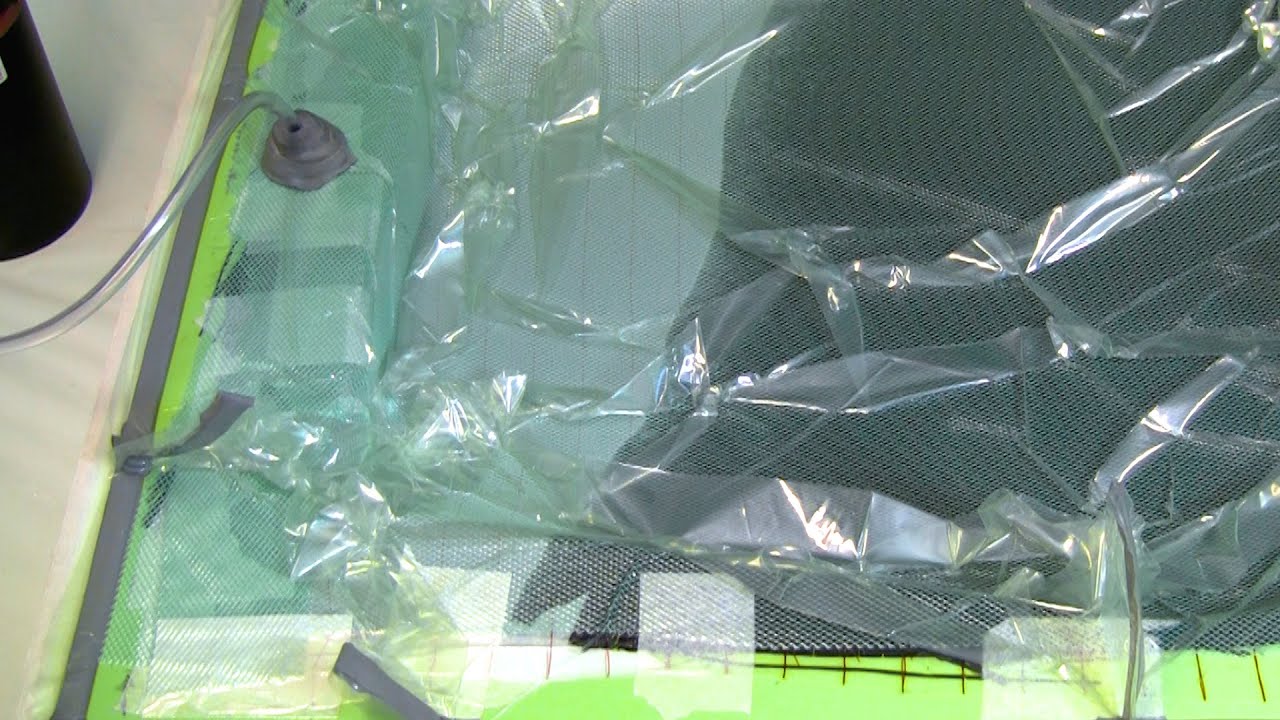

Vacuum For Carbon Fiber . In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. It works because the earth’s. Vacuum bags are a common and effective way to put pressure on composite materials. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed.

from www.youtube.com

Vacuum bags are a common and effective way to put pressure on composite materials. It works because the earth’s. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using.

How To Do Perfect Vacuum Resin Infusion of a Carbon Fibre (Fiber) Part

Vacuum For Carbon Fiber A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bags are a common and effective way to put pressure on composite materials. It works because the earth’s. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using.

From www.youtube.com

Vacuum Carbon Fiber Proses Auto Parts shorts carbonfiber carbon Vacuum For Carbon Fiber It works because the earth’s. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to put pressure on composite materials. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be. Vacuum For Carbon Fiber.

From applianceselloff.com

Best Carbon Fiber Vacuum Kit Home Appliances Vacuum For Carbon Fiber In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to. Vacuum For Carbon Fiber.

From www.shineautoproject.com

Vacuum Infused Carbon & CarbonKevlar Shine Auto Project Vacuum For Carbon Fiber Vacuum bags are a common and effective way to put pressure on composite materials. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods. Vacuum For Carbon Fiber.

From 100workfromhome.com

Best carbon fiber vacuum bagging kit The Best Home Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bags are a common and effective way to put pressure on composite. Vacuum For Carbon Fiber.

From www.rpgcarbon.com

GD Vacuum Carbon Fiber Radiator Shroud Cooling Plate racingproductgroup Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. It works because the earth’s. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. In this video. Vacuum For Carbon Fiber.

From www.pinterest.com

SkyVac 85 (Vacuum Only) Vacuums, Stainless steel canisters, Carbon fiber Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication. Vacuum For Carbon Fiber.

From 100workfromhome.com

Best carbon fiber vacuum bagging kit The Best Home Vacuum For Carbon Fiber Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Vacuum bags are a common and effective way to put pressure on composite materials. It works because the earth’s. A primer. Vacuum For Carbon Fiber.

From 100workfromhome.com

Best carbon fiber vacuum bagging kit The Best Home Vacuum For Carbon Fiber Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. It works because the earth’s. Discover the key carbon fiber molding techniques—compression. Vacuum For Carbon Fiber.

From www.dexcraft.com

Carbon Fiber Composites properties manufacturing methods pros and cons Vacuum For Carbon Fiber Vacuum bags are a common and effective way to put pressure on composite materials. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. It works because the earth’s. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be. Vacuum For Carbon Fiber.

From www.youtube.com

Carbon fiber production techniques Part 5 (1st vacuum infusion mould Vacuum For Carbon Fiber A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. It works because the earth’s. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Vacuum bagging equipment including pumps,. Vacuum For Carbon Fiber.

From www.youtube.com

Carbon Fiber DIY With NO Vacuum Bag or Special Tools! YouTube Vacuum For Carbon Fiber Vacuum bags are a common and effective way to put pressure on composite materials. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. In this video tutorial we demonstrate how to hand laminate a simple. Vacuum For Carbon Fiber.

From www.youtube.com

How to vacuuming auto carbon fiber parts YouTube Vacuum For Carbon Fiber Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to put pressure on composite materials. In this video tutorial we demonstrate. Vacuum For Carbon Fiber.

From www.carbonfiberglass.com

Deluxe vacuum bagging kit with everything you need to make the carbon Vacuum For Carbon Fiber Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Vacuum bagging equipment including pumps, vacuum generators, fittings. Vacuum For Carbon Fiber.

From www.youtube.com

Wet Layup Vacuum Bagging Cored Carbon Fiber Panel YouTube Vacuum For Carbon Fiber Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging equipment including pumps, vacuum generators, fittings. Vacuum For Carbon Fiber.

From www.gutterprovac.com

Gutter Vacuum Carbon Fiber Clamping 40 Foot Pole Kit (10 Poles Vacuum For Carbon Fiber In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do. Vacuum For Carbon Fiber.

From www.aliexpress.com

VacuumvalvenozzleselfsealingmetalReusableVacuumBagConnector Vacuum For Carbon Fiber A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. It works because. Vacuum For Carbon Fiber.

From www.youtube.com

How to Vacuum Bag Carbon Fiber YouTube Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. It works because the earth’s. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus. Vacuum For Carbon Fiber.

From www.youtube.com

How To Do Perfect Vacuum Resin Infusion of a Carbon Fibre (Fiber) Part Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and. Vacuum For Carbon Fiber.

From www.youtube.com

Carbon Fiber Lamination by Vacuum YouTube Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to put. Vacuum For Carbon Fiber.

From www.youtube.com

Vacuum Bagging a Carbon Part Complete Video YouTube Vacuum For Carbon Fiber Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. It works because the earth’s. In this video tutorial we. Vacuum For Carbon Fiber.

From 100workfromhome.com

Best carbon fiber vacuum bagging kit The Best Home Vacuum For Carbon Fiber Vacuum bags are a common and effective way to put pressure on composite materials. It works because the earth’s. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. A primer on the reasons to use vacuum bagging in composite part manufacture, and. Vacuum For Carbon Fiber.

From 471b4f6bdaadde6d.en.made-in-china.com

Mold Pressure Vacuum Bag Use Carbon Fibre Prepeg Ud Plain Twill 3K Vacuum For Carbon Fiber Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. It works because the earth’s. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. In this video. Vacuum For Carbon Fiber.

From evertech.en.made-in-china.com

Automatic Control Steel Vacuum Carbon Fiber Composite Curing Oven Vacuum For Carbon Fiber Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. It works because the earth’s. In this video tutorial we demonstrate how. Vacuum For Carbon Fiber.

From www.xline-systems.co.uk

Xline 3500w Gutter Vacuum + 35ft (10.6m) Carbon Poles Complete Vacuum For Carbon Fiber A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair. Vacuum For Carbon Fiber.

From www.indiamart.com

Carbon Fiber Vacuum Cleaner pole or Carbon fiber tube for gutter Vacuum For Carbon Fiber Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to put pressure on composite materials. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and. Vacuum For Carbon Fiber.

From www.diytrade.com

Carbon Fiber Vacuum Thermos Bottle LS024 LS carbongift (China Vacuum For Carbon Fiber A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock. Vacuum For Carbon Fiber.

From www.easycomposites.co.uk

How to Hand Laminate & Vacuum Bag a Simple Carbon Fibre Part Easy Vacuum For Carbon Fiber It works because the earth’s. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging,. Vacuum For Carbon Fiber.

From premier.en.made-in-china.com

Customized Light Weight Carbon Fiber Car Vacuum Cleaner Carbon Fiber Vacuum For Carbon Fiber Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to put pressure on composite materials. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to. Vacuum For Carbon Fiber.

From cnmosen.en.made-in-china.com

Large Vacuum Autoclave Carbon Fiber Composite Autoclave Bulletproof Vacuum For Carbon Fiber In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus films and peel plys all in stock for same day shipment. Vacuum bags are a common and effective way to. Vacuum For Carbon Fiber.

From www.youtube.com

Carbon Fiber Infusion Beginner How To YouTube Vacuum For Carbon Fiber Vacuum bags are a common and effective way to put pressure on composite materials. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. A primer on the reasons to. Vacuum For Carbon Fiber.

From www.diytrade.com

Carbon Fiber Vacuum Thermos Bottle LS024 LS carbongift (China Vacuum For Carbon Fiber Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it. Vacuum bags are a common and effective way to put pressure on composite materials. Discover the key carbon fiber molding techniques—compression molding, vacuum. Vacuum For Carbon Fiber.

From www.youtube.com

How To Build Your Own CARBON FIBER PARTS Vacuum Resin Infusion (EP Vacuum For Carbon Fiber It works because the earth’s. In this video tutorial we demonstrate how to hand laminate a simple carbon fibre part and then show methods for vacuum bagging, one using. Vacuum bags are a common and effective way to put pressure on composite materials. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter,. Vacuum For Carbon Fiber.

From clean.direct

SkyVac 30 w/ 8 Carbon Fiber Vac Poles Mid Size, Internal Vacuum For Carbon Fiber Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. It works because the earth’s. Discover the key carbon fiber molding techniques—compression molding, vacuum bagging, and autoclave molding. Vacuum bags are a common and effective way to put pressure on composite materials. A primer on the reasons to use vacuum bagging in composite part. Vacuum For Carbon Fiber.

From www.carbonfiberglass.com

Deluxe vacuum bagging kit with everything you need to make the carbon Vacuum For Carbon Fiber It works because the earth’s. Vacuum bagging is a sophisticated process used in carbon fiber production to create materials that are lighter, stronger, and more durable than their. Sometimes, as a prepreg or in a bagging application, carbon fiber needs to be vacuum pressed. Vacuum bagging equipment including pumps, vacuum generators, fittings and tools for composite fabrication and repair plus. Vacuum For Carbon Fiber.