Disadvantages Of Direct Steam Injection . As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. For processes which return the jacket water below. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop.

from www.slideserve.com

Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. For processes which return the jacket water below. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat.

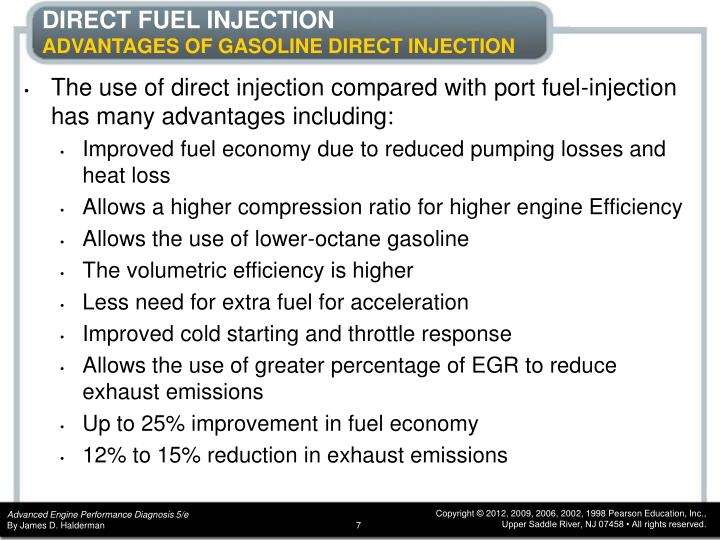

PPT CHAPTER 20 Gasoline DirectInjection Systems PowerPoint

Disadvantages Of Direct Steam Injection Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. For processes which return the jacket water below. It explains the diferences between direct and indirect heating,. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat.

From tianbaprocess.com

Direct Sterilization Process (DSUHT) TianBa Process Equipment Disadvantages Of Direct Steam Injection It explains the diferences between direct and indirect heating,. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary. Disadvantages Of Direct Steam Injection.

From blog.anaerobic-digestion.com

Direct Steam Injection Heating for Anaerobic Digestion Disadvantages Of Direct Steam Injection Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. As the condensate returns to the boiler, energy may be lost through faulty steam traps and. Disadvantages Of Direct Steam Injection.

From inproheat.com

Direct Steam Injection Systems Inproheat Industries Ltd. Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. For processes which return the jacket water below. It explains the diferences between direct and indirect heating,. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment.. Disadvantages Of Direct Steam Injection.

From tianbaprocess.com

Direct Sterilization Process (DSUHT) TianBa Process Equipment Disadvantages Of Direct Steam Injection Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection (dsi) heaters inject steam directly into the circulating water. Disadvantages Of Direct Steam Injection.

From studylib.net

Heating Water by Direct Steam Injection Disadvantages Of Direct Steam Injection Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. For processes which return the jacket water below. It explains the diferences between direct and indirect heating,. As the condensate returns to the boiler, energy may. Disadvantages Of Direct Steam Injection.

From www.reddit.com

Direct injection vs indirect injection, visualized r/tdi Disadvantages Of Direct Steam Injection For processes which return the jacket water below. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. It explains the diferences between direct and indirect heating,. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Injecting steam directly into the process fluid results in more rapid heat. Disadvantages Of Direct Steam Injection.

From inkorr.com.au

Pick Sanitary Direct Steam Injection (Heater / Cooker) Disadvantages Of Direct Steam Injection Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. It explains the. Disadvantages Of Direct Steam Injection.

From www.4btengines.com

Indirect Injection Vs. Direct Injection Engines Big Bear Engine Company Disadvantages Of Direct Steam Injection For processes which return the jacket water below. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam,. Disadvantages Of Direct Steam Injection.

From www.pro-sonix.com

Direct Steam Injection Heating Solutions from ProSonix Disadvantages Of Direct Steam Injection As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Direct steam injection involves the discharge. Disadvantages Of Direct Steam Injection.

From www.youtube.com

Steam injection and infusion system Animation YouTube Disadvantages Of Direct Steam Injection Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. It explains the. Disadvantages Of Direct Steam Injection.

From gaadistart.com

What is TDI (Turbocharged Direct Injection) Advantage and Disadvantages Disadvantages Of Direct Steam Injection It explains the diferences between direct and indirect heating,. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. For processes which return the jacket water below. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Injecting steam directly into the process fluid results in more rapid heat. Disadvantages Of Direct Steam Injection.

From www.reddit.com

How is direct steam injection for heating a tank full of water? r Disadvantages Of Direct Steam Injection Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. It explains the diferences between direct and indirect heating,. Direct steam injection works by. Disadvantages Of Direct Steam Injection.

From steaminfusion.oalgroup.com

What’s the difference between Steam Infusion & direct steam injection Disadvantages Of Direct Steam Injection As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection (dsi) heaters inject steam directly. Disadvantages Of Direct Steam Injection.

From www.researchgate.net

(PDF) Effect of Direct Steam Injection and Instantaneous UltraHigh Disadvantages Of Direct Steam Injection Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. It explains the diferences between direct and indirect. Disadvantages Of Direct Steam Injection.

From www.semanticscholar.org

Figure 2 from Analysis and Design of Direct Steam Injection for Tomato Disadvantages Of Direct Steam Injection As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. For processes which return the jacket. Disadvantages Of Direct Steam Injection.

From blog.surdry.com

The advantages of the sterilization by direct steam injection into the Disadvantages Of Direct Steam Injection Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. It explains the diferences between direct and indirect heating,. For. Disadvantages Of Direct Steam Injection.

From www.automotivespan.com

Direct Injection Advantages and Disadvantages Disadvantages Of Direct Steam Injection Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. For processes which return the jacket water below. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection (dsi) heaters inject steam directly. Disadvantages Of Direct Steam Injection.

From www.pro-sonix.com

Tips to Optimize Direct Steam Injection Heating Water Heating ProSonix Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. For processes which return the jacket water below. Direct steam injection (dsi) heaters inject steam directly. Disadvantages Of Direct Steam Injection.

From www.slideserve.com

PPT CHAPTER 20 Gasoline DirectInjection Systems PowerPoint Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. For processes which return the jacket water below. As the condensate returns to the. Disadvantages Of Direct Steam Injection.

From statiflo.com

Direct Steam Injection & heating solution from Statiflo Disadvantages Of Direct Steam Injection It explains the diferences between direct and indirect heating,. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. As the condensate returns to the boiler, energy may be lost through faulty steam traps. Disadvantages Of Direct Steam Injection.

From www.plantservices.com

Special Report The Maintenance and Design Advantages of Direct Steam Disadvantages Of Direct Steam Injection For processes which return the jacket water below. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment.. Disadvantages Of Direct Steam Injection.

From steaminfusion.oalgroup.com

Replace direct steam injection — Steam Infusion Heating, Mixing and Disadvantages Of Direct Steam Injection Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. For processes which. Disadvantages Of Direct Steam Injection.

From www.scribd.com

The Basics of Direct Steam Injection PDF PDF Steam Valve Disadvantages Of Direct Steam Injection Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. For processes which return the jacket water below. It explains. Disadvantages Of Direct Steam Injection.

From www.researchgate.net

Schematic diagram of direct steam injection process. Milk is fed Disadvantages Of Direct Steam Injection It explains the diferences between direct and indirect heating,. Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. As steam infusion maintains complete retention of. Disadvantages Of Direct Steam Injection.

From www.r-cap.com

Hydro Thermal Direct Steam Injection Heating System RCap Disadvantages Of Direct Steam Injection For processes which return the jacket water below. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to. Disadvantages Of Direct Steam Injection.

From slidetodoc.com

Pasteurization Definition Objectives Methods LTLT HTST UHT MILK Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. It explains the diferences between direct and indirect heating,. Injecting steam directly. Disadvantages Of Direct Steam Injection.

From dokumen.tips

(PDF) Direct Steam Injection for Anaerobic Acid Phase Digester Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Injecting steam directly into the process fluid results in more rapid heat. Disadvantages Of Direct Steam Injection.

From www.chegg.com

Solved direct steam injection. direct steam injection (DSI) Disadvantages Of Direct Steam Injection Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. Direct steam injection involves the discharge. Disadvantages Of Direct Steam Injection.

From www.researchgate.net

Process flow diagram. (A) Process configuration with heat supplied by Disadvantages Of Direct Steam Injection Injecting steam directly into the process fluid results in more rapid heat transfer and more eficient energy usage than indirect heat. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. It explains the diferences between direct and indirect heating,. As the condensate returns to the boiler,. Disadvantages Of Direct Steam Injection.

From www.chegg.com

Solved ii) Steaminjected gas turbines use hot turbine Disadvantages Of Direct Steam Injection For processes which return the jacket water below. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. It explains the diferences between direct and indirect heating,. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment.. Disadvantages Of Direct Steam Injection.

From www.slideserve.com

PPT CHAPTER 20 Gasoline DirectInjection Systems PowerPoint Disadvantages Of Direct Steam Injection As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. For processes which return the jacket water below. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. It explains the diferences between direct and indirect heating,.. Disadvantages Of Direct Steam Injection.

From www.pro-sonix.com

Direct Steam Injection Heating Solutions from ProSonix Disadvantages Of Direct Steam Injection Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. It explains the diferences between direct and indirect heating,. For processes which return the jacket water below. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to. Disadvantages Of Direct Steam Injection.

From www.semanticscholar.org

Figure 5 from Evaluation of UHT milk processed by direct steam Disadvantages Of Direct Steam Injection As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection (dsi) heaters inject steam directly into the circulating water loop. Direct steam injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy. As steam infusion maintains complete retention. Disadvantages Of Direct Steam Injection.

From steaminfusion.oalgroup.com

What’s the difference between Steam Infusion & direct steam injection Disadvantages Of Direct Steam Injection Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer heat. It explains the diferences between direct and indirect heating,. For processes which return the jacket water below. As the condensate returns to the boiler, energy may be lost through faulty steam traps and ancillary equipment. Direct steam injection (dsi) heaters inject. Disadvantages Of Direct Steam Injection.

From www.semanticscholar.org

[PDF] Evaluation of UHT milk processed by direct steam injection and Disadvantages Of Direct Steam Injection For processes which return the jacket water below. It explains the diferences between direct and indirect heating,. As steam infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control. Direct steam injection involves the discharge of steam bubbles into a liquid at a lower temperature to transfer. Disadvantages Of Direct Steam Injection.