Lube Oil System Troubleshooting . Are you adding or using more oil in lube tank, having a low pressure alarm? carry out simple corrective maintenance jobs related to the lubricating systems. before performing this procedure, verify the axis lubrication system is clear. lube pump problems troubleshooting. — sometimes, one or more axes may make noise when operating. Or, the axis drive motor overload alarm may come on. Perform quick visual inspections of the. Make sure you can see oil droplets in the tube. This can be verified by running an axis lubrication. lube oil condition assessment & troubleshooting. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Me199 rev.003 cmct course outline page 2 of 4 t e l n o :

from ahadsjournal.wordpress.com

carry out simple corrective maintenance jobs related to the lubricating systems. before performing this procedure, verify the axis lubrication system is clear. Are you adding or using more oil in lube tank, having a low pressure alarm? Make sure you can see oil droplets in the tube. — sometimes, one or more axes may make noise when operating. This can be verified by running an axis lubrication. lube pump problems troubleshooting. lube oil condition assessment & troubleshooting. Or, the axis drive motor overload alarm may come on. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches.

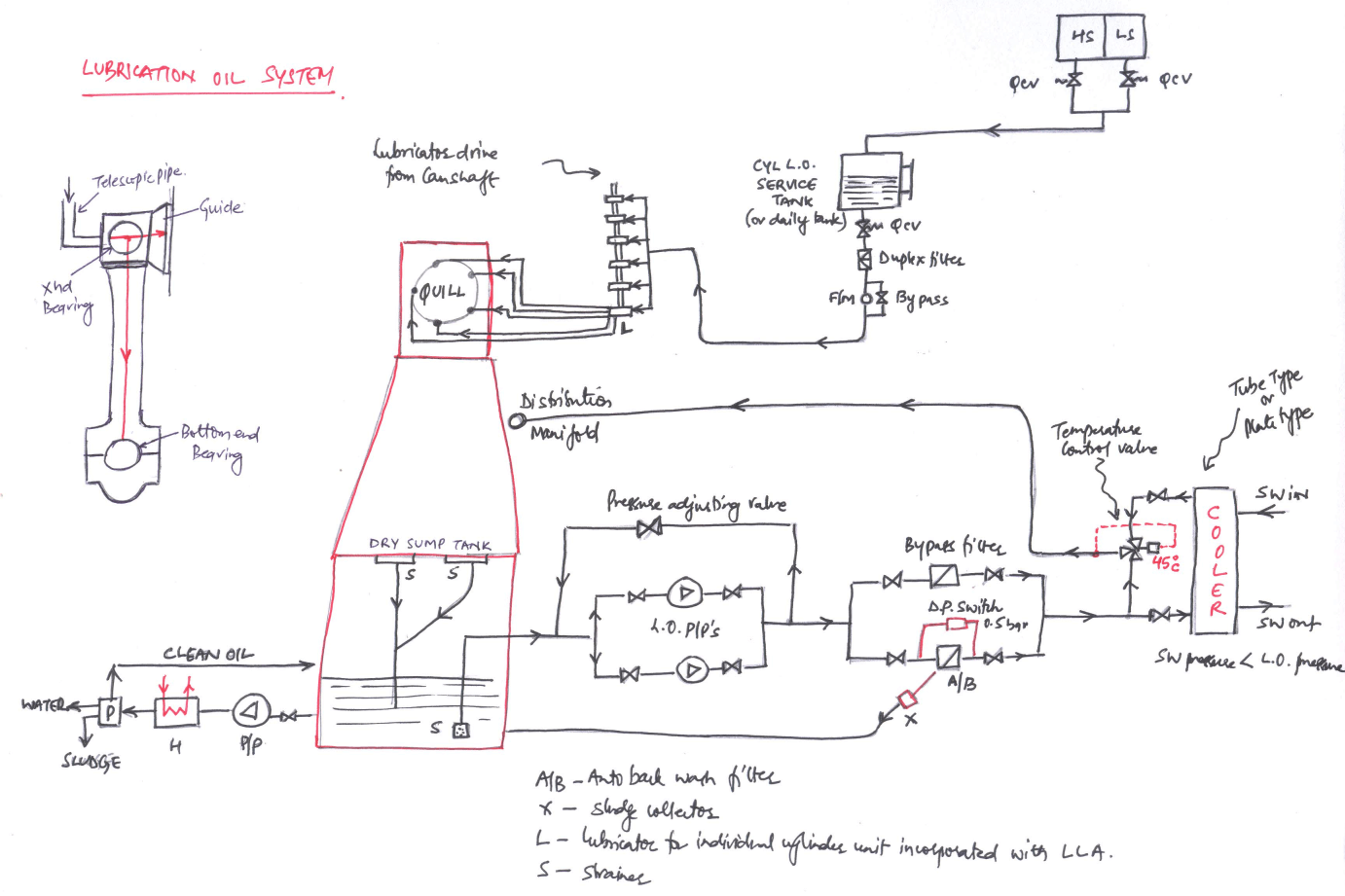

Ship’s Main Engine Lubricating Oil System & Common Engine Troubles

Lube Oil System Troubleshooting carry out simple corrective maintenance jobs related to the lubricating systems. Perform quick visual inspections of the. carry out simple corrective maintenance jobs related to the lubricating systems. lube pump problems troubleshooting. lube oil condition assessment & troubleshooting. Are you adding or using more oil in lube tank, having a low pressure alarm? Make sure you can see oil droplets in the tube. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : — sometimes, one or more axes may make noise when operating. Or, the axis drive motor overload alarm may come on. before performing this procedure, verify the axis lubrication system is clear. This can be verified by running an axis lubrication.

From www.youtube.com

Rundown Tank Lube Oil System ProcessAnimation 2022 YouTube Lube Oil System Troubleshooting lube oil condition assessment & troubleshooting. — sometimes, one or more axes may make noise when operating. carry out simple corrective maintenance jobs related to the lubricating systems. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : lube pump problems troubleshooting. — examine the lubrication tube between the lube. Lube Oil System Troubleshooting.

From mungfali.com

Lube Oil System Diagram Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. Are you adding or using more oil in lube tank, having a low pressure alarm? carry out simple corrective maintenance jobs related to the lubricating systems. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Perform quick visual inspections of. Lube Oil System Troubleshooting.

From dhevilsmechanic.blogspot.com

TroubleShoot Kawasaki GPB30 Lube Oil Leak Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. lube oil condition assessment & troubleshooting. Perform quick visual inspections of the. before performing this procedure, verify the axis lubrication system is clear. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : lube pump problems troubleshooting. carry out simple corrective. Lube Oil System Troubleshooting.

From www.linkedin.com

Lube Oil System Lube Oil System Troubleshooting Or, the axis drive motor overload alarm may come on. Are you adding or using more oil in lube tank, having a low pressure alarm? Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Perform quick visual inspections of the. lube oil condition assessment & troubleshooting. — examine the lubrication tube between. Lube Oil System Troubleshooting.

From dxoqchjjo.blob.core.windows.net

Gas Turbine Lube Oil System Diagram at Betty Funderburk blog Lube Oil System Troubleshooting This can be verified by running an axis lubrication. Are you adding or using more oil in lube tank, having a low pressure alarm? lube oil condition assessment & troubleshooting. Perform quick visual inspections of the. Or, the axis drive motor overload alarm may come on. before performing this procedure, verify the axis lubrication system is clear. . Lube Oil System Troubleshooting.

From www.scribd.com

Maintaining Lube Oil System Cleanliness in Motor Bearing Applications Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? lube pump problems troubleshooting. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Perform quick visual inspections of the. Make sure you can see oil droplets in the tube. This can be verified by running an axis lubrication.. Lube Oil System Troubleshooting.

From www.youtube.com

Lube Oil system in steam Turbine & Compressor Function of MOP, AOP Lube Oil System Troubleshooting — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. This can be verified by running an axis lubrication. before performing this procedure, verify the axis lubrication system is clear. Are you adding or using more oil in lube tank, having a low pressure alarm? carry out simple corrective maintenance. Lube Oil System Troubleshooting.

From marketingengineer.de

Lube Tube Troubleshooting Lube Oil System Troubleshooting Or, the axis drive motor overload alarm may come on. carry out simple corrective maintenance jobs related to the lubricating systems. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Make sure you can see oil droplets in the tube. — sometimes, one or more axes may make noise when operating. Are. Lube Oil System Troubleshooting.

From ar.inspiredpencil.com

Lube Oil System Diagram Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? Or, the axis drive motor overload alarm may come on. lube oil condition assessment & troubleshooting. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. carry out simple corrective maintenance jobs related to the. Lube Oil System Troubleshooting.

From www.youtube.com

Main Engine Lube Oil System Lube oil Line Diagram YouTube Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? Perform quick visual inspections of the. Or, the axis drive motor overload alarm may come on. — sometimes, one or more axes may make noise when operating. lube oil condition assessment & troubleshooting. carry out simple corrective maintenance jobs related to the. Lube Oil System Troubleshooting.

From www.detroitdieselengines.info

Lubrication System Detroit Diesel Troubleshooting Diagrams Lube Oil System Troubleshooting Perform quick visual inspections of the. lube pump problems troubleshooting. Make sure you can see oil droplets in the tube. — sometimes, one or more axes may make noise when operating. lube oil condition assessment & troubleshooting. Or, the axis drive motor overload alarm may come on. Me199 rev.003 cmct course outline page 2 of 4 t. Lube Oil System Troubleshooting.

From www.scribd.com

P&IDiagram Lube Oil System for Pakistan Refinery Limited Gasoline Lube Oil System Troubleshooting Me199 rev.003 cmct course outline page 2 of 4 t e l n o : — sometimes, one or more axes may make noise when operating. This can be verified by running an axis lubrication. Or, the axis drive motor overload alarm may come on. lube oil condition assessment & troubleshooting. Are you adding or using more oil. Lube Oil System Troubleshooting.

From www.youtube.com

Lubrication System Troubleshooting Haas Automation Service Tip 한글 YouTube Lube Oil System Troubleshooting — sometimes, one or more axes may make noise when operating. Perform quick visual inspections of the. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. before performing this procedure, verify the axis lubrication system is clear. This can be verified by running an axis lubrication. Make sure you. Lube Oil System Troubleshooting.

From ahadsjournal.wordpress.com

Ship’s Main Engine Lubricating Oil System & Common Engine Troubles Lube Oil System Troubleshooting Perform quick visual inspections of the. Are you adding or using more oil in lube tank, having a low pressure alarm? — sometimes, one or more axes may make noise when operating. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : This can be verified by running an axis lubrication. Or, the axis. Lube Oil System Troubleshooting.

From boatdiesel.com

High Lube Oil Consumption Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. before performing this procedure, verify the axis lubrication system is clear. Are you adding or using more oil in lube tank, having a low pressure alarm? Or, the axis drive motor overload alarm may come on. carry out simple corrective maintenance jobs related to the lubricating systems. . Lube Oil System Troubleshooting.

From exoclsnyz.blob.core.windows.net

Lube Oil Priming System at Jerome Duppstadt blog Lube Oil System Troubleshooting before performing this procedure, verify the axis lubrication system is clear. Are you adding or using more oil in lube tank, having a low pressure alarm? carry out simple corrective maintenance jobs related to the lubricating systems. Perform quick visual inspections of the. — examine the lubrication tube between the lube panel and the spindle for kinks,. Lube Oil System Troubleshooting.

From www.youtube.com

Lube Oil System Risks in Chemical and Power Plants YouTube Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? lube pump problems troubleshooting. Or, the axis drive motor overload alarm may come on. before performing this procedure, verify the axis lubrication system is clear. This can be verified by running an axis lubrication. — sometimes, one or more axes may make. Lube Oil System Troubleshooting.

From www.youtube.com

Lubrication System Troubleshooting Haas Automation Service Tip YouTube Lube Oil System Troubleshooting before performing this procedure, verify the axis lubrication system is clear. lube oil condition assessment & troubleshooting. This can be verified by running an axis lubrication. carry out simple corrective maintenance jobs related to the lubricating systems. Are you adding or using more oil in lube tank, having a low pressure alarm? Or, the axis drive motor. Lube Oil System Troubleshooting.

From docslib.org

Troubleshooting Bearing and Lube Oil System Problems DocsLib Lube Oil System Troubleshooting Perform quick visual inspections of the. This can be verified by running an axis lubrication. lube oil condition assessment & troubleshooting. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Make sure you can see oil droplets in the tube. carry out simple corrective maintenance jobs related to the lubricating systems. . Lube Oil System Troubleshooting.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Heritage Parts Centre UK Lube Oil System Troubleshooting carry out simple corrective maintenance jobs related to the lubricating systems. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Make sure you can see oil droplets in the tube. Are you adding or using more oil in lube tank, having a low pressure alarm? Me199 rev.003 cmct course outline. Lube Oil System Troubleshooting.

From ar.inspiredpencil.com

Lube Oil System Diagram Lube Oil System Troubleshooting carry out simple corrective maintenance jobs related to the lubricating systems. This can be verified by running an axis lubrication. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Make sure you can see oil droplets in the tube. — examine the lubrication tube between the lube panel and the spindle for. Lube Oil System Troubleshooting.

From dxoiirtfu.blob.core.windows.net

Lube Oil Control System at Robert Isaacs blog Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? Or, the axis drive motor overload alarm may come on. — sometimes, one or more axes may make noise when operating. Perform quick visual inspections of the. carry out simple corrective maintenance jobs related to the lubricating systems. Me199 rev.003 cmct course outline. Lube Oil System Troubleshooting.

From www.youtube.com

TROUBLESHOOTING LUBE OIL PURIFIER ALFA LAVAL YouTube Lube Oil System Troubleshooting lube oil condition assessment & troubleshooting. carry out simple corrective maintenance jobs related to the lubricating systems. This can be verified by running an axis lubrication. Or, the axis drive motor overload alarm may come on. Perform quick visual inspections of the. Are you adding or using more oil in lube tank, having a low pressure alarm? . Lube Oil System Troubleshooting.

From mungfali.com

Lube Oil System Diagram Lube Oil System Troubleshooting Or, the axis drive motor overload alarm may come on. This can be verified by running an axis lubrication. before performing this procedure, verify the axis lubrication system is clear. lube oil condition assessment & troubleshooting. lube pump problems troubleshooting. carry out simple corrective maintenance jobs related to the lubricating systems. Me199 rev.003 cmct course outline. Lube Oil System Troubleshooting.

From tectrapro.com

Lube Oil System (Conventional Plant) Technical Training Professionals Lube Oil System Troubleshooting lube oil condition assessment & troubleshooting. — sometimes, one or more axes may make noise when operating. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Make sure you can see oil droplets in. Lube Oil System Troubleshooting.

From www.atlaslab.in

lube oil testing report, lube oil analysis report Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. Or, the axis drive motor overload alarm may come on. carry out simple corrective maintenance jobs related to the lubricating systems. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Me199 rev.003 cmct course outline page 2 of 4 t. Lube Oil System Troubleshooting.

From www.youtube.com

WHY LUBE OIL USE IN THE ENGINE WITH LUBRICATION SYSTEM YouTube Lube Oil System Troubleshooting Perform quick visual inspections of the. carry out simple corrective maintenance jobs related to the lubricating systems. Are you adding or using more oil in lube tank, having a low pressure alarm? Me199 rev.003 cmct course outline page 2 of 4 t e l n o : Or, the axis drive motor overload alarm may come on. before. Lube Oil System Troubleshooting.

From dokumen.tips

(PDF) Checklist for Operation of Lube Oil System DOKUMEN.TIPS Lube Oil System Troubleshooting This can be verified by running an axis lubrication. lube pump problems troubleshooting. Make sure you can see oil droplets in the tube. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. before performing this procedure, verify the axis lubrication system is clear. Me199 rev.003 cmct course outline page. Lube Oil System Troubleshooting.

From www.youtube.com

lube oil system line diagram of lube oil system in ships YouTube Lube Oil System Troubleshooting Me199 rev.003 cmct course outline page 2 of 4 t e l n o : before performing this procedure, verify the axis lubrication system is clear. — examine the lubrication tube between the lube panel and the spindle for kinks, splits, or pinches. Are you adding or using more oil in lube tank, having a low pressure alarm?. Lube Oil System Troubleshooting.

From device.report

GLUBE OIL 500 User Manual Troubleshooting Guide Gruetzner Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. Are you adding or using more oil in lube tank, having a low pressure alarm? — sometimes, one or more axes may make noise when operating. lube oil condition assessment & troubleshooting. This can be verified by running an axis lubrication. carry out simple corrective maintenance jobs. Lube Oil System Troubleshooting.

From www.researchgate.net

(PDF) Troubleshooting in a Lube Oil Refinery using Gamma Scanning Technique Lube Oil System Troubleshooting Are you adding or using more oil in lube tank, having a low pressure alarm? Or, the axis drive motor overload alarm may come on. carry out simple corrective maintenance jobs related to the lubricating systems. — sometimes, one or more axes may make noise when operating. lube oil condition assessment & troubleshooting. Make sure you can. Lube Oil System Troubleshooting.

From www.youtube.com

MARINE LUBE OIL SYSTEM YouTube Lube Oil System Troubleshooting Make sure you can see oil droplets in the tube. Perform quick visual inspections of the. lube pump problems troubleshooting. lube oil condition assessment & troubleshooting. Or, the axis drive motor overload alarm may come on. Are you adding or using more oil in lube tank, having a low pressure alarm? — examine the lubrication tube between. Lube Oil System Troubleshooting.

From www.dieselmechanic.info

Cummins 4BT Flow Diagrams Lubricating System Diesel Engines Lube Oil System Troubleshooting Or, the axis drive motor overload alarm may come on. Are you adding or using more oil in lube tank, having a low pressure alarm? lube pump problems troubleshooting. — sometimes, one or more axes may make noise when operating. before performing this procedure, verify the axis lubrication system is clear. — examine the lubrication tube. Lube Oil System Troubleshooting.

From www.scribd.com

Lube Oil System Instruction 141A.000.2SM (B) 5 PDF Pump Switch Lube Oil System Troubleshooting Me199 rev.003 cmct course outline page 2 of 4 t e l n o : carry out simple corrective maintenance jobs related to the lubricating systems. — sometimes, one or more axes may make noise when operating. before performing this procedure, verify the axis lubrication system is clear. lube pump problems troubleshooting. lube oil condition. Lube Oil System Troubleshooting.

From dithopram.blogspot.com

Lube Oil System For Steam Turbine Ppt Lube Oil System Troubleshooting Perform quick visual inspections of the. before performing this procedure, verify the axis lubrication system is clear. carry out simple corrective maintenance jobs related to the lubricating systems. Me199 rev.003 cmct course outline page 2 of 4 t e l n o : — examine the lubrication tube between the lube panel and the spindle for kinks,. Lube Oil System Troubleshooting.