Brush Seal Turbine . Figure brush seal at turbine shroud (ref. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. A review of published literature is performed to analyze the. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. They are suitable for various applications in aircraft engines and industrial gas. This example shows the broad range of potential uses for brush seals.

from www.semanticscholar.org

Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. Figure brush seal at turbine shroud (ref. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. This example shows the broad range of potential uses for brush seals. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. A review of published literature is performed to analyze the. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. They are suitable for various applications in aircraft engines and industrial gas.

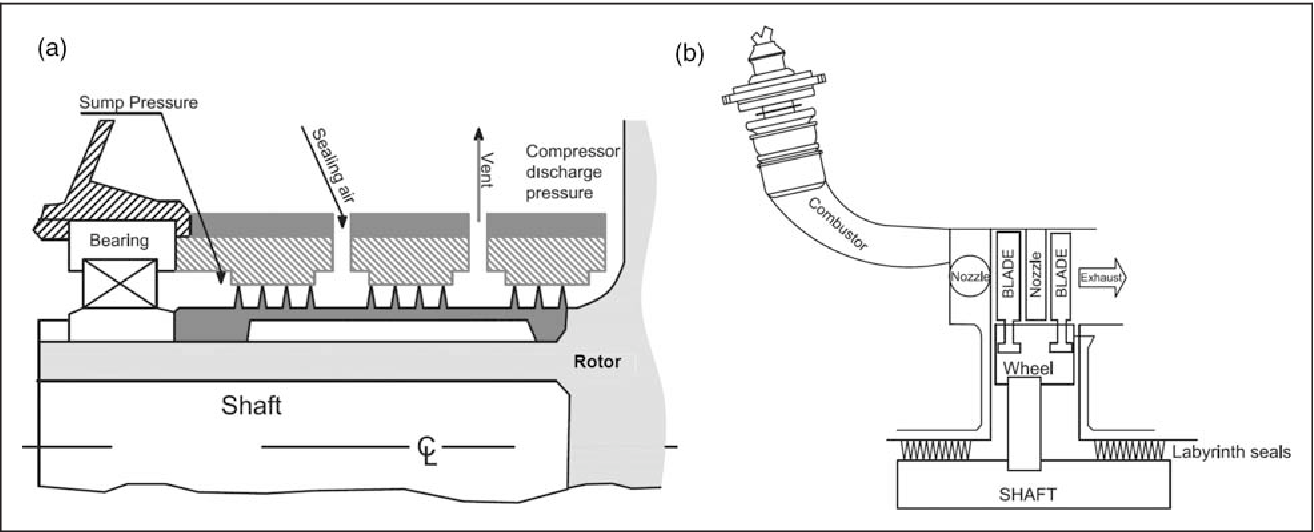

Figure 2 from Brush seals and labyrinth seals in gas turbine

Brush Seal Turbine Figure brush seal at turbine shroud (ref. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. They are suitable for various applications in aircraft engines and industrial gas. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. A review of published literature is performed to analyze the. Figure brush seal at turbine shroud (ref. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article.

From www.aircraftsystemstech.com

Aircraft Gas Turbine Engine Bearings and Seals Brush Seal Turbine They are suitable for various applications in aircraft engines and industrial gas. Figure brush seal at turbine shroud (ref. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows. Brush Seal Turbine.

From dokumen.tips

(PDF) Brush Seals for Improved Steam Turbine Performance · PDF Brush Seal Turbine A review of published literature is performed to analyze the. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. To reduce the leakage flow and improve system stability, brush seals were. Brush Seal Turbine.

From www.aviaexpo.com

Brush Seal Centurion™ Brush Seal Turbine Figure brush seal at turbine shroud (ref. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals. To reduce the. Brush Seal Turbine.

From www.mdpi.com

Energies Free FullText Effects of Front Plate Geometry on Brush Brush Seal Turbine Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. A review of published literature is performed to analyze the. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals. To reduce the leakage. Brush Seal Turbine.

From technetics.com

Reduce Leakage and Improve Output with Brush Seals Brush Seal Turbine Figure brush seal at turbine shroud (ref. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. A review of published literature is performed to analyze the. Today, steam turbine original equipment manufacturers. Brush Seal Turbine.

From www.researchgate.net

(PDF) Analysis of Brush Seal Interaction with Steam Turbine RotorShafts Brush Seal Turbine Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. This example shows the broad range of potential uses for brush seals. Today, steam turbine original equipment manufacturers (oems). Brush Seal Turbine.

From www.processingmagazine.com

Gland sealing in general purpose steam turbines Processing Magazine Brush Seal Turbine Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. They are suitable for various applications in aircraft engines and industrial gas. This example shows the broad range of potential uses for brush seals. To reduce the leakage flow and improve system stability, brush seals were. Brush Seal Turbine.

From www.bearingsplus.com

Utility Steam Turbine Brush Seals Bearings Plus Brush Seal Turbine Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. Figure brush seal at turbine shroud (ref. A review of published literature is performed to analyze the. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in. Brush Seal Turbine.

From www.gallagherseals.com

Sealing an Entire Hydroelectric Plant With Garlock Products Brush Seal Turbine Figure brush seal at turbine shroud (ref. A review of published literature is performed to analyze the. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. This example shows the broad range of potential uses for brush seals. Mtu brush seals are innovative and efficient. Brush Seal Turbine.

From part66prep.blogspot.com

Types Of Seals Used In A Gas Turbine Engine Part 66 Preparation Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. This example shows the broad range of potential uses for brush seals. They are suitable for various applications in aircraft engines and industrial gas. Figure brush seal at turbine shroud (ref. Brush seals are an alternative for labyrinths in. Brush Seal Turbine.

From www.researchgate.net

Fully Assembled Rotating Brush Seal Download Scientific Diagram Brush Seal Turbine Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Figure brush seal at turbine shroud (ref. This example shows the broad range of potential uses for brush seals. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively.. Brush Seal Turbine.

From journal.gpps.global

Investigation of a novel pressureactuated brush seal under hot steam Brush Seal Turbine Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. This example shows the broad range of potential uses for brush seals. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. Figure brush seal at turbine shroud (ref.. Brush Seal Turbine.

From www.semanticscholar.org

Figure 1 from Sealing technology for aircraft gas turbine engines Brush Seal Turbine Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. This example shows the broad range of potential uses for brush seals. They are suitable for various applications in aircraft engines and industrial gas. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to. Brush Seal Turbine.

From uspto.report

Dualended brush seal assembly and method of manufacture Patent Grant Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals. Brush seals are an alternative for labyrinths in gas turbine. Brush Seal Turbine.

From www.researchgate.net

Schematic of a brush seal. (a) The structure of a brush seal; (b) the Brush Seal Turbine Figure brush seal at turbine shroud (ref. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. The implementation of brush seals as an alternative to labyrinth seals in. Brush Seal Turbine.

From www.babbitting.com

Babbitt Bearings Hydrodynamic Bearings Brush Seal Turbine To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Figure brush seal at turbine shroud (ref. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to. Brush Seal Turbine.

From romin.re.kr

Brush Seal for Gas Turbine Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. A review of published literature is performed to analyze the. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals.. Brush Seal Turbine.

From www.tradekorea.com

Brush Seal tradekorea Brush Seal Turbine Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Figure brush seal at turbine shroud. Brush Seal Turbine.

From www.semanticscholar.org

Figure 2 from Brush seals and labyrinth seals in gas turbine Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Figure brush seal at turbine shroud (ref. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. They are suitable for various applications in aircraft engines and industrial gas. Today, steam turbine. Brush Seal Turbine.

From technetics.com

Brush Seals Group Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. This example shows the broad range of potential uses for brush seals. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. Figure brush seal at turbine shroud (ref.. Brush Seal Turbine.

From www.mdpi.com

Energies Free FullText Temperature Field and Performance Analysis Brush Seal Turbine They are suitable for various applications in aircraft engines and industrial gas. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient. Brush Seal Turbine.

From www.researchgate.net

(PDF) Brush Seal Structural Analysis and Correlation With Tests for Brush Seal Turbine Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. This example shows the broad range of potential uses for brush seals. To reduce the leakage flow and improve. Brush Seal Turbine.

From www.slideserve.com

PPT Turbine Case PowerPoint Presentation, free download ID9605532 Brush Seal Turbine They are suitable for various applications in aircraft engines and industrial gas. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. The implementation of brush. Brush Seal Turbine.

From journal.gpps.global

Investigation of a novel pressureactuated brush seal under hot steam Brush Seal Turbine To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. This example shows the broad range of potential uses for brush seals. They are suitable for various applications in aircraft engines and industrial gas. Figure brush seal at turbine shroud (ref. The implementation of brush seals as an alternative to. Brush Seal Turbine.

From www.bearingsplus.com

Utility Steam Turbine Brush Seals Bearings Plus Brush Seal Turbine Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold,. Brush Seal Turbine.

From technetics.com

Brush Seals Group Brush Seal Turbine A review of published literature is performed to analyze the. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. They are suitable for various applications in aircraft engines. Brush Seal Turbine.

From journal.gpps.global

Investigation of a novel pressureactuated brush seal under hot steam Brush Seal Turbine This example shows the broad range of potential uses for brush seals. Figure brush seal at turbine shroud (ref. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. They are suitable for various applications in aircraft engines and industrial gas. Brush seals are an alternative for labyrinths in gas turbine engine applications,. Brush Seal Turbine.

From www.indiamart.com

Steam Turbine Labyrinth Seal Turbine Labyrinth Brush Manufacturer Brush Seal Turbine Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. The implementation. Brush Seal Turbine.

From empoweringpumps.com

Excessive Steam Leakage Dramatically Reduced in Process Steam Turbine Brush Seal Turbine This example shows the broad range of potential uses for brush seals. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. They are suitable for. Brush Seal Turbine.

From journals.sagepub.com

Mathematical model of brush seals for gas turbine engines A Brush Seal Turbine Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to. Brush Seal Turbine.

From www.semanticscholar.org

Figure 5 from Brush seals and labyrinth seals in gas turbine Brush Seal Turbine The implementation of brush seals as an alternative to labyrinth seals in a gas turbine engine is outlined in this article. Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. A review of published literature is performed to analyze the. Figure brush seal at turbine. Brush Seal Turbine.

From empoweringpumps.com

Sealing HighSpeed Shafts in Turbomachinery [Fluid Sealing Association Brush Seal Turbine Brush seals are an alternative for labyrinths in gas turbine engine applications, reducing leakage by a factor up to five or tenfold, although relatively. They are suitable for various applications in aircraft engines and industrial gas. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. The implementation of brush seals as an. Brush Seal Turbine.

From eureka.patsnap.com

Brush seal and turbine using the same Eureka Patsnap Brush Seal Turbine Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. This example shows the broad range of potential uses for brush seals. They are suitable for various applications in aircraft engines and industrial gas. Today, steam turbine original equipment manufacturers (oems) have learned how to optimize brush seal design to prevent. A review. Brush Seal Turbine.

From www.slideserve.com

PPT Turbine Case PowerPoint Presentation, free download ID6232712 Brush Seal Turbine This example shows the broad range of potential uses for brush seals. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. Figure brush seal at turbine shroud (ref. Mtu brush seals are innovative and efficient sealing systems that reduce leakages by up to 90 percent. A review of published. Brush Seal Turbine.

From www.semanticscholar.org

Figure 1 from Brush seals and labyrinth seals in gas turbine Brush Seal Turbine This example shows the broad range of potential uses for brush seals. Figure brush seal at turbine shroud (ref. A review of published literature is performed to analyze the. To reduce the leakage flow and improve system stability, brush seals were developed in 1994 to replace labyrinth seals in. Brush seals are an alternative for labyrinths in gas turbine engine. Brush Seal Turbine.