Insert Tool Life Calculation . This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Maximize f n (for shorter cutting time) 3. Maximize a p (to reduce number of cuts) 2. E) create wear & flank wear. Reduce v c (to reduce heat). Different insert geometries on the tool life of the milling insert. Further the aim is to give a valuable input for optimization tests of the insert. There are many ways of defining the tool life, and the common way of. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Process of cutting tool failure. Tool wear, tool life, hand tools and machine tools. Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool life based upon the. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement.

from www.cuttinginsert.com

E) create wear & flank wear. Tool life is the duration of actual cutting time after which the tool is no longer usable. Reduce v c (to reduce heat). There are many ways of defining the tool life, and the common way of. Further the aim is to give a valuable input for optimization tests of the insert. Tool wear, tool life, hand tools and machine tools. Maximize f n (for shorter cutting time) 3. Maximize a p (to reduce number of cuts) 2. Process of cutting tool failure. This guide will show you 11 ways to radically increase your tool life and reduce tool wear.

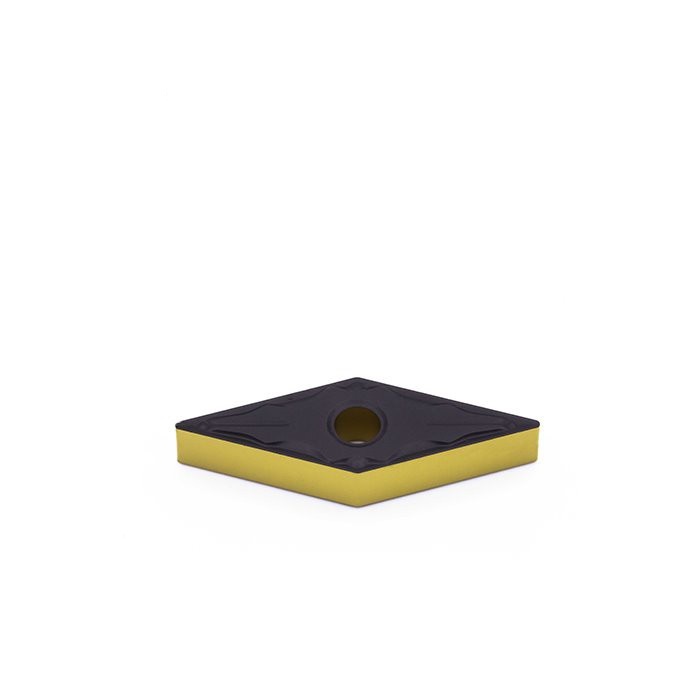

CVD Coated Insert for Extended Tool Life and Improved Productivity

Insert Tool Life Calculation Maximize a p (to reduce number of cuts) 2. Maximize a p (to reduce number of cuts) 2. Maximize f n (for shorter cutting time) 3. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Reduce v c (to reduce heat). Process of cutting tool failure. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear, tool life, hand tools and machine tools. E) create wear & flank wear. There are many ways of defining the tool life, and the common way of. Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Further the aim is to give a valuable input for optimization tests of the insert. Different insert geometries on the tool life of the milling insert. Tool life based upon the.

From turntechprecision.com

Chip off the old block How to control the chaos that is “chip Insert Tool Life Calculation There are many ways of defining the tool life, and the common way of. Process of cutting tool failure. Maximize f n (for shorter cutting time) 3. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. E) create wear & flank wear. Further the aim is to give. Insert Tool Life Calculation.

From www.alibaba.com

Tgf32l Tgf32 Tungsten Cnc Slotted Carbide Insert Tool For Metal Lathe Insert Tool Life Calculation Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Reduce v c (to reduce heat). Further the aim is to give a valuable input for optimization tests of the insert. There. Insert Tool Life Calculation.

From www.ebay.com

SPEED SYSTEMS, INC. BIT/E180AH BIT/E180AT BUSHING INSERT TOOL eBay Insert Tool Life Calculation Maximize a p (to reduce number of cuts) 2. Tool life based upon the. E) create wear & flank wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool life is the. Insert Tool Life Calculation.

From www.aliexpress.com

CNMG120404 TF IC907 carbide inserts External turning tool tungsten Insert Tool Life Calculation Maximize f n (for shorter cutting time) 3. E) create wear & flank wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Different insert geometries on the tool. Insert Tool Life Calculation.

From www.researchgate.net

Machining setup and cutting tool inserts Download Scientific Diagram Insert Tool Life Calculation Maximize f n (for shorter cutting time) 3. Tool wear, tool life, hand tools and machine tools. Reduce v c (to reduce heat). Different insert geometries on the tool life of the milling insert. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Process of cutting tool failure. Tool life is the. Insert Tool Life Calculation.

From www.youtube.com

What is Insert Types of Insert Specification of insert Material of Insert Tool Life Calculation Different insert geometries on the tool life of the milling insert. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Reduce v c (to reduce heat). Tool life is the duration of actual cutting time after which the tool is no longer usable. There are many ways of defining the tool life,. Insert Tool Life Calculation.

From www.mech4study.com

Tool Wear Flank Wear, Crater Wear and Nose Wear Mechanism mech4study Insert Tool Life Calculation Different insert geometries on the tool life of the milling insert. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. There are many ways of defining the tool life, and the common way of. Further the aim is to give a valuable input for optimization tests of the. Insert Tool Life Calculation.

From www.cuttinginsert.com

CVD Coated Insert for Extended Tool Life and Improved Productivity Insert Tool Life Calculation Maximize a p (to reduce number of cuts) 2. Tool wear, tool life, hand tools and machine tools. Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Further the aim is. Insert Tool Life Calculation.

From entagalex.blogspot.com

TOOL LIFE Insert Tool Life Calculation There are many ways of defining the tool life, and the common way of. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. E) create wear & flank wear. Tool life. Insert Tool Life Calculation.

From www.holmesbearings.co.nz

TOOL INSERT Insert Tool Life Calculation Maximize a p (to reduce number of cuts) 2. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. There are many ways of defining the tool life, and the common way of. Tool wear, tool life, hand tools and machine tools. Plus it will explain the details and. Insert Tool Life Calculation.

From www.researchgate.net

(PDF) High speed turning for hard material with PCBN inserts Tool wear Insert Tool Life Calculation Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Process of cutting tool failure. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Maximize a p (to reduce number of cuts) 2. Tool wear, tool life, hand tools. Insert Tool Life Calculation.

From www.mdpi.com

JMMP Free FullText A Unique Methodology for Tool Life Prediction Insert Tool Life Calculation Reduce v c (to reduce heat). Tool life based upon the. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. This guide will show you 11 ways to radically. Insert Tool Life Calculation.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Insert Tool Life Calculation This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Process of cutting tool failure. Maximize f n (for shorter cutting time) 3. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Tool life is the duration of actual cutting time. Insert Tool Life Calculation.

From www.stability.co

Machine Tool Life Monitoring Solution STABILITY Insert Tool Life Calculation E) create wear & flank wear. Different insert geometries on the tool life of the milling insert. Maximize a p (to reduce number of cuts) 2. There are many ways of defining the tool life, and the common way of. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Process of cutting. Insert Tool Life Calculation.

From www.researchgate.net

Tool life data for eight inserts Download Table Insert Tool Life Calculation Maximize f n (for shorter cutting time) 3. There are many ways of defining the tool life, and the common way of. Further the aim is to give a valuable input for optimization tests of the insert. Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool wear, tool life, hand tools. Insert Tool Life Calculation.

From entagalex.blogspot.com

TOOL LIFE Mechanical engineering Insert Tool Life Calculation There are many ways of defining the tool life, and the common way of. Maximize a p (to reduce number of cuts) 2. Tool wear, tool life, hand tools and machine tools. Maximize f n (for shorter cutting time) 3. Different insert geometries on the tool life of the milling insert. Tool life is the duration of actual cutting time. Insert Tool Life Calculation.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Insert Tool Life Calculation This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear, tool life, hand tools and machine tools. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool life is the duration of actual cutting time after which the tool is no. Insert Tool Life Calculation.

From www.otomotools.com

U drill inserts SPMG050204 060204 07T308 090408 110408 140512 Carbide Insert Tool Life Calculation Tool life based upon the. Different insert geometries on the tool life of the milling insert. Maximize a p (to reduce number of cuts) 2. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri E) create wear & flank wear. Maximize f n (for shorter cutting time) 3. This guide. Insert Tool Life Calculation.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection Insert Tool Life Calculation Tool life is the duration of actual cutting time after which the tool is no longer usable. Further the aim is to give a valuable input for optimization tests of the insert. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Maximize f n (for shorter cutting time) 3. E) create wear. Insert Tool Life Calculation.

From www.chegg.com

Solved A tool life of 48 mins for a cutting speed of 80 Insert Tool Life Calculation Further the aim is to give a valuable input for optimization tests of the insert. Tool wear, tool life, hand tools and machine tools. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool life based upon the. Reduce v c (to reduce heat). Process of cutting tool failure. There are many. Insert Tool Life Calculation.

From www.ctemag.com

Understanding the Identification System for Indexable Inserts Cutting Insert Tool Life Calculation Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri This guide will show you 11 ways to radically increase your tool life and reduce tool wear. There are many ways of defining the tool life, and the common way of. Maximize a p (to reduce number of cuts) 2. Process. Insert Tool Life Calculation.

From www.youtube.com

Tool Nose Radius Compensation (Manual) A look at what is required to Insert Tool Life Calculation This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Further the aim is to give a valuable input for optimization tests of the insert. Maximize a p (to reduce number of cuts) 2. Tool wear, tool life, hand tools and machine tools. Maximize f n (for shorter cutting time) 3. Process of. Insert Tool Life Calculation.

From www.mecholic.com

drill tip Insert Tool Life Calculation Further the aim is to give a valuable input for optimization tests of the insert. Reduce v c (to reduce heat). Process of cutting tool failure. Maximize a p (to reduce number of cuts) 2. Different insert geometries on the tool life of the milling insert. This guide will show you 11 ways to radically increase your tool life and. Insert Tool Life Calculation.

From www.youtube.com

Taylor's tool life equation In Metal cutting Example Problem YouTube Insert Tool Life Calculation Different insert geometries on the tool life of the milling insert. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Maximize a p (to reduce number of cuts) 2. Tool life is the duration of actual cutting time after which the tool is no longer usable. Maximize f n (for. Insert Tool Life Calculation.

From shopmetaltech.com

Positive lead angle tooling increases metal removal rates and extends Insert Tool Life Calculation There are many ways of defining the tool life, and the common way of. Reduce v c (to reduce heat). Maximize f n (for shorter cutting time) 3. Different insert geometries on the tool life of the milling insert. Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool wear, tool life,. Insert Tool Life Calculation.

From www.researchgate.net

a, b Diagram of insert and tool holder. Download Scientific Diagram Insert Tool Life Calculation Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool wear, tool life, hand tools and machine tools. Tool life based upon the. Maximize a p (to reduce number of cuts) 2. Different insert geometries on the tool life of the milling insert. Process of cutting tool failure. Reduce v c (to. Insert Tool Life Calculation.

From www.researchgate.net

(PDF) Tool Life Reliability of Indexable Cutting Inserts Insert Tool Life Calculation This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Different insert geometries on the tool life of the milling insert. Tool life based upon the. Maximize a p (to reduce number. Insert Tool Life Calculation.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Insert Tool Life Calculation Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement. Maximize f n (for shorter cutting time) 3. Tool life is the duration of actual cutting time after which the tool is no longer usable. Different insert geometries on the tool life of the milling insert. E) create wear. Insert Tool Life Calculation.

From www.youtube.com

Excel template tool, fixture history card, tool life monitoring Insert Tool Life Calculation Further the aim is to give a valuable input for optimization tests of the insert. Tool life based upon the. Maximize f n (for shorter cutting time) 3. Tool life is the duration of actual cutting time after which the tool is no longer usable. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate. Insert Tool Life Calculation.

From www.numerical.minaprem.com

Taylor’s Tool Life Formula for Machining Insert Tool Life Calculation Tool life is the duration of actual cutting time after which the tool is no longer usable. Tool wear, tool life, hand tools and machine tools. E) create wear & flank wear. Reduce v c (to reduce heat). Maximize a p (to reduce number of cuts) 2. Tool life is actual machining time by which a fresh cutting tool satisfactorily. Insert Tool Life Calculation.

From www.youtube.com

Tool life Taylor's tool life equation factors affecting tool life Insert Tool Life Calculation Tool life based upon the. Tool life is the duration of actual cutting time after which the tool is no longer usable. Maximize f n (for shorter cutting time) 3. There are many ways of defining the tool life, and the common way of. Reduce v c (to reduce heat). Tool life is actual machining time by which a fresh. Insert Tool Life Calculation.

From www.scribd.com

Formula for Press Tool Design Insert Tool Life Calculation Maximize f n (for shorter cutting time) 3. Tool wear, tool life, hand tools and machine tools. Reduce v c (to reduce heat). Tool life based upon the. Process of cutting tool failure. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Maximize a p (to reduce number of cuts). Insert Tool Life Calculation.

From www.youtube.com

feed rate calculation, rpm calculation vmc, cutting speed calculation Insert Tool Life Calculation Tool life is the duration of actual cutting time after which the tool is no longer usable. There are many ways of defining the tool life, and the common way of. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear, tool life, hand tools and machine tools. Reduce. Insert Tool Life Calculation.

From www.slideshare.net

TOOL LIFE TEST Insert Tool Life Calculation Tool life based upon the. Different insert geometries on the tool life of the milling insert. E) create wear & flank wear. Process of cutting tool failure. Tool wear, tool life, hand tools and machine tools. Maximize a p (to reduce number of cuts) 2. Reduce v c (to reduce heat). Tool life is the duration of actual cutting time. Insert Tool Life Calculation.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts Insert Tool Life Calculation Process of cutting tool failure. Tool wear, tool life, hand tools and machine tools. Tool life is the duration of actual cutting time after which the tool is no longer usable. Maximize f n (for shorter cutting time) 3. Further the aim is to give a valuable input for optimization tests of the insert. There are many ways of defining. Insert Tool Life Calculation.