Shim Type Valve Adjustment . To summarize, those steps are: Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. The rule of thumb for most mechanics is to shim the valves twice. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. After the valves have moved (almost always tighter). Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. The process involves adjusting the valve. With the engine dead cold,. Here, we go through the.

from www.hagerty.com

Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. The rule of thumb for most mechanics is to shim the valves twice. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. With the engine dead cold,. After the valves have moved (almost always tighter). Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. The process involves adjusting the valve. Here, we go through the. Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances.

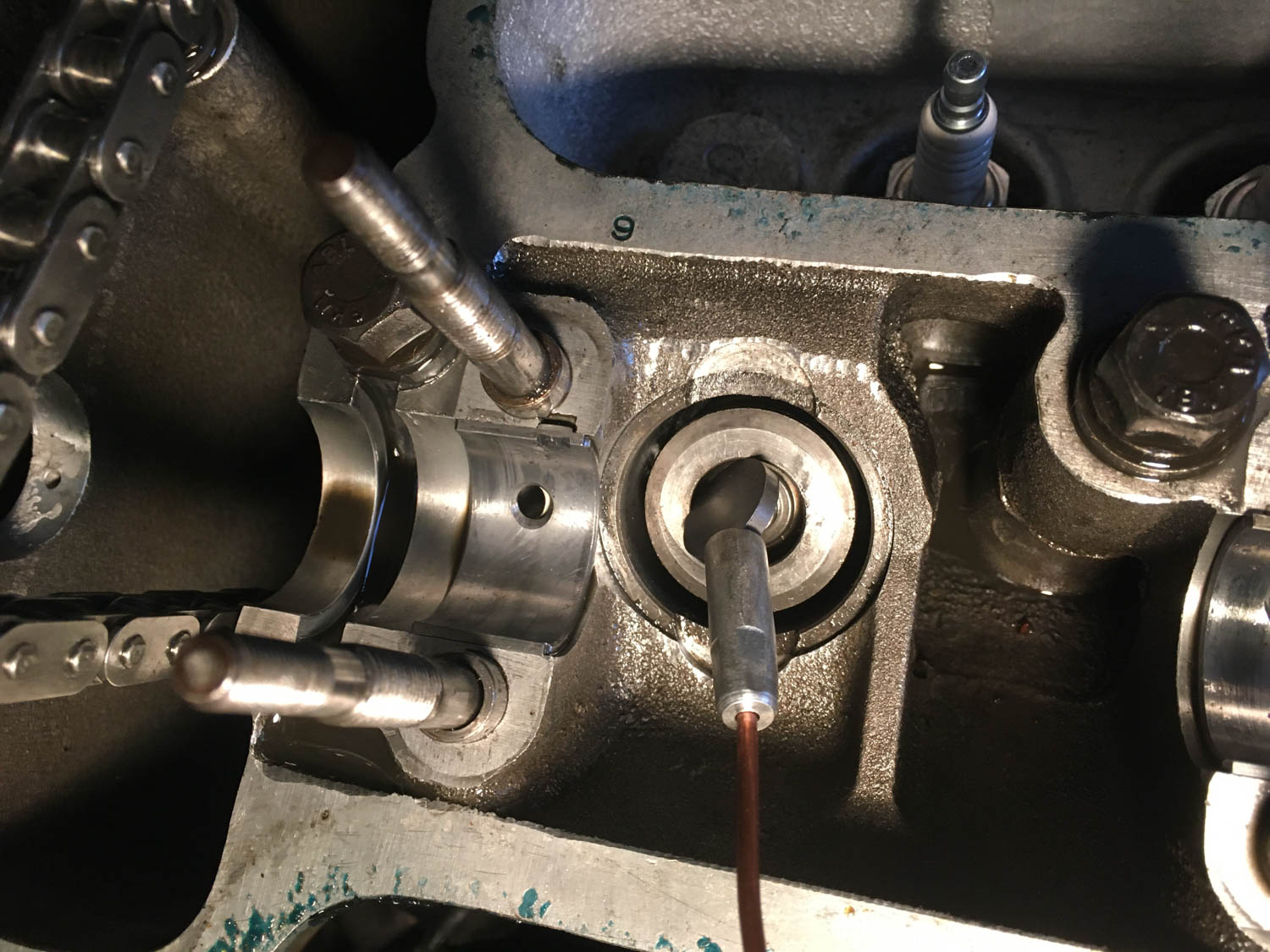

The laborious process of valve adjustment in a shimmed engine Hagerty

Shim Type Valve Adjustment Here, we go through the. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. After the valves have moved (almost always tighter). With the engine dead cold,. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. The process involves adjusting the valve. The rule of thumb for most mechanics is to shim the valves twice. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. To summarize, those steps are: Here, we go through the. Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets.

From dirtwheelsmag.com

HowTo Adjust Your Valves Dirt Wheels Magazine Shim Type Valve Adjustment The rule of thumb for most mechanics is to shim the valves twice. Here, we go through the. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. With these figures, calculate the. Shim Type Valve Adjustment.

From www.youtube.com

Valve shim Adjustment valve clearance Land cruiser 1HZ 1HDT 1PZ Shim Type Valve Adjustment Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. The process involves adjusting the valve. After the valves have moved (almost always tighter). The rule of thumb for most mechanics is to shim the valves twice. With these figures, calculate the adjustment needed and determine the new shim size for optimal. Shim Type Valve Adjustment.

From www.hagerty.com

The laborious process of valve adjustment in a shimmed engine Hagerty Shim Type Valve Adjustment Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Here, we go through the. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or. Shim Type Valve Adjustment.

From weberpower.com

Valve Adjustment Shims Individual and 4Packs Shim Type Valve Adjustment After the valves have moved (almost always tighter). The process involves adjusting the valve. To summarize, those steps are: With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. The rule of thumb for most mechanics is to shim the valves twice. With the engine dead cold,. Here, we go through the. Begin. Shim Type Valve Adjustment.

From www.yotashop.com

Valve Shimtool Toyota/Lexus Valve Adjusting Tools SHIMTOOL Shim Type Valve Adjustment The process involves adjusting the valve. The rule of thumb for most mechanics is to shim the valves twice. With the engine dead cold,. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012. Shim Type Valve Adjustment.

From www.tacomaworld.com

Valve adjustment formula World Shim Type Valve Adjustment Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. With the engine dead cold,. Here,. Shim Type Valve Adjustment.

From www.youtube.com

How to adjust shim over bucket valve clearances YouTube Shim Type Valve Adjustment After the valves have moved (almost always tighter). Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. The process involves adjusting the valve. With the engine dead cold,. The rule of thumb. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment The process involves adjusting the valve. To summarize, those steps are: The rule of thumb for most mechanics is to shim the valves twice. After the valves have moved (almost always tighter). Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. Begin by measuring the existing valve clearance, noting. Shim Type Valve Adjustment.

From www.youtube.com

VALVE ADJUSTMENT SHIM TYPE HONDA CBR YouTube Shim Type Valve Adjustment To summarize, those steps are: The process involves adjusting the valve. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. The rule of thumb for most mechanics is to shim the valves. Shim Type Valve Adjustment.

From www.youtube.com

200 Hour RZR Valve Shim Adjustment (EP393) YouTube Shim Type Valve Adjustment Here, we go through the. The process involves adjusting the valve. With the engine dead cold,. Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. To summarize, those steps are: Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Valve shimming. Shim Type Valve Adjustment.

From www.youtube.com

How To Check & Adjust Shim Type Valve Adjusters Ft. KTM Duke/RC 390 Shim Type Valve Adjustment The process involves adjusting the valve. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches.. Shim Type Valve Adjustment.

From shop.rrcperformanceengines.com

VALVE ADJUSTMENT SHIM Shim Type Valve Adjustment After the valves have moved (almost always tighter). Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the. Shim Type Valve Adjustment.

From www.youtube.com

How to adjust motorcycle valves shim style YouTube Shim Type Valve Adjustment With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Here, we go through the. The process involves adjusting the valve. The rule of thumb for most mechanics is to shim the valves twice. After the valves have moved (almost always tighter). To summarize, those steps are: Adjustment involves measuring the clearance between. Shim Type Valve Adjustment.

From www.youtube.com

Valve Adjustment Shim Type YouTube Shim Type Valve Adjustment The process involves adjusting the valve. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. With the engine dead cold,. The rule of thumb for most mechanics is to shim the valves twice. To summarize, those steps are: Last week, we talked about the basic steps to adjust valves in an engine. Shim Type Valve Adjustment.

From www.fixyourdirtbike.com

Different Types Of Valve Adjusterment In 4Stroke Motorcycle Engines Shim Type Valve Adjustment Here, we go through the. After the valves have moved (almost always tighter). The rule of thumb for most mechanics is to shim the valves twice. With the engine dead cold,. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a. Shim Type Valve Adjustment.

From www.dansmc.com

Dan's Motorcycle Valve Adjustment Shim Type Valve Adjustment Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. Here, we go through the. After the valves have moved (almost always tighter). The rule of thumb for most mechanics is to shim the valves twice. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment After the valves have moved (almost always tighter). To summarize, those steps are: The rule of thumb for most mechanics is to shim the valves twice. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning. Shim Type Valve Adjustment.

From www.youtube.com

How To Adjust Valve Shim Clearance on a BMW M3 E36 YouTube Shim Type Valve Adjustment The rule of thumb for most mechanics is to shim the valves twice. With the engine dead cold,. Here, we go through the. After the valves have moved (almost always tighter). To summarize, those steps are: With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Begin by measuring the existing valve clearance,. Shim Type Valve Adjustment.

From www.youtube.com

Valve Adjustment Shim under the Bucket YouTube Shim Type Valve Adjustment Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. With the engine. Shim Type Valve Adjustment.

From www.hotrod.com

Here’s How to Set Proper Valvespring Height Hot Rod Network Shim Type Valve Adjustment Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. To summarize, those steps are:. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment Here, we go through the. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. To summarize, those steps are: Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. With the engine dead cold,. The process involves adjusting the valve. The rule. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment With the engine dead cold,. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. The rule of thumb for most mechanics is to shim the valves twice. Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until. Shim Type Valve Adjustment.

From www.youtube.com

Motorcycle Valve Adjustment Guide With Shim Calculator How To adjust Shim Type Valve Adjustment Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. To summarize, those steps are: Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. The. Shim Type Valve Adjustment.

From www.hagerty.com

The laborious process of valve adjustment in a shimmed engine Hagerty Shim Type Valve Adjustment Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. The process involves adjusting the valve. To summarize, those steps are: Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a. Shim Type Valve Adjustment.

From www.hagerty.com

The laborious DIY process of valve adjustment in a shimmed engine, Part Shim Type Valve Adjustment Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud or rotating an eccentric until the clearance is a specified amount, usually about 0.006 to 0.012 inches. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Begin by measuring the existing valve. Shim Type Valve Adjustment.

From transmoto.com.au

HowTo Adjust Valve Clearance Transmoto Shim Type Valve Adjustment Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. To summarize, those steps are: Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. After the valves have moved (almost always tighter). Here, we go through the. Last week, we talked about the basic. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment After the valves have moved (almost always tighter). Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. Here, we go through the. The rule of thumb for most mechanics is to shim the valves twice. The process involves adjusting the valve. To summarize, those steps are: With these figures, calculate the adjustment. Shim Type Valve Adjustment.

From www.toymods.org.au

Guide Changing Valve Shims on a 7MGTE Shim Type Valve Adjustment With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. With the engine dead cold,. To summarize, those steps are: The rule of thumb for most mechanics is to shim the valves twice. The process involves adjusting the valve. Begin by measuring the existing valve clearance, noting the current shim size, and consulting. Shim Type Valve Adjustment.

From blog.pro-x.com

Checking and Adjusting Valves on Your ShimUnderBucket Style Motorcycle Shim Type Valve Adjustment To summarize, those steps are: After the valves have moved (almost always tighter). Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. Here, we go through the. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. The rule of thumb for. Shim Type Valve Adjustment.

From www.toymods.org.au

Guide Changing Valve Shims on a 7MGTE Shim Type Valve Adjustment The rule of thumb for most mechanics is to shim the valves twice. The process involves adjusting the valve. Here, we go through the. With the engine dead cold,. Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. Last week, we talked about the basic steps to adjust valves in an. Shim Type Valve Adjustment.

From www.youtube.com

Adjusting bucket & shim type valve clearance 1158 YouTube Shim Type Valve Adjustment With the engine dead cold,. The process involves adjusting the valve. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. Here, we go through the. The rule of thumb for most mechanics is to shim the valves twice. Begin by measuring the existing valve clearance, noting the current shim size, and consulting. Shim Type Valve Adjustment.

From www.youtube.com

How works shim valve adjusting in Toyota 4A FE engine YouTube Shim Type Valve Adjustment Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those with adjustable valve clearances. Begin by measuring the existing valve clearance, noting the current shim size, and consulting the manufacturer’s specifications. To summarize, those steps are: Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge and turning a threaded stud. Shim Type Valve Adjustment.

From www.youtube.com

How and why to adjust valves on a shim style Toyota 3SGTE YouTube Shim Type Valve Adjustment The rule of thumb for most mechanics is to shim the valves twice. Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. To summarize, those steps are: After the valves have moved (almost always tighter). Valve shimming is an essential maintenance procedure in many internal combustion engines, especially those. Shim Type Valve Adjustment.

From www.dirtrider.com

Dirt Shimming ShimType Valve Adjustment Dirt Rider Magazine Dirt Shim Type Valve Adjustment Last week, we talked about the basic steps to adjust valves in an engine that uses shims under bucket tappets. With these figures, calculate the adjustment needed and determine the new shim size for optimal engine performance. After the valves have moved (almost always tighter). Adjustment involves measuring the clearance between the rocker and valve stem with a feeler gauge. Shim Type Valve Adjustment.