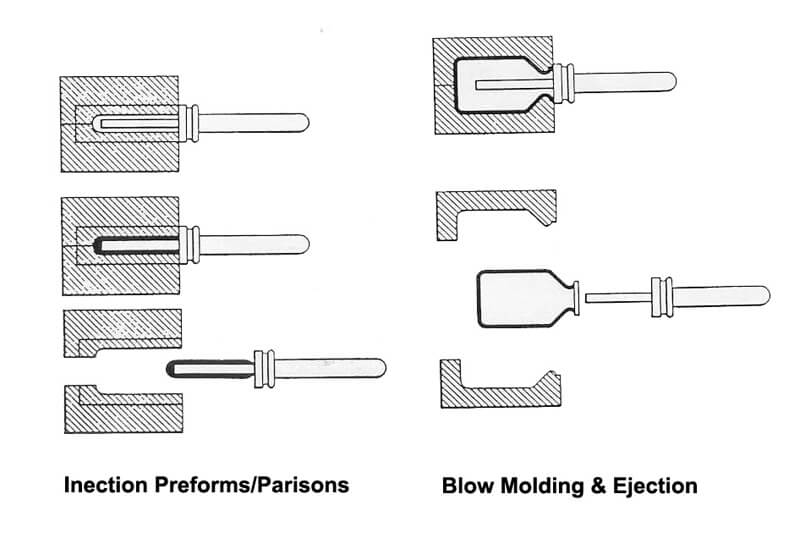

Parison Blow Molding Process . Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The parison is placed between two. The process involves heating and inflating a plastic tube known. The blow molding process unfolds through a sequence of precise steps: In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold.

from alleycho.com

Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two. The blow molding process unfolds through a sequence of precise steps: The process involves heating and inflating a plastic tube known.

Plastic Injection Blow Moulding Process Alleycho International Ltd

Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. The parison is placed between two. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. In extrusion blow molding, a parison is formed by extruding molten. The blow molding process unfolds through a sequence of precise steps: Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The process involves heating and inflating a plastic tube known.

From www.cm-pet.com

3 Main Types of Blow Molding Process and Examples CHIA MING Blow Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The parison is placed between two. The process involves heating and inflating a plastic tube known. The. Parison Blow Molding Process.

From proportionair.com

Parison Blow Molding for Plastics by ProportionAir Parison Blow Molding Process The process involves heating and inflating a plastic tube known. The parison is placed between two. The blow molding process unfolds through a sequence of precise steps: The process involves heating and inflating a plastic tube known as a parison or preform. In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a manufacturing process that. Parison Blow Molding Process.

From www.slideserve.com

PPT Blow Molding PowerPoint Presentation, free download ID6843656 Parison Blow Molding Process Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The parison is placed between two. The process involves heating and inflating a plastic tube known as a parison or preform. The process involves heating and inflating a. Parison Blow Molding Process.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Parison Blow Molding Process The parison is placed between two. In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The process involves heating and inflating a plastic. Parison Blow Molding Process.

From www.injection-molded-plastics.net

Sipco Molding Technologies Injection Molded Plastic Parison Blow Molding Process The parison is placed between two. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known. Blow. Parison Blow Molding Process.

From www.mjspackaging.com

Extrusion Blow Molding 101 MJS Packaging Parison Blow Molding Process The process involves heating and inflating a plastic tube known. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The parison is placed between two. Blow molding is a process that converts a hollow parison (or preform). Parison Blow Molding Process.

From cmppin.com

What are the 2 types of Extrusion Blow Moulding Machines? Central Parison Blow Molding Process The parison is placed between two. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The process involves heating and inflating a plastic tube known as a parison or preform. In extrusion blow molding, a parison is formed by extruding molten. The blow molding. Parison Blow Molding Process.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Parison Blow Molding Process The process involves heating and inflating a plastic tube known as a parison or preform. The process involves heating and inflating a plastic tube known. In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a manufacturing process. Parison Blow Molding Process.

From www.researchgate.net

Simulation results of the blowmolding process showing that the parison Parison Blow Molding Process The process involves heating and inflating a plastic tube known as a parison or preform. The process involves heating and inflating a plastic tube known. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. In extrusion blow molding, a parison is formed by extruding molten. The blow molding process unfolds through. Parison Blow Molding Process.

From www.oberk.com

Plastic Bottle Production What is Extrusion Blow Molding (EBM) Parison Blow Molding Process Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The blow molding process unfolds through a sequence of precise steps: Blow molding is a process that converts a hollow parison (or preform) into a shaped container by. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The parison is placed between two. In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a process that converts a hollow parison. Parison Blow Molding Process.

From blasformen.com

Extrusion Blow moulding Extrusion = First Process Step Parison Blow Molding Process The parison is placed between two. The process involves heating and inflating a plastic tube known as a parison or preform. The blow molding process unfolds through a sequence of precise steps: The process involves heating and inflating a plastic tube known. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by. Parison Blow Molding Process.

From www.pinterest.co.kr

The Given following sequence explains the process of extrusion blow Parison Blow Molding Process Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The process involves. Parison Blow Molding Process.

From www.mdpi.com

Materials Free FullText Optimization of Polymer Processing A Parison Blow Molding Process The blow molding process unfolds through a sequence of precise steps: Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two. Blow molding is. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The process involves heating and inflating a plastic tube known as a parison or preform. The process. Parison Blow Molding Process.

From www.manufacturingguide.com

Extrusion blow molding Find suppliers, processes & material Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known. The parison is placed between two. The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials.. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The parison is. Parison Blow Molding Process.

From blowmoulding.blogspot.com

Blow Moulding Types of Parison Die Heads Parison Blow Molding Process The parison is placed between two. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as. Parison Blow Molding Process.

From alleycho.com

Plastic Injection Blow Moulding Process Alleycho International Ltd Parison Blow Molding Process The process involves heating and inflating a plastic tube known as a parison or preform. In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known. Parison Blow Molding Process.

From www.youtube.com

Plastic Moulding Working Animation (Extrusion, Blow, Vacuum Forming Parison Blow Molding Process The parison is placed between two. The blow molding process unfolds through a sequence of precise steps: Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold.. Parison Blow Molding Process.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI Parison Blow Molding Process Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Blow molding is a process that converts a hollow parison. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. The blow molding process unfolds through a sequence of precise steps: The parison is placed between two. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers,. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process The blow molding process unfolds through a sequence of precise steps: In extrusion blow molding, a parison is formed by extruding molten. The parison is placed between two. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or. Parison Blow Molding Process.

From www.vrogue.co

What Is Parison Blow Molding Process Step By Step Gui vrogue.co Parison Blow Molding Process The blow molding process unfolds through a sequence of precise steps: The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The parison is placed between two. The process involves heating and inflating a plastic tube known.. Parison Blow Molding Process.

From mavink.com

Blow Molding Process Flow Chart Parison Blow Molding Process Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The blow molding process unfolds through a sequence of precise steps: In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known. Blow molding is a manufacturing process that shapes hollow plastic. Parison Blow Molding Process.

From www.researchgate.net

Extrusion blow molding process. Download Scientific Diagram Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The blow molding process unfolds through. Parison Blow Molding Process.

From www.researchgate.net

Pressandblow process (a) gob feeding, (b) parison pressing, (c Parison Blow Molding Process The parison is placed between two. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known. The process involves heating and inflating a plastic tube known as a parison or preform. In extrusion blow molding, a parison is formed by extruding molten.. Parison Blow Molding Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Parison Blow Molding Process The parison is placed between two. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform,. Parison Blow Molding Process.

From currierplastics.com

Custom Blow Molding Currier Plastics Parison Blow Molding Process The blow molding process unfolds through a sequence of precise steps: The parison is placed between two. Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a process that converts a hollow parison. Parison Blow Molding Process.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Parison Blow Molding Process Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. In extrusion blow molding, a parison is formed by extruding. Parison Blow Molding Process.

From www.researchgate.net

Simulation results of the blowmolding process showing that the parison Parison Blow Molding Process Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known. The blow molding process unfolds through a sequence of precise steps: In extrusion blow molding, a parison is formed by extruding molten. Blow molding is a process that converts a hollow parison. Parison Blow Molding Process.

From www.youtube.com

How to adjust the peripheral direction thickness of parison?Lessons Parison Blow Molding Process The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. The parison is placed between two. In extrusion blow molding, a parison is formed by extruding molten. Blow molding is. Parison Blow Molding Process.

From en.wikipedia.org

Blow molding Wikipedia Parison Blow Molding Process The blow molding process unfolds through a sequence of precise steps: The process involves heating and inflating a plastic tube known. In extrusion blow molding, a parison is formed by extruding molten. The process involves heating and inflating a plastic tube known as a parison or preform. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles,. Parison Blow Molding Process.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Parison Blow Molding Process The parison is placed between two. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. The process involves heating and inflating a plastic tube known as a parison or preform. The blow molding process unfolds through a. Parison Blow Molding Process.

From slideserve.com

PPT Blow Molding PowerPoint Presentation ID296696 Parison Blow Molding Process In extrusion blow molding, a parison is formed by extruding molten. The parison is placed between two. The blow molding process unfolds through a sequence of precise steps: Blow molding is a process that converts a hollow parison (or preform) into a shaped container by deforming it under air pressure against a mold. Blow molding is a manufacturing process that. Parison Blow Molding Process.