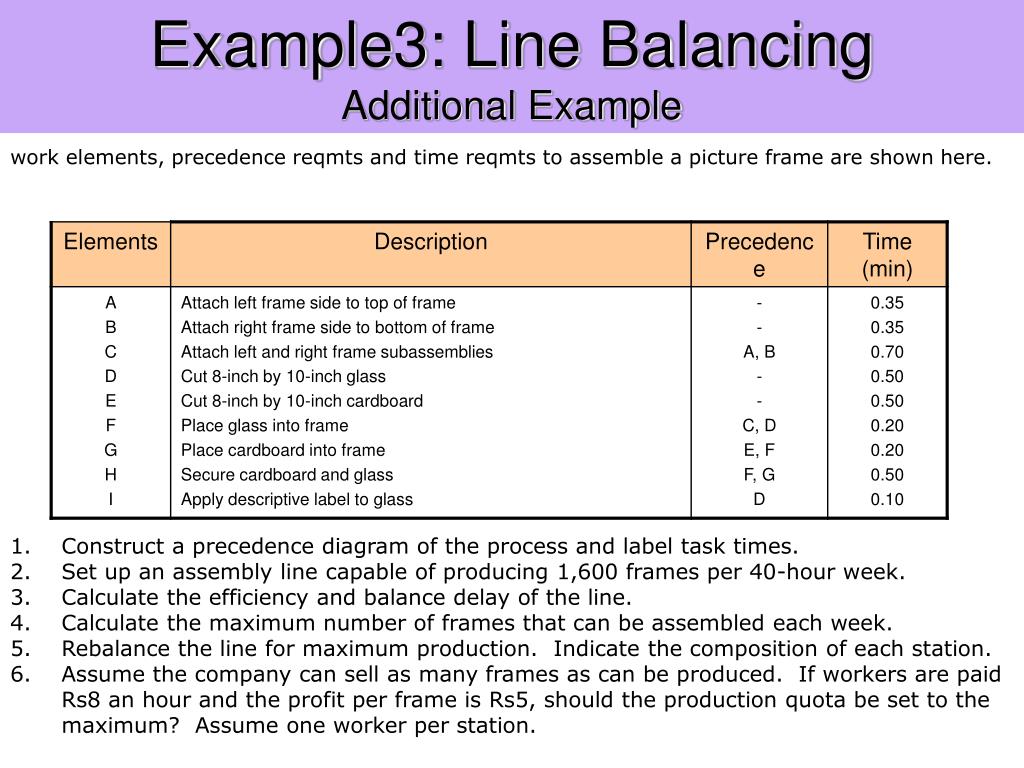

Assembly Line Balancing Example . It provides the tasks, precedence relationships, task times, required cycle time. Why is it possible to. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Also, the assembly line needs. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. Here is a possible solution for assigning workstations. Effective balancing minimizes waste and ensures that production lines run efficiently. To better understand assembly line balancing, let’s imagine a simple line balancing example. Why are tasks a & b not combined as a possible workstation? However, line balancing means different things to different manufacturers. Inspection and flash removal of plastic moulded part 1. The document describes an assembly line balancing problem to minimize balance delay. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Inspection and flash removal of plastic moulded part 2. Line a can produce 10 units per minute, line b 20 can produce units per

from www.slideserve.com

How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line a can produce 10 units per minute, line b 20 can produce units per Why is it possible to. Inspection and flash removal of plastic moulded part 1. However, line balancing means different things to different manufacturers. Here is a possible solution for assigning workstations. Effective balancing minimizes waste and ensures that production lines run efficiently. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. It provides the tasks, precedence relationships, task times, required cycle time.

PPT Assembly Line Balancing PowerPoint Presentation, free download

Assembly Line Balancing Example It provides the tasks, precedence relationships, task times, required cycle time. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Line a can produce 10 units per minute, line b 20 can produce units per Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. However, line balancing means different things to different manufacturers. Also, the assembly line needs. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Here is a possible solution for assigning workstations. Assembly process have following activities. Inspection and flash removal of plastic moulded part 1. Why is it possible to. Why are tasks a & b not combined as a possible workstation? To better understand assembly line balancing, let’s imagine a simple line balancing example. Acme manufacturing has three production lines: Effective balancing minimizes waste and ensures that production lines run efficiently. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills.

From www.intechopen.com

Assembly Line Balancing and Sequencing IntechOpen Assembly Line Balancing Example Acme manufacturing has three production lines: The document describes an assembly line balancing problem to minimize balance delay. It provides the tasks, precedence relationships, task times, required cycle time. Why is it possible to. Inspection and flash removal of plastic moulded part 2. To better understand assembly line balancing, let’s imagine a simple line balancing example. Effective balancing minimizes waste. Assembly Line Balancing Example.

From mungfali.com

Line Balancing Diagram Assembly Line Balancing Example Why is it possible to. Inspection and flash removal of plastic moulded part 1. To better understand assembly line balancing, let’s imagine a simple line balancing example. Here is a possible solution for assigning workstations. Also, the assembly line needs. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total. Assembly Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Example Effective balancing minimizes waste and ensures that production lines run efficiently. Assembly process have following activities. It provides the tasks, precedence relationships, task times, required cycle time. Inspection and flash removal of plastic moulded part 2. Why is it possible to. The document describes an assembly line balancing problem to minimize balance delay. How to do line balancing of an. Assembly Line Balancing Example.

From www.youtube.com

Assembly Line Balancing Workstations YouTube Assembly Line Balancing Example Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. Inspection and flash removal of plastic moulded part 1. Line a can produce 10 units per. Assembly Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Assembly Line Balancing Example Effective balancing minimizes waste and ensures that production lines run efficiently. Why are tasks a & b not combined as a possible workstation? Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. It provides the tasks, precedence relationships, task times, required cycle time. Assembly process have. Assembly Line Balancing Example.

From www.smlease.com

What is production Line Balancing and How to implement it? Assembly Line Balancing Example Inspection and flash removal of plastic moulded part 2. Line a can produce 10 units per minute, line b 20 can produce units per Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Assembly line balancing is a production strategy that sets an intended rate of. Assembly Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Example Why are tasks a & b not combined as a possible workstation? Line a can produce 10 units per minute, line b 20 can produce units per Effective balancing minimizes waste and ensures that production lines run efficiently. Inspection and flash removal of plastic moulded part 2. Also, the assembly line needs. It provides the tasks, precedence relationships, task times,. Assembly Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Example Inspection and flash removal of plastic moulded part 1. Also, the assembly line needs. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Effective balancing minimizes waste and ensures that production lines run efficiently. It provides the tasks, precedence relationships, task times, required cycle time. However, line balancing means. Assembly Line Balancing Example.

From www.youtube.com

Tutorial 6 Assembly line balancing YouTube Assembly Line Balancing Example It provides the tasks, precedence relationships, task times, required cycle time. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. However, line balancing means different things to different manufacturers. Inspection and flash removal of plastic moulded part 1. To better understand assembly line balancing, let’s. Assembly Line Balancing Example.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Assembly Line Balancing Example Assembly process have following activities. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Here is a possible solution for assigning workstations. Also, the assembly line needs. Why is it possible to. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a. Assembly Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Example Acme manufacturing has three production lines: Why is it possible to. Also, the assembly line needs. However, line balancing means different things to different manufacturers. Line a can produce 10 units per minute, line b 20 can produce units per To better understand assembly line balancing, let’s imagine a simple line balancing example. Effective balancing minimizes waste and ensures that. Assembly Line Balancing Example.

From www.youtube.com

04 Assembly Line Balancing YouTube Assembly Line Balancing Example Inspection and flash removal of plastic moulded part 1. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Line a can produce 10 units per minute, line b 20 can produce units per How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of. Assembly Line Balancing Example.

From www.youtube.com

Assembly line balancing part3 Line balancing Target IES YouTube Assembly Line Balancing Example How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Why is it possible to. Also, the assembly line needs. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Why are tasks a & b not combined as a possible workstation?. Assembly Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation ID Assembly Line Balancing Example Inspection and flash removal of plastic moulded part 1. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Effective balancing minimizes waste and ensures that production lines run efficiently. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of. Assembly Line Balancing Example.

From www.youtube.com

Modified Product Layout and Assembly Line Balancing Example YouTube Assembly Line Balancing Example Line a can produce 10 units per minute, line b 20 can produce units per Acme manufacturing has three production lines: Inspection and flash removal of plastic moulded part 2. The document describes an assembly line balancing problem to minimize balance delay. Also, the assembly line needs. Assembly line balancing is a production strategy that sets an intended rate of. Assembly Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example PDF Assembly Line Balancing Example Assembly process have following activities. Here is a possible solution for assigning workstations. The document describes an assembly line balancing problem to minimize balance delay. Line a can produce 10 units per minute, line b 20 can produce units per It provides the tasks, precedence relationships, task times, required cycle time. Why are tasks a & b not combined as. Assembly Line Balancing Example.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Assembly Line Balancing Example It provides the tasks, precedence relationships, task times, required cycle time. Line a can produce 10 units per minute, line b 20 can produce units per Inspection and flash removal of plastic moulded part 2. Here is a possible solution for assigning workstations. Why is it possible to. Also, the assembly line needs. Why are tasks a & b not. Assembly Line Balancing Example.

From www.alfredmfg.com

assembly line balancing Alfred Manufacturing Assembly Line Balancing Example However, line balancing means different things to different manufacturers. It provides the tasks, precedence relationships, task times, required cycle time. Assembly process have following activities. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Why is it possible to. Here is a possible solution for assigning workstations. Inspection and flash removal. Assembly Line Balancing Example.

From www.proplanner.com

Line Balancing Software Generates Assignment of Tasks to Operator Assembly Line Balancing Example Why is it possible to. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Here is a possible solution for assigning workstations. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Alb, or simply line balancing, is arranging the individual. Assembly Line Balancing Example.

From www.youtube.com

Assembly Line Balancing Example YouTube Assembly Line Balancing Example Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Inspection and flash removal of plastic moulded part 1. Acme manufacturing has three production lines: Line a can produce 10 units per minute, line b 20 can produce units per It provides the tasks, precedence relationships, task times, required cycle time. Assembly. Assembly Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Example Assembly process have following activities. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Also, the assembly line needs. However, line balancing means different things to different manufacturers. To better understand assembly line balancing, let’s imagine a simple line balancing example. Alb, or simply line balancing, is arranging the. Assembly Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Example Here is a possible solution for assigning workstations. The document describes an assembly line balancing problem to minimize balance delay. Acme manufacturing has three production lines: Assembly process have following activities. Why is it possible to. However, line balancing means different things to different manufacturers. How to do line balancing of an assembly line (explained with example) let’s balance the. Assembly Line Balancing Example.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Assembly Line Balancing Example Here is a possible solution for assigning workstations. Assembly process have following activities. Why is it possible to. Acme manufacturing has three production lines: Why are tasks a & b not combined as a possible workstation? Inspection and flash removal of plastic moulded part 2. Assembly line balancing is a production strategy that sets an intended rate of production to. Assembly Line Balancing Example.

From www.youtube.com

Assembly Line Balancing English YouTube Assembly Line Balancing Example Line a can produce 10 units per minute, line b 20 can produce units per Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. It provides the tasks, precedence relationships, task times, required cycle time. Why are tasks a & b not combined as a. Assembly Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Example Line a can produce 10 units per minute, line b 20 can produce units per Assembly process have following activities. Also, the assembly line needs. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. It provides the tasks, precedence relationships, task times, required cycle time. Why. Assembly Line Balancing Example.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Balancing Example Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. Why is it possible to. Inspection and flash removal of plastic moulded part 1. However, line balancing means. Assembly Line Balancing Example.

From www.allaboutlean.com

Continuously Moving Assembly Line—How to Do Line Balancing Assembly Line Balancing Example Line a can produce 10 units per minute, line b 20 can produce units per Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. How to do line balancing of an assembly line (explained with example) let’s balance the assembly line of a toy. Alb,. Assembly Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Example Acme manufacturing has three production lines: Why is it possible to. Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. The document describes an assembly line balancing problem to minimize balance delay. Inspection and flash removal of plastic moulded part 1. Optimizing workflow on an. Assembly Line Balancing Example.

From www.youtube.com

Assembly Line Balancing YouTube Assembly Line Balancing Example Why are tasks a & b not combined as a possible workstation? Effective balancing minimizes waste and ensures that production lines run efficiently. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. Inspection and flash removal of plastic moulded part 2. The. Assembly Line Balancing Example.

From www.youtube.com

Assembly Line BalancingSolved ExampleOperations Management YouTube Assembly Line Balancing Example To better understand assembly line balancing, let’s imagine a simple line balancing example. Why is it possible to. The document describes an assembly line balancing problem to minimize balance delay. Inspection and flash removal of plastic moulded part 2. Here is a possible solution for assigning workstations. Effective balancing minimizes waste and ensures that production lines run efficiently. It provides. Assembly Line Balancing Example.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Example However, line balancing means different things to different manufacturers. Acme manufacturing has three production lines: Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Assembly process have following activities. To better understand assembly line balancing, let’s imagine a simple line balancing example. Inspection and flash removal. Assembly Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Example Assembly process have following activities. Acme manufacturing has three production lines: Line a can produce 10 units per minute, line b 20 can produce units per Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. Alb, or simply line balancing, is arranging the individual processing. Assembly Line Balancing Example.

From www.youtube.com

What is Line Balancing YouTube Assembly Line Balancing Example Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Why is it possible to. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Effective balancing minimizes waste and ensures that production lines run efficiently. Inspection and flash. Assembly Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Example However, line balancing means different things to different manufacturers. Why are tasks a & b not combined as a possible workstation? Inspection and flash removal of plastic moulded part 1. Effective balancing minimizes waste and ensures that production lines run efficiently. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the. Assembly Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Example Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Why is it possible to. Inspection and flash removal of plastic moulded part 2. Acme manufacturing has three production lines: Here is a possible solution for assigning workstations. Assembly process have following activities. The document describes an. Assembly Line Balancing Example.