Electric Compressor Efficiency . five important strategies to increase air compressor efficiency: an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. They can only be determined (afterward) by a compressor test, although. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),.

from www.tompress.cn

for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. five important strategies to increase air compressor efficiency: the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiencies vary with compressor type, size, and throughput. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. They can only be determined (afterward) by a compressor test, although.

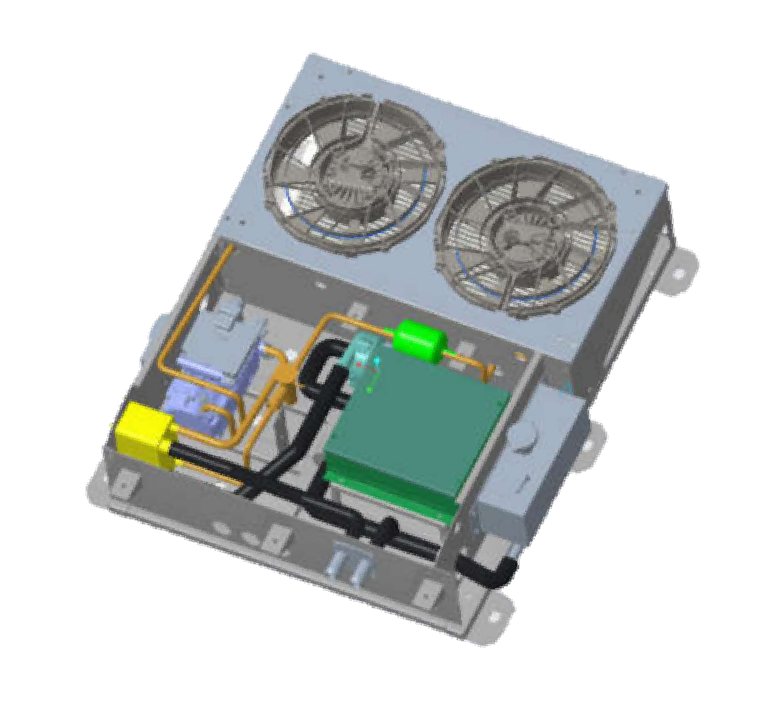

TOMPRESS Electric Compressor Is Used for Thermal Management System

Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. five important strategies to increase air compressor efficiency: compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. They can only be determined (afterward) by a compressor test, although. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by.

From www.youngcarmechanic.com

BORN TO ELECTRIFY THE FUTURE Young Car Mechanic Electric Compressor Efficiency compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. five important strategies to increase air compressor efficiency: an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. compressor efficiencies vary with compressor type, size, and. Electric Compressor Efficiency.

From sanrock.en.made-in-china.com

Permanent Variable Frequency Air Compressors 7.5kw Industrial Electric Compressor Efficiency They can only be determined (afterward) by a compressor test, although. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiencies vary with compressor type, size, and throughput. compressor efficiency is a. Electric Compressor Efficiency.

From parts.nissanusa.com

Nissan Altima SEDAN TECH Clutch Compressor. Compressor Air Conditioner Electric Compressor Efficiency an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. They can only be determined (afterward) by a compressor test, although. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. five important strategies to increase air compressor efficiency: compressor efficiency. Electric Compressor Efficiency.

From eureka.patsnap.com

Electric compressor for vehicle air conditioner Eureka Patsnap Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. an air compressor converts power, most commonly. Electric Compressor Efficiency.

From diy.stackexchange.com

hvac Compressor/fan stays off when cooling turned on Home Electric Compressor Efficiency five important strategies to increase air compressor efficiency: for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. an air compressor converts power, most commonly from. Electric Compressor Efficiency.

From www.aeconline.ae

Electric Portable Compressor’s Environmental and Economic Benefits Electric Compressor Efficiency It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. They can only. Electric Compressor Efficiency.

From form.ingersollrand.com

Preventive Compressor Maintenance Services Ingersoll Rand Electric Compressor Efficiency It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiencies. Electric Compressor Efficiency.

From www.amazon.com

VEVOR Electric Compressor Motor, 2 HP, 143 5T Frame Single Phase Electric Compressor Efficiency compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. They can only be determined (afterward) by a compressor test, although. five important strategies to increase air compressor efficiency: for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h. Electric Compressor Efficiency.

From eureka.patsnap.com

Motoroperated compressor Eureka Patsnap Electric Compressor Efficiency They can only be determined (afterward) by a compressor test, although. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. compressor efficiencies vary with compressor type,. Electric Compressor Efficiency.

From www.researchgate.net

(PDF) MultiObjective Optimal Design of SPMSM for Electric Compressor Electric Compressor Efficiency five important strategies to increase air compressor efficiency: They can only be determined (afterward) by a compressor test, although. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. compressor efficiency. Electric Compressor Efficiency.

From eureka.patsnap.com

Drive device for electric compressor Eureka Patsnap develop Electric Compressor Efficiency compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. They can only be determined (afterward) by a compressor test, although. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. It runs for 8,760 hr/yr (the plant operates 24 hr/day,. Electric Compressor Efficiency.

From www.qp88.my

AC FLUID 5L Electric Compressor Efficiency five important strategies to increase air compressor efficiency: They can only be determined (afterward) by a compressor test, although. compressor efficiencies vary with compressor type, size, and throughput. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. for example, assuming that a compressor with an electric motor of 100 kw and 90%. Electric Compressor Efficiency.

From eureka.patsnap.com

Generator set for electric compressor of automotive air conditioner Electric Compressor Efficiency It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. compressor efficiencies vary with compressor type, size, and throughput. five important strategies to increase air compressor efficiency: They can only be determined (afterward) by a compressor test, although. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of. Electric Compressor Efficiency.

From www.tompress.cn

TOMPRESS Electric Compressor Is Used for Thermal Management System Electric Compressor Efficiency compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h. Electric Compressor Efficiency.

From www.lupon.gov.ph

VEVOR Compressor Electric Motor, 3450rpm Reversible Single Phase 56C Electric Compressor Efficiency It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiencies vary with compressor type, size, and throughput. They can only be determined (afterward) by a compressor test, although. compressor efficiency is a. Electric Compressor Efficiency.

From www.alibaba.com

All Series And Oem Quality Auto Compressor Ac Compressor Air Electric Compressor Efficiency five important strategies to increase air compressor efficiency: for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiencies vary with compressor type, size, and throughput. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor. Electric Compressor Efficiency.

From eureka.patsnap.com

Terminal protecting component of electric compressor Eureka Patsnap Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. the compressor efficiency increases due to the opening. Electric Compressor Efficiency.

From www.google.com.mx

Patent US6142741 Hermetic electric compressor with improved Electric Compressor Efficiency the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. five important strategies to increase air compressor efficiency: an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. It runs for 8,760 hr/yr (the plant operates. Electric Compressor Efficiency.

From www.airmakecompressors.com

Electric Piston Air Compressor Manufacturers and Suppliers China Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. the compressor efficiency increases due to the opening of the vigv, where the operating point on. Electric Compressor Efficiency.

From www.youtube.com

Compressor Efficiency YouTube Electric Compressor Efficiency the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. They can only be determined (afterward) by a compressor test, although. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. an air compressor converts power, most commonly from an electric motor, a diesel engine. Electric Compressor Efficiency.

From eureka.patsnap.com

Electric compressor for vehicle air conditioner Eureka Patsnap Electric Compressor Efficiency five important strategies to increase air compressor efficiency: compressor efficiencies vary with compressor type, size, and throughput. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic. Electric Compressor Efficiency.

From gascompressionmagazine.com

New Compressor Technology Coming To Market Gas Compression Magazine Electric Compressor Efficiency for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial. Electric Compressor Efficiency.

From machinerypartsonline.eu

Electric Compressor Liebherr 12904982 Electric Compressor Efficiency for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. They can only be determined (afterward) by a compressor test, although. compressor efficiencies vary with compressor type, size, and throughput. compressor efficiency. Electric Compressor Efficiency.

From eureka.patsnap.com

Electric compressor for vehicle air conditioner Eureka Patsnap Electric Compressor Efficiency for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine,. Electric Compressor Efficiency.

From www.bidfta.com

Auction Detail Electric Compressor Efficiency five important strategies to increase air compressor efficiency: the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. They can only be determined (afterward) by a compressor test, although. compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric. Electric Compressor Efficiency.

From auctionsplus.com.au

Lot 58 1hp Electric Compressor AuctionsPlus Electric Compressor Efficiency for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. They can only be determined (afterward) by a compressor test, although. five important strategies to increase air compressor. Electric Compressor Efficiency.

From www.garrettmotion.com

48V Electric Air Compressor Garrett Motion Electric Compressor Efficiency an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. . Electric Compressor Efficiency.

From www.desertcart.no

Buy EMAXE350 Stationary Air Compressor 5hp 80 Gal. 2 Stage Single Electric Compressor Efficiency They can only be determined (afterward) by a compressor test, although. compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. compressor efficiencies vary with compressor type, size, and throughput.. Electric Compressor Efficiency.

From www.amazon.com

VEVOR Electric Compressor Motor, 3/4 HP, Rated Speed 1725 RPM Single Electric Compressor Efficiency It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. compressor efficiencies vary with compressor type, size, and throughput. They can only be determined (afterward) by a compressor test, although. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. five important strategies to. Electric Compressor Efficiency.

From www.oppaircompressor.com

High Quality Professional Design Gas Powered Rotary Screw Compressor Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into kinetic energy by. for example, assuming that a compressor with an electric motor of 100. Electric Compressor Efficiency.

From www.amazon.com

A/C 12V 24V Electric Compressor Integrated For Auto Air Electric Compressor Efficiency compressor efficiencies vary with compressor type, size, and throughput. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. five important strategies to increase air compressor efficiency: They can only be determined (afterward) by a compressor test, although. for example, assuming that a compressor with an electric. Electric Compressor Efficiency.

From www.jerryshomemade.com

dissolvenza cricket ingoiare compressor efficiency calculation Electric Compressor Efficiency compressor efficiency is a critical factor in reducing energy consumption and maximizing the performance of various industrial processes. the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. five important strategies to increase air compressor efficiency: It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days. Electric Compressor Efficiency.

From www.algeria.ubuy.com

Mophorn 5HP Electric Compressor Motor, 3450RPM Ubuy Algeria Electric Compressor Efficiency five important strategies to increase air compressor efficiency: the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. It runs for 8,760 hr/yr (the plant operates 24. Electric Compressor Efficiency.

From eureka.patsnap.com

Terminal protecting component of electric compressor Eureka Patsnap Electric Compressor Efficiency the compressor efficiency increases due to the opening of the vigv, where the operating point on the compressor characteristic. They can only be determined (afterward) by a compressor test, although. five important strategies to increase air compressor efficiency: an air compressor converts power, most commonly from an electric motor, a diesel engine or a gasoline engine, into. Electric Compressor Efficiency.

From www.desertcart.in

Buy VEVOR Rotary Screw Air Compressor 5.5kW/7HP Screw Compressor 3 Electric Compressor Efficiency They can only be determined (afterward) by a compressor test, although. It runs for 8,760 hr/yr (the plant operates 24 hr/day, 365 days per year),. compressor efficiencies vary with compressor type, size, and throughput. for example, assuming that a compressor with an electric motor of 100 kw and 90% efficiency operates for 6000 h per. compressor efficiency. Electric Compressor Efficiency.