Pressure Limited Injection Molding . Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Injection pressure is a crucial parameter in the process of injection molding. Conducting a pressure drop study is an important step in the. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. This is related to material selection, part design, mold design, or machine selection. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Understanding and controlling injection molding. Ensuring adequate injection pressure will help achieve consistent filling of the mold. You can figure out where you lost pressure—and how to reduce this.

from www.xcentricmold.com

This is related to material selection, part design, mold design, or machine selection. Understanding and controlling injection molding. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Conducting a pressure drop study is an important step in the. Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. You can figure out where you lost pressure—and how to reduce this.

Adding Injection Molding Features to Your Part Xcentric Mold

Pressure Limited Injection Molding You can figure out where you lost pressure—and how to reduce this. Understanding and controlling injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Injection pressure is a crucial parameter in the process of injection molding. You can figure out where you lost pressure—and how to reduce this. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). This is related to material selection, part design, mold design, or machine selection. Conducting a pressure drop study is an important step in the. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations.

From www.madearia.com

Plastic injection molding process parameter :Temperature and pressure Pressure Limited Injection Molding This is related to material selection, part design, mold design, or machine selection. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. The injection pressure is. Pressure Limited Injection Molding.

From www.xcentricmold.com

Adding Injection Molding Features to Your Part Xcentric Mold Pressure Limited Injection Molding Conducting a pressure drop study is an important step in the. This is related to material selection, part design, mold design, or machine selection. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The injection pressure is typically measured in pounds per square inch (psi) or. Pressure Limited Injection Molding.

From www.dgmfmoldclamps.com

Premolding Action Injection Molding Back Pressure Injection Molding Pressure Limited Injection Molding Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Conducting a pressure drop study is an important step in the. The maximum required injection pressure should. Pressure Limited Injection Molding.

From www.mdpi.com

Polymers Free FullText Novel Analysis Methodology of Cavity Pressure Limited Injection Molding Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Conducting a pressure drop study is an important step in the. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Understanding and controlling injection molding. Injection pressure builds by the force of the injection unit and the. Pressure Limited Injection Molding.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Understanding and controlling injection molding. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). You can figure out where you lost pressure—and how to reduce this. Injection pressure in injection molding is a pivotal factor in the process,. Pressure Limited Injection Molding.

From www.cadrex.com

Starter Guide To Injection Molding Cadrex Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Conducting a pressure drop study is an important step in the. You can figure out where you lost pressure—and how to reduce this. Injection pressure builds by the force. Pressure Limited Injection Molding.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working Pressure Limited Injection Molding Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. You can figure out where you lost pressure—and how to reduce this. Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the. Pressure Limited Injection Molding.

From predictabledesigns.com

Introduction to Injection Molding Pressure Limited Injection Molding The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Ensuring adequate injection pressure will help achieve consistent filling of the mold. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Understanding and controlling injection molding. The maximum required injection. Pressure Limited Injection Molding.

From www.jazzmold.com

Injection molding machine setting Archives Plastic Injection Mold Factory Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. This is related to material selection, part design, mold design, or machine selection. Understanding and controlling injection molding. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. You can figure out where you lost pressure—and how to. Pressure Limited Injection Molding.

From www.researchgate.net

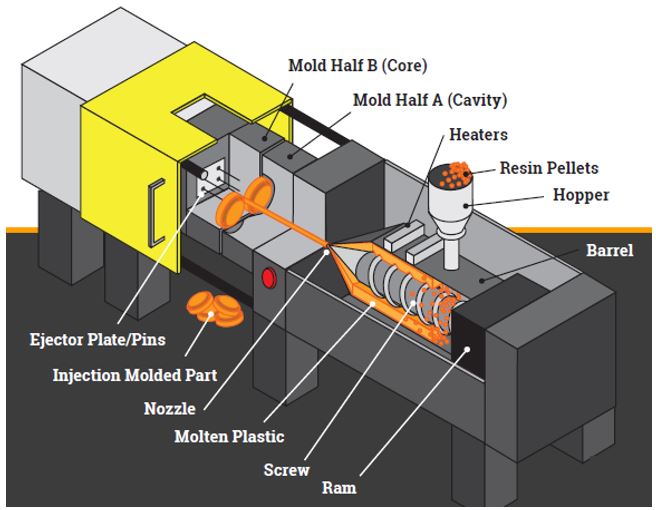

Schematic of the injection molding process. In the filling stage, a Pressure Limited Injection Molding You can figure out where you lost pressure—and how to reduce this. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Understanding and controlling injection molding. Injection pressure. Pressure Limited Injection Molding.

From www.slideserve.com

PPT Injection Moulding Technology Part 3 PowerPoint Presentation Pressure Limited Injection Molding Understanding and controlling injection molding. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Ensuring adequate injection pressure will help achieve consistent filling of the mold. The. Pressure Limited Injection Molding.

From china-plastic-injection-molding.com

How Does Plastic Injection Molding Work? Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Understanding and controlling injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Conducting a pressure drop study is an important step in the. The injection pressure is typically measured in pounds per. Pressure Limited Injection Molding.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Conducting a pressure drop study is an important step in the. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure in injection molding is. Pressure Limited Injection Molding.

From www.myplasticmold.com

Injection Molding Machine Components And Its Function Pressure Limited Injection Molding Conducting a pressure drop study is an important step in the. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. Injection pressure builds by the force of the. Pressure Limited Injection Molding.

From compositeslab.com

Reinforced Reaction Injection Molding (RRIM) Closed Molding Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The maximum required injection pressure should. Pressure Limited Injection Molding.

From www.rubbermolding.org

Rubber Injection Molding Rubber Molding Pressure Limited Injection Molding Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Conducting a pressure drop study is an important step in the. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. This is related to material selection, part design,. Pressure Limited Injection Molding.

From www.clooms.com

LowPressure Injection Molding Everything about Its Uses and Benefits Pressure Limited Injection Molding The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Understanding and controlling injection molding. Injection pressure is a crucial parameter in the process of injection molding. You. Pressure Limited Injection Molding.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Pressure Limited Injection Molding Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. You can figure out where you lost pressure—and how to reduce this. Ensuring adequate injection pressure. Pressure Limited Injection Molding.

From moldie.net

Things To Know About Backpressure Injection Molding Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). This is related to material selection,. Pressure Limited Injection Molding.

From www.iqsdirectory.com

Rubber Overmolding Process, Uses, Considerations & Benefits Pressure Limited Injection Molding Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Conducting a pressure drop study is an important step in the. Ensuring adequate injection pressure will help. Pressure Limited Injection Molding.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Pressure Limited Injection Molding This is related to material selection, part design, mold design, or machine selection. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. You can figure out where you lost pressure—and how to reduce this. Fimmtech provides the training in scientific injection molding and also provides the tools for all. Pressure Limited Injection Molding.

From www.cavitymold.com

Injection Molding Plastic Injection Molding and Mold Maker Manufacturing Pressure Limited Injection Molding Conducting a pressure drop study is an important step in the. Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The maximum required injection pressure should not be more than 80% of the maximum. Pressure Limited Injection Molding.

From www.winwinmold.com

How To Make Use Of Back Pressure in Injection Molding Process Pressure Limited Injection Molding The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar =. Pressure Limited Injection Molding.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Pressure Limited Injection Molding Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Injection pressure is a crucial parameter in the process of injection molding. You can figure out where you lost. Pressure Limited Injection Molding.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Pressure Limited Injection Molding The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. This is related to material selection, part design, mold design, or machine selection. Ensuring adequate injection pressure will. Pressure Limited Injection Molding.

From www.wsmcmold.com

Injection MoldingInjection Moulding Service Pressure Limited Injection Molding Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. You can figure out where you lost pressure—and how to reduce this. Ensuring adequate injection pressure will help achieve. Pressure Limited Injection Molding.

From plasticmoulds.net

Operation Cycle of Injection Molding Pressure Limited Injection Molding Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Injection pressure is a crucial parameter in the process of injection molding. Conducting a pressure drop study is an important step in the. Understanding and controlling injection molding. Injection pressure builds by the force of the injection unit and the. Pressure Limited Injection Molding.

From www.plasticmoulds.net

Injection Molding Process Topworks Plastic Molding Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Understanding and controlling injection molding. Ensuring adequate injection pressure will help achieve consistent filling of the mold. You can figure out where you lost pressure—and how to reduce this. Conducting a pressure drop study is an important step in the. Injection pressure in injection molding is a pivotal. Pressure Limited Injection Molding.

From www.erbiwa-mould.com

DME Mould Base Multi Cavity Pressure Injection Molding Pressure Limited Injection Molding Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Injection pressure is a crucial parameter in the process of injection molding. Injection pressure in injection molding is a pivotal. Pressure Limited Injection Molding.

From www.wundermold.com

3 Components of Injection Molding 🥇 Injection Molding Applications Pressure Limited Injection Molding The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations.. Pressure Limited Injection Molding.

From www.daobenmachinery.com

What is Back Pressure and Its Role in Injection Molding? Pressure Limited Injection Molding Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Injection pressure is a crucial parameter in the process of injection molding. Fimmtech provides the training in scientific injection molding and also provides the tools for all the. Pressure Limited Injection Molding.

From www.moldex3d.com

Improving Injection Molding Pressure Predictions Using Advanced Pressure Limited Injection Molding The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Conducting a pressure drop study is an important step in the. Fimmtech provides the training in scientific injection molding and also provides the tools for all the molding qualifictions and molding validations. This is related to material selection, part design,. Pressure Limited Injection Molding.

From www.madearia.com

Plastic injection molding process parameter :Temperature and pressure Pressure Limited Injection Molding The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. This is related to material selection, part design, mold design, or machine selection. You can figure out. Pressure Limited Injection Molding.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Pressure Limited Injection Molding Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. Ensuring adequate injection pressure will help achieve consistent filling of the mold. Fimmtech provides the training in scientific injection molding and also provides the tools. Pressure Limited Injection Molding.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Pressure Limited Injection Molding The maximum required injection pressure should not be more than 80% of the maximum available pressure on the molding machine. This is related to material selection, part design, mold design, or machine selection. Injection pressure in injection molding is a pivotal factor in the process, impacting everything from part quality to production efficiency. You can figure out where you lost. Pressure Limited Injection Molding.