Stretch Film Production Process . The tube is cooled and flattened into a film. the production process of stretch films: Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. two primary manufacturing techniques are used to produce stretch film: In this method, molten resin is extruded through a circular die to form a tube. winding a good roll of stretch film can be the most demanding part of the production process. understanding the manufacturing process, considering key factors when choosing the right type,.

from shriswastikmactech.com

two primary manufacturing techniques are used to produce stretch film: winding a good roll of stretch film can be the most demanding part of the production process. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. Air is then blown into the tube, inflating it like a balloon. In this method, molten resin is extruded through a circular die to form a tube. the production process of stretch films: The tube is cooled and flattened into a film. understanding the manufacturing process, considering key factors when choosing the right type,. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. Blown film extrusion and cast film extrusion.

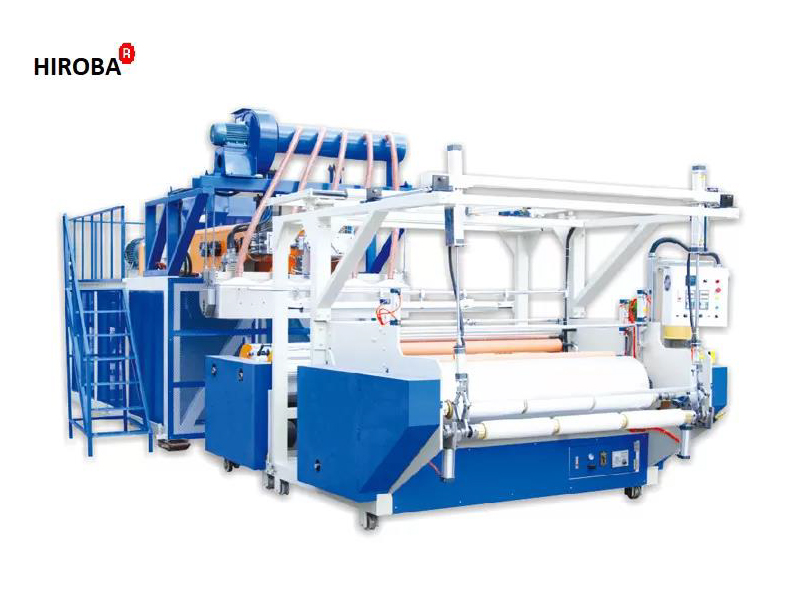

Stretch Film Rewinding Machine Manufacture & Suppliers India

Stretch Film Production Process The tube is cooled and flattened into a film. Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. the production process of stretch films: two primary manufacturing techniques are used to produce stretch film: understanding the manufacturing process, considering key factors when choosing the right type,. The tube is cooled and flattened into a film. winding a good roll of stretch film can be the most demanding part of the production process. Air is then blown into the tube, inflating it like a balloon. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. In this method, molten resin is extruded through a circular die to form a tube.

From www.youtube.com

Stretch film machine with scanner and dosing system;stretch film Stretch Film Production Process Blown film extrusion and cast film extrusion. two primary manufacturing techniques are used to produce stretch film: winding a good roll of stretch film can be the most demanding part of the production process. understanding the manufacturing process, considering key factors when choosing the right type,. The tube is cooled and flattened into a film. Air is. Stretch Film Production Process.

From respack.com.my

Stretch Films, Pallet Wraps for Hand and Machine Applications RESPACK Stretch Film Production Process understanding the manufacturing process, considering key factors when choosing the right type,. Blown film extrusion and cast film extrusion. two primary manufacturing techniques are used to produce stretch film: the production process of stretch films: The tube is cooled and flattened into a film. winding a good roll of stretch film can be the most demanding. Stretch Film Production Process.

From exoegetdd.blob.core.windows.net

Wrapping Stretch Film Machine at Susan Fischer blog Stretch Film Production Process Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. two primary manufacturing techniques are used to produce stretch film: understanding the manufacturing process, considering key factors when choosing the right type,. Air is then blown into the tube, inflating it like a. Stretch Film Production Process.

From efekt-stretch.com

Gallery Stretch Film Highquality Manual and Machine Stretch Film Stretch Film Production Process The tube is cooled and flattened into a film. winding a good roll of stretch film can be the most demanding part of the production process. In this method, molten resin is extruded through a circular die to form a tube. Air is then blown into the tube, inflating it like a balloon. two primary manufacturing techniques are. Stretch Film Production Process.

From www.ls-extrusion.com

CPE Stretch Film Production Line Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into a film. understanding the manufacturing process, considering key factors when choosing the right type,. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. Blown film extrusion and cast film extrusion. the production. Stretch Film Production Process.

From www.sml.at

Lines for stretch wrap film SML Stretch Film Production Process the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. Blown film extrusion and cast film extrusion. understanding the manufacturing process, considering key factors when choosing the right type,. In this method, molten resin is extruded through a circular die to form a tube. the production process of stretch films is. Stretch Film Production Process.

From www.suminojp.com

Bidirectional Stretch Plastic Film Production LineSUMINO PRECISION Stretch Film Production Process the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. Blown film extrusion and cast film extrusion. the production process of stretch films: two primary manufacturing techniques are used to produce stretch film: winding a good roll of stretch film can be the most demanding part of the production. Stretch Film Production Process.

From efekt-stretch.com

Sustainable development policy Stretch Film Highquality Manual and Stretch Film Production Process the production process of stretch films: Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. The tube is cooled and flattened into a film. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. winding a good roll of stretch film. Stretch Film Production Process.

From efekt-stretch.com

Technologies and refinements Stretch Film Highquality Manual and Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: the production process of stretch films: The tube is cooled and flattened into a film. Air is then blown into the tube, inflating it like a balloon. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. understanding the. Stretch Film Production Process.

From www.youtube.com

😍Machine Stretch film production process 🔧stretchfilm YouTube Stretch Film Production Process understanding the manufacturing process, considering key factors when choosing the right type,. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. two primary manufacturing techniques are used to produce stretch film: Blown film extrusion and cast film extrusion. winding a good roll of stretch film can be the most. Stretch Film Production Process.

From www.youtube.com

Stretch Film Production Process YouTube Stretch Film Production Process In this method, molten resin is extruded through a circular die to form a tube. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. Air is then blown into the tube, inflating it like. Stretch Film Production Process.

From avavinpetro.com

The Production Process of Stretch Films From 0 to 100 avavinpetro Stretch Film Production Process the production process of stretch films: two primary manufacturing techniques are used to produce stretch film: Air is then blown into the tube, inflating it like a balloon. Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. understanding the manufacturing process,. Stretch Film Production Process.

From www.youtube.com

🛠️Hand stretch film production process stretchfilm YouTube Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: In this method, molten resin is extruded through a circular die to form a tube. understanding the manufacturing process, considering key factors when choosing the right type,. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. Blown film extrusion and. Stretch Film Production Process.

From shriswastikmactech.com

Stretch Film Rewinding Machine Manufacture & Suppliers India Stretch Film Production Process understanding the manufacturing process, considering key factors when choosing the right type,. the production process of stretch films: The tube is cooled and flattened into a film. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. the cast coextrusion manufacturing method consists of melted resin pumped through several. Stretch Film Production Process.

From www.youtube.com

Wintech fully automatic Cast film extrusion ine for stretch film Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into a film. Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. understanding the manufacturing process, considering key factors when choosing the right type,. the production process of stretch films is. Stretch Film Production Process.

From www.suminocn.com

Bidirectional Stretch Film Production Line Sumino Stretch Film Production Process the production process of stretch films: Blown film extrusion and cast film extrusion. two primary manufacturing techniques are used to produce stretch film: Air is then blown into the tube, inflating it like a balloon. winding a good roll of stretch film can be the most demanding part of the production process. the production process of. Stretch Film Production Process.

From o-melhor-blog-da-internet-aovivo.blogspot.com

Stretch Film Manufacturing Process INDUSTRIAL PRODUCTS LW Stretch Film Production Process The tube is cooled and flattened into a film. understanding the manufacturing process, considering key factors when choosing the right type,. Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. In this method, molten resin is extruded through a circular die to form a tube. winding a good. Stretch Film Production Process.

From www.alibaba.com

2000mm Three Layers Five Layers Fully Automatic Cast Stretch Film Stretch Film Production Process Air is then blown into the tube, inflating it like a balloon. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. two primary manufacturing techniques are used to produce stretch film: Blown film extrusion and cast film extrusion. In this method, molten resin is extruded through a circular die to. Stretch Film Production Process.

From stretchwrappingfilm.com

Choosing Cast Stretch Film over Other Stretch Films The Leading Stretch Film Production Process the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into a film. the production process of stretch films: understanding the manufacturing process, considering key factors when choosing the right type,. Air is then. Stretch Film Production Process.

From www.youtube.com

Cast Stretch Film Manufacturing Machinery YouTube Stretch Film Production Process Air is then blown into the tube, inflating it like a balloon. Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. understanding the manufacturing process, considering key factors when choosing the right type,. In this method, molten resin is extruded through a circular. Stretch Film Production Process.

From www.chinaplasonline.com

ALLROLLEX CAST LINES FOR STRETCH FILM PRODUCTIONCOLINES CPS+ 在线供需对接平台 Stretch Film Production Process winding a good roll of stretch film can be the most demanding part of the production process. the production process of stretch films: Air is then blown into the tube, inflating it like a balloon. two primary manufacturing techniques are used to produce stretch film: the production process of stretch films is crucial in determining the. Stretch Film Production Process.

From www.sml.at

Lines for stretch wrap film SML Stretch Film Production Process the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. winding a good roll of stretch film can be the most demanding part of the production process. two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into a film. Air is then blown. Stretch Film Production Process.

From www.sml.at

Sigma Stretch expands its stretch film production SML Stretch Film Production Process winding a good roll of stretch film can be the most demanding part of the production process. two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into a film. In this method, molten resin is extruded through a circular die to form a tube. the production process of stretch films:. Stretch Film Production Process.

From www.ls-extrusion.com

CPE Stretch Film Production Line Stretch Film Production Process Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. the production process of stretch films: In this method, molten resin is extruded through a circular die to form a tube. understanding the manufacturing process, considering key factors when choosing the right type,.. Stretch Film Production Process.

From www.youtube.com

Stretch Film Manufacturing YouTube Stretch Film Production Process the production process of stretch films: The tube is cooled and flattened into a film. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. winding a good roll of stretch film can be the most demanding part of the production process. two primary manufacturing techniques are used to produce. Stretch Film Production Process.

From stretchwrappingfilm.com

Advancements in Stretch Film Production The Leading Stretch Film Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. understanding the manufacturing process, considering key factors when choosing the right type,. the production process of stretch films: Air is then blown into the tube, inflating it like a balloon.. Stretch Film Production Process.

From robopacusa.com

What To Know About the Stretch Film Conversion Process Stretch Film Production Process The tube is cooled and flattened into a film. Air is then blown into the tube, inflating it like a balloon. the production process of stretch films: two primary manufacturing techniques are used to produce stretch film: winding a good roll of stretch film can be the most demanding part of the production process. the production. Stretch Film Production Process.

From www.elecdiv.kaneka.co.jp

Film Stretching Technology Introduction|Contract Manufacturing|E & I Stretch Film Production Process In this method, molten resin is extruded through a circular die to form a tube. two primary manufacturing techniques are used to produce stretch film: Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. The tube is cooled and flattened into a film. winding a good roll of. Stretch Film Production Process.

From www.alibaba.com

2000mm Three Layers Five Layers Fully Automatic Cast Stretch Film Stretch Film Production Process Blown film extrusion and cast film extrusion. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. two primary manufacturing techniques are used to produce stretch film: Air is then blown into the tube, inflating it like a balloon. the production process of stretch films is crucial in determining the film’s. Stretch Film Production Process.

From www.signode.com

PCR Film Signode Stretch Film Production Process winding a good roll of stretch film can be the most demanding part of the production process. the production process of stretch films: The tube is cooled and flattened into a film. understanding the manufacturing process, considering key factors when choosing the right type,. In this method, molten resin is extruded through a circular die to form. Stretch Film Production Process.

From www.youtube.com

Stretch film production video YouTube Stretch Film Production Process Blown film extrusion and cast film extrusion. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. The tube is cooled and flattened into a film. two primary manufacturing techniques are used to produce stretch film: the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through. Stretch Film Production Process.

From www.youtube.com

Double layer stretch film production line for stretch film and cling Stretch Film Production Process The tube is cooled and flattened into a film. Blown film extrusion and cast film extrusion. the cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight. the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. In this method, molten resin is extruded through a. Stretch Film Production Process.

From www.linkedin.com

Stretch Film Production Line Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: Blown film extrusion and cast film extrusion. winding a good roll of stretch film can be the most demanding part of the production process. Air is then blown into the tube, inflating it like a balloon. the cast coextrusion manufacturing method consists of melted resin pumped through. Stretch Film Production Process.

From www.youtube.com

High Speed 2000mm Stretch Film Production Machine YouTube Stretch Film Production Process the production process of stretch films is crucial in determining the film’s physical properties, such as tensile. In this method, molten resin is extruded through a circular die to form a tube. Blown film extrusion and cast film extrusion. understanding the manufacturing process, considering key factors when choosing the right type,. two primary manufacturing techniques are used. Stretch Film Production Process.

From efekt-stretch.com

Stretch film recycling & Recowrap™ the regranulated film Stretch Film Stretch Film Production Process two primary manufacturing techniques are used to produce stretch film: winding a good roll of stretch film can be the most demanding part of the production process. The tube is cooled and flattened into a film. Blown film extrusion and cast film extrusion. the production process of stretch films: understanding the manufacturing process, considering key factors. Stretch Film Production Process.