Tapping Plastic Threads . tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. In your case, though, tapping might be preferred over inserts. there are many ways to use traditional fasteners in 3d printed parts. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. i need to tap a lot of holes in plastic for my job, so i found a method that.

from www.ehrenhaus.com

using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. i need to tap a lot of holes in plastic for my job, so i found a method that. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. there are many ways to use traditional fasteners in 3d printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. In your case, though, tapping might be preferred over inserts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood.

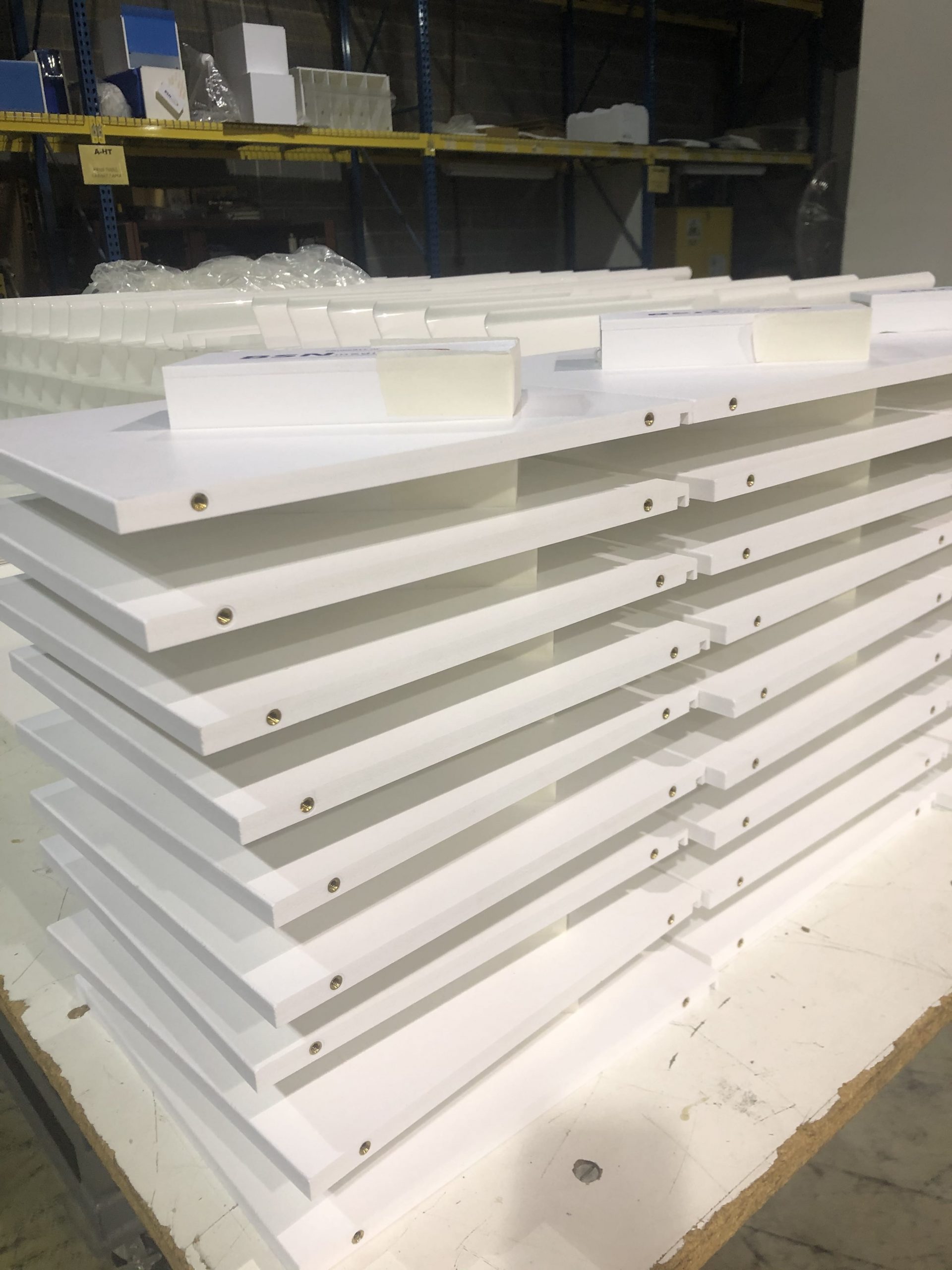

Post Fabrication Plastic Tapping, Drilling, and Trimming

Tapping Plastic Threads there are many ways to use traditional fasteners in 3d printed parts. In your case, though, tapping might be preferred over inserts. i need to tap a lot of holes in plastic for my job, so i found a method that. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. there are many ways to use traditional fasteners in 3d printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole.

From www.youtube.com

Tapping Threads In Plastic Tubes 🔩 YouTube Tapping Plastic Threads tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the. Tapping Plastic Threads.

From dxoyvaiaq.blob.core.windows.net

How To Tap New Threads In Aluminum at Gladys Jenkins blog Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. the creation of a thread in plastic requires. Tapping Plastic Threads.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Tapping Plastic Threads the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. i need to tap a lot of holes in plastic for my job, so i found a method that. tapping is the process of cutting a matching set of threads into. Tapping Plastic Threads.

From www.sandvik.coromant.com

Tapping threads what is tapping? Tapping Plastic Threads In your case, though, tapping might be preferred over inserts. there are many ways to use traditional fasteners in 3d printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. type b, type ab and other standard fasteners have a wide thread profile (also called flank. Tapping Plastic Threads.

From www.youtube.com

Internal Threading Machine, Tapping Threading Machine YouTube Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. using a. Tapping Plastic Threads.

From www.youtube.com

PTFE Tape and Plastic Threads YouTube Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. there are. Tapping Plastic Threads.

From www.conrad.com

TOOLCRAFT 88202 Plastictapping screw 2.2 mm 6 mm Star Steel zinc Tapping Plastic Threads It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. using a thread tap designed for plastic is a. Tapping Plastic Threads.

From proleantech.com

Ultimate Guide to Taps for Threads Thread Tapping Techniques and Types Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. there are many ways to use traditional fasteners in 3d printed parts. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. type b, type ab and. Tapping Plastic Threads.

From www.tappex.co.uk

A ten point guide to best design practices Tappex Threaded Inserts Tapping Plastic Threads using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type b, type ab and other standard fasteners have a wide. Tapping Plastic Threads.

From www.ehrenhaus.com

Post Fabrication Plastic Tapping, Drilling, and Trimming Tapping Plastic Threads the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. In your case, though, tapping might be preferred over inserts. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. type. Tapping Plastic Threads.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Tapping Plastic Threads In your case, though, tapping might be preferred over inserts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. there are many ways to use traditional fasteners in 3d printed parts. i need to tap a lot of holes in plastic for my job, so i found. Tapping Plastic Threads.

From www.aliexpress.com

HSS 10pcs / set Mini Tap Thread Wire Tapping Threading Grinding Carving Tapping Plastic Threads there are many ways to use traditional fasteners in 3d printed parts. i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. type b, type ab and other standard fasteners have a wide thread profile (also called flank. Tapping Plastic Threads.

From sendcutsend.com

Sheet Metal Tapping Services SendCutSend Tapping Plastic Threads It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating. Tapping Plastic Threads.

From www.directindustry.com

Threaded insert QUICKSERT® BOLLHOFF selftapping / round / for Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. tapping is the process of cutting a matching set. Tapping Plastic Threads.

From www.youtube.com

How to make a Thread Tap How to easily tap a thread DIY Thread Tap Tapping Plastic Threads there are many ways to use traditional fasteners in 3d printed parts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. It doesn’t require any extra design. Tapping Plastic Threads.

From www.alibaba.com

Cross Recessed Flat Head Pt Screws For Plastic Self Tapping Threads Ck Tapping Plastic Threads using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. there are many ways to use traditional fasteners in 3d printed parts. i need to tap a. Tapping Plastic Threads.

From www.ehrenhaus.com

Post Fabrication Plastic Tapping, Drilling, and Trimming Tapping Plastic Threads the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. tapping is the process of cutting a matching set of threads into. Tapping Plastic Threads.

From www.lasertools.co.uk

Make tapping new threads easier Laser Tools Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating. Tapping Plastic Threads.

From www.accu.co.uk

Polyfix Screws Self Tapping Screws For Plastic Accu Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. there are many ways to use traditional fasteners in 3d printed parts. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. type b, type ab and. Tapping Plastic Threads.

From mxfastener.en.made-in-china.com

Phillips Pan Threadforming Screw 30 Degree Tapping Plastic China Tapping Plastic Threads type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or. Tapping Plastic Threads.

From www.protoolreviews.com

How to Use a Tap and Die to Create or Repair Threads Pro Tool Reviews Tapping Plastic Threads tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. In your case, though, tapping might be preferred over inserts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. using a thread tap designed for plastic is. Tapping Plastic Threads.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Tapping Plastic Threads tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. In your case, though, tapping might be preferred over inserts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type. Tapping Plastic Threads.

From www.youtube.com

Tapping Operation!! Tapping Process!!How to Cut Internal Thread with Tapping Plastic Threads using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. It doesn’t require any extra design steps, and most shops that work. Tapping Plastic Threads.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Tapping Plastic Threads type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. In your case, though, tapping might be preferred over inserts. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. the creation of a thread in plastic requires. Tapping Plastic Threads.

From secon-hardware.en.made-in-china.com

Zinc Plated Phillip Zinc Wafer Truss Pan Head Self Drilling Tapping Tapping Plastic Threads i need to tap a lot of holes in plastic for my job, so i found a method that. In your case, though, tapping might be preferred over inserts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. It doesn’t require any extra design steps, and most shops. Tapping Plastic Threads.

From www.instructables.com

Tapping Threads in Aluminum Spindle 4 Steps (with Pictures Tapping Plastic Threads the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. i need to tap a lot of holes in plastic for my. Tapping Plastic Threads.

From www.youtube.com

Tapping the perfect thread YouTube Tapping Plastic Threads there are many ways to use traditional fasteners in 3d printed parts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°.. Tapping Plastic Threads.

From www.youtube.com

Quick Tip Tapping holes in plastic YouTube Tapping Plastic Threads tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. type b, type ab and other standard fasteners have a wide. Tapping Plastic Threads.

From www.amazon.in

Practical Screw Taps Tool Set, Durable Thread Tap, Convenient for Tapping Plastic Threads It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. i need to tap a lot of holes in plastic for my job, so i found a method. Tapping Plastic Threads.

From www.theengineerspost.com

10 Different Types of Thread Taps Guide] PDF Tapping Plastic Threads tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. In your case, though, tapping might be preferred over inserts. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. there. Tapping Plastic Threads.

From engineeredtoslide.com

Tapping Threads Engineered to Slide Tapping Plastic Threads type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. there are many ways to use traditional fasteners in 3d printed parts. In your case, though, tapping might be preferred over inserts. using a thread tap designed for plastic is a quick, economical way to add screw threads. Tapping Plastic Threads.

From exoknraag.blob.core.windows.net

How Do You Fix A Threaded Screw Hole at Michael Ansley blog Tapping Plastic Threads In your case, though, tapping might be preferred over inserts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. using a thread tap designed for plastic is a. Tapping Plastic Threads.

From www.youtube.com

the CHALLENGES tapping threads into stainless steel YouTube Tapping Plastic Threads using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. type b, type ab and other standard fasteners have a wide thread profile (also called flank angle) of 60°. the creation of a thread in plastic requires first drilling the hole in the plastic and then creating. Tapping Plastic Threads.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Tapping Plastic Threads the creation of a thread in plastic requires first drilling the hole in the plastic and then creating threads on the inner sides of the hole. In your case, though, tapping might be preferred over inserts. tapping is the process of cutting a matching set of threads into a piece of metal, plastic, acrylic, or wood. i. Tapping Plastic Threads.

From machinistsworkshop.net

A Tapping Block Method Tapping Plastic Threads In your case, though, tapping might be preferred over inserts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required. using a thread tap designed for plastic is a quick, economical way to add screw threads to 3d printed parts. tapping is the process of cutting a matching. Tapping Plastic Threads.