Industrial Microwave Tempering . Microwave tempering and defrosting are critical to the food processing industry. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Our systems process in hourly throughput. We offer unique tempering systems with customizable options. (7700 kg) of product per hour. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. The oven system is able to improve. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Backed by precise temperature control,.

from industrialmicrowave.com

Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. We offer unique tempering systems with customizable options. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Backed by precise temperature control,. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. (7700 kg) of product per hour. Microwave tempering and defrosting are critical to the food processing industry. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming.

Microwave Tempering and Cooking Systems Industrial Microwave (IMS)

Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Microwave tempering and defrosting are critical to the food processing industry. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. (7700 kg) of product per hour. Our systems process in hourly throughput. We offer unique tempering systems with customizable options. Backed by precise temperature control,. The oven system is able to improve. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the.

From www.4amtek.com

4AMTek 4000 Series Tempering Ovens Industrial Microwave Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. We offer unique tempering systems with customizable options. Industrial microwave. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering Our systems process in hourly throughput. We offer unique tempering systems with customizable options. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Fmt’s microwave tempering tunnel oven system (mip12). Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering Our systems process in hourly throughput. Microwave tempering and defrosting are critical to the food processing industry. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry,. Industrial Microwave Tempering.

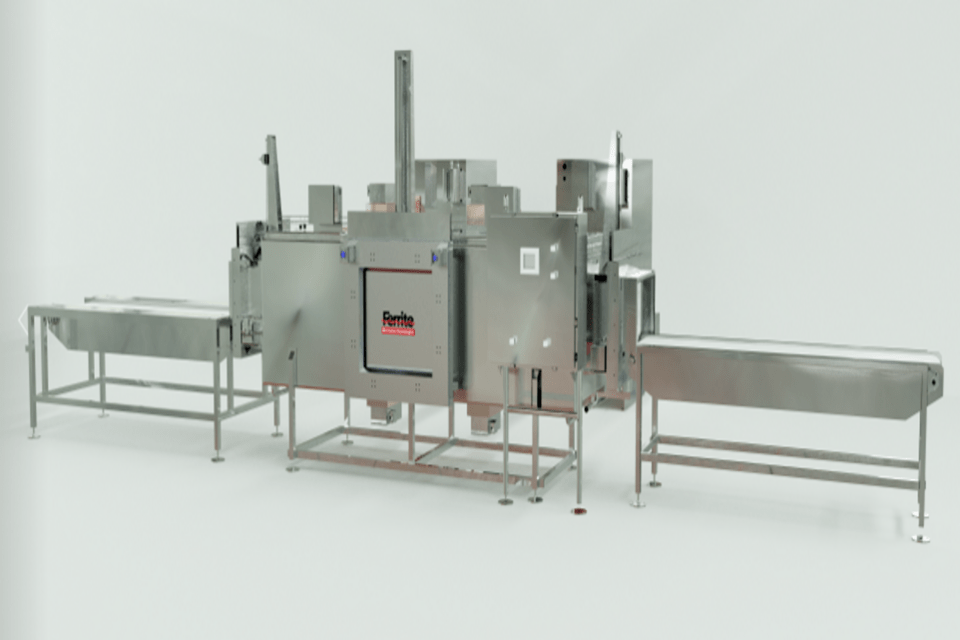

From ferriteinc.com

Microwave Tempering Systems Ferrite Microwave Technologies Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. We offer unique tempering systems with customizable options. Our continuous tempering tunnel simplifies the food tempering process from start to finish. (7700 kg) of product per hour. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and. Industrial Microwave Tempering.

From ferriteinc.com

Microwave Tempering Tunnel Oven System MIP12 Ferrite Microwave Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering and defrosting are critical to the food processing industry. Our systems process in hourly throughput. We offer unique tempering systems with customizable options. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. This system. Industrial Microwave Tempering.

From industrialmicrowave.com

Continuous Microwave Tempering Oven MIP12 Industrial Microwave Industrial Microwave Tempering Microwave tempering and defrosting are critical to the food processing industry. Our systems process in hourly throughput. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. The oven system is able to improve. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as. Industrial Microwave Tempering.

From ferriteinc.com

The Benefits of Microwave Tempering Ferrite Microwave Technologies Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Our systems process in hourly throughput. (7700 kg) of product per hour. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry,. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Backed by precise temperature control,. Industrial. Industrial Microwave Tempering.

From www.4amtek.com

4AMTek 4000 Series Tempering Ovens Industrial Microwave Industrial Microwave Tempering Backed by precise temperature control,. The oven system is able to improve. (7700 kg) of product per hour. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Our systems process in hourly throughput. We offer unique tempering systems with. Industrial Microwave Tempering.

From www.magnavale.co.uk

How Microwave Tempering Works Magnavale Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering and defrosting are critical to the food processing industry. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Backed by precise temperature control,. Our systems process in hourly throughput. The oven system is able. Industrial Microwave Tempering.

From www.4amtek.com

4AMTek 4000 Series Tempering Ovens Industrial Microwave Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. We offer unique tempering systems with customizable options. Our systems process in hourly throughput. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such. Industrial Microwave Tempering.

From industrialmicrowave.com

Continuous Microwave Tempering Oven MIP12 Industrial Microwave Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. (7700 kg) of product per hour. Microwave tempering and defrosting are critical to the food processing industry. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Microwave tempering systems provide turnkey processing solutions for frozen meat,. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

MIP 10 Brochure Industrial Microwave Systems Batch Tempering Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Our systems process in hourly throughput. Our continuous tempering tunnel simplifies the food tempering process from start to finish. We offer unique tempering systems with customizable options. Microwave. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering We offer unique tempering systems with customizable options. The oven system is able to improve. Microwave tempering and defrosting are critical to the food processing industry. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

Microwave Batch Processing Industrial Microwave Systems Tempering Industrial Microwave Tempering Microwave tempering and defrosting are critical to the food processing industry. Backed by precise temperature control,. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. (7700 kg) of product per hour. We offer unique tempering systems with. Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. Backed by precise temperature control,. Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Microwave tempering and defrosting are critical to the food processing industry. We offer unique tempering systems with customizable options. Microwave. Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. The oven system is able to improve. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering systems provide turnkey processing solutions. Industrial Microwave Tempering.

From ferriteinc.com

Microwave Tempering Tunnels Ferrite Microwave Technologies Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Our continuous tempering tunnel simplifies the food tempering process from start to finish. The oven system is able to improve. (7700 kg) of product per hour. We offer unique tempering systems with customizable options. Microwave tempering and defrosting are critical to the food processing industry.. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

Continuous Tempering Tunnel MIP 12 Industrial Microwave Systems Industrial Microwave Tempering Our systems process in hourly throughput. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Backed by precise temperature control,. Our continuous tempering tunnel simplifies the food tempering process from start to finish. The oven system is. Industrial Microwave Tempering.

From ferriteinc.com

Food Tempering Tunnel Microwave System MIP8 Ferrite Microwave Industrial Microwave Tempering This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Microwave tempering and defrosting are critical to the food processing industry. Our continuous tempering tunnel simplifies the food tempering process from start to finish. (7700 kg) of product per hour. Industrial microwave tempering is food processing equipment that uses electromagnetic waves. Industrial Microwave Tempering.

From ferriteinc.com

Microwave Tempering Systems Ferrite Microwave Technologies Industrial Microwave Tempering Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. We offer unique tempering systems with customizable options. Our continuous tempering tunnel simplifies the food tempering process from start to finish. This system offers precise control of. Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering Our systems process in hourly throughput. Microwave tempering and defrosting are critical to the food processing industry. Backed by precise temperature control,. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. We offer unique tempering systems with customizable options. The oven system is able to improve. Industrial microwave tempering is. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. The oven system is able to improve. We offer unique tempering systems with customizable options. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. (7700 kg) of product per hour. Microwave tempering and defrosting are critical to the food. Industrial Microwave Tempering.

From industrialmicrowave.com

Continuous Microwave Tempering Oven MIP12 Industrial Microwave Industrial Microwave Tempering The oven system is able to improve. Our systems process in hourly throughput. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. Industrial microwave tempering is a method food processors use to raise the temperature. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

MIP 12 Brochure Industrial Microwave Systems Tempering Tunnel Industrial Microwave Tempering We offer unique tempering systems with customizable options. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Our. Industrial Microwave Tempering.

From industrialmicrowave.com

Continuous Microwave Tempering Oven MIP12 Industrial Microwave Industrial Microwave Tempering (7700 kg) of product per hour. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. The oven system is able to improve. Backed by precise temperature control,. Microwave tempering and defrosting are critical to the food processing industry. Industrial microwave tempering. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering Microwave tempering and defrosting are critical to the food processing industry. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. The oven system is able to improve. (7700 kg) of product per hour. We offer unique. Industrial Microwave Tempering.

From industrialmicrowave.com

Industrial Microwave Tempering Industrial Microwave Systems Industrial Microwave Tempering Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Microwave tempering and defrosting are critical to the food processing industry. Our systems process in hourly throughput. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Microwave tempering systems. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

Batch Tempering Processor MIP 10 Industrial Microwave Systems Industrial Microwave Tempering Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Microwave tempering and defrosting are critical to the food processing industry. Our systems process in hourly throughput. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood, fruit, vegetables, and bakery products. Our continuous tempering tunnel simplifies the food tempering. Industrial Microwave Tempering.

From ferriteinc.com

Microwave Tempering Tunnels Ferrite Microwave Technologies Industrial Microwave Tempering Our systems process in hourly throughput. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Microwave tempering and defrosting are critical to the food processing industry. Backed by precise temperature control,. The oven system is able to improve. We offer unique tempering systems with customizable options. (7700 kg) of product per hour. Fmt’s microwave tempering tunnel. Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering We offer unique tempering systems with customizable options. Microwave tempering and defrosting are critical to the food processing industry. Our systems process in hourly throughput. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. The oven system is able to improve. Backed by precise temperature control,. Microwave tempering systems provide turnkey processing solutions for. Industrial Microwave Tempering.

From industrialmicrowave.com

Microwave Tempering and Cooking Systems Industrial Microwave (IMS) Industrial Microwave Tempering (7700 kg) of product per hour. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. The oven system is able to improve. Backed by precise temperature control,. Our systems process in hourly throughput. We offer unique tempering systems with customizable options. Our continuous tempering tunnel simplifies the food tempering process from start to finish.. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

MIP 10 Batch Tempering Operation Industrial Microwave Systems Industrial Microwave Tempering Our continuous tempering tunnel simplifies the food tempering process from start to finish. (7700 kg) of product per hour. Our systems process in hourly throughput. This system offers precise control of product temperature for further processing, such as grinding, dicing, slicing, molding, and forming. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave. Industrial Microwave Tempering.

From www.made-in-china.com

Industrial Microwave Tempering System China Industrial Microwave Industrial Microwave Tempering Industrial microwave tempering is a method food processors use to raise the temperature of deep frozen products, such as meat or fish. Our systems process in hourly throughput. We offer unique tempering systems with customizable options. Industrial microwave tempering is food processing equipment that uses electromagnetic waves to evenly raise the. (7700 kg) of product per hour. Microwave tempering and. Industrial Microwave Tempering.

From industrialmicrowavesystems.com

Batch Tempering Processor MIP 10 Industrial Microwave Systems Industrial Microwave Tempering (7700 kg) of product per hour. Fmt’s microwave tempering tunnel oven system (mip12) is our flagship continuous tempering system for industrial microwave food processing. Our continuous tempering tunnel simplifies the food tempering process from start to finish. Microwave tempering and defrosting are critical to the food processing industry. Microwave tempering systems provide turnkey processing solutions for frozen meat, poultry, seafood,. Industrial Microwave Tempering.