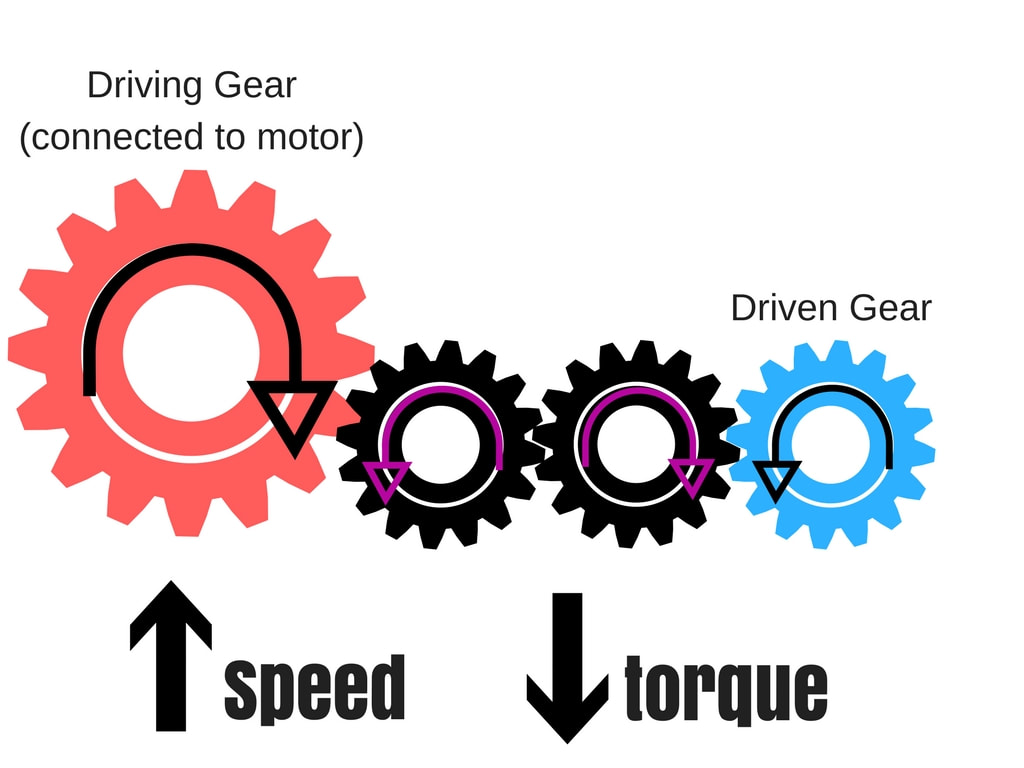

Robotics Gear Ratios . The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Thus, we can multiply the torque supplied at the motor shaft (the. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The gear ratio expresses the ratio of the output torque to the input torque. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger.

from cariwilliamzvex.weebly.com

From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The gear ratio expresses the ratio of the output torque to the input torque. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. Thus, we can multiply the torque supplied at the motor shaft (the. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower).

Gear Ratios VEX ROBOTICS COMPETITION

Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Thus, we can multiply the torque supplied at the motor shaft (the. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. The gear ratio expresses the ratio of the output torque to the input torque.

From www.youtube.com

double flywheel vex robotics (25 to 1 Gear Ratio) YouTube Robotics Gear Ratios Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Thus, we can multiply the torque supplied at the motor shaft (the. Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The ratio in size from the input (driving). Robotics Gear Ratios.

From cariwilliamzvex.weebly.com

Gear Ratios VEX ROBOTICS COMPETITION Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). The gear ratio expresses the ratio of the output torque to the input torque. Planetary gears provide a high power density,. Robotics Gear Ratios.

From www.slideserve.com

PPT FRC Robot Mechanical Principles PowerPoint Presentation, free Robotics Gear Ratios The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. We tried. Robotics Gear Ratios.

From www.scribd.com

Robotics Gears and Gear Ratios PDF Hydroelectricity Turbine Robotics Gear Ratios From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Thus, we can multiply the torque supplied at the motor shaft. Robotics Gear Ratios.

From www.slideserve.com

PPT Introduction to Lego Robotics PowerPoint Presentation, free Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. The gear ratio expresses the ratio of the output torque to the input torque. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Planetary gears provide a high power density, over 95% efficiency and, as a. Robotics Gear Ratios.

From kb.vex.com

Using Gear Ratios with the V5 Motor VEX Library Robotics Gear Ratios The gear ratio expresses the ratio of the output torque to the input torque. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Thus, we can multiply the torque supplied at the motor shaft (the. From figure 5 we know that the ratio in size from the input (driving). Robotics Gear Ratios.

From www.scribd.com

Robotics Gears and Gear Ratios PDF Gear Mechanical Engineering Robotics Gear Ratios The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Planetary gears provide a high power density, over 95% efficiency and, as a. Robotics Gear Ratios.

From www.youtube.com

Bilateral Drive Gear a Highly Backdrivable Reduction Gearbox for Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive. Robotics Gear Ratios.

From www.scribd.com

Robotics Gears and Gear Ratios PDF Gear Manufactured Goods Robotics Gear Ratios Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). From figure 5 we know that the ratio in size from the input. Robotics Gear Ratios.

From www.youtube.com

VEX IQ Mechanisms Gear Ratio YouTube Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The gear ratio expresses the ratio of the. Robotics Gear Ratios.

From www.youtube.com

BUILD STEM ROBOTS Gear Ratio A build to demonstrate the concept of Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is. Robotics Gear Ratios.

From www.seimitsu.in

Gears for Robotic Application Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The gear ratio of a robotic system is typically 20 ~ 100, which. Robotics Gear Ratios.

From robouav.org

gear ratio in robot آموزش الکترونیک برنامه نویسی رباتیک Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). We tried to understand how. Robotics Gear Ratios.

From cariwilliamzvex.weebly.com

Gear Ratios VEX ROBOTICS COMPETITION Robotics Gear Ratios Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). The gear ratio expresses the ratio of the output torque to the input. Robotics Gear Ratios.

From www.youtube.com

FLL Robot Gear Ratio Tutorial 12 YouTube Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster. Robotics Gear Ratios.

From www.pinterest.com

Gear Ratio Vex robotics, Curriculum, Knowledge Robotics Gear Ratios We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Planetary gears provide a high power density, over 95% efficiency and,. Robotics Gear Ratios.

From www.youtube.com

FLL Robot Gear Ratio Tutorial 8 YouTube Robotics Gear Ratios Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Gear ratios are one of the most common design decisions that a team. Robotics Gear Ratios.

From www.youtube.com

FLL Robot Gear Ratio Tutorial 9 YouTube Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Gear ratios are one of the most common design decisions that a. Robotics Gear Ratios.

From www.youtube.com

Robot Gear Ratio Example YouTube Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque).. Robotics Gear Ratios.

From www.pinterest.com.mx

8.4 Gear Ratios VEX EDR Curriculum Gears, Robotics club, Vex robotics Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines. Robotics Gear Ratios.

From www.os-breg.si

Gear Ratio VEX IQ STEM through Robotics Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Robotics Gear Ratios.

From www.vexforum.com

Gear Ratios VEX Forum Robotics Gear Ratios The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). The gear ratio expresses the ratio. Robotics Gear Ratios.

From www.pinterest.com

vex gear ratio Vex robotics, Robotics engineering, Robotics classes Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Thus, we can multiply the torque supplied at the motor shaft (the. From. Robotics Gear Ratios.

From www.youtube.com

Make Your VRC Robot Faster/Stronger with Gear Ratios! YouTube Robotics Gear Ratios From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). Thus, we can multiply the torque supplied at the motor shaft (the. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping. Robotics Gear Ratios.

From www.numerade.com

SOLVED The figure below shows a single robot joint/link driven through Robotics Gear Ratios Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. The ratio in size from the input (driving). Robotics Gear Ratios.

From kb.vex.com

Using VEX GO Wheels, Gears, and Pulleys VEX Library Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). Planetary. Robotics Gear Ratios.

From cariwilliamzvex.weebly.com

Gear Ratios VEX ROBOTICS COMPETITION Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. From figure 5 we know that the ratio. Robotics Gear Ratios.

From www.youtube.com

Vex Gearing Finding Ratios YouTube Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Thus, we can multiply the torque supplied at the motor shaft (the. From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque).. Robotics Gear Ratios.

From www.scribd.com

Gear Ratios Understanding Gear Ratios Team Associated Gear Robotics Gear Ratios We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Gear ratios are one of the most common design decisions that a team must master in order to optimize. Robotics Gear Ratios.

From cariwilliamzvex.weebly.com

Gear Ratios VEX ROBOTICS COMPETITION Robotics Gear Ratios Thus, we can multiply the torque supplied at the motor shaft (the. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines. Robotics Gear Ratios.

From www.youtube.com

Gear Ratio, Torque, and Speed explained through a Vex Transmission Robotics Gear Ratios The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). From figure 5 we know that the ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque). The gear ratio of a. Robotics Gear Ratios.

From www.robotpark.com

Robotic Mechanisms ALL TYPES of GEARS 51034 Robotpark ACADEMY Robotics Gear Ratios The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. The ratio in size from the input (driving) gear to the output (driven) gear determines if the output is faster (less torque) or has more torque (slower). The gear ratio expresses the ratio of. Robotics Gear Ratios.

From www.youtube.com

FLL Robot Gear Ratio Tutorial 6 YouTube Robotics Gear Ratios Gear ratios are one of the most common design decisions that a team must master in order to optimize mechanical. Planetary gears provide a high power density, over 95% efficiency and, as a result of their design, are very compact. Thus, we can multiply the torque supplied at the motor shaft (the. The gear ratio expresses the ratio of the. Robotics Gear Ratios.

From www.youtube.com

Robotics gear ratio quiz study guide YouTube Robotics Gear Ratios The gear ratio expresses the ratio of the output torque to the input torque. We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. Thus, we can multiply the torque supplied at the motor shaft (the. The ratio in size from the input (driving) gear to the output (driven). Robotics Gear Ratios.

From www.youtube.com

FLL Robot Gear Ratio Tutorial 11 YouTube Robotics Gear Ratios We tried to understand how gear backlash problems could be overcome with better motion control, sensors, ai, and new drive technologies. The gear ratio of a robotic system is typically 20 ~ 100, which means that the effective inertia and damping becomes 400 ~ 10,000 times larger. Planetary gears provide a high power density, over 95% efficiency and, as a. Robotics Gear Ratios.