K Value For Steel Pipe . 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. For steel line size larger. H = k x v² / 2g. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Fluid head loss through a fitting can be calculated by the following equation: The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. Fluid flow table of contents. This coefficient must be determined for every. H = pressure loss in terms of fluid head, i.e. Please note that because of the variation in roughness in these materials depending on the source, the. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Assume a 6 angle valve for.

from mungfali.com

H = pressure loss in terms of fluid head, i.e. Fluid flow table of contents. This coefficient must be determined for every. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. Please note that because of the variation in roughness in these materials depending on the source, the. Assume a 6 angle valve for. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. H = k x v² / 2g. Fluid head loss through a fitting can be calculated by the following equation: For steel line size larger.

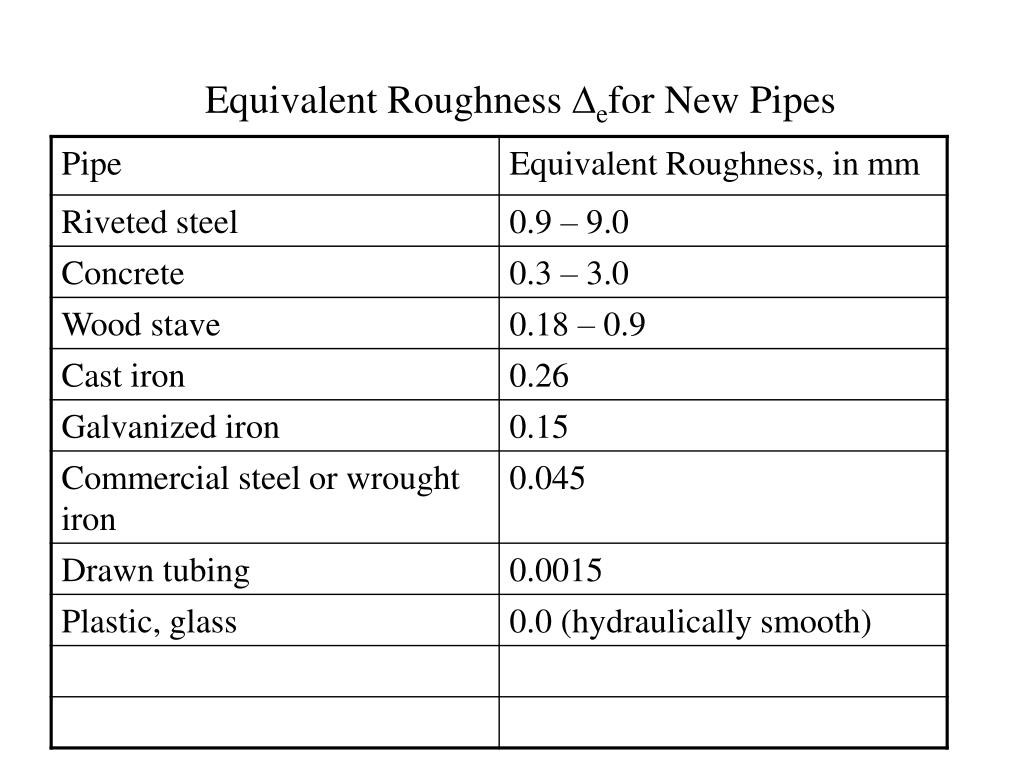

Pipe Roughness Chart

K Value For Steel Pipe For steel line size larger. H = pressure loss in terms of fluid head, i.e. Please note that because of the variation in roughness in these materials depending on the source, the. H = k x v² / 2g. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. This coefficient must be determined for every. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Fluid flow table of contents. Assume a 6 angle valve for. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. Fluid head loss through a fitting can be calculated by the following equation: For steel line size larger. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24.

From ecampusontario.pressbooks.pub

Experiment 6 Fluid Flow Minor Losses PROCTECH 2EC3 Lab Manual K Value For Steel Pipe Please note that because of the variation in roughness in these materials depending on the source, the. H = pressure loss in terms of fluid head, i.e. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. H = k x v² / 2g. The relative roughness of. K Value For Steel Pipe.

From www.thefabricator.com

Kfactors, Yfactors, and press brake bending precision K Value For Steel Pipe Please note that because of the variation in roughness in these materials depending on the source, the. This coefficient must be determined for every. H = pressure loss in terms of fluid head, i.e. Assume a 6 angle valve for. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a. K Value For Steel Pipe.

From mungfali.com

Roughness Coefficient PVC Pipe K Value For Steel Pipe 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Please note that because of the variation in roughness in these materials depending on the source, the. Assume a 6 angle valve for. For steel line size larger. H = k x v² / 2g. Fluid flow. K Value For Steel Pipe.

From www.hvacbrain.com

What is the K factor and how do we use it in HVAC applications? Hvac K Value For Steel Pipe Assume a 6 angle valve for. H = pressure loss in terms of fluid head, i.e. H = k x v² / 2g. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Determine l (friction loss in pipe fittings in terms of equivalent length in feet. K Value For Steel Pipe.

From engineerexcel.com

Loss Coefficients A Practical Guide for Engineers EngineerExcel K Value For Steel Pipe This coefficient must be determined for every. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Fluid flow table of contents. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. For steel line. K Value For Steel Pipe.

From exyiodxiq.blob.core.windows.net

Steel And Tube Stock Price at Dorothy Ball blog K Value For Steel Pipe Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Assume a 6 angle valve for. H = pressure loss in terms of fluid head, i.e. H = k x v² / 2g. This coefficient must be determined for every. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square. K Value For Steel Pipe.

From www.chuankok.com

Blogs CHUAN KOK K Value For Steel Pipe Fluid flow table of contents. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. For steel line size larger. Determine l (friction loss in. K Value For Steel Pipe.

From www.engineersedge.com

Pipe Roughness Coefficients Table Charts HazenWilliams Coefficient K Value For Steel Pipe The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Fluid head loss through a fitting can be calculated by the following equation: H = k x v² / 2g. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks. K Value For Steel Pipe.

From lessonabend.z19.web.core.windows.net

Insulation Rvalue Chart K Value For Steel Pipe For steel line size larger. Please note that because of the variation in roughness in these materials depending on the source, the. H = pressure loss in terms of fluid head, i.e. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Assume a 6 angle valve for.. K Value For Steel Pipe.

From www.yumpu.com

K Factor Quick Reference Thermo Scientific Home Page K Value For Steel Pipe H = k x v² / 2g. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Please note that because of the variation in roughness in these materials depending on the source, the. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity. K Value For Steel Pipe.

From mungfali.com

Pipe Roughness Chart K Value For Steel Pipe 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Fluid head loss through a fitting can be calculated by the following equation: H = pressure loss in terms of fluid head, i.e. Assume a 6 angle valve for. The typical k values are based on water. K Value For Steel Pipe.

From giowbccze.blob.core.windows.net

K Value Of Pipe Fittings at Kathleen Fusco blog K Value For Steel Pipe Fluid flow table of contents. This coefficient must be determined for every. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Fluid head loss through a fitting can be calculated by the following equation: Assume a 6 angle valve for. For steel line size larger. H =. K Value For Steel Pipe.

From www.slurrypipes.com.au

Low Friction Slurry Pipes UHMWPE Pipe Suppliers Call Us On 03 K Value For Steel Pipe Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Please note that because of the variation in roughness in these materials depending on the source, the. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer,. K Value For Steel Pipe.

From www.academia.edu

(PDF) Pipe Friction Loss Charts Pipe and Equivalent Length of Pipe Type K Value For Steel Pipe Fluid head loss through a fitting can be calculated by the following equation: For steel line size larger. H = k x v² / 2g. H = pressure loss in terms of fluid head, i.e. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation. K Value For Steel Pipe.

From www.tiktok.com

Commercial Steel Structured Building Auction Sale at Former K Zone Ja K Value For Steel Pipe Please note that because of the variation in roughness in these materials depending on the source, the. H = pressure loss in terms of fluid head, i.e. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then. K Value For Steel Pipe.

From www.coursehero.com

[Solved] Steam at 230C is flowing through a steel pipe k = 15.1 W/m.C K Value For Steel Pipe 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Assume a 6 angle valve for. Fluid flow table of contents. H = pressure loss in terms of fluid head, i.e. Fluid head loss through a fitting can be calculated by the following equation: The typical k. K Value For Steel Pipe.

From www.slideserve.com

PPT Pipe Sizing Basics PowerPoint Presentation, free download ID760528 K Value For Steel Pipe Fluid flow table of contents. Please note that because of the variation in roughness in these materials depending on the source, the. This coefficient must be determined for every. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. H = pressure loss in terms of fluid head,. K Value For Steel Pipe.

From partdiagramacapteu6.z13.web.core.windows.net

Gi Pipe Size Chart In Mm And Inches K Value For Steel Pipe The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. Fluid flow table of contents. Fluid head loss through a fitting can be calculated by the following equation: This coefficient must be determined. K Value For Steel Pipe.

From energy-models.com

Pipe Sizing Charts Tables K Value For Steel Pipe This coefficient must be determined for every. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. Please note that because of the variation in roughness in these materials depending on the source,. K Value For Steel Pipe.

From www.citizenpipes.net

Schedule 80 Cast Iron Pipe wall thickness Sch 80 Cast Iron Pipe Size K Value For Steel Pipe This coefficient must be determined for every. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. For steel line size larger. Please note that because of the variation in roughness in these materials depending on the source, the. Fluid head loss through a fitting can be calculated. K Value For Steel Pipe.

From mavink.com

Ppr Pipe Friction Loss Chart K Value For Steel Pipe The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. The relative roughness of a pipe is its roughness divided. K Value For Steel Pipe.

From www.numerade.com

SOLVED QI A steel pipe (K = 45.0 W/m K) having a 1.96 in O.D. is K Value For Steel Pipe The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. This coefficient must be determined for every. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight. K Value For Steel Pipe.

From engineeringness.com

Pressure Drop In Pipe Lines And Fittings Part 2 Engineeringness K Value For Steel Pipe Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. H = k x v² / 2g. Please note that because of the variation in roughness in these materials depending on. K Value For Steel Pipe.

From www.researchgate.net

1. Values of the Manning resistance coefficient (from Chow, 1959 K Value For Steel Pipe Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. Please note that because of the variation in roughness in these materials depending on the source, the. For steel line size larger. The typical k values are based on water flows for. K Value For Steel Pipe.

From csengineermag.com

high quality Galvanized steel pipe or Aluminum and chrome stainless K Value For Steel Pipe 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy.. K Value For Steel Pipe.

From www.scribd.com

k Value of Fittings Pipe (Fluid Conveyance) Valve K Value For Steel Pipe H = k x v² / 2g. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the. K Value For Steel Pipe.

From www.coursehero.com

[Solved] Steam at 230C is flowing through a steel pipe k = 15.1 W/m.C K Value For Steel Pipe This coefficient must be determined for every. H = pressure loss in terms of fluid head, i.e. Fluid head loss through a fitting can be calculated by the following equation: Please note that because of the variation in roughness in these materials depending on the source, the. The relative roughness of a pipe is its roughness divided by its internal. K Value For Steel Pipe.

From www.pumpsandsystems.com

Understand How Valves & Fittings Affect Head Loss Pumps & Systems K Value For Steel Pipe Fluid flow table of contents. H = k x v² / 2g. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Fluid head loss through a fitting can be. K Value For Steel Pipe.

From ratnamani.com

Ratnamani Metals & Tubes Ltd. K Value For Steel Pipe Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Assume a 6 angle valve for. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity. K Value For Steel Pipe.

From www.chegg.com

Solved Calculate total head loss in a new galvanized iron K Value For Steel Pipe This coefficient must be determined for every. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the pipe friction factor, which is then used in the darcy. For steel line size larger. Determine l (friction loss in pipe fittings in terms of equivalent. K Value For Steel Pipe.

From www.thefabricator.com

Analyzing the kfactor in sheet metal bending Part II K Value For Steel Pipe Fluid flow table of contents. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of fluid flowing through valves and fittings like an elbow, bend, reducer, tee, pipe. The relative roughness of a pipe is its roughness divided by its internal diameter or e /d, and this value is used in the calculation of the. K Value For Steel Pipe.

From www.octalpipefittings.com

Steel Pipe Elbow (45 and 90 degree) Types & Specifications Octalsteel K Value For Steel Pipe Fluid flow table of contents. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. The relative roughness of a pipe is its roughness divided by its internal diameter or e. K Value For Steel Pipe.

From www.youtube.com

Effective length factor (K) for columns in frame Design of Steel K Value For Steel Pipe For steel line size larger. H = k x v² / 2g. Assume a 6 angle valve for. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). H = pressure loss in terms of fluid head, i.e. Resistance coefficient k is proportional coefficient between pressure drop (head loss) and square velocity of. K Value For Steel Pipe.

From mungfali.com

Pipe Roughness Chart K Value For Steel Pipe H = k x v² / 2g. H = pressure loss in terms of fluid head, i.e. The typical k values are based on water flows for complete turbulence in schedule 40 pipe sizes up to and including 24. Please note that because of the variation in roughness in these materials depending on the source, the. The relative roughness of. K Value For Steel Pipe.

From www.pinterest.com

k Value of Fittings Pipe (Fluid Conveyance) Valve Civic eg, Valve K Value For Steel Pipe Assume a 6 angle valve for. H = k x v² / 2g. H = pressure loss in terms of fluid head, i.e. Fluid flow table of contents. 32 rows the pressure drop through common fittings and valves found in fluid piping can be calculated thanks to a friction coefficient k. Fluid head loss through a fitting can be calculated. K Value For Steel Pipe.