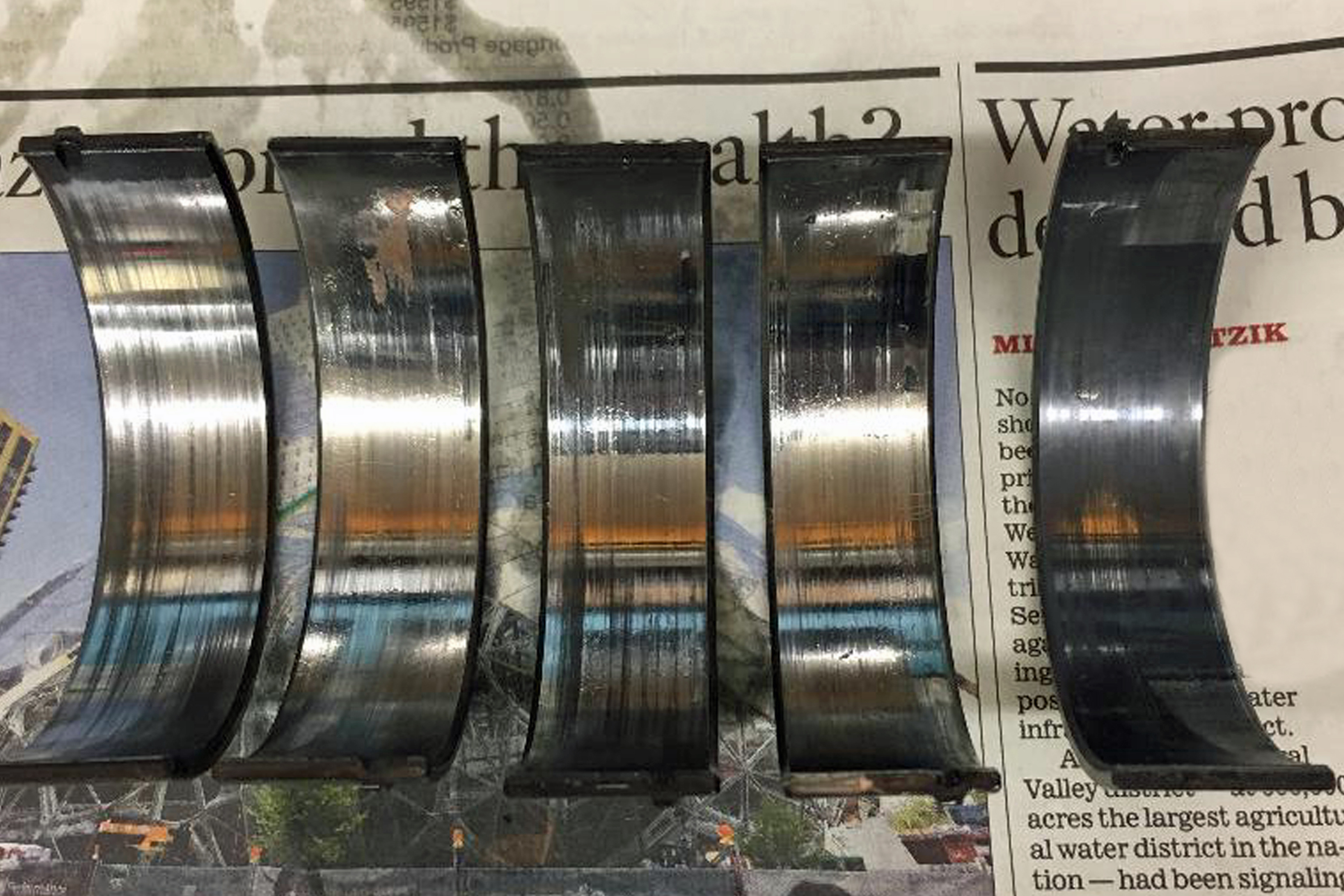

Normal Main Bearing Wear . Mixed lubrication is one of the main causes of engine bearing failures. Wear should diminish near the parting line ends of. About 2 inches in the center of each of the bearing looks copper colored. They are smooth except for at one end of each bearing. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Furthermore, some main bearings may have, a built in thrust bearing. Sand, fine metal from grinding or machining, and fine metal or. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Fine foreign material in the bearing can cause excessive abrasive wear. Uniform wear pattern over approximately 2/3 of the bearing’s surface.

from www.dragzine.com

They are smooth except for at one end of each bearing. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Mixed lubrication is one of the main causes of engine bearing failures. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Sand, fine metal from grinding or machining, and fine metal or. Furthermore, some main bearings may have, a built in thrust bearing. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. About 2 inches in the center of each of the bearing looks copper colored. Fine foreign material in the bearing can cause excessive abrasive wear. Wear should diminish near the parting line ends of.

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates

Normal Main Bearing Wear About 2 inches in the center of each of the bearing looks copper colored. Furthermore, some main bearings may have, a built in thrust bearing. Sand, fine metal from grinding or machining, and fine metal or. They are smooth except for at one end of each bearing. Wear should diminish near the parting line ends of. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Mixed lubrication is one of the main causes of engine bearing failures. Fine foreign material in the bearing can cause excessive abrasive wear. Uniform wear pattern over approximately 2/3 of the bearing’s surface. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. About 2 inches in the center of each of the bearing looks copper colored.

From www.supraforums.com

Bearing wear pattern Supra Forums Normal Main Bearing Wear About 2 inches in the center of each of the bearing looks copper colored. Fine foreign material in the bearing can cause excessive abrasive wear. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Sand, fine metal from grinding or machining, and fine metal or. Furthermore, some main bearings may have, a. Normal Main Bearing Wear.

From www.dansmc.com

Dan's Motorcycle "Plain Bearings." Normal Main Bearing Wear Uniform wear pattern over approximately 2/3 of the bearing’s surface. Furthermore, some main bearings may have, a built in thrust bearing. Fine foreign material in the bearing can cause excessive abrasive wear. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Wear should diminish near the parting line ends. Normal Main Bearing Wear.

From www.southwestairsports.com

bearing condition in paramotor engines Normal Main Bearing Wear Mixed lubrication is one of the main causes of engine bearing failures. Uniform wear pattern over approximately 2/3 of the bearing’s surface. About 2 inches in the center of each of the bearing looks copper colored. Sand, fine metal from grinding or machining, and fine metal or. The lower half of a main bearing, has a hole for passing oil,. Normal Main Bearing Wear.

From www.vrogue.co

10 Most Common Bearing Failures Poster vrogue.co Normal Main Bearing Wear Uniform wear pattern over approximately 2/3 of the bearing’s surface. They are smooth except for at one end of each bearing. Furthermore, some main bearings may have, a built in thrust bearing. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Sand, fine metal from grinding or machining, and fine metal or.. Normal Main Bearing Wear.

From ls1tech.com

Rod Bearings Ok? LS1TECH Camaro and Firebird Forum Discussion Normal Main Bearing Wear So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Fine foreign material in the bearing can cause excessive abrasive wear. About 2 inches in the center of each of the bearing looks copper colored. The lower half of a main bearing, has a hole for passing oil, to the feed holes in. Normal Main Bearing Wear.

From www.spyderchat.com

Rod Bearing Help MR2 SpyderChat Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Mixed lubrication is one of the main causes of engine bearing failures.. Normal Main Bearing Wear.

From www.hotrodders.com

Pictures, Rod bearing wear, your opinion? Hot Rod Forum Normal Main Bearing Wear So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Fine foreign material in the bearing can cause excessive abrasive wear. Mixed lubrication is one of the main causes of engine bearing failures. Sand, fine metal from grinding or machining, and fine metal or. Furthermore, some main bearings may have, a built in. Normal Main Bearing Wear.

From www.chevyhardcore.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Normal Main Bearing Wear They are smooth except for at one end of each bearing. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Fine foreign material in the bearing can cause excessive abrasive wear. About 2 inches in the center of each of the bearing looks copper colored. The lower half of a main bearing, has a hole for passing oil, to. Normal Main Bearing Wear.

From daisyvaughan.z13.web.core.windows.net

Rod Bearing Wear Chart Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. Wear should diminish near the parting line ends of. They are smooth except for at one end of each bearing. Uniform wear pattern over approximately 2/3 of the bearing’s surface. About 2 inches in the center of each of the bearing looks copper colored. The lower half of a. Normal Main Bearing Wear.

From www.m3post.com

Scary rod bearing thread s85 Page 13 Normal Main Bearing Wear Uniform wear pattern over approximately 2/3 of the bearing’s surface. Mixed lubrication is one of the main causes of engine bearing failures. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of. Normal Main Bearing Wear.

From forums.pelicanparts.com

Strange main bearing wear. Any ideas WHY? Pelican Parts Forums Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. Fine foreign material in the bearing can cause excessive abrasive wear. Uniform wear pattern over approximately 2/3 of the bearing’s surface. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. The lower half of a main bearing, has a hole for. Normal Main Bearing Wear.

From www.dragzine.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Normal Main Bearing Wear Mixed lubrication is one of the main causes of engine bearing failures. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Fine foreign material in the bearing can cause excessive abrasive wear. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Furthermore, some main bearings may have, a. Normal Main Bearing Wear.

From ls1tech.com

Odd Main bearing wear mainly 2. LS1TECH Camaro and Firebird Forum Normal Main Bearing Wear Mixed lubrication is one of the main causes of engine bearing failures. Sand, fine metal from grinding or machining, and fine metal or. Fine foreign material in the bearing can cause excessive abrasive wear. Uniform wear pattern over approximately 2/3 of the bearing’s surface. The lower half of a main bearing, has a hole for passing oil, to the feed. Normal Main Bearing Wear.

From ls1tech.com

Strange rod bearing wear pattern LS1TECH Camaro and Firebird Forum Normal Main Bearing Wear So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of each of the bearing looks copper colored. Wear should diminish near the parting line ends. Normal Main Bearing Wear.

From www.m3post.com

MRF Engineering Rod Bearings, Teardowns, Failures & Replacements Normal Main Bearing Wear About 2 inches in the center of each of the bearing looks copper colored. Fine foreign material in the bearing can cause excessive abrasive wear. Furthermore, some main bearings may have, a built in thrust bearing. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. The lower half of a main bearing,. Normal Main Bearing Wear.

From dsportmag.com

The Science Behind Modern Performance Engine Bearings Normal Main Bearing Wear Mixed lubrication is one of the main causes of engine bearing failures. Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of each of the bearing looks copper colored. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. They are smooth except for at. Normal Main Bearing Wear.

From www.jalopyjournal.com

Technical Sbc main bearing wear help The H.A.M.B. Normal Main Bearing Wear They are smooth except for at one end of each bearing. Mixed lubrication is one of the main causes of engine bearing failures. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Wear should diminish near the parting line. Normal Main Bearing Wear.

From rileywalsh.z19.web.core.windows.net

Main Bearing Wear Chart Normal Main Bearing Wear Furthermore, some main bearings may have, a built in thrust bearing. Wear should diminish near the parting line ends of. Mixed lubrication is one of the main causes of engine bearing failures. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Sand, fine metal from grinding or machining, and fine metal or. The lower half of a main bearing,. Normal Main Bearing Wear.

From www.camaroz28.com

Bearing Wear Normal? (pictures) Message Board Normal Main Bearing Wear So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. They are smooth except for at one end of each bearing. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Sand, fine metal from grinding or machining, and fine metal or. The lower half of a main bearing, has a hole for. Normal Main Bearing Wear.

From www.onallcylinders.com

Ask Away Explaining Mysterious Rod Bearing Failure Normal Main Bearing Wear So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. They are smooth except for at one end of each bearing. Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of each of the bearing looks copper colored. The lower half of a main bearing,. Normal Main Bearing Wear.

From www.camaroz28.com

Main bearing wear pictures. Advice? Message Board Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. Fine foreign material in the bearing can cause excessive abrasive wear. About 2 inches in the center of each of the bearing looks copper colored. Wear should diminish near the parting line ends of. Mixed lubrication is one of the main causes of engine bearing failures. Furthermore, some main. Normal Main Bearing Wear.

From www.reddit.com

Is this kind of bearing wear normal? r/EngineBuilding Normal Main Bearing Wear Uniform wear pattern over approximately 2/3 of the bearing’s surface. About 2 inches in the center of each of the bearing looks copper colored. Furthermore, some main bearings may have, a built in thrust bearing. They are smooth except for at one end of each bearing. Sand, fine metal from grinding or machining, and fine metal or. So, the upper. Normal Main Bearing Wear.

From www.reddit.com

How bad is the wear on these bearings? Out of a 350 sbc. r/EngineBuilding Normal Main Bearing Wear About 2 inches in the center of each of the bearing looks copper colored. Uniform wear pattern over approximately 2/3 of the bearing’s surface. They are smooth except for at one end of each bearing. Wear should diminish near the parting line ends of. So, the upper half of a main bearing, commonly has an oil groove, on the inner. Normal Main Bearing Wear.

From www.clubegolfpt.com

"Problema" motores BLS e BXE Página 2 Clube Golf Portugal Normal Main Bearing Wear Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of each of the bearing looks copper colored. They are smooth except for at one end of each bearing. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Mixed lubrication is one. Normal Main Bearing Wear.

From carolinadunebuggies.com

MAIN BEARING SET, .50/.25 Normal Main Bearing Wear Furthermore, some main bearings may have, a built in thrust bearing. About 2 inches in the center of each of the bearing looks copper colored. Mixed lubrication is one of the main causes of engine bearing failures. They are smooth except for at one end of each bearing. Uniform wear pattern over approximately 2/3 of the bearing’s surface. So, the. Normal Main Bearing Wear.

From www.camaroz28.com

Bearing Wear Normal? (pictures) Message Board Normal Main Bearing Wear The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. They are smooth except for at one end of each bearing. Wear should diminish near the parting line ends of. Sand, fine metal from grinding or machining, and fine metal or. Furthermore, some main bearings may have, a built in. Normal Main Bearing Wear.

From repairengineroamer88.z22.web.core.windows.net

Main Crank Bearings 03 Tahoe Normal Main Bearing Wear They are smooth except for at one end of each bearing. Sand, fine metal from grinding or machining, and fine metal or. About 2 inches in the center of each of the bearing looks copper colored. Wear should diminish near the parting line ends of. So, the upper half of a main bearing, commonly has an oil groove, on the. Normal Main Bearing Wear.

From www.reddit.com

Normal connecting rod bearing wear? Asking about the light spot next to Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Fine foreign material in the bearing can cause excessive abrasive wear. About 2 inches in the center of each of the bearing looks copper colored. They are smooth except. Normal Main Bearing Wear.

From www.ford-trucks.com

Crankshaft bearing wear Ford Truck Enthusiasts Forums Normal Main Bearing Wear Uniform wear pattern over approximately 2/3 of the bearing’s surface. About 2 inches in the center of each of the bearing looks copper colored. Fine foreign material in the bearing can cause excessive abrasive wear. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. They are smooth except for at one end. Normal Main Bearing Wear.

From www.onallcylinders.com

Bearing Down Engine Crankshaft & Cam Bearing Basics Normal Main Bearing Wear Wear should diminish near the parting line ends of. Fine foreign material in the bearing can cause excessive abrasive wear. Mixed lubrication is one of the main causes of engine bearing failures. Furthermore, some main bearings may have, a built in thrust bearing. They are smooth except for at one end of each bearing. The lower half of a main. Normal Main Bearing Wear.

From garage.grumpysperformance.com

measuring crank bearing journals Grumpys Performance Garage Normal Main Bearing Wear About 2 inches in the center of each of the bearing looks copper colored. Mixed lubrication is one of the main causes of engine bearing failures. Furthermore, some main bearings may have, a built in thrust bearing. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. They are smooth. Normal Main Bearing Wear.

From forums.pelicanparts.com

Glyco rod bearing wear Pelican Parts Forums Normal Main Bearing Wear Fine foreign material in the bearing can cause excessive abrasive wear. Furthermore, some main bearings may have, a built in thrust bearing. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Mixed lubrication is one of the main causes of engine bearing. Normal Main Bearing Wear.

From honda-tech.com

Excessive rod bearing wear? Ls vtec HondaTech Honda Forum Discussion Normal Main Bearing Wear Wear should diminish near the parting line ends of. Furthermore, some main bearings may have, a built in thrust bearing. Uniform wear pattern over approximately 2/3 of the bearing’s surface. The lower half of a main bearing, has a hole for passing oil, to the feed holes in the crankshaft. Mixed lubrication is one of the main causes of engine. Normal Main Bearing Wear.

From www.youtube.com

Main Bearing And BigEnd Bearing Wear YouTube Normal Main Bearing Wear Furthermore, some main bearings may have, a built in thrust bearing. Mixed lubrication is one of the main causes of engine bearing failures. Uniform wear pattern over approximately 2/3 of the bearing’s surface. Wear should diminish near the parting line ends of. Sand, fine metal from grinding or machining, and fine metal or. The lower half of a main bearing,. Normal Main Bearing Wear.

From ls1tech.com

Odd Main bearing wear mainly 2. LS1TECH Camaro and Firebird Forum Normal Main Bearing Wear Sand, fine metal from grinding or machining, and fine metal or. About 2 inches in the center of each of the bearing looks copper colored. Uniform wear pattern over approximately 2/3 of the bearing’s surface. So, the upper half of a main bearing, commonly has an oil groove, on the inner surface. Fine foreign material in the bearing can cause. Normal Main Bearing Wear.