Rebar Steel Manufacturing Process . The steel rebar are at high temperature when they leave the last rolling stand. Heating, rolling, and forming of reinforced bar: Tmt reinforcement steel manufacturing process is shown below: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The production process is as follows: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized.

from www.slideshare.net

Tmt reinforcement steel manufacturing process is shown below: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The steel rebar are at high temperature when they leave the last rolling stand. Heating, rolling, and forming of reinforced bar:

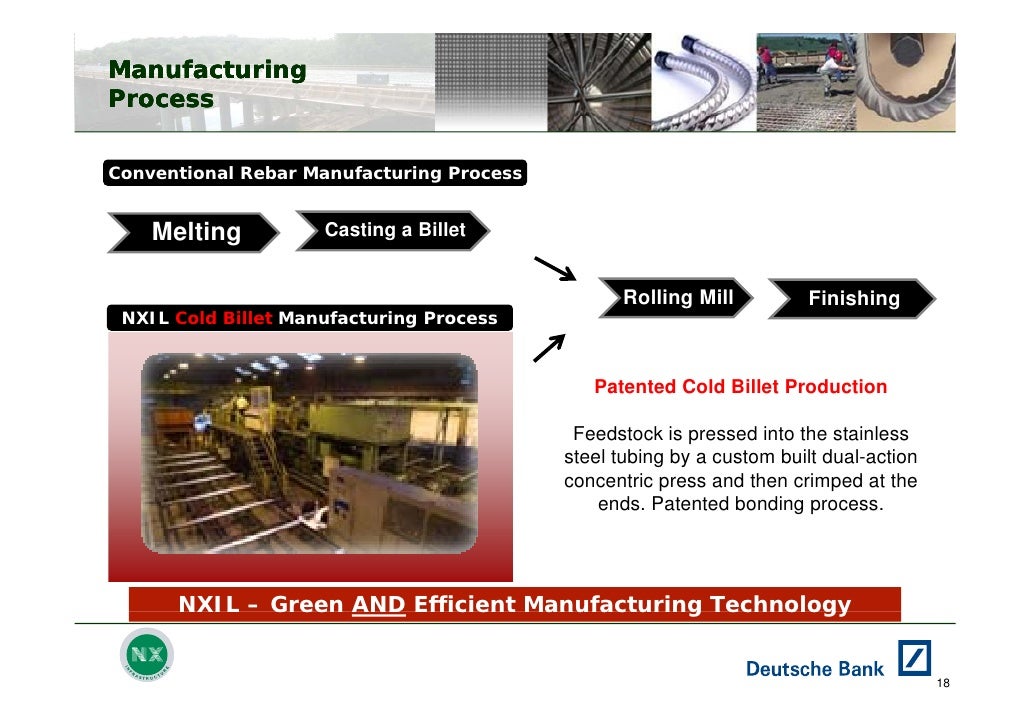

Manufacturing Process Stainless Clad Rebar

Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Heating, rolling, and forming of reinforced bar: The steel rebar are at high temperature when they leave the last rolling stand. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Tmt reinforcement steel manufacturing process is shown below: The production process is as follows: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling.

From supplychainn.blogspot.com

Supplychain Pictures Oracle Steel Making Flow Lines / Steel Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Heating, rolling, and forming of reinforced bar: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling.. Rebar Steel Manufacturing Process.

From www.yokogawa.com

Instruments and Solution for Iron & Steel Industry PDF Yokogawa Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Tmt reinforcement steel manufacturing process is shown below: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Heating, rolling, and forming of reinforced bar:. Rebar Steel Manufacturing Process.

From www.researchgate.net

Steel making process. Download Scientific Diagram Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The process begins with scrap steel being melted in an electric arc furnace, converting solid. Rebar Steel Manufacturing Process.

From www.reddit.com

Comparing Additive Manufacturing Vs Subtractive Manufacturing What Are Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Heating, rolling, and forming of reinforced bar: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Tmt reinforcement steel manufacturing process is shown below: The. Rebar Steel Manufacturing Process.

From stsiholding.com

Steel Rebars STSI Holding Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Heating, rolling, and forming of reinforced bar: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The production process is as follows: Tmt reinforcement steel manufacturing process is shown below: The steel rebar. Rebar Steel Manufacturing Process.

From www.slideshare.net

Manufacturing Process Stainless Clad Rebar Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Tmt reinforcement steel manufacturing process is shown below: Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: Heating, rolling,. Rebar Steel Manufacturing Process.

From allsteelchoices.blogspot.com

Steel Bar Manufacturing Process Steel Choices Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the. Rebar Steel Manufacturing Process.

From steel-manufacturing.cceta.org

Most Incredible Manufacturing Process Of Rebar Steel CCETA Rebar Steel Manufacturing Process Tmt reinforcement steel manufacturing process is shown below: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel rebar are at high temperature when. Rebar Steel Manufacturing Process.

From civilengpro.com

Types of Steel Reinforcement For Construction — Civil Engineering Profile Rebar Steel Manufacturing Process Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel rebar are at high temperature when they leave the last rolling stand. Tmt reinforcement. Rebar Steel Manufacturing Process.

From www.rocheindustry.com

White Paper The Complete Guide To Sheet Metal Fabrication Rebar Steel Manufacturing Process Heating, rolling, and forming of reinforced bar: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: The steel billets are heated to approximately 1200 °c (2192 f). Rebar Steel Manufacturing Process.

From www.slideshare.net

Manufacturing Process Stainless Clad Rebar Rebar Steel Manufacturing Process The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The steel rebar are at high temperature when they leave the last rolling stand. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size. Rebar Steel Manufacturing Process.

From www.pinterest.com

What Are Rebar Couplers Engineering Discoveries Rebar Steel Manufacturing Process Heating, rolling, and forming of reinforced bar: The steel rebar are at high temperature when they leave the last rolling stand. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Tmt reinforcement steel manufacturing process is shown below: The production process is as follows:. Rebar Steel Manufacturing Process.

From www.ccmrolling.com

Rebar/deformed bar production line Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Tmt reinforcement steel manufacturing process is shown below: Heating, rolling, and forming of reinforced bar: The production process is as follows: The steel rebar are at high temperature when they leave the last rolling stand. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into. Rebar Steel Manufacturing Process.

From www.permanentsteel.com

ERW Pipe Manufacturing Process Rebar Steel Manufacturing Process Tmt reinforcement steel manufacturing process is shown below: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The production process is as follows: The steel rebar are at high temperature when they leave the last rolling stand. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement. Rebar Steel Manufacturing Process.

From isteel.in

9 Factors That Construction Bars Manufacturers and Buyers Rebar Steel Manufacturing Process The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Heating, rolling, and forming of reinforced bar: Tmt reinforcement steel manufacturing process is shown below: The process begins with scrap steel being melted in. Rebar Steel Manufacturing Process.

From www.contractorssteel.com

How Is Rebar Made? Contractors Steel Rebar Steel Manufacturing Process The production process is as follows: The steel rebar are at high temperature when they leave the last rolling stand. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The process begins with scrap steel being melted in an electric arc. Rebar Steel Manufacturing Process.

From www.youtube.com

Manufacturing Process Rebar Mass Production Process of Rebar YouTube Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel rebar are at high temperature when they leave the last rolling stand. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282. Rebar Steel Manufacturing Process.

From www.youtube.com

Amazing Manufacturing Process of Rebar Steel in The Factory YouTube Rebar Steel Manufacturing Process The production process is as follows: Heating, rolling, and forming of reinforced bar: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel rebar are at high temperature when they leave the. Rebar Steel Manufacturing Process.

From www.steelsupplylp.com

Tour of Gerdau's Midlothian Steel Mill Steel Supply LP Rebar Steel Manufacturing Process The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into. Rebar Steel Manufacturing Process.

From www.newsteelconstruction.com

An introduction to steelmaking Rebar Steel Manufacturing Process The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The steel rebar are at high temperature when they leave the last rolling stand. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The. Rebar Steel Manufacturing Process.

From www.youtube.com

Amazing Manufacturing Process of 9mm Rebar Iron Rods \\ Production of Rebar Steel Manufacturing Process The steel rebar are at high temperature when they leave the last rolling stand. Heating, rolling, and forming of reinforced bar: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to. Rebar Steel Manufacturing Process.

From www.youtube.com

Rolling Mill Rebar Production Flowchart YouTube Rebar Steel Manufacturing Process The production process is as follows: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The. Rebar Steel Manufacturing Process.

From supplychainn.blogspot.com

Supplychain Pictures Oracle Steel Making Flow Lines / Steel Rebar Steel Manufacturing Process The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Tmt reinforcement steel manufacturing process is shown below: The production process is as follows: Heating, rolling, and forming of reinforced bar: Rebar fabrication refers to the process of cutting, bending, and assembling. Rebar Steel Manufacturing Process.

From www.contractorssteel.com

Contractors Steel Carries Steel Rebar, Including Epoxy Coated Rebar Rebar Steel Manufacturing Process The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The process begins with scrap steel being. Rebar Steel Manufacturing Process.

From www.eurofer.eu

What is steel and how is steel made? Rebar Steel Manufacturing Process Tmt reinforcement steel manufacturing process is shown below: Heating, rolling, and forming of reinforced bar: The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into. Rebar Steel Manufacturing Process.

From ravilakrapgdie42.blogspot.com

Industrial Engineering Design & Process of Steel Bloom Rebar Steel Manufacturing Process Heating, rolling, and forming of reinforced bar: The production process is as follows: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets. Rebar Steel Manufacturing Process.

From vasgroup.vn

Rebar Rebar Steel Manufacturing Process The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282 f) and then rolled to reshape the billets into the final size and. Heating, rolling, and forming of reinforced bar: Tmt reinforcement steel manufacturing process is shown below: Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized.. Rebar Steel Manufacturing Process.

From www.structuralguide.com

Rebar Guide for Design and Construction Structural Guide Rebar Steel Manufacturing Process Heating, rolling, and forming of reinforced bar: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Tmt reinforcement steel manufacturing process is shown below: Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: The steel rebar are at high temperature when they leave the last rolling stand.. Rebar Steel Manufacturing Process.

From metallurgymaterial.blogspot.com

Current Steel Manufacturing Process Metallurgy Materials Rebar Steel Manufacturing Process Heating, rolling, and forming of reinforced bar: The steel rebar are at high temperature when they leave the last rolling stand. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The process begins with scrap steel being melted in an electric arc furnace, converting. Rebar Steel Manufacturing Process.

From www.yangtzesteel.com

ASTM A615 Grade 60 75 HRB 400 600 Deformed Rebar Steel 12 16mm Rebar Rebar Steel Manufacturing Process The steel rebar are at high temperature when they leave the last rolling stand. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The production process is as follows: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The steel billets are heated to approximately 1200 °c (2192 f) to 1250 °c (2282. Rebar Steel Manufacturing Process.

From www.pinterest.com

Amazing Scale! process of mass production of rebar. Korean Steel Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. Tmt reinforcement steel manufacturing process is shown below: The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The steel rebar are at high temperature when they leave the last rolling stand. Heating, rolling, and forming of reinforced bar: The steel billets are. Rebar Steel Manufacturing Process.

From www.youtube.com

Making Rebar From Scrap Metal/How Is Made YouTube Rebar Steel Manufacturing Process The production process is as follows: Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Tmt reinforcement steel manufacturing process is shown below: Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. The steel. Rebar Steel Manufacturing Process.

From www.luoyangsndl.com

Steel Rebar Rolling Mill Production Line Luoyang Shennai Power Rebar Steel Manufacturing Process The steel rebar are at high temperature when they leave the last rolling stand. Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Tmt reinforcement steel manufacturing process is shown below: Rebar fabrication refers to the process of cutting, bending, and assembling. Rebar Steel Manufacturing Process.

From www.steels-supplier.com

Steel Plate and Steel Pipe Production Process Flowchart Rebar Steel Manufacturing Process The steel rebar are at high temperature when they leave the last rolling stand. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. The steel billets are heated to approximately 1200 °c (2192. Rebar Steel Manufacturing Process.

From www.youtube.com

Manufacturing process of Steel Bars Rebar Steel Making Process YouTube Rebar Steel Manufacturing Process Walking heating furnace→rough rolling mill→intermediate rolling mill→finishing rolling. The process begins with scrap steel being melted in an electric arc furnace, converting solid metal into liquid form. Rebar fabrication refers to the process of cutting, bending, and assembling steel reinforcement bars to create customized. Tmt reinforcement steel manufacturing process is shown below: Heating, rolling, and forming of reinforced bar: The. Rebar Steel Manufacturing Process.