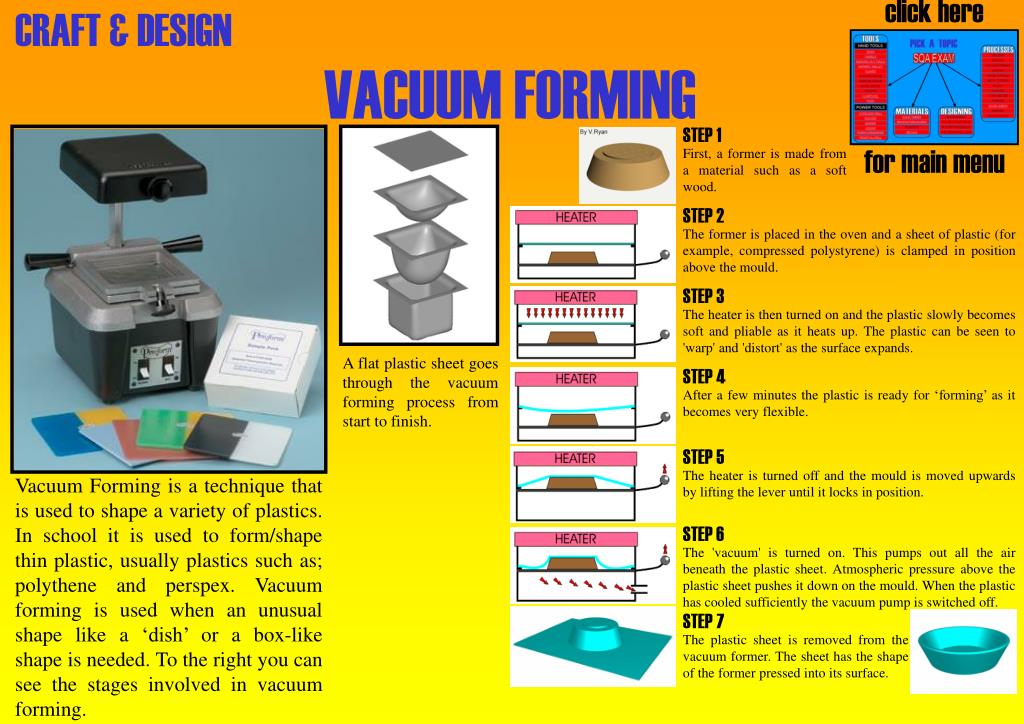

How To Use A Vacuum Former Step By Step . First, a former is made from a material such as a soft wood. A vacuum is then used to suck out the air between the mold and the plastic, causing the. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The first step involves selecting the appropriate type of plastic sheet. Use a vacuum former to rapidly create unique products. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Extruding plastic isn't the only way you can have a.

from www.slideserve.com

Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Use a vacuum former to rapidly create unique products. First, a former is made from a material such as a soft wood. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. Extruding plastic isn't the only way you can have a. The first step involves selecting the appropriate type of plastic sheet. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. A vacuum is then used to suck out the air between the mold and the plastic, causing the.

PPT VACUUM FORMING PowerPoint Presentation, free download ID6902792

How To Use A Vacuum Former Step By Step Extruding plastic isn't the only way you can have a. A vacuum is then used to suck out the air between the mold and the plastic, causing the. Extruding plastic isn't the only way you can have a. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Use a vacuum former to rapidly create unique products. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. First, a former is made from a material such as a soft wood. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. The first step involves selecting the appropriate type of plastic sheet. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms.

From blog.adafruit.com

How to Make a Vacuum Forming Machine « Adafruit Industries Makers How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. A vacuum is then used to suck out the air between the mold and the plastic, causing the. The first step involves selecting the appropriate type of plastic sheet. Extruding plastic isn't the only way you can have a. The edges or sides. How To Use A Vacuum Former Step By Step.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research How To Use A Vacuum Former Step By Step A vacuum is then used to suck out the air between the mold and the plastic, causing the. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. The. How To Use A Vacuum Former Step By Step.

From ja-w-barcelonie.blogspot.com

Diy Vacuum Forming Machine Plans Evelynviolets Woodworking Plans Easy How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms.. How To Use A Vacuum Former Step By Step.

From theprodesigngroup.com

6 Simple Steps to Vacuum Forming The Pro Design Group Gardena, CA How To Use A Vacuum Former Step By Step The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. Vacuum forming,. How To Use A Vacuum Former Step By Step.

From craftvac.com

WHAT IS VACUUM FORMING ? How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. A vacuum. How To Use A Vacuum Former Step By Step.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect How To Use A Vacuum Former Step By Step The first step involves selecting the appropriate type of plastic sheet. A vacuum is then used to suck out the air between the mold and the plastic, causing the. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. The edges or sides are shaped at an angle. How To Use A Vacuum Former Step By Step.

From www.youtube.com

How to Use A Vacuum Former Engineering KS3 Plastic Manufacturing How To Use A Vacuum Former Step By Step A vacuum is then used to suck out the air between the mold and the plastic, causing the. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. First, a former is made from a material such as a soft wood. Use a vacuum former to. How To Use A Vacuum Former Step By Step.

From www.slideshare.net

Vacuum Forming How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. First, a former is made from a material such as a soft wood. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt How To Use A Vacuum Former Step By Step Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. Extruding plastic isn't the only way you can have a. The first step involves selecting the appropriate type of plastic sheet. The edges or sides are shaped at an angle so that when the plastic is. How To Use A Vacuum Former Step By Step.

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. A vacuum is then used to suck out the air between the mold and the plastic, causing. How To Use A Vacuum Former Step By Step.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research How To Use A Vacuum Former Step By Step The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Using a Vacuum Former to Make Molds! Mold Press YouTube How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. A vacuum is then used to suck out the air between the mold and the plastic, causing the. The. How To Use A Vacuum Former Step By Step.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. Extruding plastic isn't the only way you can have a. A vacuum is then used to suck out the air between the mold and the plastic, causing. How To Use A Vacuum Former Step By Step.

From formlabs.com

Introduction to Vacuum Forming How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Use a. How To Use A Vacuum Former Step By Step.

From www.goconqr.com

VACUUM FORMING Mapa Mental How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. The first step involves selecting the appropriate type of plastic sheet. The vacuum forming process involves heating a plastic. How To Use A Vacuum Former Step By Step.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The first step involves selecting the appropriate type of plastic sheet. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. A vacuum is then used to suck out. How To Use A Vacuum Former Step By Step.

From www.pinterest.se

vacuum forming GCSE_Graphics_Packaging Exam revision, Vacuum How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Use a vacuum former to rapidly create unique products. Extruding plastic isn't the only way you can have a. The first step involves selecting the appropriate type of plastic sheet. The vacuum forming process involves heating a plastic sheet until it’s. How To Use A Vacuum Former Step By Step.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics How To Use A Vacuum Former Step By Step The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The first step involves selecting the appropriate type of plastic sheet. A vacuum is then used to. How To Use A Vacuum Former Step By Step.

From www.instructables.com

Vacuum Former 8 Steps (with Pictures) Instructables How To Use A Vacuum Former Step By Step A vacuum is then used to suck out the air between the mold and the plastic, causing the. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. The first step involves selecting the appropriate type of plastic sheet. The vacuum forming process involves heating a. How To Use A Vacuum Former Step By Step.

From makerblock.com

How to Use a Vacuum Former MakerBlock How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. Extruding plastic isn't the only way you can have a. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming,. How To Use A Vacuum Former Step By Step.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. Extruding plastic isn't the only way you can have a. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. The first step involves selecting the appropriate type of plastic sheet.. How To Use A Vacuum Former Step By Step.

From www.youtube.com

How to Make a Larger Vacuum Former I Like To Make Stuff YouTube How To Use A Vacuum Former Step By Step Extruding plastic isn't the only way you can have a. First, a former is made from a material such as a soft wood. Use a vacuum former to rapidly create unique products. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The vacuum forming process involves heating a plastic sheet. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Vacuum Forming With 3D Printed Molds Vacuum Forming Process Step By How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. A vacuum is then used to suck out the air between the mold and the plastic, causing the. Vacuum forming, the simplest thermoforming method, uses vacuum pressure. How To Use A Vacuum Former Step By Step.

From www.youtube.com

How to use a Vacuum Former (SHORT) YouTube How To Use A Vacuum Former Step By Step Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. A vacuum is then used to suck out the air between the mold and the plastic, causing the. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Vacuum Forming Step By Step Guide YouTube How To Use A Vacuum Former Step By Step The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic. How To Use A Vacuum Former Step By Step.

From www.slideshare.net

Vacuum Forming How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into precise, usable forms. The edges or sides are shaped at an angle so that when the plastic is formed over. How To Use A Vacuum Former Step By Step.

From www.youtube.com

The Ultimate DIY Vacuum Former Part 2 YouTube How To Use A Vacuum Former Step By Step The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Use a vacuum former to rapidly create unique products. First, a former is made. How To Use A Vacuum Former Step By Step.

From www.youtube.com

In The Know Machine III Vacuum Forming Process YouTube How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Extruding plastic isn't the only way you can have a. The first step involves selecting the appropriate type of plastic sheet. First, a former is made from a material such as a soft wood. A vacuum is then used to suck. How To Use A Vacuum Former Step By Step.

From formlabs.com

Introduction to Vacuum Forming How To Use A Vacuum Former Step By Step The first step involves selecting the appropriate type of plastic sheet. Extruding plastic isn't the only way you can have a. In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum.. How To Use A Vacuum Former Step By Step.

From www.slideshare.net

Vacuum Forming How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. First, a former is made from a material such as a soft wood. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. The first step involves selecting the appropriate type of plastic sheet. Vacuum forming, also. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY How To Use A Vacuum Former Step By Step Use a vacuum former to rapidly create unique products. The first step involves selecting the appropriate type of plastic sheet. First, a former is made from a material such as a soft wood. A vacuum is then used to suck out the air between the mold and the plastic, causing the. The vacuum forming process involves heating a plastic sheet. How To Use A Vacuum Former Step By Step.

From www.youtube.com

Vacuum forming 01 main process YouTube How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. A vacuum is then used to suck out the air between the mold and the plastic, causing the. Extruding plastic isn't the only way you can have a. The edges or sides are shaped at an angle so that when the. How To Use A Vacuum Former Step By Step.

From www.slideserve.com

PPT VACUUM FORMING PowerPoint Presentation, free download ID6902792 How To Use A Vacuum Former Step By Step Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. First, a former is made from a material such as a soft wood. The first step involves. How To Use A Vacuum Former Step By Step.

From www.youtube.com

How to use a Vacuum Former YouTube How To Use A Vacuum Former Step By Step The edges or sides are shaped at an angle so that when the plastic is formed over it, the former can be removed easily. Extruding plastic isn't the only way you can have a. The vacuum forming process involves heating a plastic sheet until it’s pliable, placing it over a mold, and then using a vacuum. Vacuum forming, also known. How To Use A Vacuum Former Step By Step.

From www.youtube.com

How To Vacuum Form in 3 Easy Steps YouTube How To Use A Vacuum Former Step By Step In essence, it involves heating a plastic sheet until it’s pliable, then draping it over a mold. First, a former is made from a material such as a soft wood. Use a vacuum former to rapidly create unique products. Vacuum forming, also known as thermoforming, is a plastic molding process that leverages heat and vacuum to shape plastic sheets into. How To Use A Vacuum Former Step By Step.