Tool Defect And Possible Remedy . Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. defect management is a process that helps to monitor and manage construction defects. Defects can be the result of errors in drawings,. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. what is equipment failure?

from welding.org.au

utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. what is equipment failure? Defects can be the result of errors in drawings,. defect management is a process that helps to monitor and manage construction defects.

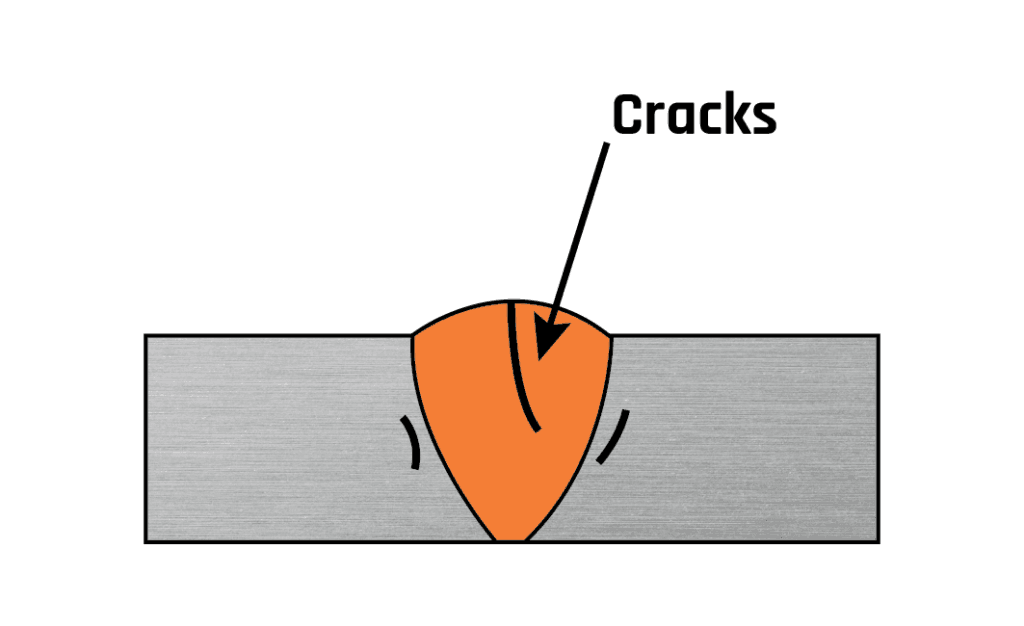

The 7 Most Common Welding Defects, Causes & Remedies Australian

Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. Defects can be the result of errors in drawings,. what is equipment failure? tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. defect management is a process that helps to monitor and manage construction defects. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect.

From www.researchgate.net

Typical defect modes in matched tool forming. Download Scientific Diagram Tool Defect And Possible Remedy Defects can be the result of errors in drawings,. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. what is equipment failure? defect management is a process that helps to monitor and manage construction defects. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate. Tool Defect And Possible Remedy.

From www.youtube.com

Welding defects cause and remedies YouTube Tool Defect And Possible Remedy what is equipment failure? tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. defect management is a process that helps to monitor and manage. Tool Defect And Possible Remedy.

From www.numerade.com

SOLVED 'maintaning tools and equipment patulong po thanks ) ACTVITY 5 Tool Defect And Possible Remedy tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. Defects can be the result of errors in drawings,. defect management is a process that helps to monitor and manage construction defects. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate. Tool Defect And Possible Remedy.

From toolshaunt.com

What is Welding Defects Types, Causes and Remedies? Tools Haunt Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. defect management is a process that helps to monitor and manage construction defects. tools that have historically been used in. Tool Defect And Possible Remedy.

From www.youtube.com

Defects in casting and their Causes & remedies YouTube Tool Defect And Possible Remedy tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. what is equipment failure? Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. utilize diagnostic tools such as remote monitoring and predictive maintenance for. Tool Defect And Possible Remedy.

From www.pinterest.com

12 Defect Checking Tools Every Homeowner Should Know Homeowner Tool Defect And Possible Remedy utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. what is equipment failure? defect management is a process that helps to monitor and manage construction defects. tools that have historically been used in. Tool Defect And Possible Remedy.

From www.theengineerspost.com

12 Types of Defects [Their Causes & Remedies] PDF Tool Defect And Possible Remedy defect management is a process that helps to monitor and manage construction defects. what is equipment failure? utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be the result of errors in. Tool Defect And Possible Remedy.

From mavink.com

Defect Tracking Life Cycle Tool Defect And Possible Remedy what is equipment failure? tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. defect management is a process that helps to monitor and manage construction defects. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their. Tool Defect And Possible Remedy.

From welding.tpub.com

Table 33. Arc Welding Defects, Causes, and Remedies Tool Defect And Possible Remedy Defects can be the result of errors in drawings,. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or. Tool Defect And Possible Remedy.

From pdfslide.net

Defects of Farm Tool and Remedies Tool Defect And Possible Remedy what is equipment failure? utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. defect management is a process that helps to monitor and manage construction defects. Defects can be the result of errors in. Tool Defect And Possible Remedy.

From www.scribd.com

Cline Tool Wear Cause and Remedy Chart PDF Tool Defect And Possible Remedy utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. what is equipment failure? defect management is a process that helps to monitor and manage construction defects. Defects can be. Tool Defect And Possible Remedy.

From jewelrymonk.com

Tool Preparing and Defect Avoidance (Part2) Jewelry Monk Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. defect management is a process that helps to monitor and manage construction defects. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. tools that have historically been used in. Tool Defect And Possible Remedy.

From www.numerade.com

SOLVED ACTIVITY SHEET 1.41 Directions Using the given table below Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses,. Tool Defect And Possible Remedy.

From www.aiophotoz.com

19 Common Types Of Welding Defectscauses And Remedies Images and Tool Defect And Possible Remedy what is equipment failure? Defects can be the result of errors in drawings,. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear. Tool Defect And Possible Remedy.

From hygger.io

Defect Management Tools Tool Defect And Possible Remedy what is equipment failure? Defects can be the result of errors in drawings,. defect management is a process that helps to monitor and manage construction defects. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tools that have historically been used in support of planned maintenance to find defects that are hidden. Tool Defect And Possible Remedy.

From www.vrogue.co

19 Common Types Of Welding Defectscauses Remedies vrogue.co Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. what is equipment failure? defect management is a process that helps to monitor and manage construction defects. Defects can be the result of errors in drawings,. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate. Tool Defect And Possible Remedy.

From www.youtube.com

TLE 7 QUARTER 3 LESSON 1CHECK FARM TOOLS FOR FAULTS AND DEFECTS IN Tool Defect And Possible Remedy defect management is a process that helps to monitor and manage construction defects. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers. Tool Defect And Possible Remedy.

From www.semanticscholar.org

Defects, Causes and Their Remedies in Casting Process A Review Tool Defect And Possible Remedy tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be the result of errors in drawings,. what is equipment failure? tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. utilize diagnostic. Tool Defect And Possible Remedy.

From ahssinsights.org

Tooling and Die Wear AHSS Guidelines Tool Defect And Possible Remedy tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be the result of errors in drawings,. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. utilize diagnostic tools such as remote monitoring. Tool Defect And Possible Remedy.

From www.youtube.com

Broken Gardening Tool Restoration YouTube Tool Defect And Possible Remedy tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. Defects can be the result of errors in drawings,. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. defect management is a process that helps. Tool Defect And Possible Remedy.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Tool Defect And Possible Remedy defect management is a process that helps to monitor and manage construction defects. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or. Tool Defect And Possible Remedy.

From www.harveyperformance.com

Tool Deflection & Its Remedies In The Loupe Tool Defect And Possible Remedy what is equipment failure? tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. Defects can be the result of errors in drawings,. utilize diagnostic tools such as remote monitoring. Tool Defect And Possible Remedy.

From www.scribd.com

317349520DefectsofFarmToolandRemedies.docx Farmworker Tool Defect And Possible Remedy what is equipment failure? defect management is a process that helps to monitor and manage construction defects. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses,. Tool Defect And Possible Remedy.

From www.youtube.com

Welding defects and their Remedies YouTube Tool Defect And Possible Remedy what is equipment failure? tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. defect management is a process that helps to monitor and manage construction defects. tools that. Tool Defect And Possible Remedy.

From hsseworld.com

Defective Tools Safe Work PracticePhoto of today HSSE WORLD Tool Defect And Possible Remedy what is equipment failure? Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. defect management is a process that helps to monitor and manage construction defects. Defects can be the result of errors in drawings,. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate. Tool Defect And Possible Remedy.

From www.educba.com

Defect Tracking Tools List of Popular Defect Tracking Tools With Features Tool Defect And Possible Remedy tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. what is equipment failure? utilize diagnostic tools such as remote monitoring and predictive maintenance for. Tool Defect And Possible Remedy.

From www.pinterest.jp

Process Defects Types of Defects Defects Tool Defect And Possible Remedy tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. defect management is a process that helps to monitor and manage construction defects. what is equipment failure? Equipment failure refers to the malfunction, breakdown, or. Tool Defect And Possible Remedy.

From welding.org.au

The 7 Most Common Welding Defects, Causes & Remedies Australian Tool Defect And Possible Remedy what is equipment failure? tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be the result of errors in drawings,. utilize diagnostic. Tool Defect And Possible Remedy.

From www.scribd.com

Design Analysis and Overview of Press Tool With Its Defects and Tool Defect And Possible Remedy utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. Defects can be the result of errors in drawings,. defect management is a process that helps to monitor and manage construction defects. tools that have. Tool Defect And Possible Remedy.

From www.numerade.com

SOLVED tool defect and possible remedy Tool Defect And Possible Remedy tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. defect management is a process that helps to monitor and manage construction defects. what is equipment failure? utilize diagnostic. Tool Defect And Possible Remedy.

From www.vrogue.co

What Is Welding Defects Types Causes And Remedies Too vrogue.co Tool Defect And Possible Remedy Equipment failure refers to the malfunction, breakdown, or inability of machinery, tools, or devices to perform their intended function. Defects can be the result of errors in drawings,. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of. Tool Defect And Possible Remedy.

From trackssno.weebly.com

Welding defects causes and remedies pdf trackssno Tool Defect And Possible Remedy utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be. Tool Defect And Possible Remedy.

From brainly.ph

Activity 4 Maintaining Tools and Equipment Directions Using the given Tool Defect And Possible Remedy defect management is a process that helps to monitor and manage construction defects. Defects can be the result of errors in drawings,. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. utilize diagnostic tools such as remote monitoring and predictive maintenance for accurate defect. Equipment failure refers to. Tool Defect And Possible Remedy.

From www.scribd.com

Defects & Remedies of Farm Tools PDF Tool Defect And Possible Remedy Defects can be the result of errors in drawings,. tools that have historically been used in support of planned maintenance to find defects that are hidden from the human senses, can also. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. what is equipment failure? utilize diagnostic. Tool Defect And Possible Remedy.

From www.vrogue.co

What Is Welding Defects Types Causes And Remedies Too vrogue.co Tool Defect And Possible Remedy what is equipment failure? defect management is a process that helps to monitor and manage construction defects. tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to. Defects can be the result of errors in drawings,. tools that have historically been used in support of planned maintenance to. Tool Defect And Possible Remedy.