Molding Wire Cutter . tungsten wire exists for wire cutting because it is a hard and tough electrode. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. This article explores the applications in which wire edm has found its way. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. moldmaking using wire edm. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. The high tensile strength makes it useful for.

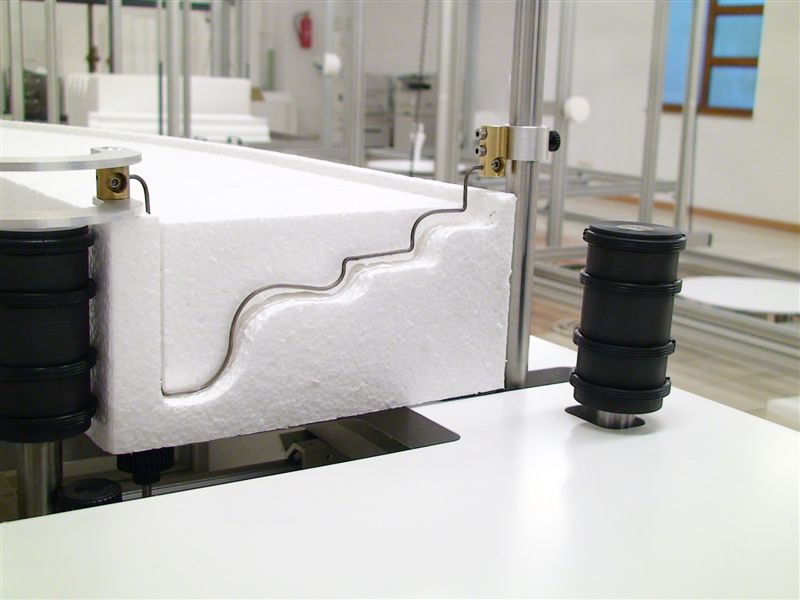

from hotwiresystems.com

This article explores the applications in which wire edm has found its way. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. moldmaking using wire edm. The high tensile strength makes it useful for. tungsten wire exists for wire cutting because it is a hard and tough electrode. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire.

Hot wire CNC foam cutting machines Base & Arch Cutter

Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. tungsten wire exists for wire cutting because it is a hard and tough electrode. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. This article explores the applications in which wire edm has found its way. moldmaking using wire edm. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength makes it useful for. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed.

From hotwiresystems.com

Hot wire CNC foam cutting machines Base & Arch Cutter Molding Wire Cutter This article explores the applications in which wire edm has found its way. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. in mold making process, wire cutting is widely used for making. Molding Wire Cutter.

From www.venmarkinternational.com

HARD WIRE CUTTER CUTS BOTH ENDS PERFECTLY SQUARE Venmark International Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. The high tensile strength makes it useful for. moldmaking using wire edm. This article explores the applications in which wire edm has found its way. At present, many molds are processed by fast wire cutting machine, and the surface roughness. Molding Wire Cutter.

From www.youtube.com

Using this new hot wire EPS foam molding and shape cutter YouTube Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength makes it useful for. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. This article explores the applications in which wire edm has found its. Molding Wire Cutter.

From www.lupon.gov.ph

Wirecutter Electric Chainsaw lupon.gov.ph Molding Wire Cutter The high tensile strength makes it useful for. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. This article explores the applications in which wire edm has found its way. in mold making. Molding Wire Cutter.

From www.ht-instruments.com

220/170, 1000V Insulated cutting tools , For copper and aluminium Molding Wire Cutter This article explores the applications in which wire edm has found its way. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. moldmaking using wire edm. the. Molding Wire Cutter.

From lunatools.com

MOULDING CUTTER 29 MM Luna tools Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. At present, many molds are processed. Molding Wire Cutter.

From www.amazon.co.uk

Precision Wire Cutter, Boenfu 150mm Length Diagonal Side Cutter Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength makes it useful for. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. using a dielectric solution to control the electrical discharge and applying. Molding Wire Cutter.

From www.sears.com

Wire Cutter 4 1/2" Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. tungsten wire exists for wire cutting because it is a hard and tough electrode. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength. Molding Wire Cutter.

From german-hand-tools.com

NWS Wire Cutters Page 2 Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. This article explores the applications in which wire edm has found its way. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. using a dielectric solution to control. Molding Wire Cutter.

From www.dxengineering.com

Gripple CUTTER14 Gripple Large Cable Cutters DX Engineering Molding Wire Cutter the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. This article explores the applications in which wire edm has found its way. moldmaking using wire edm. in mold making process, wire cutting. Molding Wire Cutter.

From www.walmart.com

Diagonal Cutting Plier 5Inch Precision Wire Side Cutter Molding Wire Cutter the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. The high tensile strength makes it useful for. tungsten wire exists for wire cutting because it is a hard and tough electrode. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece. Molding Wire Cutter.

From www.aliexpress.com

45 120 Deg Multi Angle Mitre Electric Automatic Trunking Scissor Wire Molding Wire Cutter tungsten wire exists for wire cutting because it is a hard and tough electrode. moldmaking using wire edm. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core. Molding Wire Cutter.

From thisandthatframing.com

いたしませ Klein Tools 63028 Cable Cutter, Coaxial Cable Cutter cuts up to 3 Molding Wire Cutter moldmaking using wire edm. This article explores the applications in which wire edm has found its way. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. tungsten wire exists for wire cutting because it is a hard and tough electrode. the wire edm cutting process involves several. Molding Wire Cutter.

From diyguidance.com

5 Best Wire Cutters for Electricians & DIY Workers Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. moldmaking using wire edm. This article explores the applications in which wire edm has found its way. The high tensile strength makes it useful for. At present, many molds are processed by fast wire cutting machine, and the surface roughness. Molding Wire Cutter.

From jonard.com

Copper COAX & Network Cable Cutter Jonard Tools Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. The high tensile strength makes it useful for. using a dielectric solution to control the electrical discharge and applying. Molding Wire Cutter.

From www.gtglass.com

Universal Molding Cutter GT Tools® Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. This article explores the applications in which wire edm has found its way. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. tungsten wire exists for wire. Molding Wire Cutter.

From rhinotools.com.au

Copper Cable Cutters Rhino Electricians Tools Molding Wire Cutter moldmaking using wire edm. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. tungsten wire exists for wire cutting because it is a hard and tough electrode. in mold. Molding Wire Cutter.

From www.jbee.biz

JB6610HD Heavy Duty Molding cutter DEMO J Bee Enterprises Molding Wire Cutter At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. . Molding Wire Cutter.

From www.steris-ims-instruments.com

Compound Action Large Wire Cutter To Cut 5.5mm Dia Max With Tungsten Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. This article explores the applications in which wire edm has found its way. tungsten wire exists for wire cutting because it is a hard and tough electrode. At present, many molds are processed by fast wire cutting machine, and the. Molding Wire Cutter.

From texbrite.com

4inchMoldingCutter.Det Molding Wire Cutter This article explores the applications in which wire edm has found its way. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. The high tensile strength makes it useful for. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. . Molding Wire Cutter.

From www.gtglass.com

Universal Molding Cutter GT Tools® Molding Wire Cutter tungsten wire exists for wire cutting because it is a hard and tough electrode. The high tensile strength makes it useful for. This article explores the applications in which wire edm has found its way. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. in mold making process,. Molding Wire Cutter.

From fazziosurplus.com

Remote Hydraulic Wire Cutter Joseph Fazzio, Incorporated Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. moldmaking using wire edm. This article explores the applications in which wire edm has found its way. tungsten wire exists for wire cutting because it is a hard and tough electrode. At present, many molds are. Molding Wire Cutter.

From www.lowes.com

CRAFTSMAN Wire Cutter/Stripper at Molding Wire Cutter moldmaking using wire edm. The high tensile strength makes it useful for. tungsten wire exists for wire cutting because it is a hard and tough electrode. This article explores the applications in which wire edm has found its way. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. . Molding Wire Cutter.

From www.parts-express.com

91/4" Large Gauge Wire & Cable Cutter Molding Wire Cutter At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. moldmaking using wire edm. The high tensile strength makes it useful for. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. using a dielectric solution to control. Molding Wire Cutter.

From www.desertcart.co.il

Buy Miter Cutter 45 to 135 Degree Multi Angle Miter Shear Cutter Soft Molding Wire Cutter This article explores the applications in which wire edm has found its way. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. moldmaking using wire edm. using a dielectric solution to control. Molding Wire Cutter.

From alexnld.com

Drillpro 10 Piece 1/2 Inch Shank Architectural Molding Router Bit Set Molding Wire Cutter The high tensile strength makes it useful for. tungsten wire exists for wire cutting because it is a hard and tough electrode. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. This article explores the applications in which wire edm has found its way. the wire edm cutting. Molding Wire Cutter.

From www.ebay.com

Cable Cutter Cut Up To 35mm2 Wire Cutter NEW! for sale online Molding Wire Cutter moldmaking using wire edm. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. tungsten wire exists for wire cutting because it is a hard and tough electrode. This article explores the applications in which wire edm has found its way. At present, many molds are. Molding Wire Cutter.

From www.wehomachinery.com

top quality Four cutter planer industrial wood molding machine suppliers Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. The high tensile strength makes it useful for. At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. This article explores the applications in which wire edm has found its way. tungsten. Molding Wire Cutter.

From www.german-hand-tools.com

NWS Wire Cutters Molding Wire Cutter using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. tungsten wire exists for wire cutting because it is a hard and tough electrode. The high tensile strength makes it useful for. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion,. Molding Wire Cutter.

From www.jbee.biz

JB6610 Miter Master Extra Large Capacity Cutter Made in Germany J Bee Molding Wire Cutter This article explores the applications in which wire edm has found its way. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength makes it useful for. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut. Molding Wire Cutter.

From www.orthotechnology.com

Hard Wire Cutter Ortho Technology Molding Wire Cutter This article explores the applications in which wire edm has found its way. moldmaking using wire edm. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. tungsten wire exists for wire cutting because it is a hard and tough electrode. The high tensile strength makes it useful. Molding Wire Cutter.

From www.german-hand-tools.com

NWS Wire Cutters Molding Wire Cutter in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. The high tensile strength makes it useful for. moldmaking using wire edm. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed. At present, many molds are processed. Molding Wire Cutter.

From www.artnews.com

Best Art Wire Cutters for Sculpture and More Molding Wire Cutter the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a. Molding Wire Cutter.

From www.hillarysboatshop.com.au

Wire Cutter 530mm T/S 8.0mm Max Dia Swaging Tools and Wire Cutters Molding Wire Cutter At present, many molds are processed by fast wire cutting machine, and the surface roughness of workpiece after. the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,.. Molding Wire Cutter.

From www.kleintools.com

Compact Cable Cutter 63055 Klein Tools For Professionals since 1857 Molding Wire Cutter the wire edm cutting process involves several key steps, including setup, flushing and die sinking, spark erosion, and wire. in mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes,. This article explores the applications in which wire edm has found its way. The high tensile strength makes. Molding Wire Cutter.