Gear Sliding Velocity . The direction of the sliding velocity. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. Gear rolling & sliding velocity. The velocity of point q , considered as a point on wheel. It is influenced by the. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll.

from www.slideserve.com

Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. It is influenced by the. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. The direction of the sliding velocity. The velocity of point q , considered as a point on wheel. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear rolling & sliding velocity. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as:

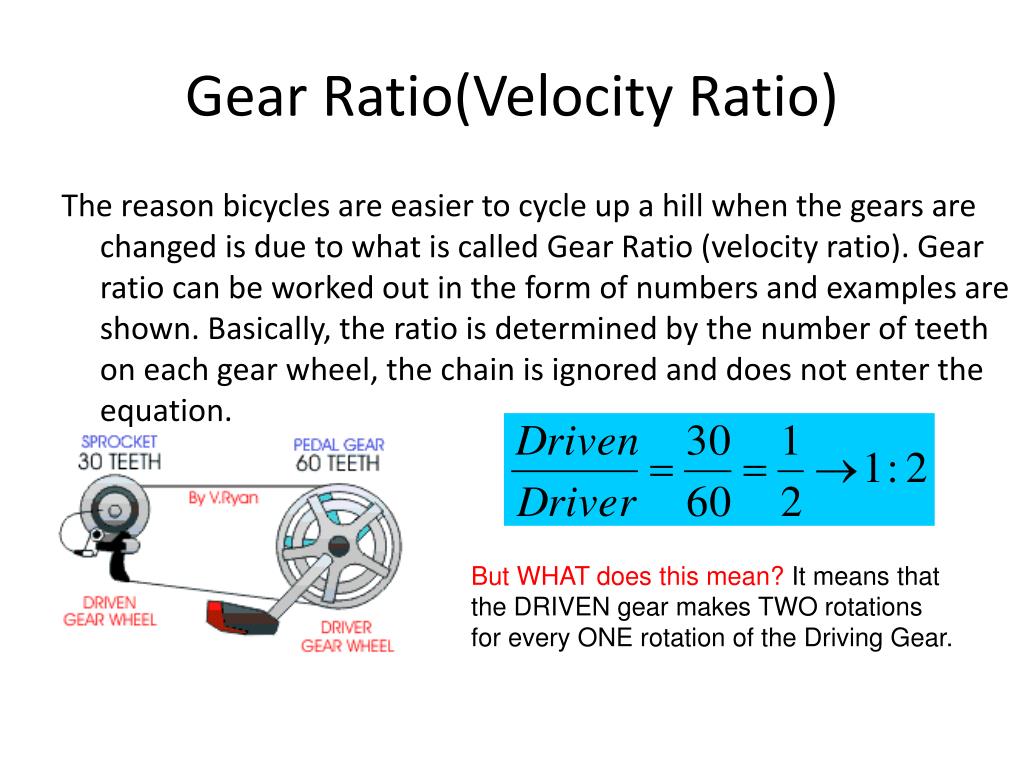

PPT Gears and Gear Ratios PowerPoint Presentation, free download ID

Gear Sliding Velocity The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The velocity of point q , considered as a point on wheel. Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. The direction of the sliding velocity. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. Gear rolling & sliding velocity. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. It is influenced by the.

From www.youtube.com

velocity of sliding in gear YouTube Gear Sliding Velocity Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The direction of the. Gear Sliding Velocity.

From www.youtube.com

Velocity Ratio of Gear Drive YouTube Gear Sliding Velocity The velocity of point q , considered as a point on wheel. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: Gear tooth sliding velocity is defined as a difference. Gear Sliding Velocity.

From www.youtube.com

GEARSNUMERICAL ON GEARS Contact Ratio, Angle of Action, Sliding Gear Sliding Velocity The direction of the sliding velocity. It is influenced by the. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. Gear rolling & sliding velocity. The velocity of sliding is the velocity of one tooth. Gear Sliding Velocity.

From www.youtube.com

Simple gear train / Velocity ratio of simple gear train / How to Gear Sliding Velocity The direction of the sliding velocity. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path. Gear Sliding Velocity.

From www.researchgate.net

Sliding velocity and sum of velocity along the path of contact of the Gear Sliding Velocity Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. The velocity of point q , considered as. Gear Sliding Velocity.

From www.chegg.com

Solved 15.49 The outer gear C rotates with an angular Gear Sliding Velocity This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. The velocity of point q , considered as a point on wheel. The direction. Gear Sliding Velocity.

From www.slideserve.com

PPT Gears ‘n stuff Angular Velocity PowerPoint Presentation, free Gear Sliding Velocity Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The direction of the sliding velocity. The sliding and rolling velocities move the profile contact from the. Gear Sliding Velocity.

From www.researchgate.net

Sliding velocity of the shaving cutter and work gear Download Gear Sliding Velocity It is influenced by the. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. Gear tooth sliding velocity is. Gear Sliding Velocity.

From mechanicalenotes.com

Sliding Mesh Gearbox Components, Working, Advantages, Disadvantages Gear Sliding Velocity Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. Gear rolling & sliding velocity. Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. The sliding and rolling velocities move the profile contact from. Gear Sliding Velocity.

From www.youtube.com

Velocity of sliding in gear engagement YouTube Gear Sliding Velocity Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear rolling & sliding velocity. The direction of the sliding velocity. Sliding velocity is the relative velocity in a transverse plane of. Gear Sliding Velocity.

From www.tec-science.com

Engaging of involute gears (meshing) tecscience Gear Sliding Velocity It is influenced by the. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear rolling & sliding velocity. Figure 4 shows the sliding and. Gear Sliding Velocity.

From www.tec-science.com

Engaging of involute gears (meshing) tecscience Gear Sliding Velocity Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. It is influenced by the. Sliding velocity is the relative velocity in a transverse. Gear Sliding Velocity.

From www.researchgate.net

a) Shows the sliding velocity (V slide ), rolling velocity (V roll Gear Sliding Velocity This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The sliding and rolling velocities move the profile contact from the top of the gear tooth. Gear Sliding Velocity.

From www.pinterest.com

What is Sliding Mesh Gearbox? How different speeds of gears like first Gear Sliding Velocity It is influenced by the. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. The direction of the sliding velocity. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Sliding velocity is the relative velocity in a transverse plane of. Gear Sliding Velocity.

From www.researchgate.net

Combination of sliding and rolling in gear teeth and worthy contacting Gear Sliding Velocity The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. The velocity of sliding is the velocity of one tooth relative to its mating. Gear Sliding Velocity.

From www.youtube.com

Sliding mesh gear box YouTube Gear Sliding Velocity Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. It is influenced by the. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. Gear rolling & sliding velocity. Gear tooth sliding velocity is. Gear Sliding Velocity.

From www.chegg.com

Solved 1662. If the gear rotates with an angular velocity Gear Sliding Velocity Gear rolling & sliding velocity. The direction of the sliding velocity. It is influenced by the. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: This study investigated the development. Gear Sliding Velocity.

From www.researchgate.net

(PDF) Sliding velocity in profile corrected gears Gear Sliding Velocity The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. The direction of the sliding velocity. Sliding velocity is the relative velocity in a transverse plane of a common contact. Gear Sliding Velocity.

From www.slideserve.com

PPT Simple Machines Gears, Velocity Ratios and Mechanical Advantage Gear Sliding Velocity The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point. Gear Sliding Velocity.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Gear Sliding Velocity The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The velocity of point q , considered as a point on wheel. Gear rolling & sliding velocity. This study investigated the development of material loss along the face and flank regions of the gear tooth, with. Gear Sliding Velocity.

From www.artofit.org

Understanding gear ratios Artofit Gear Sliding Velocity Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Figure 4 shows the sliding and. Gear Sliding Velocity.

From www.slideshare.net

Gear Gear Sliding Velocity This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Gear rolling & sliding velocity. The velocity of point q , considered as a point on wheel. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the. Gear Sliding Velocity.

From www.numerade.com

SOLVED A gear reduction system 10 points consists of three gears, A, B Gear Sliding Velocity The direction of the sliding velocity. The velocity of point q , considered as a point on wheel. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Gear tooth sliding velocity is defined as a difference. Gear Sliding Velocity.

From www.youtube.com

Sliding mesh gearbox How Gearbox works Construction and Operation Gear Sliding Velocity Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. It is influenced by the. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. This study investigated the development. Gear Sliding Velocity.

From www.youtube.com

5.[IN HINDI]VELOCITY OF SLIDING OF TEETH(SLIDING VELOCITY OF GEAR)KOM Gear Sliding Velocity Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point.. Gear Sliding Velocity.

From www.youtube.com

Gear Basics and Relations Velocity Ratio Example 2 YouTube Gear Sliding Velocity The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The velocity of point q , considered as a point on wheel. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear rolling & sliding. Gear Sliding Velocity.

From www.slideserve.com

PPT Term 3 Topic 3 Unit 1 Mechanical systems & control (machines Gear Sliding Velocity The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. It is influenced by the. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each. Gear Sliding Velocity.

From www.coursehero.com

[Solved] A pair of gears having 40 and 20 teeth respectively is Gear Sliding Velocity It is influenced by the. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The velocity of point q , considered as a point on wheel. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: Figure 4 shows the sliding and. Gear Sliding Velocity.

From www.chegg.com

Solved 1669. If the gear rotates with an angular velocity Gear Sliding Velocity The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Gear rolling & sliding velocity. The direction of the sliding velocity. Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. This study investigated the development of material loss along the. Gear Sliding Velocity.

From www.researchgate.net

Example of the dependence of the sliding velocity of the regulated thin Gear Sliding Velocity Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. The. Gear Sliding Velocity.

From www.tec-science.com

How does a threespeed gear hub work? tecscience Gear Sliding Velocity Gear rolling & sliding velocity. Gear tooth sliding velocity is defined as a difference between rolling velocities of teeth in mesh. The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Sliding velocity is the relative velocity in a transverse plane of a common contact point between mating gear teeth.. Gear Sliding Velocity.

From www.researchgate.net

Gear mesh geometry for specific sliding calculation (Abderazek et al Gear Sliding Velocity The direction of the sliding velocity. This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: Gear rolling & sliding velocity. The sliding and rolling velocities move the profile contact from the top of the gear tooth. Gear Sliding Velocity.

From www.slideserve.com

PPT Gears and Gear Ratios PowerPoint Presentation, free download ID Gear Sliding Velocity The sliding and rolling velocities move the profile contact from the top of the gear tooth to the pitch point. Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. It is influenced by the. The velocity of point q , considered as a point on wheel. The velocity of sliding is. Gear Sliding Velocity.

From www.researchgate.net

Sliding velocity of the shaving cutter and work gear Download Gear Sliding Velocity Figure 4 shows the sliding and rolling velocity vectors of a typical zerol gear set for each path of contact point for the 10 discussed roll. It is influenced by the. The velocity of sliding is the velocity of one tooth relative to its mating tooth along the common tangent at the point of contact. The velocity of point q. Gear Sliding Velocity.

From www.youtube.com

VELOCITY OF SLIDING IN GEAR FACE PROBLEM(SOLVED) YouTube Gear Sliding Velocity Sliding friction loss is an increase in power consumption, where the magnitude depends on the point of contact. It is influenced by the. Sliding velocity is the relative tangential velocity of the tooth profiles, calculated as: This study investigated the development of material loss along the face and flank regions of the gear tooth, with detailed. The sliding and rolling. Gear Sliding Velocity.