A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done . discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. fault detection and diagnosis is a key component of many operations management automation systems. (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing.

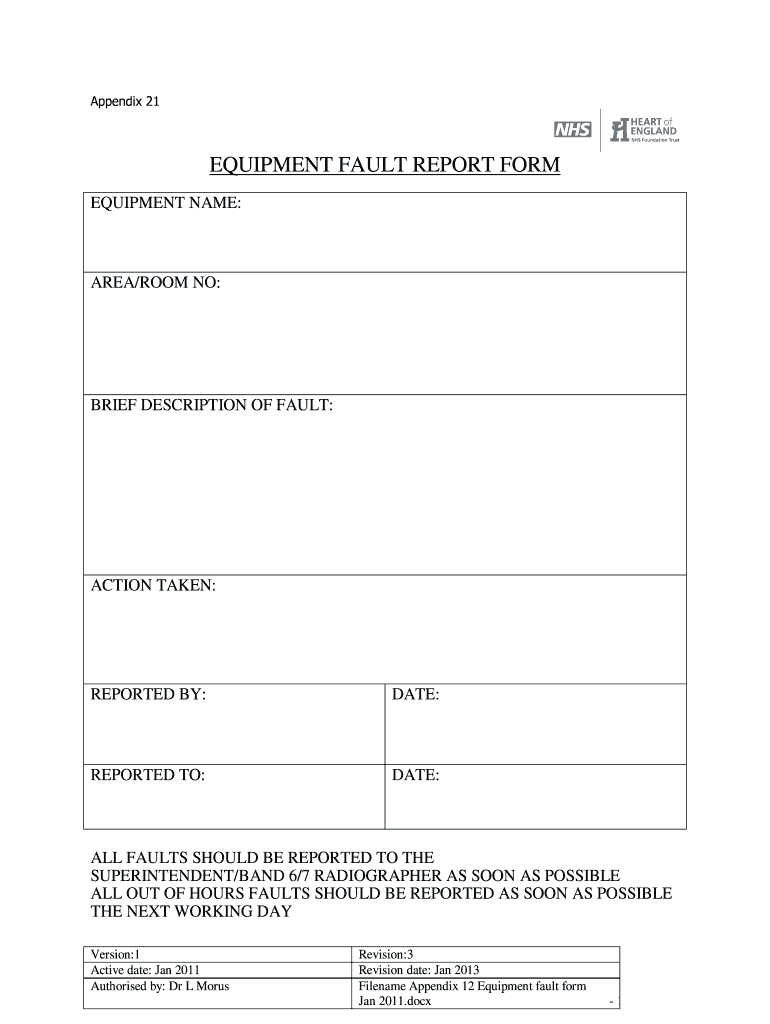

from www.pdffiller.com

maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. diagnostic process for all type of equipment are: fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection (3). — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance.

Fault Report Template Fill Online, Printable, Fillable, Blank pdfFiller

A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection (3). fault detection and diagnosis is a key component of many operations management automation systems. diagnostic process for all type of equipment are:

From www.mdpi.com

Advances in Machine Fault Diagnosis MDPI Books A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises,. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From manualzz.com

DIAGNOSTIC AND FAULT CODES Manualzz A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From docs.oracle.com

Diagnostics Process SPARC T58 Server Service Manual A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. maintenance troubleshooting is the systematic. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Flowchart for fault detection and localization Download Scientific A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

The flowchart of fault diagnosis Download Scientific Diagram A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. fault detection and diagnosis is a key component of many operations management automation systems. diagnostic process for all type of equipment are: — key indicators of equipment defects include abnormal noises, vibrations, leaks, and. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From content.iospress.com

A simulation model based fault diagnosis method for bearings IOS Press A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection (3). maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.youtube.com

How to diagnose electrical faults with ease using the Power Probe A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. (1) symptom analysis (2) equipment inspection (3). fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Intelligent fault diagnosis framework based on DSF. Download A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. diagnostic process for all type of equipment are: fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.metertrac.com.au

MeterTrac Motor Fault Diagnosis & Protection Systems A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.youtube.com

How To Diagnose A Faulty ECU and Make it Workable Again !! YouTube A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. (1) symptom analysis (2) equipment inspection (3). — key. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.slideshare.net

Advanced automotive fault diagnosis tom denton A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom analysis (2) equipment inspection (3). fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Flow chart of the proposed fault diagnosis method. Download A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. diagnostic process for all type of equipment are: (1) symptom. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.youtube.com

Land Rover Suspension Fault Diagnose & Reset Diagnostic Tool YouTube A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. maintenance troubleshooting is the systematic process of identifying and addressing issues in. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Flowchart of fault diagnosis. Download Scientific Diagram A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. (1) symptom analysis. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.slideserve.com

PPT CH08 Testing the Programs PowerPoint Presentation, free download A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. diagnostic process for all type of equipment are: fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

General framework for fault detection methodology. Download A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. fault detection. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Classification of fault diagnostic methods. Download Scientific Diagram A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. fault detection and diagnosis is a key component of many operations management automation. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From allautos.com.au

Diagnostics Fault Finding Allautos A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. (1) symptom analysis (2) equipment inspection (3). diagnostic process for. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From issuu.com

The Benefits of Implementing a Fault Detection and Diagnosis System in A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done (1) symptom analysis (2) equipment inspection (3). fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. diagnostic process for all type of equipment are: maintenance troubleshooting is the systematic process of identifying and addressing issues in. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.mdpi.com

Applied Sciences Free FullText RollingElement Bearing Fault A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. diagnostic process for all type of equipment are: maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. discovering. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.slideshare.net

Fault diagnosis of bearing A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From mungfali.com

Fault Finding Flow Chart A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. diagnostic process for all type of equipment are: fault detection and diagnosis. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.youtube.com

Diagnostic Assistance Search Fault Code YouTube A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From es.slideshare.net

Advanced automotive fault diagnosis tom denton A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done fault detection and diagnosis is a key component of many operations management automation systems. (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. maintenance troubleshooting is the systematic. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Structure of the proposed fault diagnostic system. Download A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: (1) symptom analysis (2) equipment inspection (3). — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of many operations management automation systems. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.henankeda.com

Diagnosing faults in automatic transmission How a Car Works A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: fault detection and diagnosis is a key component of many operations management automation systems. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.crossco.com

How To Decrease Equipment Energy Consumption Cross Company A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.pdffiller.com

Fault Report Template Fill Online, Printable, Fillable, Blank pdfFiller A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: (1) symptom analysis (2) equipment inspection (3). maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. fault detection and diagnosis is a key component of. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Simplified scheme for the explanation of the fault diagnosis part A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done fault detection and diagnosis is a key component of many operations management automation systems. maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.swiftsparks.com

Equipment Fault Report Template PROFESSIONAL TEMPLATES PROFESSIONAL A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. maintenance troubleshooting is the. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.gorsmith.co.uk

Testing & Inspections GorSmith Electrical A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: — key. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From excellencebiomedicalengineering.blogspot.com

EXCELLENCE BIOMEDICAL ENGINEERING Fault Finding on Medical Devices A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. fault detection and diagnosis is a key component of many operations management automation systems. diagnostic process for all type of equipment are: discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.slideserve.com

PPT Datadriven Methods for Monitoring, Fault Diagnosis, Control and A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done (1) symptom analysis (2) equipment inspection (3). diagnostic process for all type of equipment are: maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. discovering and diagnosing faults successfully requires common sense, awareness,. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From psychometric-success.com

Sample Fault Diagnosis Tests A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done diagnostic process for all type of equipment are: (1) symptom analysis (2) equipment inspection (3). fault detection and diagnosis is a key component of many operations management automation systems. — key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. maintenance troubleshooting is the systematic process of identifying and addressing issues in. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.

From www.researchgate.net

Flowchart of the proposed fault diagnosis method. Download Scientific A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done (1) symptom analysis (2) equipment inspection (3). discovering and diagnosing faults successfully requires common sense, awareness, and knowledge of how the equipment operates, as well as applying a logical. diagnostic process for all type of equipment are: maintenance troubleshooting is the systematic process of identifying and addressing issues in faulty components and systems, employing. fault detection. A Fault Is Found With A Piece Of Diagnostic Equipment. What Needs To Be Done.