List Of Raw Material Requirements . Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. 92 examples of raw materials. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Monitor current levels of raw materials and components on hand. Effective bom management is crucial for. The mrp process follows three main steps: Precise list of all the raw materials needed to create a product, including quantities and instructions. A bom essentially provides a. Identify when materials need to be replenished in order to meet.

from www.slideserve.com

Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production. Precise list of all the raw materials needed to create a product, including quantities and instructions. A bom essentially provides a. Identify when materials need to be replenished in order to meet. 92 examples of raw materials. Effective bom management is crucial for. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. A raw material is a relatively unprocessed material that is a basic economic input.

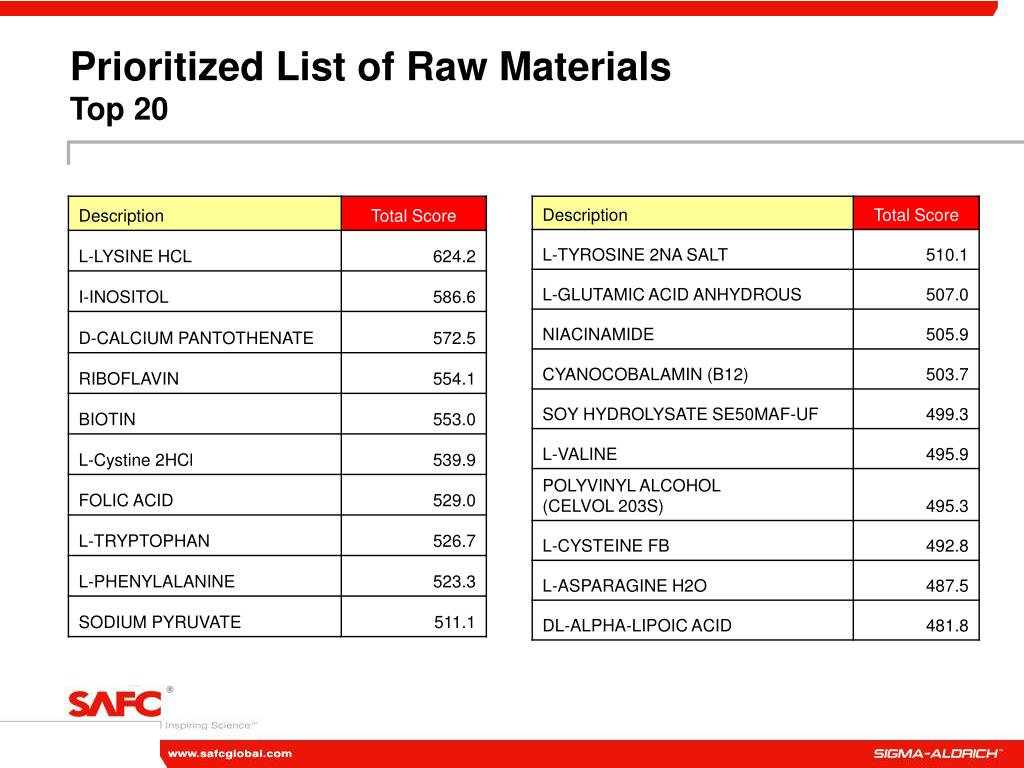

PPT SAFC Biosciences Raw Materials Characterization Initiative

List Of Raw Material Requirements Monitor current levels of raw materials and components on hand. A raw material is a relatively unprocessed material that is a basic economic input. 92 examples of raw materials. Monitor current levels of raw materials and components on hand. Effective bom management is crucial for. The mrp process follows three main steps: Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Precise list of all the raw materials needed to create a product, including quantities and instructions. Identify when materials need to be replenished in order to meet. Mrp converts the master schedule of production. A bom essentially provides a. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product.

From www.deskera.com

Raw Materials Inventory Management Guide List Of Raw Material Requirements Effective bom management is crucial for. A raw material is a relatively unprocessed material that is a basic economic input. Precise list of all the raw materials needed to create a product, including quantities and instructions. Monitor current levels of raw materials and components on hand. Material requirements planning (mrp) is a planning and control system for inventory, production, and. List Of Raw Material Requirements.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide List Of Raw Material Requirements A raw material is a relatively unprocessed material that is a basic economic input. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. The mrp process follows three main steps: 92 examples of raw materials. Precise list of all the raw materials needed to create a product, including. List Of Raw Material Requirements.

From www.slideserve.com

PPT CHAPTER 5 OPERATIONS MANAGEMENT PowerPoint Presentation, free List Of Raw Material Requirements Effective bom management is crucial for. Monitor current levels of raw materials and components on hand. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Mrp converts the master schedule of production. Identify when materials need to be replenished in order to meet. 92 examples of raw materials.. List Of Raw Material Requirements.

From www.slideserve.com

PPT Source of Raw Material PowerPoint Presentation, free download List Of Raw Material Requirements A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Monitor current levels of raw materials and components on hand. Identify when materials need to be replenished in order to meet. The mrp process. List Of Raw Material Requirements.

From www.pinterest.com

Raw material list at Pottery club Raw materials, Pottery, Mineral stone List Of Raw Material Requirements A raw material is a relatively unprocessed material that is a basic economic input. Identify when materials need to be replenished in order to meet. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a. List Of Raw Material Requirements.

From www.scribd.com

List of Raw Materials PDF List Of Raw Material Requirements 92 examples of raw materials. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. Identify when materials need to be replenished in order to meet. Mrp converts the master schedule of production. Monitor current levels of raw materials and components on hand. A bom essentially provides a. Precise. List Of Raw Material Requirements.

From www.youtube.com

raw material Stock format in excel YouTube List Of Raw Material Requirements Precise list of all the raw materials needed to create a product, including quantities and instructions. 92 examples of raw materials. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A bom essentially provides a. Identify when materials need to be replenished in order to meet. A bill of materials (bom) is a comprehensive. List Of Raw Material Requirements.

From newtutorialshed.blogspot.com

Raw Material Schedule Tutorial Shed List Of Raw Material Requirements A bom essentially provides a. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. Monitor current levels of raw materials and components on hand. Precise list of all the raw materials needed to create a product, including quantities and instructions. A raw material is a relatively unprocessed material. List Of Raw Material Requirements.

From ansi.ph

6 Benefits Material Requirement Planning Brings to Manufacturers List Of Raw Material Requirements Mrp converts the master schedule of production. A bom essentially provides a. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A raw material is a relatively unprocessed material that is a basic economic input. 92 examples of raw materials. The mrp process follows three main steps: Precise list of all the raw materials. List Of Raw Material Requirements.

From efinancemanagement.com

Material Requirements Planning (MRP) All You Need To Know List Of Raw Material Requirements Effective bom management is crucial for. Precise list of all the raw materials needed to create a product, including quantities and instructions. 92 examples of raw materials. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Mrp converts the master schedule of production. A raw material is a. List Of Raw Material Requirements.

From www.complianceonline.com

CGMP controlled Raw Materials Regulations and Best Practices List Of Raw Material Requirements 92 examples of raw materials. A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A bom essentially provides a. Monitor current levels of raw materials and components. List Of Raw Material Requirements.

From www.metal-am.com

Material selection for injection moulding tooling by Additive Manufacturing List Of Raw Material Requirements A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Identify when materials. List Of Raw Material Requirements.

From www.pinterest.jp

A budget that shows how much quantity of direct raw material is List Of Raw Material Requirements Mrp converts the master schedule of production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A raw material is a relatively unprocessed material that is a basic economic input. 92 examples of raw materials. Effective bom management is crucial for. A bom essentially provides a. Identify when materials need to be replenished in. List Of Raw Material Requirements.

From www.slideserve.com

PPT SAFC Biosciences Raw Materials Characterization Initiative List Of Raw Material Requirements 92 examples of raw materials. Mrp converts the master schedule of production. Identify when materials need to be replenished in order to meet. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A raw material is a relatively unprocessed material that is a basic economic input. Monitor current. List Of Raw Material Requirements.

From solutionpharmacy.in

GMP Requirements Solution Parmacy List Of Raw Material Requirements Monitor current levels of raw materials and components on hand. 92 examples of raw materials. The mrp process follows three main steps: A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Precise list of all the raw materials needed to create a product, including quantities and instructions. A. List Of Raw Material Requirements.

From www.slideserve.com

PPT Source of Raw Material PowerPoint Presentation, free download List Of Raw Material Requirements Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production. Monitor current levels of raw materials and components on hand. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A bom essentially provides a. A bill. List Of Raw Material Requirements.

From www.slideshare.net

Raw material List Of Raw Material Requirements Monitor current levels of raw materials and components on hand. Effective bom management is crucial for. The mrp process follows three main steps: Precise list of all the raw materials needed to create a product, including quantities and instructions. A raw material is a relatively unprocessed material that is a basic economic input. Identify when materials need to be replenished. List Of Raw Material Requirements.

From www.scribd.com

Bulk Material Requirements Checklist PDF List Of Raw Material Requirements Mrp converts the master schedule of production. The mrp process follows three main steps: A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. Material requirements planning (mrp). List Of Raw Material Requirements.

From www.researchgate.net

Raw Material Requirements (MP = purified MAb). Download Scientific List Of Raw Material Requirements The mrp process follows three main steps: A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. A bom essentially provides a. Monitor current levels of raw materials and components on hand. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required. List Of Raw Material Requirements.

From slidesdocs.com

Raw Material Inventory Monthly Report Excel Template And Google Sheets List Of Raw Material Requirements A bom essentially provides a. Identify when materials need to be replenished in order to meet. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. The mrp process follows three main steps: Mrp converts the master schedule of production. A raw material is a relatively unprocessed material that. List Of Raw Material Requirements.

From solicofg.com

Raw Material Comparison Solico FG List Of Raw Material Requirements Monitor current levels of raw materials and components on hand. Identify when materials need to be replenished in order to meet. 92 examples of raw materials. Mrp converts the master schedule of production. A raw material is a relatively unprocessed material that is a basic economic input. Material requirements planning (mrp) is a planning and control system for inventory, production,. List Of Raw Material Requirements.

From www.slideteam.net

Analyzing Future Raw Material Requirements And Accessibility Promoting List Of Raw Material Requirements Mrp converts the master schedule of production. A raw material is a relatively unprocessed material that is a basic economic input. 92 examples of raw materials. Monitor current levels of raw materials and components on hand. The mrp process follows three main steps: Identify when materials need to be replenished in order to meet. A bom essentially provides a. A. List Of Raw Material Requirements.

From elements.visualcapitalist.com

Charted The Raw Material Needs of Energy Technologies List Of Raw Material Requirements A raw material is a relatively unprocessed material that is a basic economic input. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. The mrp process follows three main steps: A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to. List Of Raw Material Requirements.

From www.inpaspages.com

Raw material control process List Of Raw Material Requirements A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. Identify when materials need to be replenished in order to meet. Material requirements planning (mrp) is a planning. List Of Raw Material Requirements.

From www.slideshare.net

Sample Business Plan Presentation List Of Raw Material Requirements The mrp process follows three main steps: Identify when materials need to be replenished in order to meet. A raw material is a relatively unprocessed material that is a basic economic input. Precise list of all the raw materials needed to create a product, including quantities and instructions. Monitor current levels of raw materials and components on hand. Mrp converts. List Of Raw Material Requirements.

From www.studocu.com

Business Plan Chapter 5 Raw Materials Raw materials are materials or List Of Raw Material Requirements Effective bom management is crucial for. The mrp process follows three main steps: Identify when materials need to be replenished in order to meet. A bom essentially provides a. 92 examples of raw materials. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Material requirements planning (mrp) is. List Of Raw Material Requirements.

From www.slideshare.net

Raw materials and their uses List Of Raw Material Requirements Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A bom essentially provides a. Monitor current levels of raw materials and components on hand. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. The mrp process follows three main steps: 92 examples. List Of Raw Material Requirements.

From www.slideteam.net

6 Months Raw Material Procurement Process Roadmap Presentation List Of Raw Material Requirements A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. Mrp converts the master schedule of production. 92 examples of raw materials. A bom essentially provides a. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Effective. List Of Raw Material Requirements.

From www.researchgate.net

Raw material requirements (1 batch = 11.5 kg MP) Download Table List Of Raw Material Requirements Effective bom management is crucial for. The mrp process follows three main steps: A bom essentially provides a. A raw material is a relatively unprocessed material that is a basic economic input. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Monitor current levels of raw materials and. List Of Raw Material Requirements.

From www.researchgate.net

List of imported raw materials and their local substitutes Download Table List Of Raw Material Requirements Identify when materials need to be replenished in order to meet. Mrp converts the master schedule of production. Effective bom management is crucial for. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. 92 examples of raw materials. A raw material is a relatively unprocessed material that is a basic economic input. Precise list. List Of Raw Material Requirements.

From template.wps.com

EXCEL of Raw Material Inventory Monthly Report.xlsx WPS Free Templates List Of Raw Material Requirements A bom essentially provides a. Mrp converts the master schedule of production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Effective bom management is crucial for. Precise list of all the raw materials needed to create a product, including quantities and instructions. A bill of materials (bom) is a comprehensive list of all. List Of Raw Material Requirements.

From template.wps.com

EXCEL of Raw Material Management Form.xlsx WPS Free Templates List Of Raw Material Requirements 92 examples of raw materials. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Effective bom management is crucial for. Identify when materials need to be replenished in order to meet. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. A bill. List Of Raw Material Requirements.

From www.youtube.com

Raw Materials Inventory in Cost Accounting Definition, Formula List Of Raw Material Requirements Monitor current levels of raw materials and components on hand. A bom essentially provides a. Precise list of all the raw materials needed to create a product, including quantities and instructions. A bill of materials (bom) is a comprehensive list of all the materials, components, and subassemblies required to manufacture a product. Material requirements planning (mrp) is a planning and. List Of Raw Material Requirements.

From elements.visualcapitalist.com

Charted The Raw Material Needs of Energy Technologies List Of Raw Material Requirements Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Monitor current levels of raw materials and components on hand. A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. 92 examples of raw materials. Effective bom management is crucial for. Precise list of. List Of Raw Material Requirements.

From www.researchgate.net

Raw material requirements and costs. Download Scientific Diagram List Of Raw Material Requirements Effective bom management is crucial for. A bom essentially provides a. A bill of materials (bom) is a comprehensive list of all raw materials, components, and assemblies required to build a product. A raw material is a relatively unprocessed material that is a basic economic input. Mrp converts the master schedule of production. 92 examples of raw materials. Identify when. List Of Raw Material Requirements.