Control Valve Jerking . Undersized or worn valve actuators. While some issues are easy to spot, others require a powerful. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts.

from automationforum.co

While some issues are easy to spot, others require a powerful. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Undersized or worn valve actuators. Dust, dirt, moisture or oil in the air supply. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Control valves that aren’t working correctly can cause problems for your entire system. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes.

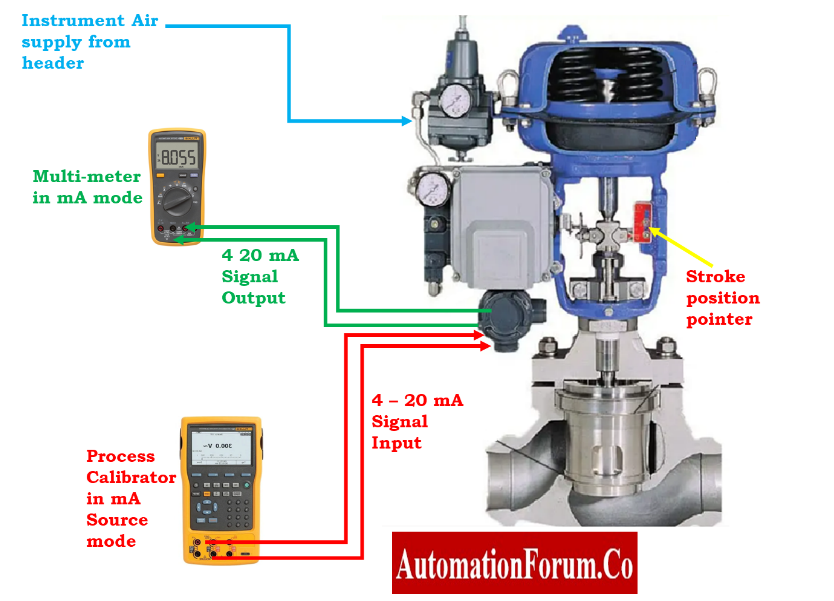

What is control valve stroke checking, and how is it done?

Control Valve Jerking Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Control valves that aren’t working correctly can cause problems for your entire system. While some issues are easy to spot, others require a powerful. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Undersized or worn valve actuators.

From www.flowcontrolequip.com

Fisher® EBody Sliding Stem Control Valves Flow Control Equipment Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Dust, dirt, moisture or oil in the air supply. Undersized or worn valve actuators. While some issues are easy to spot, others require a powerful. Control valves that aren’t working correctly can cause problems for your entire system. Vibrations, turbulence, or cavitation could indicate. Control Valve Jerking.

From www.kosokentintrol.com

Products / Control valve_肯特流体控制(深圳)有限公司 Control Valve Jerking While some issues are easy to spot, others require a powerful. Control valves that aren’t working correctly can cause problems for your entire system. Undersized or worn valve actuators. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is. Control Valve Jerking.

From automationforum.co

What is control valve stroke checking, and how is it done? Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Control valves that aren’t working correctly can cause problems for your entire system. These problems can include friction sticking,. Control Valve Jerking.

From www.youtube.com

How Helix Fuel Pumps Work! (Jerk Piston Variable Injection Pump) YouTube Control Valve Jerking Undersized or worn valve actuators. Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require a powerful. Vibrations, turbulence, or cavitation could indicate. Control Valve Jerking.

From www.emersonautomationexperts.com

Specifying Severe Service Control Valves Control Valve Jerking Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Undersized or worn valve actuators. While some issues are easy to spot, others require a powerful. These problems. Control Valve Jerking.

From instrumentationtools.com

Control Valve Passing Problem after Overhauling Job Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. While some issues are easy to spot, others require a powerful. Control valves that aren’t working correctly can cause problems for your entire system.. Control Valve Jerking.

From automationcommunity.com

Calibration Procedure of a Control Valve Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Dust, dirt, moisture or oil in the air supply. Control valves that aren’t working correctly can cause problems for your entire system. Control. Control Valve Jerking.

From www.youtube.com

Fisher 3582 Control ValveSeven Steps for Calibration(Zero & Span Control Valve Jerking While some issues are easy to spot, others require a powerful. Dust, dirt, moisture or oil in the air supply. Control valves that aren’t working correctly can cause problems for your entire system. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Undersized or worn valve actuators. These problems. Control Valve Jerking.

From www.cranefs.com

D996F Electronic Pressure Independent Control Valve (EPICV) Crane Control Valve Jerking Undersized or worn valve actuators. Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so. Control Valve Jerking.

From circuitlibwinding.z21.web.core.windows.net

Control Valve Parts And Functions Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Dust, dirt, moisture. Control Valve Jerking.

From instrumentationtools.com

Control Valve in Nutshell Valve Design and Selection Factors Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. While some issues are easy to spot, others require a powerful. Control valve problems can severely affect control loop performance and, unless. Control Valve Jerking.

From shopee.com.my

TECNOCONTROL Emergency Shut Off Jerk Valve Size 3/4", 1", 1 1/4", 2 Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. While some issues are easy to spot, others require a powerful. These problems can include friction sticking, flashing, cavitation,. Control Valve Jerking.

From automationcommunity.com

Control Valves Automation Community Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Dust, dirt, moisture or oil in the air supply. While some issues are easy to spot, others require a powerful. Undersized or worn valve actuators. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and. Control Valve Jerking.

From www.acads.com.my

Jerk On/Off Valves ACADS ENGINEERING (M) SDN BHD Control Valve Jerking Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require a powerful. Undersized or worn valve actuators. Control valves that aren’t working correctly can cause. Control Valve Jerking.

From automationcommunity.com

145 Control Valve Interview Questions and Answers Control Valve Jerking While some issues are easy to spot, others require a powerful. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Control valves that aren’t working correctly can cause problems for your entire system. Vibrations, turbulence, or cavitation could indicate that. Control Valve Jerking.

From www.cibsejournal.com

Module 140 Pressureindependent control valves in variable volume Control Valve Jerking Dust, dirt, moisture or oil in the air supply. While some issues are easy to spot, others require a powerful. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Vibrations, turbulence, or cavitation. Control Valve Jerking.

From automationforum.co

26 Instrumentation and Control Engineering Control Valve Jerking Dust, dirt, moisture or oil in the air supply. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Control valve problems can severely affect control loop performance and, unless eliminated, they can. Control Valve Jerking.

From control.com

Valve Positioners Basic Principles of Control Valves and Actuators Control Valve Jerking Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. While some issues are easy to spot, others require a powerful. Control valves that aren’t working correctly can cause problems for your entire system. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion.. Control Valve Jerking.

From www.acads.com.my

Boldrin Group Jerk On/Off Valves SM Series ACADS ENGINEERING (M) SDN BHD Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Control valves that aren’t working correctly can cause problems for your entire system. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. These problems can include friction sticking,. Control Valve Jerking.

From www.linquip.com

Control Valve Parts Names & Functions (PDF + PPT) Linquip Control Valve Jerking Undersized or worn valve actuators. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. While some issues are easy to spot, others require a powerful. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can. Control Valve Jerking.

From www.comet-integrated.com

Comet Integrated Sdn Bhd Jerk Valve Control Valve Jerking Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can include friction sticking, flashing, cavitation, choked flow,. Control Valve Jerking.

From www.taiwantrade.com

8000 Series Diaphragm Actuated Control Valves Control Valve Jerking Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Dust, dirt, moisture. Control Valve Jerking.

From nonnuoc.com.vn

Jerk valve Geca 1/2", 3/4", 1" Pmax 6 bar CÔNG TY NHH NHIỆT CƠ ĐIỆN Control Valve Jerking Dust, dirt, moisture or oil in the air supply. While some issues are easy to spot, others require a powerful. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Control valves that aren’t working correctly can cause problems for your entire system. Undersized or worn valve actuators. Control valve problems can severely affect. Control Valve Jerking.

From exouiqprh.blob.core.windows.net

How Does A Height Control Valve Work at Eunice Bagwell blog Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Undersized or worn valve actuators. Control valves that aren’t working correctly can cause problems for your entire system. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning. Control Valve Jerking.

From automationforum.co

SelfOperated Pressure Control Valve Working Principle Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. While some issues are easy to spot, others require a powerful. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Control valves that aren’t working correctly can cause. Control Valve Jerking.

From instrumentationtools.com

How to Do Maintenance of Control Valve Which is Stuck in Field? Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Dust, dirt, moisture or oil in the air supply. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Undersized or worn valve actuators. Control valve problems can severely affect control loop performance. Control Valve Jerking.

From blog.thepipingmart.com

Globe Valve vs Control Valve What's the Difference Control Valve Jerking Undersized or worn valve actuators. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. While some issues are easy to spot, others require a powerful. Control valves that. Control Valve Jerking.

From www.studocu.com

Control Valve Cavitation and Flashing Control Valve Cavitation and Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. These problems can include friction sticking, flashing, cavitation, choked flow,. Control Valve Jerking.

From catalog.udlvirtual.edu.pe

Butterfly Valve Maintenance Checklist Catalog Library Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require a powerful. Dust, dirt, moisture or oil in the air supply. Undersized or worn valve actuators. Control valves that aren’t working correctly can cause problems for your entire system. Control valve problems can severely affect. Control Valve Jerking.

From www.pneumaticairactuator.com

1/2" Cage Guided Globe Control Valve Multistage Trims Quick Opening Control Valve Jerking Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. Dust, dirt, moisture or oil in the air supply. Undersized or worn valve actuators. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require. Control Valve Jerking.

From www.wsdsolution.com

What should we do if the control valve packing leaks? Your exclusive Control Valve Jerking Control valves that aren’t working correctly can cause problems for your entire system. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. While some issues are easy to spot, others require a powerful. Undersized or worn valve actuators. These problems can include friction sticking, flashing, cavitation, choked flow,. Control Valve Jerking.

From theinstrumentguru.com

Control valve Calibration Control Valve Jerking Control valves that aren’t working correctly can cause problems for your entire system. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require a powerful. Dust, dirt, moisture or oil in the air supply. Control valve problems can severely affect control loop performance and, unless. Control Valve Jerking.

From engineeringlearn.com

Flow Control Valve Definition, Types, Components & Working Principle Control Valve Jerking Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Dust, dirt, moisture. Control Valve Jerking.

From automationforum.co

Control Valve Body Materials AutomationForum Control Valve Jerking Dust, dirt, moisture or oil in the air supply. Control valves that aren’t working correctly can cause problems for your entire system. Vibrations, turbulence, or cavitation could indicate that your control valve is faulty, so you should check for broken or worn parts. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While. Control Valve Jerking.

From design.udlvirtual.edu.pe

What Are The Three Types Of Control Valves Used In Hydraulic Systems Control Valve Jerking These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. While some issues are easy to spot, others require a powerful. Control valve problems can severely affect control loop performance and, unless eliminated, they can make controller tuning a challenging (sometimes. Dust, dirt, moisture or oil in the air supply. Undersized or worn valve. Control Valve Jerking.