Define Oil Groove . The oil flow of a bearing with a circular groove is about 2.5 times. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The groove is cut on the external or outer surface of the workpiece. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil groove is commonly made in the upper shell where the oil hole is located. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. The cutting tool is usually positioned.

from eriks.com

The cutting tool is usually positioned. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The oil groove is commonly made in the upper shell where the oil hole is located. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The groove is cut on the external or outer surface of the workpiece. The oil flow of a bearing with a circular groove is about 2.5 times. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations.

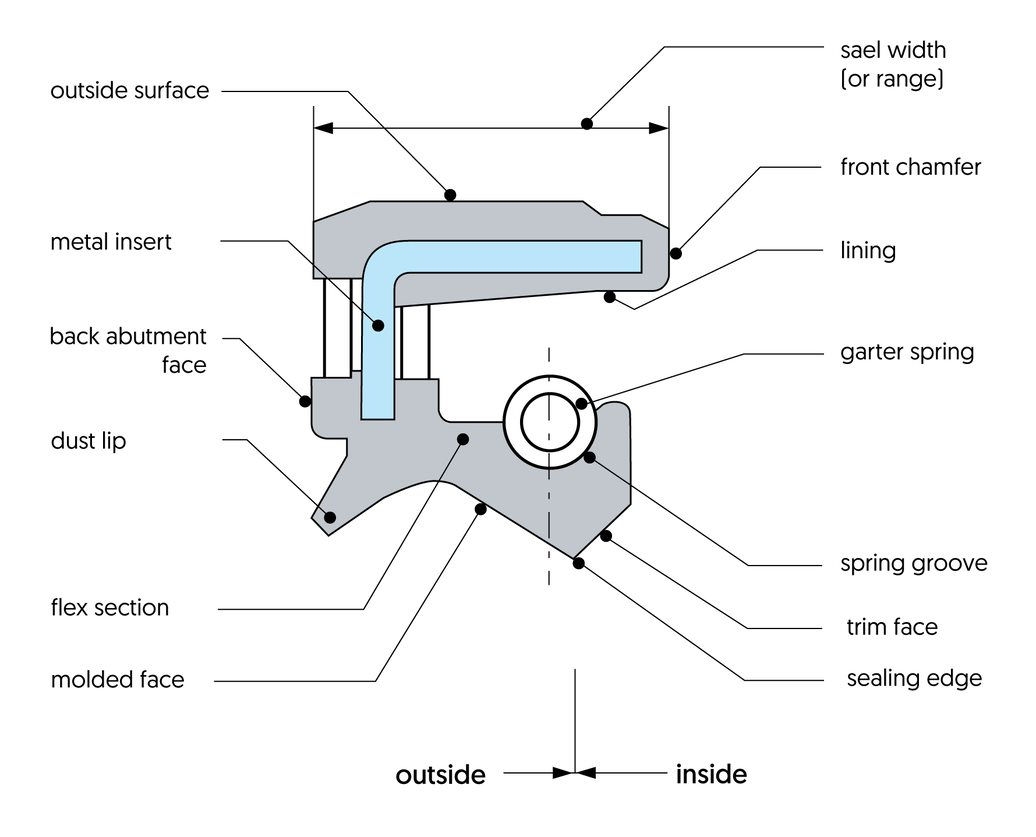

Guide to oil seals for your application

Define Oil Groove The cutting tool is usually positioned. The oil groove is commonly made in the upper shell where the oil hole is located. The cutting tool is usually positioned. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil flow of a bearing with a circular groove is about 2.5 times. The groove is cut on the external or outer surface of the workpiece. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations.

From cncmakers.com

Large lead 8shaped oil groove machin Define Oil Groove The oil groove is commonly made in the upper shell where the oil hole is located. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The oil flow of. Define Oil Groove.

From www.youtube.com

Oil Groove Bushing Type YouTube Define Oil Groove The cutting tool is usually positioned. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil. Define Oil Groove.

From faq.out-club.ru

BASE ENGINE Define Oil Groove A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The groove is cut on. Define Oil Groove.

From www.youtube.com

Oil Groove in CNC Turning center. YouTube Define Oil Groove A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. The oil groove is commonly made in the upper shell where the oil hole is located. The groove is cut on the external or outer surface of the workpiece. Grooving, also called recessing, is an important machining operation that is done. Define Oil Groove.

From eriks.com

Guide to oil seals for your application Define Oil Groove Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. The oil flow of a bearing with a circular groove is about 2.5 times. The oil groove is commonly made in the upper shell where the oil hole is located. Grooving is a machining operation performed on a lathe machine. Define Oil Groove.

From rerev.com

Tire groove definition and meaning REREV Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil flow of a bearing with a circular groove is about 2.5 times. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. Grooves cut into flat or cylindrical bearing. Define Oil Groove.

From cezwbikz.blob.core.windows.net

Types Of Gaskets And Their Applications Pdf at Mary blog Define Oil Groove The cutting tool is usually positioned. The oil groove is commonly made in the upper shell where the oil hole is located. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. A 180º groove is sufficient for providing the required amount of oil to the connecting. Define Oil Groove.

From www.youtube.com

oil grooves in bush on Lathe YouTube Define Oil Groove Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. The oil groove is commonly made in the upper shell where the oil hole is located. Grooving, also called. Define Oil Groove.

From www.researchgate.net

Examples of grooves. (A) A series of smooth parallel grooves. Total Define Oil Groove The cutting tool is usually positioned. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The oil groove is commonly made in the upper shell where the oil hole is located. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. Grooving is. Define Oil Groove.

From www.nationalbronze.com

Oil Grooves in Cast Bronze Bearings National Bronze Manufacturing Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The groove is cut on the external or outer surface of the workpiece. The cutting tool is usually positioned. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove. Define Oil Groove.

From www.researchgate.net

Schematic sketch of oil grooves. Download Scientific Diagram Define Oil Groove The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil groove is commonly made in the upper shell where the oil hole is located. The oil flow of. Define Oil Groove.

From manilaflashreport.blogspot.com

Custom Lathe Tool Cuts Complex Oil Grooves Define Oil Groove A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving is. Define Oil Groove.

From www.youtube.com

How do we define GROOVE? YouTube Define Oil Groove The oil flow of a bearing with a circular groove is about 2.5 times. The groove is cut on the external or outer surface of the workpiece. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooving, also called recessing, is an important machining operation that is done on cnc. Define Oil Groove.

From www.themetalchic.com

Metalchic Atlas Bronze Bearing Design Guide Chapter Seven Oil Define Oil Groove The oil groove is commonly made in the upper shell where the oil hole is located. The groove is cut on the external or outer surface of the workpiece. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. The process is done using differently designed tools on the basis. Define Oil Groove.

From www.youtube.com

The technique of making twoway oil grooves on albronze bushings YouTube Define Oil Groove The oil groove is commonly made in the upper shell where the oil hole is located. The oil flow of a bearing with a circular groove is about 2.5 times. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The cutting tool is usually positioned. Grooving is a machining operation performed on a. Define Oil Groove.

From cncmakers.com

Large lead 8shaped oil groove machin Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. The groove is cut on the external or outer surface of the workpiece. The oil groove is commonly made in. Define Oil Groove.

From www.practicalmachinist.com

Oil Groove Design Page 3 Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil flow of a bearing with a circular groove is about 2.5 times. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The process is done using differently designed. Define Oil Groove.

From www.nationalbronze.com

Oil Grooves for Bronze Bushings National Bronze Manufacturing Define Oil Groove The cutting tool is usually positioned. The groove is cut on the external or outer surface of the workpiece. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. This groove can be used in combination with a straight axial groove but the axial groove must be located in the. Define Oil Groove.

From www.hollywoodchryslerjeep.com

Gearhead Piston Rings Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The oil groove is commonly made in the upper shell where the oil hole is located. Grooving is a machining operation. Define Oil Groove.

From www.bronzelube.com

Oil Groove Bronze Bushings Custom Size & Bronze Material Define Oil Groove Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The oil flow of a bearing with a circular groove is about 2.5 times. The oil groove is commonly made in the upper shell where the oil hole is located. A 180º groove is sufficient for providing the required amount of oil to the. Define Oil Groove.

From www.pumpsandsystems.com

Grooved Versus Flanged Connections Define Oil Groove A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The oil groove is commonly made in the upper shell where the oil hole is located. Grooves cut. Define Oil Groove.

From www.youtube.com

machining oil grooves YouTube Define Oil Groove Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. The oil flow of a bearing with a circular groove is about 2.5 times. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. A 180º. Define Oil Groove.

From cncmakers.com

8shaped oil groove making with GSK92 Define Oil Groove The cutting tool is usually positioned. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooving is a machining operation performed on a lathe machine to create a narrow, linear. Define Oil Groove.

From www.bearingface.com

Oil Groove Bushing OilFree Bushings Casting Bronze Define Oil Groove The oil flow of a bearing with a circular groove is about 2.5 times. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Define Oil Groove.

From www.bronzelube.com

Self Lubricating Bronze Groove Bearings Metric & Inch Size Define Oil Groove Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. The oil flow of a bearing with a circular groove is about 2.5 times. A 180º groove is sufficient for providing the required amount. Define Oil Groove.

From www.practicalmachinist.com

Oil Groove Design Page 5 Define Oil Groove A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. The process. Define Oil Groove.

From www.practicalmachinist.com

Oil Groove Design Page 7 Define Oil Groove The oil flow of a bearing with a circular groove is about 2.5 times. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. The oil groove is commonly made in the upper. Define Oil Groove.

From www.youtube.com

How to make oil grooves /Left and Right Thread YouTube Define Oil Groove Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The cutting tool is usually positioned. The groove is cut on the external or outer surface of the workpiece. The process is done using. Define Oil Groove.

From www.sunrisegr.com

Guide Bar X Oil Groove standard die component guide bar Define Oil Groove The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area.. Define Oil Groove.

From www.youtube.com

Machining oil grooves in large hinge pin YouTube Define Oil Groove The oil groove is commonly made in the upper shell where the oil hole is located. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface. Define Oil Groove.

From eureka.patsnap.com

Spiraloilgroove extrusion screw tap Eureka wisdom buds develop Define Oil Groove This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface. Define Oil Groove.

From www.youtube.com

oil groove programming in turning Siemens Oil Groove on Od YouTube Define Oil Groove The oil flow of a bearing with a circular groove is about 2.5 times. The cutting tool is usually positioned. The groove is cut on the external or outer surface of the workpiece. A 180º groove is sufficient for providing the required amount of oil to the connecting rod bearing, which it. Grooving, also called recessing, is an important machining. Define Oil Groove.

From www.youtube.com

simple and faster method outside oil grooves processing . YouTube Define Oil Groove The oil groove is commonly made in the upper shell where the oil hole is located. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The process is done using differently designed tools on the basis of dimensional, shape, and hardness considerations. Grooving is a machining operation performed on a lathe machine to. Define Oil Groove.

From www.practicalmachinist.com

Oil Groove Design Define Oil Groove The oil flow of a bearing with a circular groove is about 2.5 times. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a workpiece. The cutting tool is usually positioned. The oil groove is commonly made in the upper shell where the oil hole is located.. Define Oil Groove.

From www.youtube.com

Turning internal oil grooves YouTube Define Oil Groove Grooves cut into flat or cylindrical bearing surfaces and fed by oilways, through which oil is distributed over the bearing. This groove can be used in combination with a straight axial groove but the axial groove must be located in the unloaded area. Grooving, also called recessing, is an important machining operation that is done on cnc lathe machines. The. Define Oil Groove.