Car Floor Metal Thickness . In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. For the floor supports i use 16 gauge. Car makers use aluminum killed. The carbon content in either one is kept low to aid formability. Or the floor pans i use 18 gauge. Get the right steel gauge for your floor pan repair. Sheet metal thickness is vital for vehicle durability. I used 16 gage flat sheet for a 24 x 43. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Learn how to identify steel thickness and choose the right gauge for your car restoration project. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Ford used 19 gauge on most exterior sheetmetal untill the.

from tjibc.com

For the floor supports i use 16 gauge. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Get the right steel gauge for your floor pan repair. Learn how to identify steel thickness and choose the right gauge for your car restoration project. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. I used 16 gage flat sheet for a 24 x 43. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Or the floor pans i use 18 gauge. The carbon content in either one is kept low to aid formability. Car makers use aluminum killed.

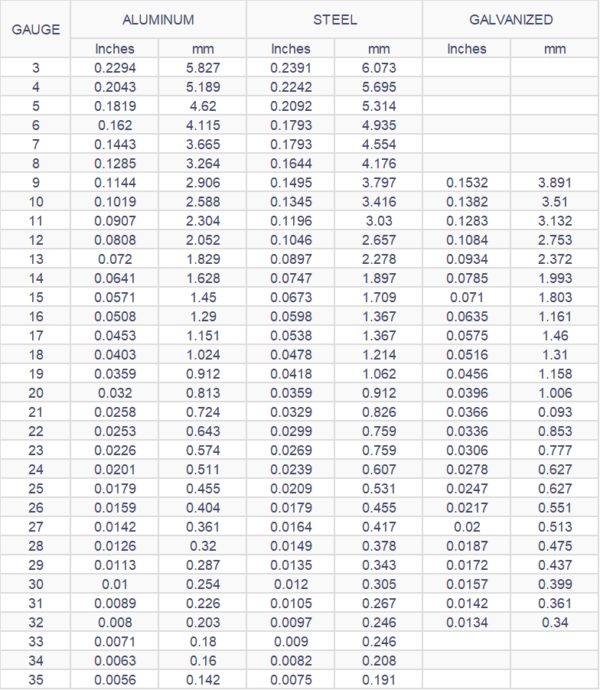

Gauge Steel Thickness Sheet Metal Gauge Chart IBC Group

Car Floor Metal Thickness For the floor supports i use 16 gauge. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Car makers use aluminum killed. Get the right steel gauge for your floor pan repair. The carbon content in either one is kept low to aid formability. Or the floor pans i use 18 gauge. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Learn how to identify steel thickness and choose the right gauge for your car restoration project. For the floor supports i use 16 gauge. I used 16 gage flat sheet for a 24 x 43. Sheet metal thickness is vital for vehicle durability. Ford used 19 gauge on most exterior sheetmetal untill the. Commercial quality hot or cold rolled sheet is typically 1008 or 1010.

From automotive-aluminium.com

Car Body Sheet Metal Haomei Aluminum Car Floor Metal Thickness I used 16 gage flat sheet for a 24 x 43. Sheet metal thickness is vital for vehicle durability. For the floor supports i use 16 gauge. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Ford used 19 gauge on most exterior sheetmetal untill the. Or the floor pans. Car Floor Metal Thickness.

From www.metafab.com

Sheet Metal Material Thickness Guide Meta Fab, Inc. Car Floor Metal Thickness For the floor supports i use 16 gauge. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or. Car Floor Metal Thickness.

From gtsparkplugs.com

Sheet Metal Gauge Chart GTSparkplugs Car Floor Metal Thickness Learn how to identify steel thickness and choose the right gauge for your car restoration project. The carbon content in either one is kept low to aid formability. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Get the right steel gauge for your floor. Car Floor Metal Thickness.

From www.slide-lok.com

Best Floor Coating for Auto Mechanic Shops & Garages Car Floor Metal Thickness Learn how to identify steel thickness and choose the right gauge for your car restoration project. The carbon content in either one is kept low to aid formability. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Or the floor pans. Car Floor Metal Thickness.

From classhirsch.z21.web.core.windows.net

Stainless Steel Sheet Metal Gauge Thickness Chart Pdf Car Floor Metal Thickness In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. Sheet metal thickness is vital for vehicle durability. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Car makers use aluminum killed.. Car Floor Metal Thickness.

From www.researchgate.net

Dimensions (in mm) of each steel decking profile. Download Scientific Car Floor Metal Thickness The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. I used 16 gage flat sheet for a 24 x 43. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers,. Car Floor Metal Thickness.

From wiringmsregineysle5.z19.web.core.windows.net

Sheet Metal Gauge Thickness Chart Inches Car Floor Metal Thickness Commercial quality hot or cold rolled sheet is typically 1008 or 1010. I used 16 gage flat sheet for a 24 x 43. The carbon content in either one is kept low to aid formability. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Learn how to identify steel thickness. Car Floor Metal Thickness.

From procon.com.pk

Sheet Metal Body Parts PROCON Car Floor Metal Thickness Ford used 19 gauge on most exterior sheetmetal untill the. Learn how to identify steel thickness and choose the right gauge for your car restoration project. For the floor supports i use 16 gauge. Get the right steel gauge for your floor pan repair. Car makers use aluminum killed. Beads and bends will add stiffness, so you can use thinner. Car Floor Metal Thickness.

From allautoexperts.com

Essential Guide to Choosing the Right Car Floor Mats Car Floor Metal Thickness Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Car makers use aluminum killed. Sheet metal thickness is vital for vehicle durability. The carbon content in either one is kept low to aid formability. Or the floor pans i use 18 gauge. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door. Car Floor Metal Thickness.

From fixlibrarylaboregikn.z4.web.core.windows.net

How To Determine Automotive Wire Gauge Size Car Floor Metal Thickness Sheet metal thickness is vital for vehicle durability. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Car makers use aluminum killed. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting. Car Floor Metal Thickness.

From www.lazada.com.ph

1pc Length 300mm 304 Stainless Steel Bar Plate Rob Flat Steel Thickness Car Floor Metal Thickness Commercial quality hot or cold rolled sheet is typically 1008 or 1010. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. I used 16 gage flat sheet for a 24. Car Floor Metal Thickness.

From www.automotive-aluminium.com

Car Body Sheet Metal Haomei Aluminum Car Floor Metal Thickness For the floor supports i use 16 gauge. Get the right steel gauge for your floor pan repair. The carbon content in either one is kept low to aid formability. Car makers use aluminum killed. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Beads and bends will add stiffness,. Car Floor Metal Thickness.

From mungfali.com

Mil Thickness Conversion Chart Car Floor Metal Thickness Get the right steel gauge for your floor pan repair. For the floor supports i use 16 gauge. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. Ford used 19 gauge on most exterior sheetmetal untill the. The standard measurement for this thickness is “gauge,” with. Car Floor Metal Thickness.

From kanyanaengineering.com.au

Sheet Metal Thickness Guide & Size Charts (Gauge, mm & Inches Car Floor Metal Thickness For the floor supports i use 16 gauge. The carbon content in either one is kept low to aid formability. Or the floor pans i use 18 gauge. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly. Car Floor Metal Thickness.

From www.youtube.com

Car Floor Lamination Waterproof Lamination Dzire🚙🚗 Floor Car Floor Metal Thickness The carbon content in either one is kept low to aid formability. Sheet metal thickness is vital for vehicle durability. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Learn how to identify steel thickness and choose the right gauge for your car restoration project. I used 16 gage flat sheet for a. Car Floor Metal Thickness.

From allsteelchoices.blogspot.com

Steel Gage Thickness Chart Steel Choices Car Floor Metal Thickness Learn how to identify steel thickness and choose the right gauge for your car restoration project. Car makers use aluminum killed. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Get the right steel gauge for your floor pan repair. Sheet metal thickness is vital. Car Floor Metal Thickness.

From circuitplaurorgaxordxg.z19.web.core.windows.net

Sheet Metal 16 Gauge Thickness Car Floor Metal Thickness Car makers use aluminum killed. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. The carbon content in either one is kept low to aid formability. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin.. Car Floor Metal Thickness.

From www.pinterest.co.uk

Sheet Metal Materials, Standard Sizes & Forming Processes Sheet Car Floor Metal Thickness In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. For the floor supports i use 16 gauge. Sheet metal thickness is vital for vehicle durability. Get the right steel gauge for your floor pan. Car Floor Metal Thickness.

From fyoiusdoj.blob.core.windows.net

How To Gauge Metal Thickness at Stefan Fitzsimmons blog Car Floor Metal Thickness Sheet metal thickness is vital for vehicle durability. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. For the floor supports i use 16 gauge. Car makers use aluminum killed. Or the floor pans i use 18 gauge. What thickness or gauge is standard automotive sheetmetal. Car Floor Metal Thickness.

From dokumen.tips

(PDF) Steel Sheet Thickness Tolerance DOKUMEN.TIPS Car Floor Metal Thickness Get the right steel gauge for your floor pan repair. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Car makers use aluminum killed. The carbon content in either one is kept low to aid formability. Ford used 19 gauge on most exterior sheetmetal untill the. Learn how to identify steel thickness and. Car Floor Metal Thickness.

From eziil.com

Metal Strength Chart A Detailed Guide to Metal Strengths Car Floor Metal Thickness Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Get the right steel gauge for your floor pan repair. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a. Car Floor Metal Thickness.

From ethanparkin.z21.web.core.windows.net

Aluminum Gauge Thickness Chart Car Floor Metal Thickness Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Ford used 19 gauge on most exterior sheetmetal untill the. Or the floor pans i use 18 gauge. The carbon content in either one is kept low to aid formability. For the floor supports i use 16 gauge. What thickness or gauge is standard automotive sheetmetal on american. Car Floor Metal Thickness.

From www.yumisteel.com

Different construction use different specifications metal steel sheet Car Floor Metal Thickness Learn how to identify steel thickness and choose the right gauge for your car restoration project. The carbon content in either one is kept low to aid formability. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. I used 16 gage flat sheet for a. Car Floor Metal Thickness.

From www.summitracing.com

Auto Metal Direct 4008466 Auto Metal Direct Floor Pans Summit Racing Car Floor Metal Thickness Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Or the floor pans i use 18 gauge. Sheet metal thickness is vital for vehicle durability. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide sheet metal pliers, drill and. Car makers use aluminum killed. Learn how to identify. Car Floor Metal Thickness.

From steeldetailingtech.blogspot.com

Steel Detailing TECH GAUGE THICKNESS IN INCH CHART Car Floor Metal Thickness Ford used 19 gauge on most exterior sheetmetal untill the. Learn how to identify steel thickness and choose the right gauge for your car restoration project. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. In order to fabricate a basic floor pan patch, you need a welder, body hammer, cutting wheel, wide. Car Floor Metal Thickness.

From tjibc.com

Gauge Steel Thickness Sheet Metal Gauge Chart IBC Group Car Floor Metal Thickness Sheet metal thickness is vital for vehicle durability. For the floor supports i use 16 gauge. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Or the floor pans i use 18 gauge. The carbon content in either one is kept low to aid formability. The standard measurement for this thickness is “gauge,” with a higher gauge. Car Floor Metal Thickness.

From wiringfixklangel516pr.z21.web.core.windows.net

How Thick Is 10 Gauge Sheet Steel Car Floor Metal Thickness For the floor supports i use 16 gauge. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Ford used 19 gauge on most exterior sheetmetal untill the. The carbon content in either one is kept low to aid formability. Commercial quality hot or cold rolled sheet is typically 1008 or. Car Floor Metal Thickness.

From www.carid.com

Auto Metal Direct® 40534681R Front Passenger Side Floor Pan Patch Car Floor Metal Thickness What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. The carbon content in either one is kept low to aid formability. Car makers use aluminum killed. For the floor supports i use 16 gauge. Or the floor pans i use 18 gauge. Sheet metal thickness is vital for vehicle durability.. Car Floor Metal Thickness.

From favpng.com

Car Floor Steel Angle, PNG, 500x500px, Car, Automotive Exterior, Floor Car Floor Metal Thickness What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. I used 16 gage flat sheet for a 24 x 43. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. The carbon content in either one is kept low to aid formability. For the floor supports i use. Car Floor Metal Thickness.

From www.walmart.com

FlooringInc Diamond Nitro Rolls Standard Grade Stainless Steel 7.5'x25 Car Floor Metal Thickness Ford used 19 gauge on most exterior sheetmetal untill the. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. Learn how to identify steel thickness and choose the right gauge for your car restoration project. Get the right steel gauge for your floor pan repair.. Car Floor Metal Thickness.

From www.youtube.com

Inventor How To Change Sheet Metal Thickness Tutorial YouTube Car Floor Metal Thickness What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Sheet metal thickness is vital for vehicle durability. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. In order to fabricate a. Car Floor Metal Thickness.

From learninglibzeberhardt.z13.web.core.windows.net

Standard Aluminum Sheet Metal Thickness Chart Car Floor Metal Thickness Get the right steel gauge for your floor pan repair. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Car makers use aluminum killed. For the floor supports i use 16 gauge. The carbon content in either one is kept low. Car Floor Metal Thickness.

From www.summitracing.com

Auto Metal Direct 4001067 Auto Metal Direct Front Floor Pans Summit Car Floor Metal Thickness Learn how to identify steel thickness and choose the right gauge for your car restoration project. Get the right steel gauge for your floor pan repair. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. What thickness or gauge is standard automotive sheetmetal on american. Car Floor Metal Thickness.

From forum.ih8mud.com

Chassis metal thickness? IH8MUD Forum Car Floor Metal Thickness Sheet metal thickness is vital for vehicle durability. Get the right steel gauge for your floor pan repair. Ford used 19 gauge on most exterior sheetmetal untill the. The carbon content in either one is kept low to aid formability. Commercial quality hot or cold rolled sheet is typically 1008 or 1010. Learn how to identify steel thickness and choose. Car Floor Metal Thickness.

From www.approvedsheetmetal.com

Sheet Metal Material Thickness (Updated for 2024) ASM Car Floor Metal Thickness Car makers use aluminum killed. What thickness or gauge is standard automotive sheetmetal on american vehicles, such as a door skin or fender skin. Ford used 19 gauge on most exterior sheetmetal untill the. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner. Or the floor pans i use 18 gauge. I used. Car Floor Metal Thickness.