Copper Nickel Hardness . The 70/30 copper nickel alloys have great resistance to sea water. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. Rockwell hardness test is one of. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. pure copper is relatively soft, with a brinell hardness of around 36 hb. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. copper nickel alloys are of two types which include 70/30 and 90/10.

from www.metallurgy.nist.gov

pure copper is relatively soft, with a brinell hardness of around 36 hb. The 70/30 copper nickel alloys have great resistance to sea water. copper nickel alloys are of two types which include 70/30 and 90/10. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. However, the hardness of copper alloys can be significantly increased through. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. Rockwell hardness test is one of. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance.

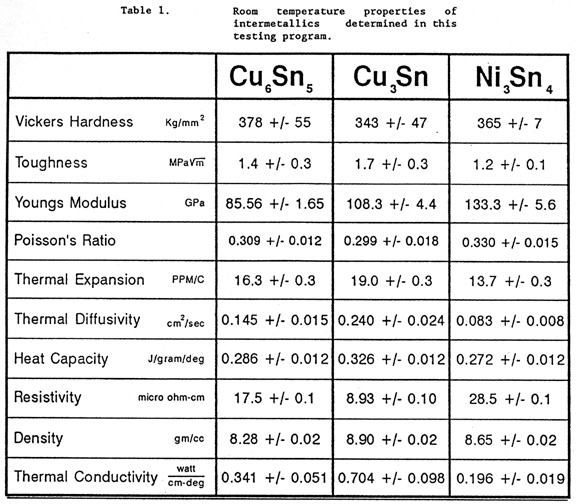

Mechanical Properties of Intermetallic Compounds Formed Between Tin

Copper Nickel Hardness Rockwell hardness test is one of. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. copper nickel alloys are of two types which include 70/30 and 90/10. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. Rockwell hardness test is one of. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. pure copper is relatively soft, with a brinell hardness of around 36 hb. The 70/30 copper nickel alloys have great resistance to sea water.

From www.highnickelsalloy.com

Copper Nickel 90/10 Plates, CuNi 90/10 Sheets, Cupro Nickel 90/10 Wire Copper Nickel Hardness c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. pure copper is relatively soft, with. Copper Nickel Hardness.

From www.researchgate.net

Hardness and layer thickness in copper electroplating on low carbon Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. Rockwell hardness test is one of. copper nickel alloys are of two types which include 70/30 and 90/10. pure copper is relatively soft, with a brinell hardness of around 36 hb. However, the hardness of copper alloys can. Copper Nickel Hardness.

From www.mercuremetals.in

Cupro Nickel 70/30 Cupro Nickel ProductsMercure Metals & Alloys Pvt Ltd. Copper Nickel Hardness However, the hardness of copper alloys can be significantly increased through. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. copper nickel alloys are of two types which include 70/30 and 90/10. c71500 is a copper alloy widely used in applications that demand high strength and corrosion. Copper Nickel Hardness.

From www.researchgate.net

(PDF) Effect of Current Density on Hardness of Low Carbon Steel Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. Rockwell hardness test is one of. However, the hardness of copper alloys can be significantly increased through. pure copper is relatively soft,. Copper Nickel Hardness.

From www.carbonsteel-tube.com

ASTM B111 C70600 Copper Nickel Alloy Pipe , High Hardness Cupro Nickel Pipe Copper Nickel Hardness copper nickel alloys are of two types which include 70/30 and 90/10. Rockwell hardness test is one of. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. the addition of nickel to copper improves its strength and durability and. Copper Nickel Hardness.

From www.materialalloy.com

Hot Rolled Monel K500 Pipe , Copper Nickel Alloy With High Hardness Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. pure copper is relatively soft, with a brinell hardness of around 36 hb. copper nickel alloys are of two types which include 70/30 and 90/10. Rockwell hardness test is one of. c71500 is a copper alloy widely. Copper Nickel Hardness.

From www.youtube.com

Hardenability of Steels YouTube Copper Nickel Hardness In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. Rockwell hardness test is one of. copper nickel alloys are of two types which include 70/30 and 90/10. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell. Copper Nickel Hardness.

From kjfasteners.com

Copper Nickel & Exotic Materials KJ Fasteners, Inc. Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. copper nickel alloys are of two types which include 70/30 and 90/10. However, the hardness of copper alloys can be significantly increased through. pure copper is relatively soft, with a brinell hardness of around 36 hb. the. Copper Nickel Hardness.

From www.metallurgy.nist.gov

Mechanical Properties of Intermetallic Compounds Formed Between Tin Copper Nickel Hardness copper nickel alloys are of two types which include 70/30 and 90/10. However, the hardness of copper alloys can be significantly increased through. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness,. Copper Nickel Hardness.

From www.copper.org

Resources Standards & Properties Copper & Copper Microstructures Copper Nickel Hardness the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. pure copper is relatively soft, with a brinell hardness of around 36 hb. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. In this article, we will explore. Copper Nickel Hardness.

From blog.thepipingmart.com

Copper vs Nickel What's the Difference Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. The 70/30 copper. Copper Nickel Hardness.

From www.alibaba.com

Hardness Of Cobalt Nickel Beryllium Copper Alloys Bar Round Rod Price Copper Nickel Hardness pure copper is relatively soft, with a brinell hardness of around 36 hb. However, the hardness of copper alloys can be significantly increased through. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. copper nickel alloys are of two types which include 70/30 and 90/10. Rockwell hardness test is one. Copper Nickel Hardness.

From material-properties.org

Nickel Strength Hardness Elasticity Crystal Structure Copper Nickel Hardness c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. The 70/30 copper nickel alloys have great resistance to sea water. However, the hardness of copper alloys can be significantly increased through. Rockwell hardness test is one of. pure copper is relatively soft, with a brinell hardness of around 36 hb. . Copper Nickel Hardness.

From mungfali.com

ASTM Hardness Conversion Chart Copper Nickel Hardness pure copper is relatively soft, with a brinell hardness of around 36 hb. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. Rockwell hardness test is one of. c71500 is a copper alloy widely used in applications that demand high strength and. Copper Nickel Hardness.

From dokumen.tips

(PDF) Microstructure and hardness development in a coppernickel Copper Nickel Hardness the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. copper nickel alloys are of two types which include 70/30 and 90/10. The 70/30 copper nickel alloys have great resistance to sea. Copper Nickel Hardness.

From keymetals.com

Hardness Chart Key Metals Copper Nickel Hardness c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. copper nickel alloys are of two types which include 70/30 and 90/10. The 70/30 copper nickel alloys have great resistance to sea water. In this article, we will explore what c71500. Copper Nickel Hardness.

From blog.thepipingmart.com

Separating Nickel from Copper 3 Easy Steps Copper Nickel Hardness In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. copper nickel alloys are of two types which include 70/30 and 90/10. Rockwell hardness test is one of. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell. Copper Nickel Hardness.

From fittinoxforge.com

Copper Nickel Alloy Fittinox Industries Copper Nickel Hardness Rockwell hardness test is one of. The 70/30 copper nickel alloys have great resistance to sea water. However, the hardness of copper alloys can be significantly increased through. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. pure copper is relatively soft, with a brinell hardness of around 36 hb. . Copper Nickel Hardness.

From www.citizenpipes.net

nickel alloys chemical compositionChemical composition of Nickel Copper Nickel Hardness pure copper is relatively soft, with a brinell hardness of around 36 hb. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. The 70/30 copper nickel alloys have great resistance to. Copper Nickel Hardness.

From br.pinterest.com

Metal Hardness Chart based on Rockwell scale and ductility. Metal Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. However, the hardness of copper alloys can be significantly increased through. The 70/30 copper nickel alloys have great resistance to sea water. copper nickel alloys are of two types which include 70/30 and 90/10. pure copper is relatively. Copper Nickel Hardness.

From www.nuclear-power.com

Hardness of Copper Alloys Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. The 70/30 copper nickel alloys have great resistance to sea water. pure copper is relatively soft, with a brinell hardness of around. Copper Nickel Hardness.

From www.researchgate.net

4 Hardness of Copper Zinc alloy and copper zinc alloy with 3 wt. and Copper Nickel Hardness Rockwell hardness test is one of. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. The 70/30 copper nickel alloys have great resistance to sea water. c71500 is. Copper Nickel Hardness.

From www.techni-cast.com

Copper Nickels Copper Nickel Hardness c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. Rockwell hardness test is one of. pure copper is relatively soft, with a brinell hardness of around 36 hb. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. the addition. Copper Nickel Hardness.

From pmfirst.com

PM Hardness Chart 6 Moly Super Duplex Copper Nickel Alloys6 Moly Copper Nickel Hardness In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. pure copper is relatively soft, with a brinell hardness of around 36 hb. copper nickel alloys are of two types which include 70/30 and 90/10. 73 rows atomic number chemical symbol name. Copper Nickel Hardness.

From blog.thepipingmart.com

Copper Nickel Corrosion An Overview Copper Nickel Hardness Rockwell hardness test is one of. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. pure copper is relatively soft, with a brinell hardness of around 36 hb. However, the hardness of copper alloys can be significantly increased through. c71500 is a copper alloy widely used in. Copper Nickel Hardness.

From www.copper.org

Standards & Properties Mechanical Properties of Copper and Copper Copper Nickel Hardness In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. The 70/30 copper nickel alloys have great resistance to sea water. However, the hardness of. Copper Nickel Hardness.

From blog.thepipingmart.com

Copper Nickel Plating Process An Overview Copper Nickel Hardness The 70/30 copper nickel alloys have great resistance to sea water. pure copper is relatively soft, with a brinell hardness of around 36 hb. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. the addition of nickel to copper. Copper Nickel Hardness.

From aradbranding.com

Copper Nickel Alloy (Cupro Nickel) Pipe Tube 70 30 Ratio Corrosion Copper Nickel Hardness In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion, erosion and. Rockwell hardness test is one of. The 70/30 copper nickel alloys have great resistance to. Copper Nickel Hardness.

From blog.thepipingmart.com

Copper Nickel vs Stainless Steel What's the Difference Copper Nickel Hardness The 70/30 copper nickel alloys have great resistance to sea water. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. copper nickel alloys are of two types which include 70/30 and 90/10. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness,. Copper Nickel Hardness.

From blog.thepipingmart.com

Advantages and Disadvantages of Copper Nickel Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. The 70/30 copper nickel alloys have great resistance to sea water. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. copper nickel alloys. Copper Nickel Hardness.

From www.tradeindia.com

Copper Nickel Sheet Hardness Hard at Best Price in Mumbai Trident Copper Nickel Hardness 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. However, the hardness of copper alloys can be significantly increased through. pure copper is relatively soft, with a brinell hardness of around 36 hb. Rockwell hardness test is one of. the addition of nickel to copper improves its. Copper Nickel Hardness.

From issuu.com

Datasheet For Copper Nickel by steelpipesfactory Issuu Copper Nickel Hardness pure copper is relatively soft, with a brinell hardness of around 36 hb. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment, welding, and corrosion resistance. copper nickel alloys are of two types which include 70/30 and 90/10. 73 rows atomic number chemical symbol name. Copper Nickel Hardness.

From www.copper.org

Standards & Properties Mechanical Properties of Copper and Copper Copper Nickel Hardness The 70/30 copper nickel alloys have great resistance to sea water. pure copper is relatively soft, with a brinell hardness of around 36 hb. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. the addition of nickel to copper improves its strength and durability and also the resistance to corrosion,. Copper Nickel Hardness.

From www.chemistrylearner.com

Cupronickel (CopperNickel) Facts, Composition, Properties, Uses Copper Nickel Hardness pure copper is relatively soft, with a brinell hardness of around 36 hb. The 70/30 copper nickel alloys have great resistance to sea water. 73 rows atomic number chemical symbol name mohs hardness [1] vickers hardness (mpa) [1] brinell hardness (mpa) [1] brinell. Rockwell hardness test is one of. the addition of nickel to copper improves its. Copper Nickel Hardness.

From www.pipingmaterial.ae

Copper nickel plate cupro nickel sheet suppliers in UAE, Middle East Copper Nickel Hardness The 70/30 copper nickel alloys have great resistance to sea water. c71500 is a copper alloy widely used in applications that demand high strength and corrosion resistance. However, the hardness of copper alloys can be significantly increased through. In this article, we will explore what c71500 is and discuss its composition, physical and mechanical properties, applications, hardness, heat treatment,. Copper Nickel Hardness.