Stainless Steel Polish Grades . Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. the right finish can make a product easier to maintain or give it added durability. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. It is used for cosmetic applications such as mirrors and reflectors. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. All you need to know. what is the stainless steel surface finish? Take a close look at that piece of stainless steel. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect.

from maisieweston.z13.web.core.windows.net

learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. Take a close look at that piece of stainless steel. All you need to know. the right finish can make a product easier to maintain or give it added durability. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. It is used for cosmetic applications such as mirrors and reflectors.

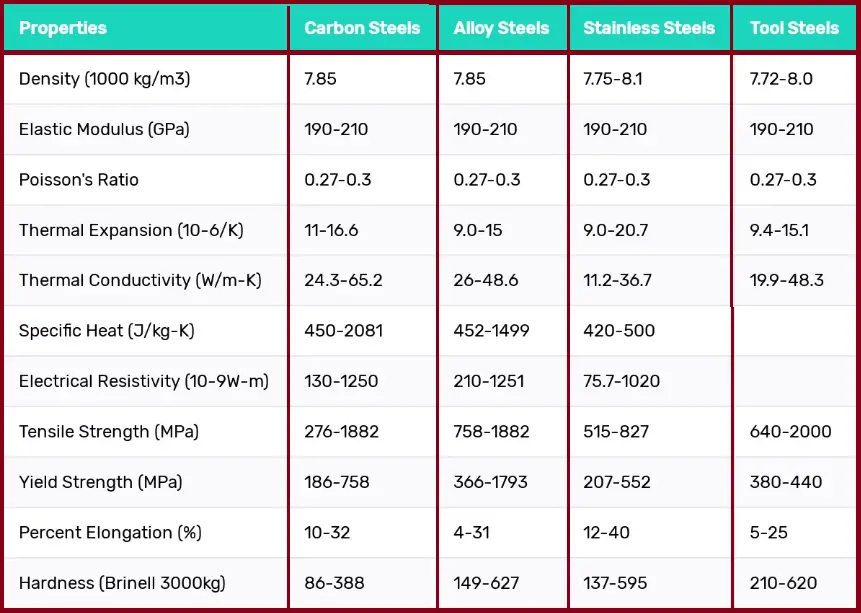

Stainless Steel Grade Chart

Stainless Steel Polish Grades what is the stainless steel surface finish? All you need to know. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. Take a close look at that piece of stainless steel. It is used for cosmetic applications such as mirrors and reflectors. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. the right finish can make a product easier to maintain or give it added durability. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. what is the stainless steel surface finish? Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services.

From www.pinterest.com.au

Stainless Steel comes in many grades which all have different features Stainless Steel Polish Grades polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Take a close look at that piece of stainless steel. Polishing evens out the surface of the metal by using abrasive. Stainless Steel Polish Grades.

From www.namanpipe.com

Stainless Steel Equivalent Grades 304/ 316 European Standard Stainless Steel Polish Grades Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. the right finish can make a product. Stainless Steel Polish Grades.

From yijinsolution.com

Stainless Steel Grades Chart 2023 Updated Stainless Steel Polish Grades Take a close look at that piece of stainless steel. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. polishing stainless steel to. Stainless Steel Polish Grades.

From removeandreplace.com

Stainless Steel Grades and Types Stainless Steel Polish Grades It is used for cosmetic applications such as mirrors and reflectors. what is the stainless steel surface finish? All you need to know. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Take a close. Stainless Steel Polish Grades.

From www.cmpionline.com

A Guide To Stainless Steel Polishing Finishes Stainless Steel Polish Grades Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. It is. Stainless Steel Polish Grades.

From www.midwaymetals.com.au

Stainless Steel Grades & Details Australia Midway Metals Stainless Steel Polish Grades 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. All you need to know. Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. Stainless steel possesses unique qualities. Stainless Steel Polish Grades.

From www.foodconsultingafrica.com

A guide for stainless steel grades in the food industry Stainless Steel Polish Grades In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. what is the stainless steel surface finish? Stainless steel possesses unique qualities such as high strength,. Stainless Steel Polish Grades.

From www.youtube.com

How To Polish Stainless Steel Sheet To Mirror Finish (No. 8 Finish Stainless Steel Polish Grades Take a close look at that piece of stainless steel. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. All you need to know. Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. Polishing evens. Stainless Steel Polish Grades.

From www.abrasionresistantpipe.com

Stainless steel sheet finishes Stainless Steel Polish Grades learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. what is the stainless steel surface finish? Compare the characteristics, applications and roughness values. Stainless Steel Polish Grades.

From www.cmpionline.com

Custom Polishing Services Custom Fabrication Services Stainless Steel Polish Grades Take a close look at that piece of stainless steel. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. All you need to know. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. what. Stainless Steel Polish Grades.

From www.eurosteel.co.za

Stainless Steel Grades and Classifications Explained Euro Steel Stainless Steel Polish Grades Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. It is used for cosmetic applications such as mirrors and reflectors. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Polishing is used to remove surface oxidation, enhance the appearance of metal, create. Stainless Steel Polish Grades.

From www.esteelsuppliers.com

stainless steel grades stainless steel families High Temperature Stainless Steel Polish Grades 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. All you need to know. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and. Stainless Steel Polish Grades.

From www.pinterest.ca

Stainless Steel Grades and Types Stainless Stainless Steel Polish Grades Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. It is used for cosmetic applications such as mirrors and reflectors. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding. Stainless Steel Polish Grades.

From www.empireabrasives.com

Ultimate Guide Stainless Steel Fabrication, Grinding, and Finishing Stainless Steel Polish Grades Take a close look at that piece of stainless steel. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. It is used for cosmetic applications such as mirrors and reflectors. the right finish can make a product easier to maintain or give it added. Stainless Steel Polish Grades.

From basterfield.co.za

Understanding Stainless Steel Grades Blog Basterfield Stainless Steel Polish Grades It is used for cosmetic applications such as mirrors and reflectors. Take a close look at that piece of stainless steel. what is the stainless steel surface finish? polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of. Stainless Steel Polish Grades.

From ar.inspiredpencil.com

Types Of Stainless Steel Finishes Stainless Steel Polish Grades the right finish can make a product easier to maintain or give it added durability. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches,. Stainless Steel Polish Grades.

From dxomwelfk.blob.core.windows.net

Polishing Compound For Stainless at Kathleen Bickerstaff blog Stainless Steel Polish Grades Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their. Stainless Steel Polish Grades.

From www.pbo.co.uk

How to polish stainless steel in the at home Practical Boat Stainless Steel Polish Grades In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. what is the stainless steel surface finish? the right finish can make a product easier to maintain or give it added durability. It is used for cosmetic applications such as mirrors and. Stainless Steel Polish Grades.

From www.namanpipe.com

Stainless Steel Equivalent Grades 304/ 316 European Standard Stainless Steel Polish Grades 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Polishing is used to remove surface oxidation, enhance. Stainless Steel Polish Grades.

From www.aaa-metals.com

Stainless Steel Polishing Services AAA Metals Stainless Steel Polish Grades what is the stainless steel surface finish? In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. Take a close look at that piece of stainless steel. All you need to know. Stainless steel possesses unique qualities such as high strength, excellent wear. Stainless Steel Polish Grades.

From answerzonegerste.z1.web.core.windows.net

Stainless Steel Finish Chart Stainless Steel Polish Grades 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. the right finish can make. Stainless Steel Polish Grades.

From labbyag.es

Stainless Steel Grades Comparison Chart Labb by AG Stainless Steel Polish Grades the right finish can make a product easier to maintain or give it added durability. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Polishing is used to. Stainless Steel Polish Grades.

From falcon-metals.com

Buy Industrial Metal 431 (UNS S43100) Stainless Steel Grades Products Stainless Steel Polish Grades Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Polishing is used to remove surface. Stainless Steel Polish Grades.

From blog.thepipingmart.com

HeatResistant Stainless Steel Grades A Complete Guide Stainless Steel Polish Grades what is the stainless steel surface finish? Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. Take a close look at that piece. Stainless Steel Polish Grades.

From www.eurosteel.co.za

Stainless Steel Sheet and Plate Finishes Euro Steel, SA Stainless Steel Polish Grades In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Polishing. Stainless Steel Polish Grades.

From ponasa.condesan-ecoandes.org

Steel Finish Chart Ponasa Stainless Steel Polish Grades It is used for cosmetic applications such as mirrors and reflectors. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. All you need to know. what is the stainless steel surface finish? Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance. Stainless Steel Polish Grades.

From reysrefinedradiance.wordpress.com

Stainless Steel Grades A Comprehensive Guide for Jewelry Making and Stainless Steel Polish Grades Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. what. Stainless Steel Polish Grades.

From maisieweston.z13.web.core.windows.net

Stainless Steel Grade Chart Stainless Steel Polish Grades polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. what is the stainless steel surface finish? 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are. Stainless Steel Polish Grades.

From www.amardeepsteel.com

Stainless Steel Grades A Comprehensive Guide Stainless Steel Polish Grades Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Compare the characteristics, applications and roughness values of each finish and see examples of laser cutting services. Take a close look at that piece of stainless steel. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a. Stainless Steel Polish Grades.

From onlinemetalsupply.com

Guide to Stainless Steel Sheet Finishes Mill, Polished, Brushed Stainless Steel Polish Grades Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. 8 (mirror) the most reflective surface of stainless steel commonly available, it is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. Take a close look at that. Stainless Steel Polish Grades.

From vishwastainless.blogspot.com

Definite Guide On Stainless Steel Grades Stainless Steel Polish Grades In this ultimate guide, the team at red label abrasives will break down the different types of stainless steel finishes, their applications, and why they matter. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. polishing stainless steel to a gloss finish will improve. Stainless Steel Polish Grades.

From www.cutlery.uk.com

Different Grades of Stainless Steel Lincoln House Cutlery Stainless Steel Polish Grades All you need to know. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. Polishing is used to remove surface oxidation, enhance the appearance of metal,. Stainless Steel Polish Grades.

From www.alibaba.com

Metal Plate Surface Finish Stainless Steel Sheet No.8 Finish Brushing Stainless Steel Polish Grades It is used for cosmetic applications such as mirrors and reflectors. what is the stainless steel surface finish? Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. Compare. Stainless Steel Polish Grades.

From www.unifiedalloys.com

Stainless Steel Grades and Families Explained Unified Alloys Stainless Steel Polish Grades polishing stainless steel to a gloss finish will improve corrosion resistance, as it smooths crevices where rust can collect. Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. Take a close look at that piece of stainless steel. In this ultimate guide, the team at red label abrasives will. Stainless Steel Polish Grades.

From www.scribd.com

Stainless Steel Grade Chart PDF Stainless Steel Steel Stainless Steel Polish Grades learn about different types of stainless steel finishes according to en and astm standards, such as mill, polished, brushed, patterned and coloured finishes. It is used for cosmetic applications such as mirrors and reflectors. Take a close look at that piece of stainless steel. what is the stainless steel surface finish? 8 (mirror) the most reflective surface of. Stainless Steel Polish Grades.