Thermoset Injection Moulding Process . The answer is thermoset injection molding is quite similar to traditional injection molding with. Pellets of thermoplastic material are heated until they melt. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Read about thermoset injection moulding with our guide for engineers. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. This process cures the part so it can never be melted again. The material then cures inside the mold. Learn what materials are best used in this process, and its benefits. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The molten material is injected into a mold cavity under high pressure.

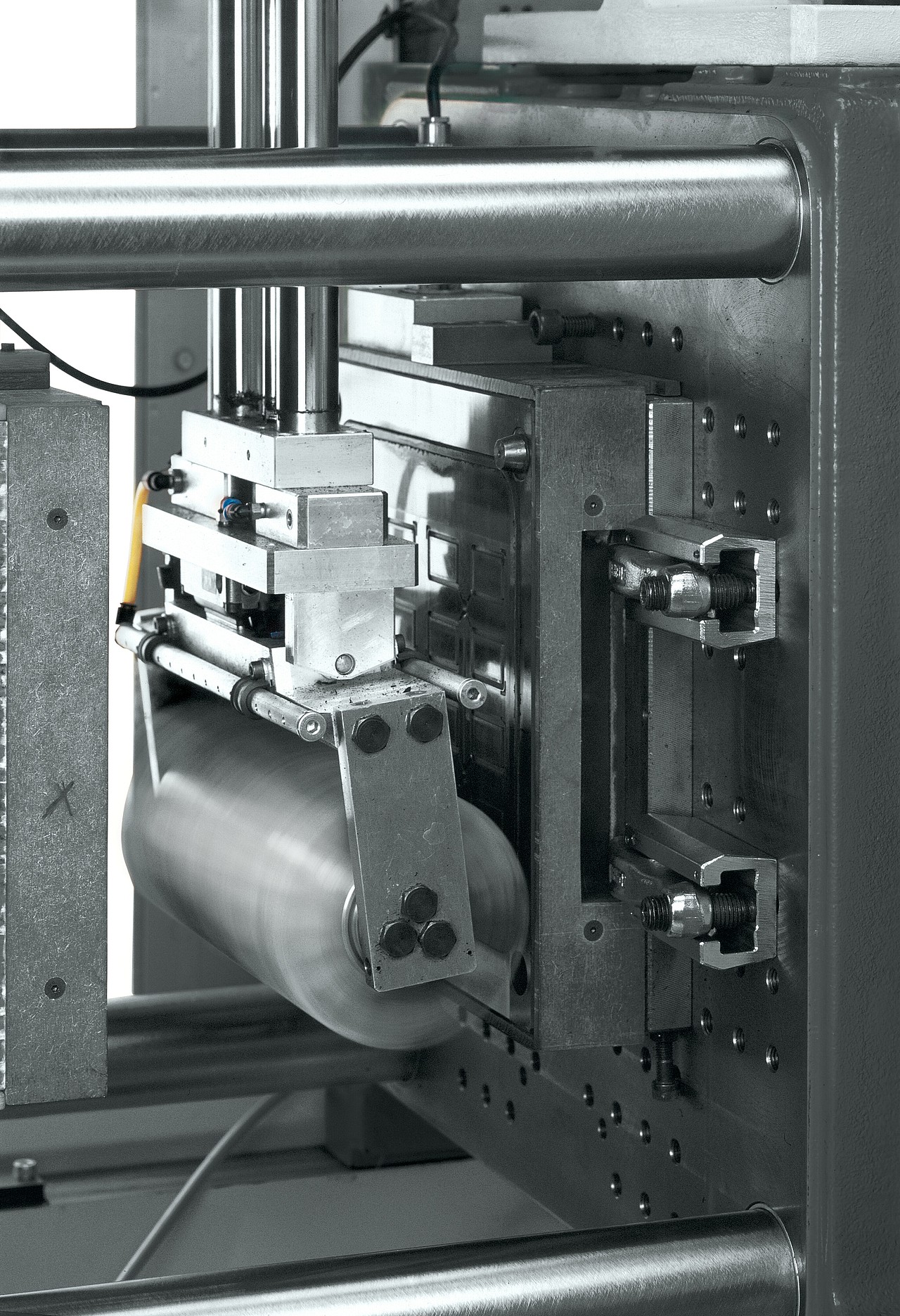

from www.arburg.com

Learn what materials are best used in this process, and its benefits. This process cures the part so it can never be melted again. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. Pellets of thermoplastic material are heated until they melt. Read about thermoset injection moulding with our guide for engineers. The molten material is injected into a mold cavity under high pressure. The answer is thermoset injection molding is quite similar to traditional injection molding with. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift.

Thermoset injection moulding ARBURG

Thermoset Injection Moulding Process The material then cures inside the mold. Read about thermoset injection moulding with our guide for engineers. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Pellets of thermoplastic material are heated until they melt. This process cures the part so it can never be melted again. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. The material then cures inside the mold. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. The molten material is injected into a mold cavity under high pressure. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The answer is thermoset injection molding is quite similar to traditional injection molding with. Learn what materials are best used in this process, and its benefits.

From www.tandfonline.com

Full article Study of material homogeneity in the long fiber thermoset Thermoset Injection Moulding Process In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Learn what materials are best used in this process, and its benefits. The material then cures inside the mold. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Thermoset injection molding uses a specialized injection. Thermoset Injection Moulding Process.

From blog.mar-bal.com

Five Forms of Thermoset Processing Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Pellets of thermoplastic material are heated until they melt. Read about thermoset injection moulding with our guide for engineers. The molten material is injected into a mold cavity under high pressure. Thermoset injection molding uses a specialized injection molding machine equipped with a. Thermoset Injection Moulding Process.

From www.arburg.com

Thermoset injection moulding ARBURG Thermoset Injection Moulding Process In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. Learn what materials are best used in this process, and its benefits. The material then cures. Thermoset Injection Moulding Process.

From www.slideserve.com

PPT Thermoplastic Injection Molding & Moldmaking Process PowerPoint Thermoset Injection Moulding Process Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The molten material is injected into a mold cavity under high pressure. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. The material then cures. Thermoset Injection Moulding Process.

From ramanthermosets.com

Injection / compression /transfer moulding facility for thermosets Thermoset Injection Moulding Process The answer is thermoset injection molding is quite similar to traditional injection molding with. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Pellets of. Thermoset Injection Moulding Process.

From technologystudent.com

Further Questions on Polymers Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. The answer is thermoset injection molding is quite similar to traditional injection molding with. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production. Thermoset Injection Moulding Process.

From www.mdpi.com

Polymers Free FullText Innovative Injection Molding Process for Thermoset Injection Moulding Process This process cures the part so it can never be melted again. Pellets of thermoplastic material are heated until they melt. The answer is thermoset injection molding is quite similar to traditional injection molding with. The molten material is injected into a mold cavity under high pressure. Thermoset injection molding process offers a very fast cycle time compared to a. Thermoset Injection Moulding Process.

From www.lcrapid.com

A Brief Introduction of Injection Molding of Thermosetting Plastics Thermoset Injection Moulding Process Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. This process cures the part so it can never be melted again. In thermoset injection molding, cold material is injected into an extremely hot mold to. Thermoset Injection Moulding Process.

From www.freepik.com

Steps extrusion moulding of a thermoplastic. illustration learning for Thermoset Injection Moulding Process Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. Read about thermoset injection moulding with our guide for engineers. Pellets of thermoplastic material are heated until they melt. The answer is thermoset injection molding is quite similar to traditional injection molding with.. Thermoset Injection Moulding Process.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Thermoset Injection Moulding Process Learn what materials are best used in this process, and its benefits. The material then cures inside the mold. The answer is thermoset injection molding is quite similar to traditional injection molding with. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Pellets of thermoplastic material are heated until they melt. Thermoset. Thermoset Injection Moulding Process.

From econengineering.com

Application of thermosetting metallic composite mould inserts in Thermoset Injection Moulding Process The molten material is injected into a mold cavity under high pressure. This process cures the part so it can never be melted again. Learn what materials are best used in this process, and its benefits. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce. Thermoset Injection Moulding Process.

From acplasticsltd.co.uk

Injection Moulding Company Liverpool, UK AC Plastics Thermoset Injection Moulding Process This process cures the part so it can never be melted again. The answer is thermoset injection molding is quite similar to traditional injection molding with. Learn what materials are best used in this process, and its benefits. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder. Thermoset Injection Moulding Process.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Thermoset Injection Moulding Process The molten material is injected into a mold cavity under high pressure. The answer is thermoset injection molding is quite similar to traditional injection molding with. Read about thermoset injection moulding with our guide for engineers. Learn what materials are best used in this process, and its benefits. In thermoset injection molding, cold material is injected into an extremely hot. Thermoset Injection Moulding Process.

From www.treatstock.com

Guides A Closer Look at Reaction Injection Molding Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. This process cures the part so it can never be melted again. The material then cures inside the mold. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce. Thermoset Injection Moulding Process.

From www.researchgate.net

(PDF) Modification of the Thermoset Injection Moulding Process for Thermoset Injection Moulding Process Learn what materials are best used in this process, and its benefits. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Pellets of thermoplastic material are heated until they melt. The answer is thermoset injection molding is quite similar to traditional injection molding with. Read about thermoset injection moulding with our guide. Thermoset Injection Moulding Process.

From blog.mar-bal.com

[Infographic] BMC Molding Processes 101 Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. This process cures the part so it can never be melted again. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. Read about thermoset injection. Thermoset Injection Moulding Process.

From get-it-made.co.uk

Thermoset Injection Moulding Guide Get It Made Thermoset Injection Moulding Process Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold. Thermoset Injection Moulding Process.

From mavink.com

Injection Molding Cycle Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. The answer is thermoset injection molding is quite similar. Thermoset Injection Moulding Process.

From www.the-gold-blog.com

Overview On Thermoset Moulding Industry Everything About Business Thermoset Injection Moulding Process Learn what materials are best used in this process, and its benefits. The molten material is injected into a mold cavity under high pressure. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The answer is thermoset injection molding is quite similar. Thermoset Injection Moulding Process.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Thermoset Injection Moulding Process In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Learn what materials are best used in this process, and its benefits. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a. Thermoset Injection Moulding Process.

From ramanthermosets.com

Injection / compression /transfer moulding facility for thermosets Thermoset Injection Moulding Process Learn what materials are best used in this process, and its benefits. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. The molten material is injected into a mold cavity under high pressure. This process. Thermoset Injection Moulding Process.

From www.youtube.com

Automation in Thermoset Molding YouTube Thermoset Injection Moulding Process Read about thermoset injection moulding with our guide for engineers. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. The molten material is injected into a mold cavity under high pressure. This process cures the part so it can never be melted again. Thermoset injection molding uses a specialized injection molding machine. Thermoset Injection Moulding Process.

From witmold.com

Difference between Thermoset & Thermoplastic Injection Molding WIT MOLD Thermoset Injection Moulding Process This process cures the part so it can never be melted again. The answer is thermoset injection molding is quite similar to traditional injection molding with. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Pellets of thermoplastic material are heated until they melt. The molten material is injected into a mold. Thermoset Injection Moulding Process.

From www.researchgate.net

Process sequence for the integrative combination of prepreg compression Thermoset Injection Moulding Process This process cures the part so it can never be melted again. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Thermoset injection molding process offers a very fast cycle time compared to a compression. Thermoset Injection Moulding Process.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Thermoset Injection Moulding Process Learn what materials are best used in this process, and its benefits. The answer is thermoset injection molding is quite similar to traditional injection molding with. Read about thermoset injection moulding with our guide for engineers. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. The material then cures inside the mold.. Thermoset Injection Moulding Process.

From www.plasticmoulds.net

Injection Molding Process Thermoset Injection Moulding Process Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Pellets of thermoplastic material are heated until they melt. Read about thermoset injection moulding with our guide for engineers. This process cures the part so it. Thermoset Injection Moulding Process.

From msicarolina.com

What Is Thermoset Molding? Manufacturing Services, Inc. Thermoset Injection Moulding Process In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Pellets of thermoplastic material are heated until they melt.. Thermoset Injection Moulding Process.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Thermoset Injection Moulding Process In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Learn what materials are best used in this process,. Thermoset Injection Moulding Process.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Thermoset Injection Moulding Process Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The answer is thermoset injection molding is quite similar to traditional injection molding with. Learn what materials are best used in this process, and its benefits. This process cures the part so it. Thermoset Injection Moulding Process.

From www.inoxcast.com

Thermoplastic Injection Molding Best Provider Inox Casting Thermoset Injection Moulding Process Pellets of thermoplastic material are heated until they melt. Learn what materials are best used in this process, and its benefits. The molten material is injected into a mold cavity under high pressure. The answer is thermoset injection molding is quite similar to traditional injection molding with. In thermoplastic injection molding, plastic material is melted and injected into a mold. Thermoset Injection Moulding Process.

From www.stechfordmouldings.co.uk

Thermoset Injection Moulding — Stechford Mouldings Thermoset Injection Moulding Process This process cures the part so it can never be melted again. In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. Read about thermoset injection moulding with our guide for engineers. Learn what materials are best used in this process, and its benefits. In thermoplastic injection molding, plastic material is melted and. Thermoset Injection Moulding Process.

From mould-technology.blogspot.com

Introduction to Mold Engineering of Thermoplastic Injection Mold Thermoset Injection Moulding Process Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. The answer is thermoset injection molding is quite similar. Thermoset Injection Moulding Process.

From www.youtube.com

Plastic Injection Moulding Machine Process Animation Construction and Thermoset Injection Moulding Process The material then cures inside the mold. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. The molten material is injected into a mold cavity under high pressure. In thermoset injection molding, cold material is injected into an extremely hot mold to. Thermoset Injection Moulding Process.

From www.weetect.com

Polycarbonate Injection Molding The Complete Guide Wee Tect Thermoset Injection Moulding Process In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. This process cures the part so it can never be melted again. Thermoset injection molding uses a specialized injection molding machine equipped with a plunger or a reciprocating screw to inject the heated thermosetting material into the mold cavity. In thermoplastic injection molding,. Thermoset Injection Moulding Process.

From www.injectionmoldchina.com

4 Types of Plastic Moulding Thermoset Injection Moulding Process This process cures the part so it can never be melted again. The molten material is injected into a mold cavity under high pressure. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. In thermoplastic. Thermoset Injection Moulding Process.