Propeller Shaft Nut Torque . Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. You may reference table 1 for the correct torque for. If the applied torque gets too low, the propeller can break the prop shaft when (hate it when that happens.) you could always refer to standard tables of bolt torque. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Always refer to the instructions included with your hub kit for detailed. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. When you tighten, or torque, the nut to spec, the nut is tight because it is. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Secure it with the aft. Wait for 5 to 10 minutes. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder.

from innovationdiscoveries.space

As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. Secure it with the aft. Wait for 5 to 10 minutes. (hate it when that happens.) you could always refer to standard tables of bolt torque. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. You may reference table 1 for the correct torque for. Always refer to the instructions included with your hub kit for detailed. When you tighten, or torque, the nut to spec, the nut is tight because it is.

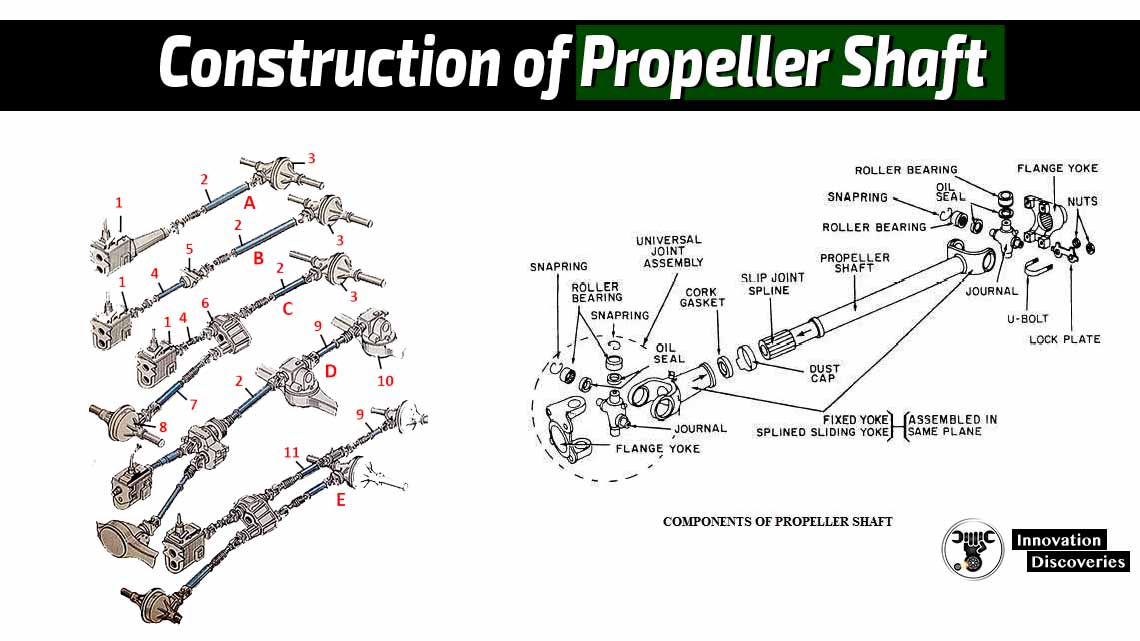

Construction of Propeller Shaft

Propeller Shaft Nut Torque (hate it when that happens.) you could always refer to standard tables of bolt torque. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. When you tighten, or torque, the nut to spec, the nut is tight because it is. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Wait for 5 to 10 minutes. Secure it with the aft. If the applied torque gets too low, the propeller can break the prop shaft when Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. (hate it when that happens.) you could always refer to standard tables of bolt torque. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. Always refer to the instructions included with your hub kit for detailed. You may reference table 1 for the correct torque for.

From www.researchgate.net

The forces and torque acting on the model propeller (Solidworks 2014 Propeller Shaft Nut Torque If the applied torque gets too low, the propeller can break the prop shaft when Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off.. Propeller Shaft Nut Torque.

From galvinconanstuart.blogspot.com

Freightliner Drive Shaft Diagram General Wiring Diagram Propeller Shaft Nut Torque You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank. Propeller Shaft Nut Torque.

From innovationdiscoveries.space

Construction of Propeller Shaft Propeller Shaft Nut Torque Always refer to the instructions included with your hub kit for detailed. When you tighten, or torque, the nut to spec, the nut is tight because it is. If the applied torque gets too low, the propeller can break the prop shaft when Wait for 5 to 10 minutes. You’d select the recommended torque for the bolt diameter of the. Propeller Shaft Nut Torque.

From wuling.id

Propeller Shaft Functions, Types and How They Work Wuling Propeller Shaft Nut Torque The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. You may reference table 1 for the correct torque for. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. Align the splines of the propeller with the splines on the shaft and. Propeller Shaft Nut Torque.

From www.numerade.com

SOLVED Torsional Spring Constant of a Propeller Shaft AMPLE 1.6 Propeller Shaft Nut Torque If the applied torque gets too low, the propeller can break the prop shaft when Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Always refer to the instructions included with your hub kit for detailed. Torque for installation of fixed pitch propellers is contained in the. Propeller Shaft Nut Torque.

From www.theengineerspost.com

Propeller Shaft Diagram, Parts, Types, Functions [PDF] Propeller Shaft Nut Torque Always refer to the instructions included with your hub kit for detailed. If the applied torque gets too low, the propeller can break the prop shaft when As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Align. Propeller Shaft Nut Torque.

From wuling.id

Propeller Shaft Functions, Types and How They Work Wuling Propeller Shaft Nut Torque Wait for 5 to 10 minutes. If the applied torque gets too low, the propeller can break the prop shaft when Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. (hate it when. Propeller Shaft Nut Torque.

From www.newkidscar.com

Propeller Shaft Diagram Car Anatomy in Diagram Propeller Shaft Nut Torque Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. You may reference table. Propeller Shaft Nut Torque.

From www.marineinsight.com

Procedure For Ship Propeller Renewal Propeller Shaft Nut Torque Wait for 5 to 10 minutes. You may reference table 1 for the correct torque for. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. Secure it with the. Propeller Shaft Nut Torque.

From www.researchgate.net

Propeller thrust, torque and RPM Download Scientific Diagram Propeller Shaft Nut Torque You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. Always refer to the instructions included with your hub kit for detailed. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. Torque for installation of fixed. Propeller Shaft Nut Torque.

From peparts.honda.com

Honda Power Products Parts Parts look up and information Propeller Shaft Nut Torque (hate it when that happens.) you could always refer to standard tables of bolt torque. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. Wait for 5 to 10 minutes. You may reference table 1 for the. Propeller Shaft Nut Torque.

From www.kitplanes.com

Torque Wrench Basics KITPLANES Propeller Shaft Nut Torque Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. Secure it with the aft. (hate it when that happens.) you could always refer to. Propeller Shaft Nut Torque.

From innovationdiscoveries.space

How Propeller Works & Functions Of Propeller Propeller Shaft Nut Torque As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. Wait for 5 to 10 minutes. Secure it with the aft. If the applied. Propeller Shaft Nut Torque.

From www.slideserve.com

PPT ??? Propeller Thrust, Torque & RPM PowerPoint Presentation ID Propeller Shaft Nut Torque When you tighten, or torque, the nut to spec, the nut is tight because it is. You may reference table 1 for the correct torque for. Wait for 5 to 10 minutes. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the. Propeller Shaft Nut Torque.

From www.mechanical-knowledge.com

PROPELLER SHAFT FUNCTION, TYPES, COMPONENTS AND REQUIREMENTS Propeller Shaft Nut Torque As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. If the applied torque gets too low, the propeller can break the prop shaft when Align the splines of the propeller with the splines on the shaft and. Propeller Shaft Nut Torque.

From www.tohighlander.com

Toyota Highlander Service Manual Drive shaft / propeller shaft / axle Propeller Shaft Nut Torque Secure it with the aft. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Wait for 5 to 10 minutes. You may reference table 1 for the correct torque for. If the applied torque gets too low, the propeller can break the prop shaft when Always refer. Propeller Shaft Nut Torque.

From toyota.udlvirtual.edu.pe

Toyota Propeller Shaft Torque Latest Toyota News Propeller Shaft Nut Torque When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. The propeller nuts purpose is to make sure the prop. Propeller Shaft Nut Torque.

From www.slideserve.com

PPT Chapter 3 / The Propeller PowerPoint Presentation, free download Propeller Shaft Nut Torque Secure it with the aft. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. Wait for 5 to 10 minutes. The propeller nuts purpose is to make. Propeller Shaft Nut Torque.

From www.2carpros.com

Torque for Drive Shaft Bolts What Is the Torque Spec to Replace Propeller Shaft Nut Torque If the applied torque gets too low, the propeller can break the prop shaft when When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. When you tighten, or torque, the nut. Propeller Shaft Nut Torque.

From tacomaworld.com

The Torque Spec. Guide World Propeller Shaft Nut Torque The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. If the applied torque gets too low, the propeller can break the prop shaft when As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick. Propeller Shaft Nut Torque.

From answerbun.com

Reacting Propeller Torque? Engineering Propeller Shaft Nut Torque Wait for 5 to 10 minutes. Always refer to the instructions included with your hub kit for detailed. You may reference table 1 for the correct torque for. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. The propeller nuts purpose is to make sure the prop is seated snugly against. Propeller Shaft Nut Torque.

From www.unitedpropeller.ca

Inboard Propeller Installation Procedures Orillia United Propeller Propeller Shaft Nut Torque Secure it with the aft. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. (hate it when that happens.) you could always refer to standard tables of bolt torque. Align the splines of the propeller. Propeller Shaft Nut Torque.

From innovationdiscoveries.space

Construction of Propeller Shaft Propeller Shaft Nut Torque Wait for 5 to 10 minutes. Secure it with the aft. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or. Propeller Shaft Nut Torque.

From www.dreamstime.com

Rubber Coupling of the Propeller Shaft for Smooth Transmission of Propeller Shaft Nut Torque When you tighten, or torque, the nut to spec, the nut is tight because it is. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. Wait for 5 to. Propeller Shaft Nut Torque.

From www.youtube.com

propeller shaft explained YouTube Propeller Shaft Nut Torque You may reference table 1 for the correct torque for. Secure it with the aft. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. (hate it when that. Propeller Shaft Nut Torque.

From www.tacomaworld.com

The Torque Spec. Guide World Propeller Shaft Nut Torque Secure it with the aft. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Wait for 5 to 10 minutes. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. (hate it when. Propeller Shaft Nut Torque.

From www.justanswer.com

Propeller Shaft & Torque Tube Q&A, Diagrams & Differences JustAnswer Propeller Shaft Nut Torque Secure it with the aft. If the applied torque gets too low, the propeller can break the prop shaft when As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. You may reference table 1 for the correct. Propeller Shaft Nut Torque.

From wuling.id

Propeller Shaft Functions, Types and How They Work Wuling Propeller Shaft Nut Torque The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. You may reference table 1 for the correct torque for. Always refer to the instructions included with your hub kit for detailed. Align the splines of the propeller with the splines on the shaft and slide the. Propeller Shaft Nut Torque.

From www.futek.com

How to Measure Thrust of a Propeller VTOL Propeller Thrust Measurement Propeller Shaft Nut Torque Wait for 5 to 10 minutes. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. You may reference table 1 for the correct torque for. Secure it with the aft. Align the splines of the propeller with the splines on the shaft and slide the propeller. Propeller Shaft Nut Torque.

From www.researchgate.net

Propeller thrust and torque coefficient. Download Scientific Diagram Propeller Shaft Nut Torque Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Always refer to the instructions included with your hub kit for detailed. You may reference table 1 for the correct torque for. When the nut bottoms out against the propeller, it seats itself tight by gripping the outer. Propeller Shaft Nut Torque.

From peparts.honda.com

Honda Power Products Parts Parts look up and information Propeller Shaft Nut Torque When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. (hate it when that happens.) you could always refer to standard tables of bolt torque. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. As one applies more torque. Propeller Shaft Nut Torque.

From html.rhhz.net

Propeller Torque Load and Propeller Shaft Torque Response Correlation Propeller Shaft Nut Torque When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. You may reference table 1 for the correct torque for. Always refer to the instructions included with your hub. Propeller Shaft Nut Torque.

From propshopinc.com

How to measure nut size for a marine shaft The Prop Shop Propeller Shaft Nut Torque When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. When you tighten, or torque, the nut to spec, the nut is tight because it is. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. Secure it with the aft. If. Propeller Shaft Nut Torque.

From www.youtube.com

How propeller shaft works. YouTube Propeller Shaft Nut Torque When the nut bottoms out against the propeller, it seats itself tight by gripping the outer flank harder. As one applies more torque to the larger nut, which has twice as many threads and is therefore more powerful, the thick nut begins lifting (or unloading) the half nut off the. Torque for installation of fixed pitch propellers is contained in. Propeller Shaft Nut Torque.

From www.youtube.com

Propeller Shaft Working Drive Shaft Automobile Engineering Basics Propeller Shaft Nut Torque Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft. Torque for installation of fixed pitch propellers is contained in the aircraft maintenance manual. Always refer to the instructions included with your hub kit for detailed. You may reference table 1 for the correct torque for. Secure it. Propeller Shaft Nut Torque.