An Vs Jic Flare . jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. An fittings use an increased root radius thread (j thread) and a tighter. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. the most notable difference between these standards are in the threads. key differences between an and jic fittings. Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications.

from www.qchydraulics.com

These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. An fittings use an increased root radius thread (j thread) and a tighter. Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. the most notable difference between these standards are in the threads. key differences between an and jic fittings. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and.

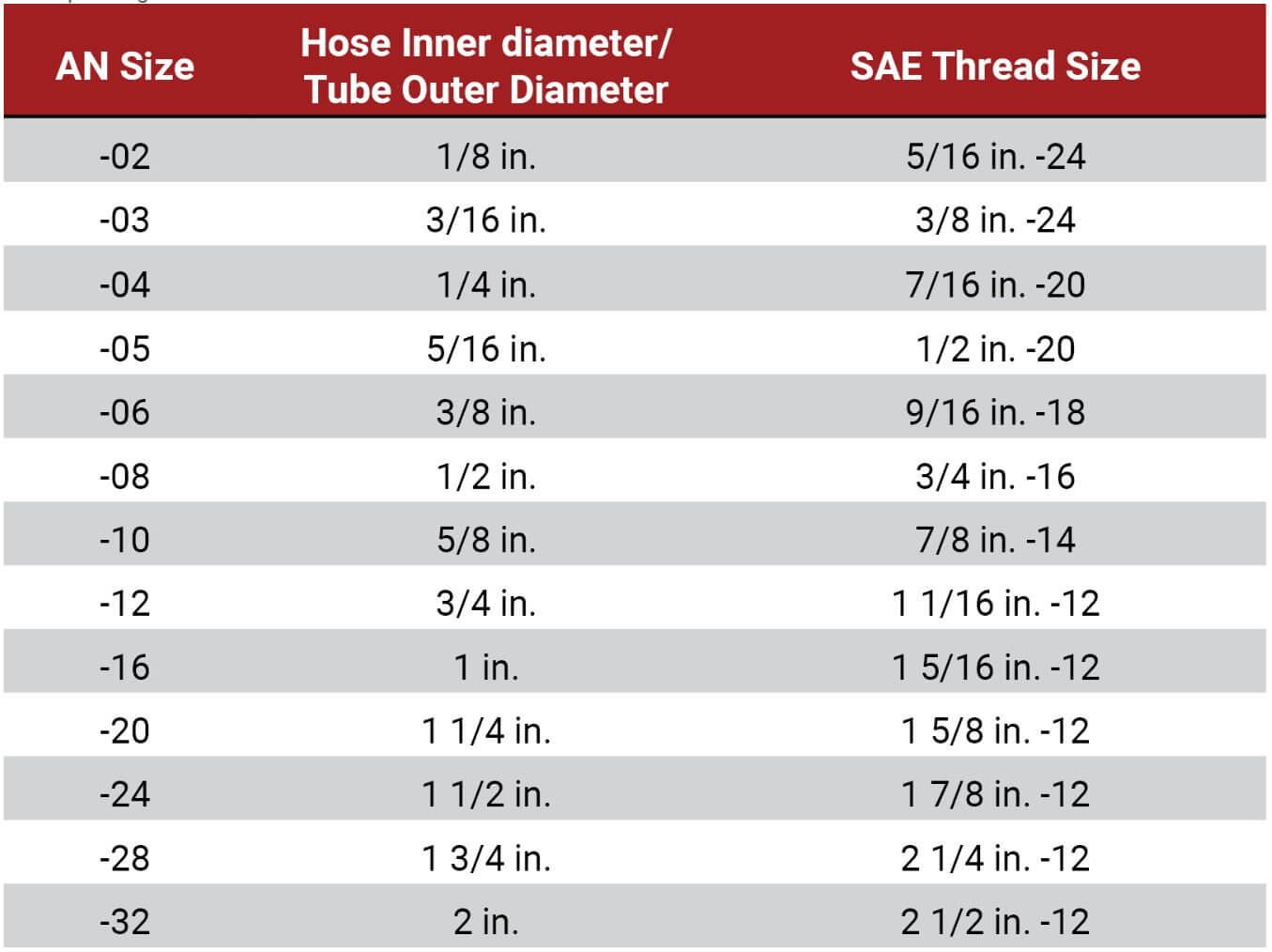

An Fitting Size Chart A guide To the right Size QC Hydraulics

An Vs Jic Flare key differences between an and jic fittings. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. An fittings use an increased root radius thread (j thread) and a tighter. Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. the most notable difference between these standards are in the threads. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. key differences between an and jic fittings.

From www.rhhardware.com

The Battle of Fittings JIC 37 Degree Flare vs SAE 45 Degree Flare An Vs Jic Flare key differences between an and jic fittings. the most notable difference between these standards are in the threads. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. jic and an fittings are the 37° flare fitting originated during wwii, designed to. An Vs Jic Flare.

From aimersmetal.com

Difference between JIC and SAE flare fittings An Vs Jic Flare the most notable difference between these standards are in the threads. key differences between an and jic fittings. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. jic and an fittings are both threaded fittings with a flared end which are used. An Vs Jic Flare.

From exotulqfy.blob.core.windows.net

Gas Range Fitting Size at William Dunklin blog An Vs Jic Flare jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. the most notable difference between these standards are in the threads. key differences between an and jic fittings. These threads have a root radius. An Vs Jic Flare.

From www.triadtechnologies.com

JIC vs. AN Fittings A HeadtoHead Comparison An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. key differences between an and jic fittings. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. Both male and female fittings adhere to class 3a/3b unj/unjf radiused. An Vs Jic Flare.

From hydraulicfitting.cn

JIC vs SAE Flare Fittings Which is Better? Sinopulse hydraulic An Vs Jic Flare to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. key differences between an and jic fittings. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. Though these fittings are similar in appearance and. An Vs Jic Flare.

From www.besteflon.com

News What's the Difference Between AN and JIC Fittings? An Vs Jic Flare These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and.. An Vs Jic Flare.

From www.stainlesssteelfittings.com

Stainless fitting thread guide for NPT, JIC, ORB, SAE, British, Metric An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. the most notable difference between these standards are in the threads. Though these fittings. An Vs Jic Flare.

From www.valvers.com

AN and JIC Fittings An Vs Jic Flare Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. An fittings use an increased root radius thread (j thread) and a tighter. Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. to use jic fittings with rigid tubing, the end of the tubing. An Vs Jic Flare.

From rubberandspecialties.com

JIC vs. SAE Flare Fittings Rubber & Specialties,Inc. An Vs Jic Flare the most notable difference between these standards are in the threads. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. learn the key differences between jic vs an fittings,. An Vs Jic Flare.

From www.carid.com

Redhorse Performance® 826208045 8262 Series Male AN/JIC Flare to An Vs Jic Flare to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. key differences between an and jic fittings. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. the most. An Vs Jic Flare.

From www.linkedin.com

Understanding Tube Flaring and Flanging Applications, ORFS and JIC 37 An Vs Jic Flare to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. Though these fittings are similar in appearance and will connect with one another, it is not. An Vs Jic Flare.

From www.air-way.com

Flares for Tubing AirWay Manufacturing An Vs Jic Flare the most notable difference between these standards are in the threads. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Both male and female fittings adhere to class 3a/3b unj/unjf. An Vs Jic Flare.

From www.jiayuanfitting.com

SAE thread JIC fitting size chart Knowledge Yuyao Jiayuan Hydraulic An Vs Jic Flare Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. the most notable difference between these standards are in the threads. An fittings use an increased root radius thread (j thread) and a tighter. Though these fittings are similar. An Vs Jic Flare.

From exodtzsws.blob.core.windows.net

Jic Fitting Thread Dimensions at Brenda Artis blog An Vs Jic Flare These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. An fittings use an increased root radius thread (j thread) and a tighter. learn the key differences between. An Vs Jic Flare.

From favfittings.com

JIC Flare 37 Degree Fittings FAV Fittings and Valves An Vs Jic Flare Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. An fittings use an increased root radius thread (j thread) and a tighter. the most notable difference between these standards are in the threads. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Though. An Vs Jic Flare.

From www.sxfitting.com

Jic Hydraulic Fittings Size Chart An Vs Jic Flare These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. key differences between an and jic fittings. jic and an fittings are both threaded fittings with a flared end which are used. An Vs Jic Flare.

From www.fav.net.in

JIC Fittings Flare Fittings 37 degree,SAE Flare Fittings An Vs Jic Flare learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. key differences between an and jic fittings. jic and an fittings are both threaded fittings. An Vs Jic Flare.

From www.qchydraulics.com

An Fitting Size Chart A guide To the right Size QC Hydraulics An Vs Jic Flare jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. These threads have a root radius that strengthens the thread, offering tighter tolerances and better. An Vs Jic Flare.

From exodtzsws.blob.core.windows.net

Jic Fitting Thread Dimensions at Brenda Artis blog An Vs Jic Flare These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose. An Vs Jic Flare.

From www.youtube.com

Identifying JIC Fittings and Differences Between Flared AdaptorsJIS An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. the most notable difference between these standards are in the threads. An fittings use an increased root radius thread (j thread) and a tighter. These threads have a root radius that strengthens the thread, offering. An Vs Jic Flare.

From exoojcbhq.blob.core.windows.net

Bulkhead Fitting Chart at Daniel Richards blog An Vs Jic Flare Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. the most notable difference between these standards are in the threads. learn the. An Vs Jic Flare.

From www.carid.com

RHP® 8161 Series Male AN/JIC Flare to Metric Inverted Adapter An Vs Jic Flare key differences between an and jic fittings. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. learn the key differences between jic vs an fittings, including their uses, compatibility,. An Vs Jic Flare.

From fluidpowerjournal.com

Screwed on Right The Pros and Cons of JIC Hydraulic Fittings Fluid An Vs Jic Flare An fittings use an increased root radius thread (j thread) and a tighter. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. the most notable difference between these standards are in the threads. jic and an fittings are both threaded fittings with. An Vs Jic Flare.

From www.ebay.com.au

37 Degree Punch and Die set suit Professional Flaring Tool AN and JIC An Vs Jic Flare Though these fittings are similar in appearance and will connect with one another, it is not advisable to use them interchangeably. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose. An Vs Jic Flare.

From fluiddrivecoupling.com

JIS vs JIC fitting standards Knowledge EVERPOWER GROUP CO., LTD. An Vs Jic Flare An fittings use an increased root radius thread (j thread) and a tighter. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. learn the key differences between jic vs an. An Vs Jic Flare.

From dxocnemtg.blob.core.windows.net

Difference Between Jis And Jic Fittings at Greg Barr blog An Vs Jic Flare to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Though these fittings are similar in appearance and will connect with one another, it. An Vs Jic Flare.

From hydraxio.com

JIC Hydraulic Fittings Hydraxio China SS Hydraulic Fittings An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. key differences between an and jic fittings. jic and an fittings are both threaded fittings with a. An Vs Jic Flare.

From www.amazon.com

Performance Tool W80671 37 Degree Flaring Tool For AN and An Vs Jic Flare These threads have a root radius that strengthens the thread, offering tighter tolerances and better fatigue life. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. the most notable difference between these standards are in the threads. An fittings use an increased root radius thread (j thread) and a tighter. learn the key differences. An Vs Jic Flare.

From exoxelnim.blob.core.windows.net

Are There Different Types Of Hydraulic Hose at Helen Drake blog An Vs Jic Flare jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. the most notable difference between these standards are in the threads. key differences between an and jic fittings. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. to use jic fittings with. An Vs Jic Flare.

From leonwheeler.z13.web.core.windows.net

Jic Hydraulic Fittings Chart An Vs Jic Flare to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. An fittings use an increased root radius thread (j thread) and a tighter. key differences between an and jic fittings. Though these fittings are similar in appearance and will connect with one another, it. An Vs Jic Flare.

From hydraxio.com

Understanding the Differences AN vs. JIC Fittings Hydraxio China SS An Vs Jic Flare An fittings use an increased root radius thread (j thread) and a tighter. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. learn the key differences between jic vs an. An Vs Jic Flare.

From www.hydraulicsdirect.com

6802 JIC to ORB 37° JIC SAE Flare Male x SAE ORing Boss ORB Male An Vs Jic Flare learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. to use jic fittings with rigid tubing, the end of the tubing must be flared to 37° to match the coned seating surface of. jic and an fittings are both threaded fittings with a flared end which are used. An Vs Jic Flare.

From hydraxio.com

JIC Fittings Chart Hydraxio China SS Hydraulic Fittings Manufacturer An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. the most notable difference between these standards are in the threads. to use. An Vs Jic Flare.

From racegearwa.com.au

Fragola AN Fitting 37 Degree JIC Flaring Tool For 3/16", 1/4", 5/16 An Vs Jic Flare An fittings use an increased root radius thread (j thread) and a tighter. Both male and female fittings adhere to class 3a/3b unj/unjf radiused root threads. key differences between an and jic fittings. the most notable difference between these standards are in the threads. learn the key differences between jic vs an fittings, including their uses, compatibility,. An Vs Jic Flare.

From in.pinterest.com

Male JIC flare fitting dimension SAE J514 ISO 84342 Zhejiang, Sae An Vs Jic Flare jic and an fittings are the 37° flare fitting originated during wwii, designed to tight tolerances for the us army and navy, and. learn the key differences between jic vs an fittings, including their uses, compatibility, and how to choose the. to use jic fittings with rigid tubing, the end of the tubing must be flared to. An Vs Jic Flare.