Lube Oil Piping . oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. In typical train steams or. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its.

from www.youtube.com

for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. In typical train steams or. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its.

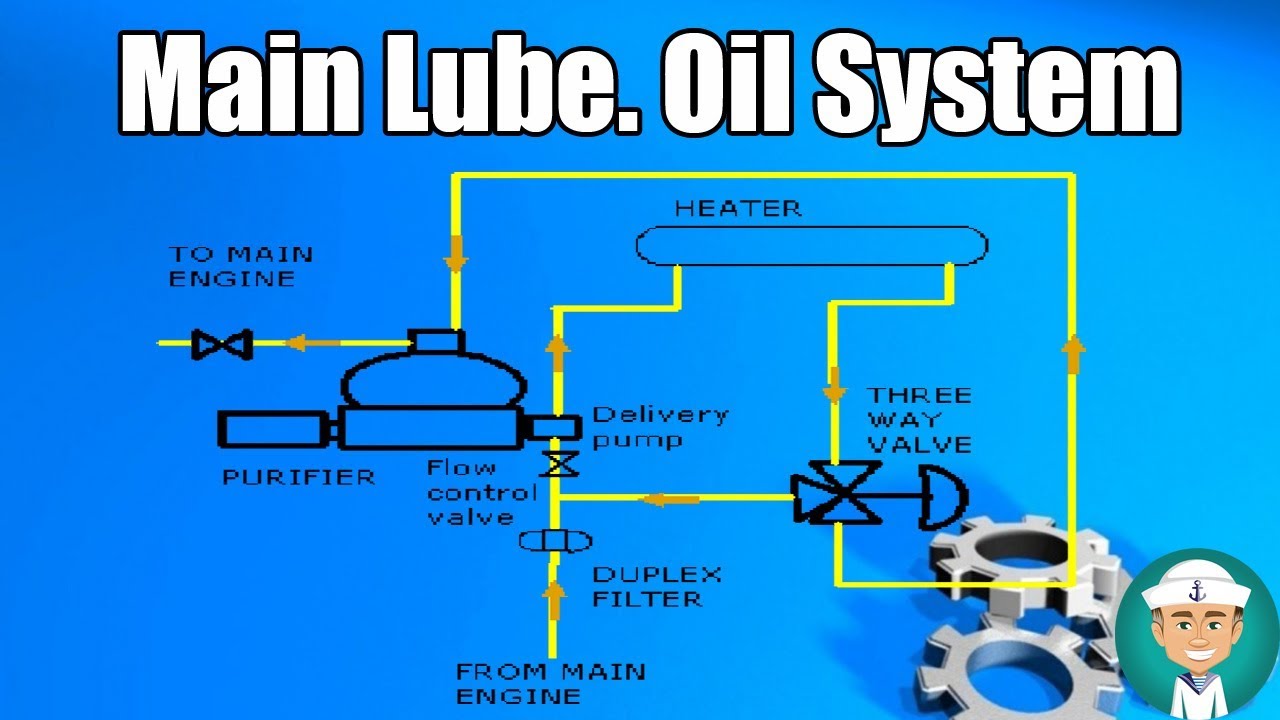

Main Lubricating Oil System YouTube

Lube Oil Piping circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. In typical train steams or. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted.

From www.linkedin.com

Lube Oil System Lube Oil Piping In typical train steams or. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. the circulating lubrication oil system is essential for cooling and. Lube Oil Piping.

From www.precisionfiltration.com

Lube Oil Flush of Gas Turbine Backup Generator Precision Filtration Lube Oil Piping for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable. Lube Oil Piping.

From dir.indiamart.com

Lube Oil System at Best Price in India Lube Oil Piping the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production. Lube Oil Piping.

From www.slideserve.com

PPT Lube Oil System Flushing PowerPoint Presentation, free download Lube Oil Piping carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. piping subject to internal head pressure from oil in the tank must be fitted with. Lube Oil Piping.

From exoclsnyz.blob.core.windows.net

Lube Oil Priming System at Jerome Duppstadt blog Lube Oil Piping circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. In typical train steams or. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. oil. Lube Oil Piping.

From www.ebay.ie

Genuine YANMAR 3GM 3GMF 3GM30 3GM30F Lube Oil Feed Pipe 128370 Lube Oil Piping the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. In typical train steams or. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a. Lube Oil Piping.

From www.bottomlinemarine.com

Genuine YANMAR 1GM 1GM10 lube oil pipe 12817039020 Lubrication Lube Oil Piping piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its.. Lube Oil Piping.

From thepipingtalk.com

Back pressure valve on Lube Oil System The piping talk Lube Oil Piping In typical train steams or. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. for larger machines and production lines, lincoln offers systems to. Lube Oil Piping.

From thepipingtalk.com

Mineral Lube oil and Synthetic lube oil for turbomachinery The piping Lube Oil Piping In typical train steams or. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which. Lube Oil Piping.

From www.scribd.com

LHD5&6E1L1IMTG3001P_R0_Iso Dwg of Lube Oil Piping for unit 5 PDF Lube Oil Piping oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. In typical train steams or. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. the circulating lubrication oil system is essential for cooling and. Lube Oil Piping.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Heritage Parts Centre UK Lube Oil Piping the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. oil flow through the lube oil. Lube Oil Piping.

From www.scribd.com

Piping Lube OilOilconsole en PDF Pump Instrumentation Lube Oil Piping oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. carry out. Lube Oil Piping.

From www.aliexpress.us

10PCSJNtypelubricationBrassoilPipeFitting4mm6mmFitting Lube Oil Piping oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. In typical train steams or. carry out the flushing of lube oil piping through the fine mesh into the. Lube Oil Piping.

From www.youtube.com

Lube Oil Pumping Skid P&ID Pump Skid 3D Link In Description Lube Oil Piping the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger. Lube Oil Piping.

From www.youtube.com

Main Lubricating Oil System YouTube Lube Oil Piping for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. carry out the flushing of lube oil piping through the fine mesh into the return header for. Lube Oil Piping.

From dxorvhhca.blob.core.windows.net

Lubricating Oil Jet at Joshua McCoy blog Lube Oil Piping oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. In typical train steams or. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump. Lube Oil Piping.

From www.youtube.com

Marine Diesel Engine Lubricating oil system YouTube Lube Oil Piping 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. In typical train steams or. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. the circulating lubrication oil system is essential for cooling and lubricating. Lube Oil Piping.

From www.ebay.co.uk

Auto Lube Grease M8 x1 Lubrication Brass oil Pipe Fitting 4mm Tube Lube Oil Piping for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. 15 rows. Lube Oil Piping.

From www.youtube.com

LUBE OIL SYSTEM of STEAM TURBINE YouTube Lube Oil Piping In typical train steams or. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. carry out the flushing of lube oil piping through the fine mesh into the return header. Lube Oil Piping.

From leistritzcorp.com

Optimizing Lube Oil Pumps for Rotating Machinery Lube Oil Piping carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers.. Lube Oil Piping.

From www.eng-tips.com

Lube oil piping Pipelines, Piping and Fluid Mechanics engineering Lube Oil Piping 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. In typical train steams or. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. for larger machines and production lines, lincoln offers systems to lubricate. Lube Oil Piping.

From forums.cgsociety.org

CGTalk Lube oil flow through piping Lube Oil Piping for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. In typical train steams or. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. the circulating lubrication oil system is essential for cooling and lubricating all kinds of. Lube Oil Piping.

From caliberbeauty.blogspot.com

Fuel Oil System Piping Diagram caliberbeauty Lube Oil Piping circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. In typical train steams or. piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of. Lube Oil Piping.

From circuitenginecutty88.z22.web.core.windows.net

Piping Diagram Of Fuel Oil System Lube Oil Piping In typical train steams or. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. piping subject to internal head pressure from oil in the tank must be fitted. Lube Oil Piping.

From www.youtube.com

Main Engine Lube Oil Line Diagram YouTube Lube Oil Piping carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. In typical train steams or. piping subject to internal head pressure from oil in the tank must. Lube Oil Piping.

From hydrosolsystem.com

Lube Oil Piping Cleaning by Hydrosol System Hydrosol System Lube Oil Piping oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. 15 rows. Lube Oil Piping.

From www.youtube.com

Rundown Tank Lube Oil System ProcessAnimation 2022 YouTube Lube Oil Piping In typical train steams or. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers.. Lube Oil Piping.

From www.eng-tips.com

Lube oil piping Pipelines, Piping and Fluid Mechanics engineering Lube Oil Piping piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. carry out the. Lube Oil Piping.

From boatmanuals.tpub.com

Figure 211. Lubricating oil system piping diagram. Lube Oil Piping circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. . Lube Oil Piping.

From www.pigging-systems.com

Sustainable Lube Oil Pigging In Piping Pipe Cleaning Pigging Systems Lube Oil Piping In typical train steams or. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. carry. Lube Oil Piping.

From thepipingtalk.com

Back pressure valve on Lube Oil System The piping talk Lube Oil Piping In typical train steams or. oil flow through the lube oil cooler is typically regulated by a temperature control system consisting of a controller inserted. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump. Lube Oil Piping.

From forums.cgsociety.org

CGTalk Lube oil flow through piping Lube Oil Piping carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge. Lube Oil Piping.

From www.scribd.com

ST4B4898 Rev1 Support Drawing of Lube Oil Piping PDF Lube Oil Piping for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from. circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. . Lube Oil Piping.

From www.ecolnorthamerica.com

Ecol North America Hydrodynamic cleaning and flushing of lubrication Lube Oil Piping In typical train steams or. the circulating lubrication oil system is essential for cooling and lubricating all kinds of rotating machinery. 15 rows oil is drained from the pistons and bearings into the diesel engine sump, from which the scavenge pump takes its. for larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings. Lube Oil Piping.

From whatispiping.com

Oil Mist Lubrication System What Is Piping Lube Oil Piping piping subject to internal head pressure from oil in the tank must be fitted with remotely operable positive shutoff. In typical train steams or. carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. oil flow through the lube oil cooler is typically regulated by. Lube Oil Piping.