Brazing Aluminum Without Flux . — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This article is intended as a general guide to aluminium brazing practices. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. This process, melting a filler metal at lower. — brazing of aluminium alloys was made possible by development of: Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide on aluminium without harming the underlying. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often.

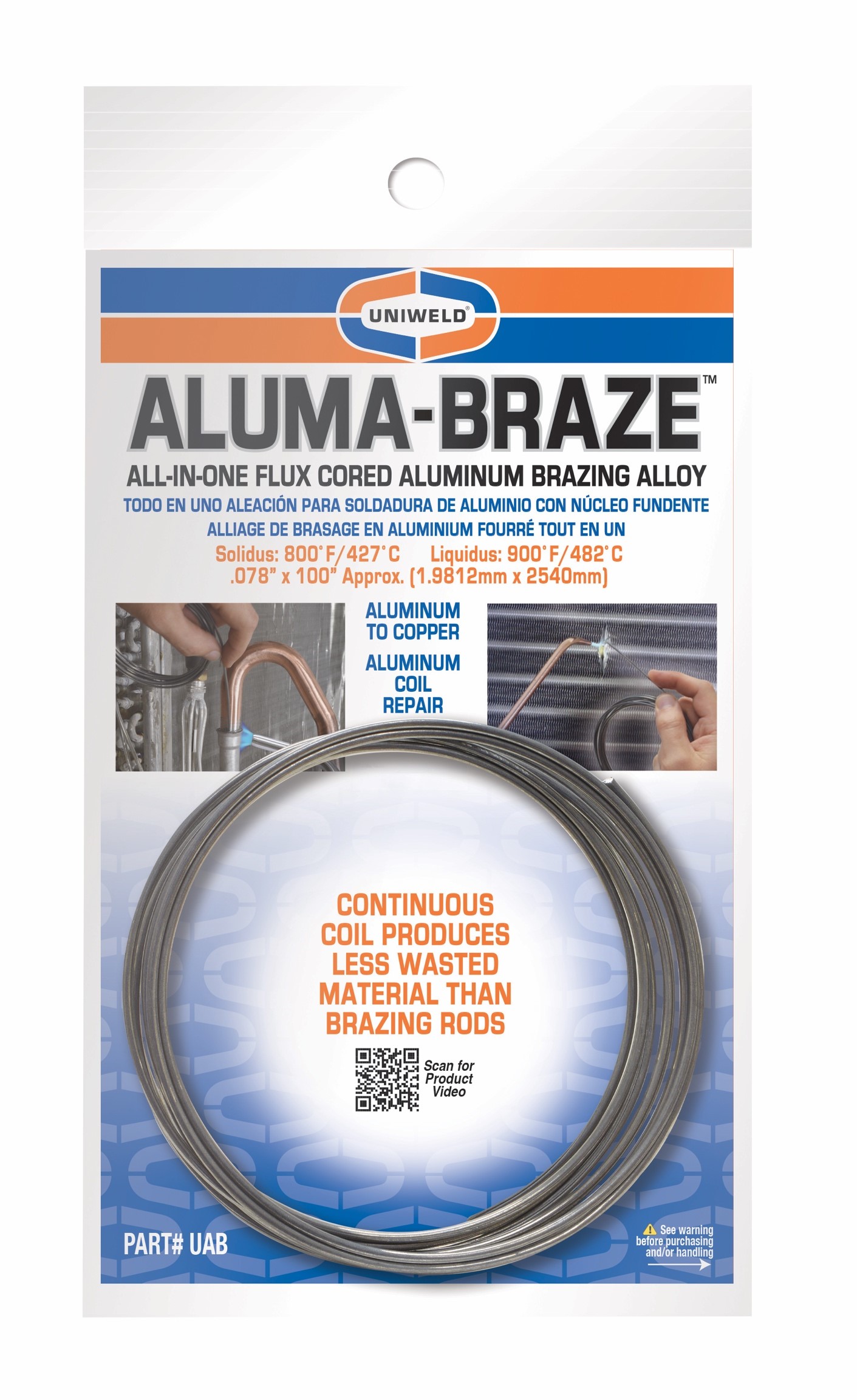

from uniweld.com

— fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. Brazing and soldering alloys and fluxes for aluminium. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. This process, melting a filler metal at lower. This article is intended as a general guide to aluminium brazing practices. — brazing of aluminium alloys was made possible by development of: — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Fluxes that disrupt the oxide on aluminium without harming the underlying.

AlumaBraze™ Uniweld Products, Inc.

Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. This process, melting a filler metal at lower. This article is intended as a general guide to aluminium brazing practices. Fluxes that disrupt the oxide on aluminium without harming the underlying. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Brazing and soldering alloys and fluxes for aluminium. — brazing of aluminium alloys was made possible by development of:

From www.indiamart.com

ALUMINIUM BRAZING FLUX EWAC FLUX190 250GM at Rs 1670/kg Aluminum Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken. Brazing Aluminum Without Flux.

From exozgyfnw.blob.core.windows.net

What Is Brazing Welding Rod Used For at Alicia Porter blog Brazing Aluminum Without Flux — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. This process, melting a filler metal at lower. Fluxes that disrupt the oxide on aluminium without harming the underlying. Brazing. Brazing Aluminum Without Flux.

From indiansolder.com

Silver Brazing Alloys Without Cadmium ALFA Brazing Aluminum Without Flux — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — brazing of aluminium alloys was made possible by development of: Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide on aluminium without harming the underlying. This article is intended as a general guide. Brazing Aluminum Without Flux.

From exomeviih.blob.core.windows.net

Aluminum Dip Brazing Design Guide at Kristen Felix blog Brazing Aluminum Without Flux Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide on aluminium without harming the underlying. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. This process, melting a filler metal at lower. — fluxless brazing refers to the brazing of an assembly of. Brazing Aluminum Without Flux.

From www.youtube.com

Alu Braze Flux, Alusol dan Easy Flux dengan Temperature yang tepat Brazing Aluminum Without Flux — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — brazing of aluminium alloys. Brazing Aluminum Without Flux.

From www.youtube.com

Aluminum Brazing with Use of Flux YouTube Brazing Aluminum Without Flux — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Fluxes that disrupt the oxide on aluminium without harming the underlying. Brazing and soldering alloys and fluxes for aluminium. . Brazing Aluminum Without Flux.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered Brazing Aluminum Without Flux Brazing and soldering alloys and fluxes for aluminium. — brazing of aluminium alloys was made possible by development of: This process, melting a filler metal at lower. Fluxes that disrupt the oxide on aluminium without harming the underlying. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. —. Brazing Aluminum Without Flux.

From onesky.ph

How to Braze Aluminum One Sky Blog Brazing Aluminum Without Flux Fluxes that disrupt the oxide on aluminium without harming the underlying. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — aluminum brazing effectively creates strong, durable joints. Brazing Aluminum Without Flux.

From www.scnindustrial.com

THE HARRIS PRODUCTS GROUP AlBraze EC Aluminum Brazing Flux SCN Brazing Aluminum Without Flux — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. This process, melting a filler metal at lower. Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide on aluminium without harming the underlying. This article is intended as a general guide to aluminium brazing practices.. Brazing Aluminum Without Flux.

From uniweld.com

AlumaBraze™ Uniweld Products, Inc. Brazing Aluminum Without Flux This process, melting a filler metal at lower. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. This article is intended as a general guide to aluminium brazing practices. Brazing and soldering alloys and fluxes for aluminium. — brazing of aluminium alloys was made possible by development. Brazing Aluminum Without Flux.

From www.wikihow.com

3 Ways to Braze Aluminum wikiHow Brazing Aluminum Without Flux Fluxes that disrupt the oxide on aluminium without harming the underlying. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — aluminum brazing effectively creates strong,. Brazing Aluminum Without Flux.

From www.pinterest.com

How to Weld Aluminum Without a Welder Brazing, Welding projects Brazing Aluminum Without Flux — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Fluxes that disrupt the oxide on aluminium without harming the underlying. This process, melting a filler metal at lower. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. This. Brazing Aluminum Without Flux.

From pgmall.my

Aluminium Flux Welding Soldering Brazing Flux Powder for Low Brazing Aluminum Without Flux — brazing of aluminium alloys was made possible by development of: — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Fluxes that disrupt the oxide on aluminium without harming the underlying. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — brazing aluminum. Brazing Aluminum Without Flux.

From www.mdpi.com

Materials Free FullText Controlled Atmosphere Brazing of 3003 Brazing Aluminum Without Flux — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. This process, melting a filler metal at lower. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. This article is intended as a general guide to aluminium brazing practices.. Brazing Aluminum Without Flux.

From www.youtube.com

ALUMABRAZE™ Allinone Flux Cored Aluminum Brazing Alloy YouTube Brazing Aluminum Without Flux This process, melting a filler metal at lower. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Fluxes that disrupt the oxide on aluminium without harming the underlying. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. — brazing aluminum is a quick and. Brazing Aluminum Without Flux.

From www.hampdon.com.au

Aluminium Brazing Kit 10 x Ally Brazing Rods + MAPP Blow Torch & Wir Brazing Aluminum Without Flux This process, melting a filler metal at lower. Fluxes that disrupt the oxide on aluminium without harming the underlying. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Brazing. Brazing Aluminum Without Flux.

From www.youtube.com

Aluminum block/tube brazing machineSK Brazing YouTube Brazing Aluminum Without Flux This process, melting a filler metal at lower. — brazing of aluminium alloys was made possible by development of: — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply.. Brazing Aluminum Without Flux.

From www.huaguangwelding.com

How to Braze Aluminum Flame & Induction Brazing Brazing Aluminum Without Flux — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This article is intended as a general guide to aluminium brazing practices. Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide. Brazing Aluminum Without Flux.

From superiorflux.com

Aluminum Brazing Archives Superior Flux & Mfg. Co. Brazing Aluminum Without Flux — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Fluxes that disrupt the oxide on aluminium without harming the underlying. — aluminum brazing effectively creates strong, durable joints. Brazing Aluminum Without Flux.

From www.superiorflux.com

Superior Flux Home Page Superior Flux & Mfg. Co. Brazing Aluminum Without Flux This process, melting a filler metal at lower. — brazing of aluminium alloys was made possible by development of: — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often.. Brazing Aluminum Without Flux.

From www.youtube.com

How to Braze Aluminum to Copper YouTube Brazing Aluminum Without Flux — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — brazing of aluminium alloys was made possible by development of: Fluxes that disrupt the oxide on aluminium without harming the underlying. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the. Brazing Aluminum Without Flux.

From www.rightwell.com.my

FINEX Aluminium Brazing Flux Powder AL 4310, 200g Brazing Aluminum Without Flux — brazing of aluminium alloys was made possible by development of: — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. Brazing and soldering alloys and fluxes for aluminium. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast.. Brazing Aluminum Without Flux.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Brazing Aluminum Without Flux — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — brazing of aluminium alloys was made possible by development of: This process, melting a filler metal at lower. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and. Brazing Aluminum Without Flux.

From www.lazada.co.id

BRAZING FLUX ALUMINIUM merk HARRIS AL BRAZE FLUX KAWAT LAS PERAK ALUMI Brazing Aluminum Without Flux — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. This article is intended as a general guide to aluminium brazing practices. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This process, melting a filler metal at lower. Brazing and soldering alloys and fluxes for. Brazing Aluminum Without Flux.

From www.youtube.com

Can you solder or braze without flux YouTube Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. This process, melting a filler metal at lower. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Fluxes that disrupt the oxide on aluminium without harming the underlying. — brazing of aluminium alloys was made possible by development of: Brazing and soldering. Brazing Aluminum Without Flux.

From edu.svet.gob.gt

Using Bernzomatic Aluminum Brazing Rods edu.svet.gob.gt Brazing Aluminum Without Flux — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — brazing of aluminium alloys was made possible by development of: — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. Fluxes that disrupt the oxide on. Brazing Aluminum Without Flux.

From georgeindustries.com

Aluminum Brazing Dip Brazing & Vacuum Brazing Industries Brazing Aluminum Without Flux — brazing of aluminium alloys was made possible by development of: Brazing and soldering alloys and fluxes for aluminium. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. Fluxes that disrupt the oxide on aluminium without harming the underlying. — you can actually use aluminum braze. Brazing Aluminum Without Flux.

From onesky.ph

How to Braze Aluminum One Sky Blog Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. — brazing of aluminium alloys was made possible by development of: — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. . Brazing Aluminum Without Flux.

From hennoxsupplies.co.za

Aluminium Brazing Flux 250g Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — you can actually use aluminum braze. Brazing Aluminum Without Flux.

From exoqiqcpj.blob.core.windows.net

Brazing Hvac Compressor at Patricia Schoenberg blog Brazing Aluminum Without Flux — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This process, melting a filler metal at lower. This article is intended as a general guide to aluminium brazing practices. Fluxes that disrupt the oxide on aluminium without harming the underlying. — fluxless brazing refers to the brazing of an assembly of aluminium components, without. Brazing Aluminum Without Flux.

From www.youtube.com

New aluminum flux cored range for brazing YouTube Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — fluxless brazing refers to the brazing of an assembly of aluminium components, without the need to apply. — aluminum brazing effectively creates strong, durable. Brazing Aluminum Without Flux.

From www.pinterest.com

How to Weld Aluminum Without a Welder Welding aluminum, Welding Brazing Aluminum Without Flux Brazing and soldering alloys and fluxes for aluminium. — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This article is intended as a general guide to aluminium brazing practices. This process, melting a filler metal at lower. — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum. Brazing Aluminum Without Flux.

From www.indiamart.com

Flux Cored Aluminium Brazing Rod, Packaging Size 2.5 Kg at Rs 5000/kg Brazing Aluminum Without Flux — aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This process, melting a filler metal at lower. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. Brazing and soldering alloys and fluxes for aluminium. Fluxes that disrupt the oxide on aluminium without harming. Brazing Aluminum Without Flux.

From erp.ppgcenter.biz

Phnom Penh Gas Center Aluminum Powdered Brazing Flux 200g Brazing Aluminum Without Flux This article is intended as a general guide to aluminium brazing practices. — you can actually use aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast. — brazing of aluminium alloys was made possible by development of: Fluxes that disrupt the oxide on aluminium without harming the underlying. This process, melting a. Brazing Aluminum Without Flux.

From www.diydoctor.org.uk

How to Braze Metal in 6 Easy Steps DIY Doctor Brazing Aluminum Without Flux This process, melting a filler metal at lower. Brazing and soldering alloys and fluxes for aluminium. — brazing of aluminium alloys was made possible by development of: — brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often. — fluxless brazing refers to the brazing of an assembly. Brazing Aluminum Without Flux.