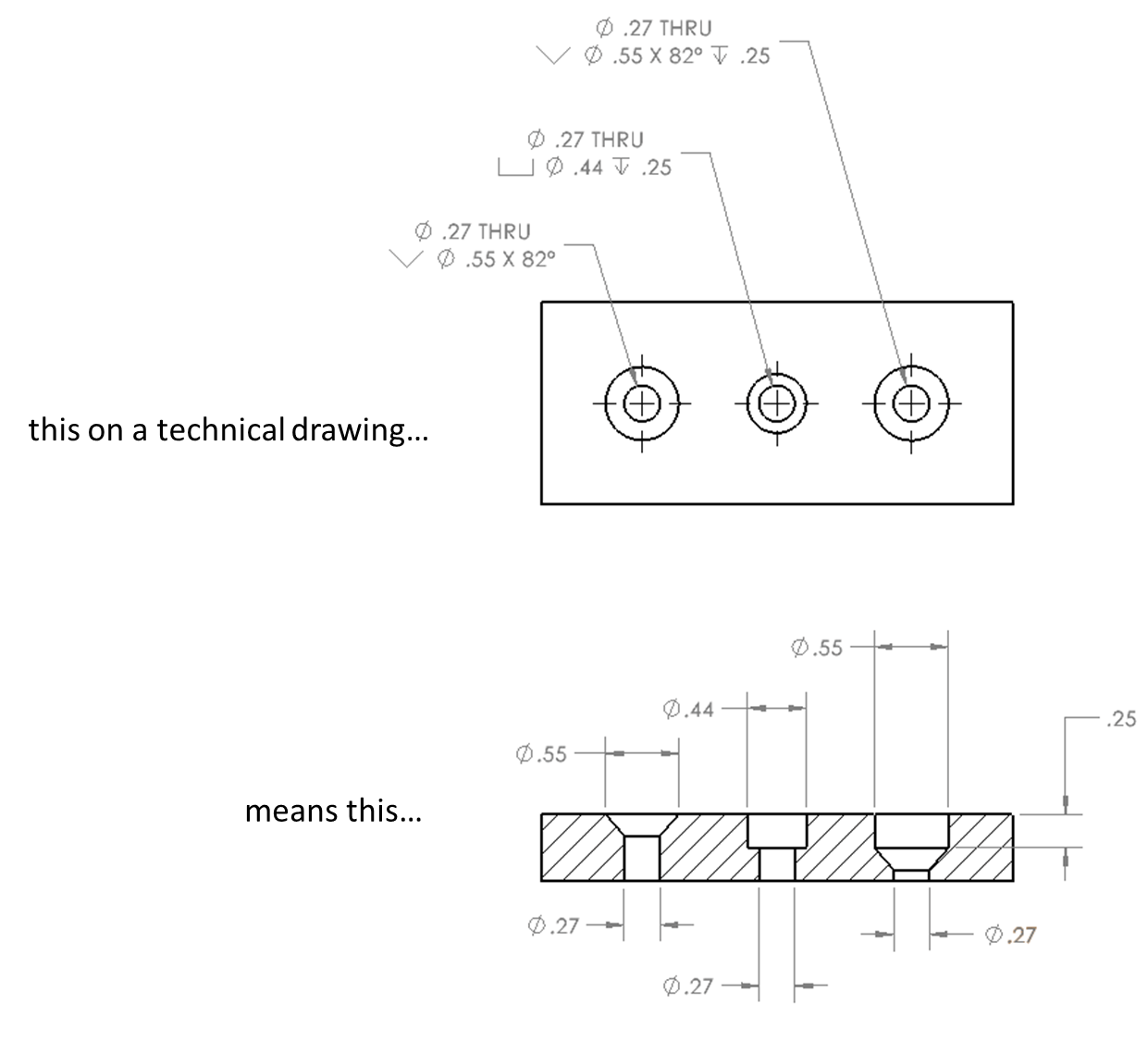

How To Label Countersunk Holes . A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. To add a hole callout: Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. The countersink symbol is used to indicate that a countersink hole feature is required.

from sendcutsend.com

The countersink symbol is used to indicate that a countersink hole feature is required. Countersunk holes are used for applications where a countersunk bolt or screw is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. To add a hole callout: Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,.

The Benefits of Countersinking SendCutSend

How To Label Countersunk Holes To add a hole callout: To add a hole callout: Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersunk holes are used for applications where a countersunk bolt or screw is required. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The countersink symbol is used to indicate that a countersink hole feature is required.

From www.wisc-online.com

Countersink Example3 OER How To Label Countersunk Holes Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. To add a hole callout: Countersink holes, characterized by their conical shape, are designed to accommodate flush or. How To Label Countersunk Holes.

From www.youtube.com

How to make Countersink Holes in SolidWorks by Hole Wizard Command How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. To add a hole callout: Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. The purpose of a countersink is to allow a. How To Label Countersunk Holes.

From www.youtube.com

How to Drill a CounterSunk Hole for Flat Head Screw YouTube How To Label Countersunk Holes Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Click hole callout (annotation toolbar), or click insert. How To Label Countersunk Holes.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge How To Label Countersunk Holes Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. To add a hole callout: Click hole callout (annotation toolbar), or click insert > annotations > hole callout. This article will explore what countersink holes are, their uses, and how to. How To Label Countersunk Holes.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Countersinks get added to holes as either a way to. How To Label Countersunk Holes.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts How To Label Countersunk Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The countersink symbol is used to indicate that a countersink hole feature is required.. How To Label Countersunk Holes.

From powermentools.com

How to Drill Countersink Holes A StepbyStep Guide to Making Perfect How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. To add a hole callout: Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. A countersink is an angled. How To Label Countersunk Holes.

From mechheart.com

What is a Countersunk Screw? MECHHEART How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. The countersink symbol is used to indicate that a countersink hole feature is required. Countersink holes, characterized. How To Label Countersunk Holes.

From powermentools.com

How to Drill Countersink Holes A StepbyStep Guide to Making Perfect How To Label Countersunk Holes Click hole callout (annotation toolbar), or click insert > annotations > hole callout. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. To add a hole callout: Countersinks get added to. How To Label Countersunk Holes.

From dobemy.com

How to Drill Countersunk Holes A StepbyStep Guide DOBEMY How To Label Countersunk Holes A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersunk holes are used for applications where a countersunk bolt or screw is required. To add a hole callout: This article will explore what countersink holes are, their uses, and how to apply ansi. How To Label Countersunk Holes.

From www.innova-systems.co.uk

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems How To Label Countersunk Holes The countersink symbol is used to indicate that a countersink hole feature is required. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. A countersink is an angled taper applied to. How To Label Countersunk Holes.

From www.slideserve.com

PPT ADVANCED MECHANICAL DRAFTING PowerPoint Presentation, free How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. The countersink symbol is used to indicate that a countersink. How To Label Countersunk Holes.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. To add a hole callout: Countersinks get added to holes as either a way to specify a chamfer for protective. How To Label Countersunk Holes.

From campolden.org

How To Get Countersink Symbol In Autocad Templates Sample Printables How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. Click hole callout (annotation toolbar), or click insert. How To Label Countersunk Holes.

From www.youtube.com

Create a Hole Using Hole Wizard in Solidworks, Simple Hole, Countersink How To Label Countersunk Holes To add a hole callout: Countersunk holes are used for applications where a countersunk bolt or screw is required. The countersink symbol is used to indicate that a countersink hole feature is required. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Countersinks get added to. How To Label Countersunk Holes.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow How To Label Countersunk Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. The countersink symbol is used to indicate that a countersink hole feature is required. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing.. How To Label Countersunk Holes.

From www.xometry.com

Spotface vs. Counterbore Holes in Machining Differences and Uses Xometry How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Countersink holes, characterized by their conical shape, are. How To Label Countersunk Holes.

From forums.autodesk.com

Add hole type counterbored+countersunk Autodesk Community How To Label Countersunk Holes To add a hole callout: The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. This article will explore what countersink holes are, their uses, and. How To Label Countersunk Holes.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits How To Label Countersunk Holes A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersunk holes are used for applications. How To Label Countersunk Holes.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly How To Label Countersunk Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Countersunk holes are used for applications where a countersunk bolt or screw is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. How To Label Countersunk Holes.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible How To Label Countersunk Holes Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole. How To Label Countersunk Holes.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Label Countersunk Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a. How To Label Countersunk Holes.

From www.slideshare.net

Class 14 presentation How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The countersink symbol is used to indicate that a countersink hole feature is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. How To Label Countersunk Holes.

From www.researchgate.net

Configuration of the double countersunk hole. Download Scientific Diagram How To Label Countersunk Holes To add a hole callout: This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials,. How To Label Countersunk Holes.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Label Countersunk Holes The countersink symbol is used to indicate that a countersink hole feature is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersunk holes are used for applications where a countersunk bolt or screw is required. The purpose of a countersink is. How To Label Countersunk Holes.

From okdor.com

How to countersink a hole? How To Label Countersunk Holes The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersunk holes are used for applications where a countersunk bolt or screw is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head. How To Label Countersunk Holes.

From www.youtube.com

PLTW IED 5.5 Countersink in Fusion 360 YouTube How To Label Countersunk Holes Countersunk holes are used for applications where a countersunk bolt or screw is required. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. A countersink. How To Label Countersunk Holes.

From www.youtube.com

Countersink laser holes YouTube How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to. How To Label Countersunk Holes.

From en.wikipedia.org

Countersink Wikipedia How To Label Countersunk Holes Click hole callout (annotation toolbar), or click insert > annotations > hole callout. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Countersunk holes are used for applications where a countersunk. How To Label Countersunk Holes.

From shuntool.com

The Ultimate Guide To Drilling Countersunk Holes In Chrome Plated Metal How To Label Countersunk Holes The countersink symbol is used to indicate that a countersink hole feature is required. Countersunk holes are used for applications where a countersunk bolt or screw is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise,. How To Label Countersunk Holes.

From engineersbible.com

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible How To Label Countersunk Holes This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The countersink symbol is used to indicate that a countersink hole feature is required. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. How To Label Countersunk Holes.

From www.youtube.com

SolidWorks Drafting Tutorial Countersinks Hole Angle Bracket How To Label Countersunk Holes Countersinks get added to holes as either a way to specify a chamfer for protective purposes or to allow a fastener such as a screw head to be recessed. The countersink symbol is used to indicate that a countersink hole feature is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. To add a hole. How To Label Countersunk Holes.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial How To Label Countersunk Holes A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. The purpose of a countersink is to allow a fastener, typically. How To Label Countersunk Holes.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 How To Label Countersunk Holes To add a hole callout: Countersunk holes are used for applications where a countersunk bolt or screw is required. The countersink symbol is used to indicate that a countersink hole feature is required. Click hole callout (annotation toolbar), or click insert > annotations > hole callout. Countersinks get added to holes as either a way to specify a chamfer for. How To Label Countersunk Holes.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY How To Label Countersunk Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Click hole callout (annotation toolbar), or click insert > annotations >. How To Label Countersunk Holes.